Professional Documents

Culture Documents

Moment Connections to Column Webs

Uploaded by

Amro Ahmad AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moment Connections to Column Webs

Uploaded by

Amro Ahmad AliCopyright:

Available Formats

MOMENT CONNECTIONS TO COLUMN WEBS

By M. Thomas Ferrell This article will present details that will accommodate mill and shop tolerances of structural members, as well as providing for material ductility. It will also present limit state strength considerations for both moment connections with field welded beam flanges and field bolted flange plates.

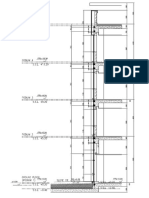

MOMENT CONNECTION WITH FIELD WELDED BEAM FLANGES (FIGURE 1)

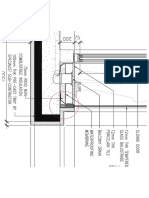

1. The connection plates must be the same grade of material as the weak axis moment beam. 2. The connection plate has been extended minimum beyond the column flange to provide better toughness and ductility. AISCs Manual of Steel Construction (LRFD) Volume IIConnections, pages 10-60 through 10-65, has summarized results of nine simulated weak axis FR moment connection tests performed by Driscoll, et. al., to aid in selection of details to ensure ductility. 3. The top connection plate thickness is equal to tf plus . This additional thickness is necessary to accommodate tolerances for fabrication and beam flange tilt. Note that the bottom of this connection plate is aligned with the bottom of the beam top flange.

4. The bottom connection plate thickness is equal to tf plus 3/8. This is necessary to accommodate tolerances for fabrication and beam flange tilt plus possi-

ble overrun/under-run in the beam depth. Note that the centerline of this connection plate is aligned with the centerline of the bottom flange of the beam.

Modern Steel Construction / March 1998

nection plates must be designed for shear stresses due to the eccentricity from the neutral axis of the bolt group to the edge of the column flange. If a column web doubler is required due to a strong axis moment beam, then the additional stresses from the shear plate must be considered in determining the thickness of the web doubler plate.

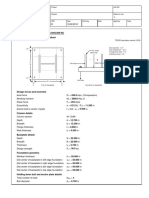

MOMENT CONNECTIONS WITH BEAM FLANGE PLATES (FIGURE 2)

1. It is not necessary for the flange plates to be the same grade of material of the weak axis moment beam. 2. Oversized holes should be used in the flange plates to allow for mill tolerances in the column beam. These connections with oversized holes must be designed as slip critical. If tension control bolts are used, if possible use a bolt gage that will allow bolts at the bottom flange to be tightened from inside of the beam flange. In many cases, this is not possible due to beam flange widths and beam depths. 3. Shims must be provided at the top or bottom flanges to accommodate fabrication and mill tolerances for flange tilt plus possible overrun/under-run in beam depths. Fabricators normally prefer the shims to be at the bottom flange due to restrictions on programming of shop equipment. If shims are provided at the top flange, the detail can be provided to serve as a deck support (figure 3). 4. The flange plates must be designed for tension yielding, tension rupture, and compression strength. 5. The flange bolts must be designed for shear strength. 6. The beam design flexural strength with regard to net section must be determined to assure that the net beam section is adequate without reinforcing.

5. The welds for connection plates to the column flanges must be designed for shear forces. These welds may also be subjected to tensile/compression and shear forces when these plates serve as stiffener plates for a strong axis moment beam. Use fillet welds where possible. It is good practice to deduct twice the weld size from the length of plate available for welding so that the welds do not terminate at the edges of the plate or column flange. If calculated stresses are transferred through the welds at the column web, then back-up stiffener plates must be provided.

