Professional Documents

Culture Documents

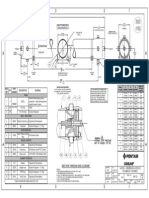

General Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure Transmitter

Uploaded by

Jorge GuerreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Specifications: DFS Diaphragm Seals For Model YA53 Gauge Pressure Transmitter

Uploaded by

Jorge GuerreroCopyright:

Available Formats

<<Contents>> <<Index>>

General Specifications

GS 6P1D4-E

DFS Diaphragm Seals For Model YA53 Gauge Pressure Transmitter

DFS Diaphragm Seals are used to prevent process fluids from coming into direct contact with the gauge pressure sensing elements. A sealed measuring system (primary element, seal and connecting tubing) is evacuated and completely filled with a liquid medium which transmits pressure changes. The diaphragm seal permits effective measurement in the following application examples:

s APPLICATION

q When a temperature fall causes crystallization or solidification. q When a temperature rise causes reaction or putrefaction. q When solidification or putrefaction occurs as the result of a stagnant process fluid in lead pipe or in a pressure element. q When material of measuring elements is not sufficiently corrosion resistant to process fluid.

s STANDARD SPECIFICATIONS

Instrument Model: q Models YA53 -S S, Except A, G and H Capsules. Construction: Wafer flange type. Flange Size and Rating: Nominal 2 inches ANSI Class 150, 300 or 600, or DIN DN50 PN10/16, PN25/40 or PN64 modified flange, whichever specified. Span and Range: Minimum and Maximum Spans: 15 and 1500 psi, 1 and 100 kg/cm2 or bar, or 0.1 and 10 MPa. Range Limits: 0.38 psi absolute and 1500 psi, 20 mmHg absolute and 100 kg/cm2, 2.7 kPa absolute and 10 MPa, 27 mbar absolute and 100 bar. Working Pressure Limits: 20 mmHg absolute (2.7 kPa absolute, or 27 mbar absolute) and the flange rating. Accuracy: 0.25 % of span. Wetted Parts: Diaphragm: JIS SUS 316L. Raised Face of Wafer Flange: JIS SUS 316L. Flange Material: Carbon steel or JIS SUS 304 stainless steel, whichever specified. Not wetted by process. Capillary Tubing: JIS SUS 316 stainless steel tubing with PVC-sheathed JIS SUS 304 stainless steel flexible armor. (Maximum operating temperature is 212 F (100 C)). Capillary lengths are 1, 2, 3, 4 or 5 meters, whichever specified.

Yokogawa Electric Corporation 2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan Tel.: 81-422-52-5690 Fax : 81-422-52-2018 GS 6P1D4-E Copyright Oct. 1988 (YK) 4th Edition Mar. 1998 (YK)

Fill Fluid: Silicone oil.

Process Temperature Limits and Ambient Temperature Limits

Process temperature limits -22 to 248 F (-30 to 120 C) 68 to 482 F (20 to 250 C) Ambient temperature limits 14 to 212 F (-10 to 100 C) 14 to 212 F (-10 to 100 C) Specific gravity *1 0.94 1.07

T01E.EPS

Fill fluid Silicone Oil Suffix Code 2 Silicone Oil Suffix Code 0

*1:

Approximately value of 77 F (25 C)

<<Contents>> <<Index>>

s MODEL AND SUFFIX CODES

Model //DFS Flange size Flange material Suffix code ........................... -WC . . . . . . . . . . . . . . . . . . . . . . . K....................... S....................... 150. . . . . . . . . . . . . . . . . . . . 300. . . . . . . . . . . . . . . . . . . . 600. . . . . . . . . . . . . . . . . . . . 16D . . . . . . . . . . . . . . . . . . . 40D . . . . . . . . . . . . . . . . . . . 64D . . . . . . . . . . . . . . . . . . . -0 . . . . . . . . . . . . . . . . . . . Wetted parts material Filling fluid Capillary tube length (m) -2 . . . . . . . . . . . . . . . . 0............... 2............... L . . . . . . . . . . . -1. . . . . . . . . . Additional features Diaphragm seal Nominal 2 inches (50 mm) or DN50 for pressure Carbon steel JIS SUS 304 stainless steel ANSI Class 150 ANSI Class 300 ANSI Class 600 DIN PN10/16 DIN PN25/40 DIN PN64 Always 0 JIS SUS 316L stainless steel Silicon oil (20 to 250 C) (68 to 482 F) Silicon oil (-30 to 120 C) (-22 to 248 F) Specify capillary tube length (m) in (1, 2, 3, 4 or 5 meters) Always 1 Options