6. Bolts for the shear plate to beam web are normally located outside of the column flanges. This practice simplifies beam erection and allows access to tighten the bolts with use of an impact wrench. Short slots should be used in the plate and standard holes in the beam web. Flange welds should be completed before the bolts are tightened. The short slots will hold top of beam elevation and allow for weld shrinkage to occur at the flange welds. The bolts are designed for shear forces only (no eccentricity). The welds for the shear plate-to-column web are designed for shear only. The welds for the shear plate-to-con-

Modern Steel Construction / March 1998

7. The welds for the flange plates to the column flanges/webs are designed using the same criteria used for the connection plates for the field welded flange moment beams in figure 1. 8. The web shear plate design is the same as for the field welded flange moment beams. This article is adapted from a paper by M. Thomas Ferrell, P.E., for the 1998 National Steel Construction Conference. Ferrell is President of Ferrell Engineering, Inc., a specialty structural engineering firm located in Birmingham, AL.

You might also like

- Connections: Best Tips of The 21st CenturyDocument4 pagesConnections: Best Tips of The 21st Centurysymon ellimac100% (1)

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionslael00No ratings yet

- Dropping Main Reinforcement Bas For Use As Support BarsDocument4 pagesDropping Main Reinforcement Bas For Use As Support BarsElie Farhat100% (1)

- Anchor Rods and Base Plates ExplainedDocument3 pagesAnchor Rods and Base Plates Explainedpenneng0% (2)

- Simple Steel ConnectionsDocument7 pagesSimple Steel ConnectionsShams Abbas NaqviNo ratings yet

- 30 Rules For Good Connections.5Document4 pages30 Rules For Good Connections.5chipchipperson100% (1)

- 30 Good RulesDocument4 pages30 Good RulesSamet Karataş100% (1)

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Connection CostsDocument3 pagesConnection CostsShajit KumarNo ratings yet

- 24 Tips For Simplifying Braced Frame ConnectionsDocument2 pages24 Tips For Simplifying Braced Frame Connectionsgpax42100% (1)

- Steel DetailerDocument3 pagesSteel DetailerKooroshNo ratings yet

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.No ratings yet

- Specifying CamberDocument3 pagesSpecifying CamberarsiajanNo ratings yet

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Connecting: Making Connections With HSS Members Is Easier Than You Might Think!Document4 pagesConnecting: Making Connections With HSS Members Is Easier Than You Might Think!PauloAndresSepulvedaNo ratings yet

- SteelWise Anchor RodsDocument3 pagesSteelWise Anchor RodsvNo ratings yet

- Revised RCSC Specification-Simplified, Clarified, Andimproved PDFDocument5 pagesRevised RCSC Specification-Simplified, Clarified, Andimproved PDFfarhadmrt6923No ratings yet

- Stability Bracing Requirements for Intermediate Nodal Column BracesDocument27 pagesStability Bracing Requirements for Intermediate Nodal Column BracesMeylana Arum KandilasariNo ratings yet

- Engineering For Steel ConstructionDocument2 pagesEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- Practical Compactness and Bracing Provisions For The Design of Single Angle BeamsDocument7 pagesPractical Compactness and Bracing Provisions For The Design of Single Angle Beamsbruno_alqNo ratings yet

- AISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFDocument24 pagesAISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFhoustonhimselfNo ratings yet

- Site FixesDocument4 pagesSite FixesBalaji SampathNo ratings yet

- Designing HSS Connections PDFDocument4 pagesDesigning HSS Connections PDF112160rbcNo ratings yet

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsDocument151 pagesDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxNo ratings yet

- Weld Symbols PDFDocument2 pagesWeld Symbols PDFSwagat MohapatraNo ratings yet

- ESQUEMAS UNIONES MetalicasDocument165 pagesESQUEMAS UNIONES MetalicasGuillermo Hortigüela Cordoba100% (6)

- Fundamentals of Beam BracingDocument16 pagesFundamentals of Beam BracinghungNo ratings yet

- Bolt Spec ReviewDocument2 pagesBolt Spec ReviewameensderajNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- Behaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingDocument12 pagesBehaviour and Stability of Double Coped Beam To Girder Connections Under Combined LoadingKLNo ratings yet

- 005 Connections 2Document69 pages005 Connections 2Siam100% (1)

- SWD-CSA-A23.3-04 Shear Wall Design ManualDocument82 pagesSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimNo ratings yet

- Simple Shear Connections SteelwiseDocument4 pagesSimple Shear Connections SteelwiseAnil K Vishwa100% (1)

- Aisc JournalDocument90 pagesAisc JournalRene BermudezNo ratings yet

- Especificaciones de MaterialesDocument6 pagesEspecificaciones de MaterialesArturo AppleyxrdNo ratings yet

- Design Manual of HSS PDFDocument72 pagesDesign Manual of HSS PDFTizianoPereaNo ratings yet

- CIVDES2 Lecture Notes - 13 Bolted ConnectionDocument26 pagesCIVDES2 Lecture Notes - 13 Bolted ConnectionVivian RositaNo ratings yet

- Struc Steel Erection AidsDocument3 pagesStruc Steel Erection AidsSridhar MaharajaNo ratings yet

- HHS Connection DesignDocument3 pagesHHS Connection Designwii2001No ratings yet

- Researchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadDocument10 pagesResearchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadNishant GaurNo ratings yet

- Discussion - Design of W-Shapes For Combined Bending and TorsionDocument2 pagesDiscussion - Design of W-Shapes For Combined Bending and TorsionnaimNo ratings yet

- Bolted ConnectionsDocument135 pagesBolted ConnectionsDhruv patelNo ratings yet

- Aisc Ansi - Aisc360-05 To 1999 LRFD ComparisonDocument24 pagesAisc Ansi - Aisc360-05 To 1999 LRFD ComparisonErik TrigosoNo ratings yet

- Reinforcing Steel in Slabs On Grade - tcm45-346883Document3 pagesReinforcing Steel in Slabs On Grade - tcm45-346883Ralf SnellNo ratings yet

- Sixteen tips for fostering collaboration on splice designDocument4 pagesSixteen tips for fostering collaboration on splice designKamal HalawiNo ratings yet

- Designing HSS ConnectionsDocument8 pagesDesigning HSS ConnectionsjarnebergNo ratings yet

- Bolt Is A Metal Pin With A Head Formed at One End and Shank Threaded at The Other EndDocument25 pagesBolt Is A Metal Pin With A Head Formed at One End and Shank Threaded at The Other Endgoutham sankarNo ratings yet

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsDocument7 pagesRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsnuwan01100% (1)

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocument5 pagesGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaNo ratings yet

- Reinforcement Detailing Guide for Concrete StructuresDocument6 pagesReinforcement Detailing Guide for Concrete StructurescherogonyaNo ratings yet

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaNo ratings yet

- Connection Design GuidelinesDocument4 pagesConnection Design GuidelinesABDUL REHMANNo ratings yet

- World of PipingDocument13 pagesWorld of PipingHafiz Usama ShahzadNo ratings yet

- Bolted Beam Splice: (A) Conventional SpliceDocument11 pagesBolted Beam Splice: (A) Conventional SpliceKimberly Binay-anNo ratings yet

- Anchor Bolt and Anchor Base PlateDocument2 pagesAnchor Bolt and Anchor Base PlateHugo Mario Ariza PalacioNo ratings yet

- Glulam Construction and Connection DetailsDocument7 pagesGlulam Construction and Connection DetailsNiceman NatiqiNo ratings yet

- 5 SlimDek Connection - AW 48240Document12 pages5 SlimDek Connection - AW 48240in678No ratings yet

- Or Less: How To Determine The Best Connections For Steel Joists and Metal DeckDocument4 pagesOr Less: How To Determine The Best Connections For Steel Joists and Metal DeckMinh Tâm TrầnNo ratings yet

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliNo ratings yet

- A 308 Service Block Sections Details1578487928531Document1 pageA 308 Service Block Sections Details1578487928531techNo ratings yet

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliNo ratings yet

- A 503 Window Schedule1699537950122Document1 pageA 503 Window Schedule1699537950122Amro Ahmad AliNo ratings yet

- Mathcad - Inputs Design As Per DEWADocument3 pagesMathcad - Inputs Design As Per DEWAAmro Ahmad AliNo ratings yet

- Podium Section ModelDocument1 pagePodium Section ModelAmro Ahmad AliNo ratings yet

- I-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BDocument1 pageI-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BAmro Ahmad AliNo ratings yet