T02E.EPS

Description

Process flange rating

s OPTIONS

Additional features Operating temperature correction Description Specity adjustment temperature in blank of OTC , also keep in mind following limitation. Adjusting range: 176 to 482 F (80 to 250 C) set temperatures within limits for filling fluid and FEP teflon diaphragm. Specify NV, when ambient temperature exceeds 212 F (100 C) or use of PVC is prohibited. Pressure and temperature limits when using teflon diaphragm pressure range: 0 to 300 psi (0 to 20kg/cm2 ) Wetted part temperature: 68 to 302 F (+20 to 150 C) Additionally specify/T on the end of suffix code Daifloil #3 *2 (for oxygen service) (Irrespective of capillary length) Wetted part temperature: -4 to 248 F (-20 to 120 C) Ambient temperature: 0 to 176 F (0 to 80 C) Ethylene glycol (for low temperature) Wetted part temperature: -58 to 212 F (-50 to 100 C) Ambient temperature: -40 to 212 F (-40 to 100 C) Silicon oil (for high temperature) Wetted part temperature: 50 to 572 F (10 to 300 C) Ambient temperature: 14 to 212 F (-10 to 100 C) Suffix codes OTC

Capillary without PVC sheaths

NV

FEP teflon diaphragm *1 (with Daifloil)

Change of filling fluid

Filling fluid code 1 Filling fluid code 3 Filling fluid code 4

T03E.EPS

Change of filling fluid

Change of filling fluid

s ORDERING INSTRUCTIONS

Specify the following when ordering; 1. Model and suffix codes for instrument, with which DFS seal is used, and diaphragm seal. 2. Option desired. 3. Calibrated range. 4. Tag number and application.

*1: *2:

FEP Teflon is the abbreviation for tetrafluoroethylene-hexafluoropropylene polymer. Daifloil: Trademark of Daikin Kogyo Company (Japan) for chlorotrifluoroethylene.

All Rights Reserved. Copyright 1988, Yokogawa Electric Corporation

GS 6P1D4-E

4th Edition Mar.10,1998-00

<<Contents>> <<Index>>

Maximum flange pressure rating or 140 psi

Process Pressure (mmHg abs)

1000 500 200 100 50 20 5 32 120

Usable Range

Atmospheric Pressure

210

300

390

480

F01.EPS

Process Fluid Temperature (F) Figure 1. Process Fluid Temperature and Pressure Ranges

s DIMENSIONS

Flange size and rating 2 inch ANSI class 150 2 inch ANSI class 300 2 inch ANSI class 600 DIN DN50 PN10/16 DIN DN50 PN25/40 DIN DN50 PN64

D 6 152.4 6.5 165.1 6.5 165.1 6.5 165 6.5 165 7.09 180

t 0.75 19.1 0.88 22.4 1 25.4 0.71 18 0.79 20 1.02 26

C 4.75 120.7 5 127.0 5 127.0 4.92 125 4.92 125 4.92 125

n 4 8 8 4 4 4

h 0.75 19.1 0.75 19.1 0.75 19.1 0.71 18 0.71 18 0.87 22

T04E.EPS

All Rights Reserved. Copyright 1988, Yokogawa Electric Corporation

GS 6P1D4-E

4th Edition Mar.10,1998-00

You might also like

- Design of O-Rings For SealingDocument87 pagesDesign of O-Rings For Sealingsiva rajaNo ratings yet

- Design Calculations For Pressure VesselsDocument54 pagesDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNo ratings yet

- Gear CalculationDocument58 pagesGear CalculationSachin KubasadNo ratings yet

- Oilfield Hoses Fittings AccembliesDocument29 pagesOilfield Hoses Fittings Accembliesthapa786mNo ratings yet

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarNo ratings yet

- To Study The Bending Behavior of Z-SecDocument10 pagesTo Study The Bending Behavior of Z-SecFaisal SardarNo ratings yet