- I-501.17 (c00) XD Penthouse - Upper Floor RCP - Part ADocument1 pageI-501.17 (c00) XD Penthouse - Upper Floor RCP - Part AAmro Ahmad AliNo ratings yet

- M-GW-03-51dB DOOR-proposal Model PDFDocument1 pageM-GW-03-51dB DOOR-proposal Model PDFAmro Ahmad AliNo ratings yet

- Anchor Analysis - HorizontalDocument7 pagesAnchor Analysis - HorizontalAmro Ahmad AliNo ratings yet

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliNo ratings yet

- 5120544-Spo-A-5906-0 (T)Document1 page5120544-Spo-A-5906-0 (T)Amro Ahmad AliNo ratings yet

- Updated Schematic Design Rev10Document1 pageUpdated Schematic Design Rev10Amro Ahmad AliNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Aed130164 00 DD SD 0404 CDocument1 pageAed130164 00 DD SD 0404 CAmro Ahmad AliNo ratings yet

- Aed130164 00 DD SD 0403 CDocument1 pageAed130164 00 DD SD 0403 CAmro Ahmad AliNo ratings yet

- UuhtgDocument1 pageUuhtgAmro Ahmad AliNo ratings yet

- Aed130164 00 DD SD 0427 CDocument1 pageAed130164 00 DD SD 0427 CAmro Ahmad AliNo ratings yet

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliNo ratings yet

- Plan & ElevationDocument1 pagePlan & ElevationAmro Ahmad AliNo ratings yet

- Ar 13 SectionDocument1 pageAr 13 SectionAmro Ahmad AliNo ratings yet

- Eff AreaDocument1 pageEff AreaAmro Ahmad AliNo ratings yet

- 600 Glass Balustrade ARCH DET 3-2-2016Document1 page600 Glass Balustrade ARCH DET 3-2-2016Amro Ahmad AliNo ratings yet

- Plate MatDocument12 pagesPlate MatPrantik Adhar SamantaNo ratings yet

- Bill No.3Document14 pagesBill No.3Amro Ahmad AliNo ratings yet

- M GW 03 51dB DOOR Proposal ModelDocument1 pageM GW 03 51dB DOOR Proposal ModelAmro Ahmad AliNo ratings yet

- Grid & Detail ModelDocument1 pageGrid & Detail ModelAmro Ahmad AliNo ratings yet

- KWT NG 01 03 00Document1 pageKWT NG 01 03 00Amro Ahmad AliNo ratings yet

- Ar-39 Wall SecDocument1 pageAr-39 Wall SecAmro Ahmad AliNo ratings yet

- Sdgcover Arup HandbookDocument4 pagesSdgcover Arup HandbookmhanNo ratings yet

- 2021NOV PSAD UnlockedDocument7 pages2021NOV PSAD UnlockedKristelle V. TorrealbaNo ratings yet

- Macro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtDocument28 pagesMacro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtHemant SonawadekarNo ratings yet

- Chapter 4.1 MortarDocument20 pagesChapter 4.1 MortarnahomNo ratings yet

- Strength Aspects of Glass Fibre Reinforced Concrete PDFDocument5 pagesStrength Aspects of Glass Fibre Reinforced Concrete PDFTushar SharmaNo ratings yet

- DocumentDocument42 pagesDocumentEmmanuel Asare Bediako AppiahNo ratings yet

- SWD Qty AnalysisDocument1 pageSWD Qty AnalysisRajansinh ZalaNo ratings yet

- Everything You Need to Know About WallsDocument26 pagesEverything You Need to Know About WallsdeependraNo ratings yet

- Manhole DetailsDocument1 pageManhole DetailsJanakiram GoudNo ratings yet

- NORTH DIRECTION KEY PLANDocument15 pagesNORTH DIRECTION KEY PLANBinSayeedNo ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- Etabs TutorialDocument10 pagesEtabs Tutorialsalahaddinsharif67% (3)

- Design of Rectangular Footing Col at Edge - 3Document27 pagesDesign of Rectangular Footing Col at Edge - 3Glenn SarneNo ratings yet