- CMB Iso 6020-2Document63 pagesCMB Iso 6020-2David AlbellaNo ratings yet

- For Harsh and Hazardous Locations: Exe EnclosuresDocument79 pagesFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonNo ratings yet

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- Swagelok Hose MS 01 167Document28 pagesSwagelok Hose MS 01 167ashok_04meNo ratings yet

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- Desuperheater That Combines Proven Technologies For Better Operational EconomyDocument4 pagesDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Trampa Socket WeldDocument2 pagesTrampa Socket WeldOscar Nieves ZamoraNo ratings yet

- Trampa Termodinamica PDFDocument2 pagesTrampa Termodinamica PDFriquelme0788No ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet

- AE AccessoriesDocument16 pagesAE AccessoriesmisaelzaNo ratings yet

- Transmision de Presion DiferencialDocument12 pagesTransmision de Presion DiferencialRuben Arteaga'No ratings yet

- Model 7721 Mechanical Tee, Female Threaded OutletDocument3 pagesModel 7721 Mechanical Tee, Female Threaded OutletDavid EnríquezNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Si 83 - ENDocument52 pagesSi 83 - ENBabis PapadopoulosNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- Autoclave Engineers Accessories GuideDocument20 pagesAutoclave Engineers Accessories Guidecmct0819No ratings yet

- NAB Deltapi 2011Document6 pagesNAB Deltapi 2011manashbdNo ratings yet

- 40SS Series: High Pressure Stainless Steel FilterDocument8 pages40SS Series: High Pressure Stainless Steel FilterYair Alexis Muñoz RojasNo ratings yet

- Opti Flux 4000 Spec SheetDocument8 pagesOpti Flux 4000 Spec SheetAhmad Adel El TantawyNo ratings yet

- T-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary WellsDocument12 pagesT-Series Thermowells Model TF Flanged Wells, Model TT Threaded Wells, Model TW Weld-In Wells, and Model TS Sanitary Wellssalmo83:18No ratings yet

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDocument11 pagesInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisNo ratings yet

- Ebara FssDocument19 pagesEbara FssHardi YantoNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Gas industry gas pressure regulator technical descriptionDocument12 pagesGas industry gas pressure regulator technical descriptionBranko BabicNo ratings yet

- Ashcroft PI 1259 Duragauge Pressure GaugeDocument2 pagesAshcroft PI 1259 Duragauge Pressure GaugejplutodNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- MS 02 316Document12 pagesMS 02 316gazwang478No ratings yet

- General Specifications: PI Components Remote Diaphragm Seals For Pressure TransmittersDocument22 pagesGeneral Specifications: PI Components Remote Diaphragm Seals For Pressure TransmittersSithu ZawNo ratings yet

- DS ACC Cooling Element en Us 17070Document4 pagesDS ACC Cooling Element en Us 17070behnamatgNo ratings yet

- Principle of Operation: Target Inline FlowmeterDocument7 pagesPrinciple of Operation: Target Inline Flowmeterابزار دقیقNo ratings yet

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Re 25402Document16 pagesRe 25402ShortcutterNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument4 pagesDiaphragm Valve, Metal: ConstructionDenial BasanovicNo ratings yet

- Ashcroft 1279 Duragauge Pressure GaugeDocument2 pagesAshcroft 1279 Duragauge Pressure Gaugepecueca168112No ratings yet

- GEA PHE Fullywelded Phe en 1Document12 pagesGEA PHE Fullywelded Phe en 1gemagdyNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Hansaflex HousingsDocument79 pagesHansaflex Housingsrazand23No ratings yet

- DWG REF QTY Number Description Material Shell: Order SectionDocument2 pagesDWG REF QTY Number Description Material Shell: Order SectionRamanNegiNo ratings yet

- TF4 Mar 20 06Document6 pagesTF4 Mar 20 06DANIZACHNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Series 618: Pressure Relief ValvesDocument4 pagesSeries 618: Pressure Relief ValvesCarlos Alfredo Vargas CuellarNo ratings yet

- High Pressure Forged Gate Valves Pressure Temperature RatingsDocument16 pagesHigh Pressure Forged Gate Valves Pressure Temperature Ratingsg9g9No ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- Garnituri Flanse SAEDocument85 pagesGarnituri Flanse SAEcudalbgeoNo ratings yet

- Metal Diaphragm Valve Technical SpecificationsDocument6 pagesMetal Diaphragm Valve Technical SpecificationsDenial BasanovicNo ratings yet

- Asco Valve 8327Document2 pagesAsco Valve 8327Yorkist100% (1)

- Pneumatically Operated Diaphragm ValveDocument8 pagesPneumatically Operated Diaphragm ValveRavi ChaurasiaNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- L-Dens 427F Ex Density Sensor SpecificationsDocument6 pagesL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Ficha Tecnica PikotekDocument2 pagesFicha Tecnica Pikoteking_arriagaNo ratings yet

- That You Answer The Questions in Section One As Fully As Possible in A Written Letter, and Complete The Remaining Sections On This FormDocument2 pagesThat You Answer The Questions in Section One As Fully As Possible in A Written Letter, and Complete The Remaining Sections On This FormJorge GuerreroNo ratings yet

- Lab #2 - Phase SequenceDocument6 pagesLab #2 - Phase SequenceJorge GuerreroNo ratings yet

- Electrical and Computer - Electronics, Controls, and Communications CBT Exam SpecificationsDocument3 pagesElectrical and Computer - Electronics, Controls, and Communications CBT Exam SpecificationsJorge GuerreroNo ratings yet

- Lab Report #1Document5 pagesLab Report #1Jorge GuerreroNo ratings yet

- OP11O AbstractsDocument387 pagesOP11O AbstractsJorge GuerreroNo ratings yet

- Lect5-Optical Fibers 2Document134 pagesLect5-Optical Fibers 2trlp1712100% (1)

- Problem Set 4-2020 PDFDocument3 pagesProblem Set 4-2020 PDFJorge GuerreroNo ratings yet

- EE I8500 Optical Signal Processing SyllabusDocument1 pageEE I8500 Optical Signal Processing SyllabusJorge GuerreroNo ratings yet

- Bode PlotsDocument8 pagesBode Plotsselaroth168No ratings yet

- PhotonicStyles21-1-4-12 - 1Document7 pagesPhotonicStyles21-1-4-12 - 1z.umul9031No ratings yet

- Hands-On Deep Learning For Images With TensorFlow - Build Intelligent Computer Vision Applications Using TensorFlow and KerasDocument1 pageHands-On Deep Learning For Images With TensorFlow - Build Intelligent Computer Vision Applications Using TensorFlow and KerasJorge GuerreroNo ratings yet

- JLT Sub Template 2018 Equations EnabledDocument9 pagesJLT Sub Template 2018 Equations EnabledJorge GuerreroNo ratings yet

- IEEE VTS Traction Power Substation Standards Meeting AgendaDocument1 pageIEEE VTS Traction Power Substation Standards Meeting AgendaJorge GuerreroNo ratings yet

- WC-2020 PromiseCalendar GodIsHereDocument17 pagesWC-2020 PromiseCalendar GodIsHereJorge GuerreroNo ratings yet

- Ccny Syllabus EE6530Document2 pagesCcny Syllabus EE6530Jorge GuerreroNo ratings yet

- Rsoft Application: Estimation of Silicon Photonics Foundry YieldDocument2 pagesRsoft Application: Estimation of Silicon Photonics Foundry YieldJorge GuerreroNo ratings yet

- CSI Virtual Resumepalooza July 9Document1 pageCSI Virtual Resumepalooza July 9Jorge GuerreroNo ratings yet

- Claim For Standard Govt Headstone or MarkerDocument5 pagesClaim For Standard Govt Headstone or MarkerroyalloyalroyNo ratings yet

- Sensors 11 02580 PDFDocument12 pagesSensors 11 02580 PDFJorge GuerreroNo ratings yet

- Bode PlotsDocument8 pagesBode Plotsselaroth168No ratings yet

- MSW Student Handbook PDFDocument120 pagesMSW Student Handbook PDFJorge GuerreroNo ratings yet

- Form - Fillable.nanofabrication & Nanodevices.m Begliarbekov - Course Eval - Spring 2020.DMDocument3 pagesForm - Fillable.nanofabrication & Nanodevices.m Begliarbekov - Course Eval - Spring 2020.DMJorge GuerreroNo ratings yet