- 6kN Pile Fixing 10 - 2011 PDFDocument2 pages6kN Pile Fixing 10 - 2011 PDFsfdjlksfdNo ratings yet

- NMSCEL Sample Project Gantt ChartDocument4 pagesNMSCEL Sample Project Gantt ChartRamkrishna KansaraNo ratings yet

- Useful RCC Design Tips for Beam, Slab, Column, Footing, WallsDocument7 pagesUseful RCC Design Tips for Beam, Slab, Column, Footing, WallsUsman ShahidNo ratings yet

- Comparative Study of Cantilever and Counter Fort Retaining Wall-46768Document4 pagesComparative Study of Cantilever and Counter Fort Retaining Wall-46768Editor IJAERDNo ratings yet

- 13 - Chapter13Document27 pages13 - Chapter13HundeejireenyaNo ratings yet

- March MPR 2012Document52 pagesMarch MPR 2012HenRique Xavi InestaNo ratings yet

- Zudio Kabir NagarDocument20 pagesZudio Kabir NagarParmeet sharmaNo ratings yet

- 2792CP Stone SlabDocument11 pages2792CP Stone SlabKhan SakNo ratings yet

- AAC MaterialDocument11 pagesAAC MaterialLuca CarusoNo ratings yet

- Hy-Rib: Permanent Formwork For Concrete Product BrochureDocument4 pagesHy-Rib: Permanent Formwork For Concrete Product Brochuremeetvisu118No ratings yet

- Design of Prestressed Concrete Bridges Made CompositeDocument52 pagesDesign of Prestressed Concrete Bridges Made CompositeBara AlsayedNo ratings yet

- Design Considerations For Reinforced Concrete Flat Slab Floor SystemDocument4 pagesDesign Considerations For Reinforced Concrete Flat Slab Floor SystemPaul MachariaNo ratings yet

- Earthquake Resistant Design of StructuresDocument2 pagesEarthquake Resistant Design of Structuresdurga7civilNo ratings yet

- 6-Bridge Inspection and Repair Methods-Timber Bridge Repair Details and Best PracticesDocument67 pages6-Bridge Inspection and Repair Methods-Timber Bridge Repair Details and Best PracticesChris FindlayNo ratings yet

- Steel structure load analysis reportDocument6 pagesSteel structure load analysis reportApichartj JusuayNo ratings yet

- CEREMA Construction OA PDFDocument285 pagesCEREMA Construction OA PDFAlexandros Gi100% (1)

- Types and Uses of TrussesDocument14 pagesTypes and Uses of TrussesRomani Noel S. Chavez Jr.No ratings yet

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- The Importance of Being Earnest: Classic Tales EditionFrom EverandThe Importance of Being Earnest: Classic Tales EditionRating: 4.5 out of 5 stars4.5/5 (42)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtFrom EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtRating: 4 out of 5 stars4/5 (60)

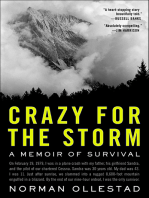

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticFrom EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticRating: 3.5 out of 5 stars3.5/5 (10)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesFrom Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Bright & Bold Cozy Modern Quilts: 20 Projects, Easy Piecing, Stash BustingFrom EverandBright & Bold Cozy Modern Quilts: 20 Projects, Easy Piecing, Stash BustingNo ratings yet

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- Other People's Dirt: A Housecleaner's Curious AdventuresFrom EverandOther People's Dirt: A Housecleaner's Curious AdventuresRating: 3.5 out of 5 stars3.5/5 (104)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesFrom EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesRating: 3.5 out of 5 stars3.5/5 (7)

- Handmade: Creative Focus in the Age of DistractionFrom EverandHandmade: Creative Focus in the Age of DistractionRating: 4.5 out of 5 stars4.5/5 (25)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- 127 Hours Movie Tie- In: Between a Rock and a Hard PlaceFrom Everand127 Hours Movie Tie- In: Between a Rock and a Hard PlaceRating: 4 out of 5 stars4/5 (46)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogFrom EverandLessons from Tara: Life Advice from the World's Most Brilliant DogRating: 4.5 out of 5 stars4.5/5 (42)