- Laser Diode: Product Specification Sheet L658P040Document1 pageLaser Diode: Product Specification Sheet L658P040Jorge GuerreroNo ratings yet

- Instructor: Nelly FazioDocument3 pagesInstructor: Nelly FazioJorge GuerreroNo ratings yet

- Camello Final ExamDocument1 pageCamello Final ExamJorge GuerreroNo ratings yet

- Ethernet Passive Optical Network Epon Building A Next884Document40 pagesEthernet Passive Optical Network Epon Building A Next884angelpyNo ratings yet

- Machine LearningDocument2 pagesMachine LearningJorge GuerreroNo ratings yet

- Modeling and Simulation of Ethernet Passive Optical Network (EPON) Experiment Platform Based On OPNET ModelerDocument6 pagesModeling and Simulation of Ethernet Passive Optical Network (EPON) Experiment Platform Based On OPNET ModelerJorge GuerreroNo ratings yet

- Adjunct Representative Faculty Senate LetterDocument2 pagesAdjunct Representative Faculty Senate LetterJorge GuerreroNo ratings yet

- Advance Statistics Project Guidance: Class Presentation (3/15 PTS) : This Will Be A 4-5 Minute Powerpoint PresentationDocument1 pageAdvance Statistics Project Guidance: Class Presentation (3/15 PTS) : This Will Be A 4-5 Minute Powerpoint PresentationJorge GuerreroNo ratings yet

- Algebra:: N N N N N N 1B 2B ZoneDocument6 pagesAlgebra:: N N N N N N 1B 2B Zonevenedick sapongayNo ratings yet

- Synthesis of Flavone from 2-HydroxyacetophenoneDocument11 pagesSynthesis of Flavone from 2-Hydroxyacetophenonearefeena100% (2)

- Chapter-2-LEVEL MEASUREMENTDocument26 pagesChapter-2-LEVEL MEASUREMENTMohammed YusufNo ratings yet

- Chemistry May:June 2015 Paper 43Document9 pagesChemistry May:June 2015 Paper 43Kamini Maria SaldanhaNo ratings yet

- GtryeDocument66 pagesGtryePholNo ratings yet

- Sistema STRESSTEELDocument41 pagesSistema STRESSTEELJonathan FelixNo ratings yet

- Course Outline Heat, Waves & Sound LabDocument3 pagesCourse Outline Heat, Waves & Sound LabphooolNo ratings yet

- Comparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisDocument8 pagesComparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisPanagiotis GkezerlisNo ratings yet

- 221 Chloride and SulfateDocument1 page221 Chloride and SulfatesofianesedkaouiNo ratings yet

- Iso 02834-1-2006Document12 pagesIso 02834-1-2006frodo frodoNo ratings yet

- PRE 309 Homework 1 Chemical Reaction EngineeringDocument1 pagePRE 309 Homework 1 Chemical Reaction EngineeringrahulsaxenaNo ratings yet

- IIT-JEE Syllabus: RSM79 PH I PP CH 1Document34 pagesIIT-JEE Syllabus: RSM79 PH I PP CH 1NayanKishorkumarThakkerNo ratings yet

- Mutu Manajemen PDFDocument238 pagesMutu Manajemen PDFirdawanNo ratings yet

- 8629 - 1t3 Protection of Steel From CorrosionDocument50 pages8629 - 1t3 Protection of Steel From Corrosionkranthi kumarNo ratings yet

- Dietrich 2017Document10 pagesDietrich 2017Zulfi Nur Amrina RosyadaNo ratings yet

- Outline For PhotosynthesisDocument6 pagesOutline For Photosynthesiswitzy11No ratings yet

- R311 Catalyst 06.2004 msds3434Document6 pagesR311 Catalyst 06.2004 msds3434rawaronteksNo ratings yet

- FLuid LabDocument7 pagesFLuid LabArik EthanNo ratings yet

- Computational Chemistry: Semester Ii M.SC Chemistry M.G University KottayamDocument15 pagesComputational Chemistry: Semester Ii M.SC Chemistry M.G University KottayamDr. Partha Sarathi SenguptaNo ratings yet

- Flow of Fluids ReportDocument21 pagesFlow of Fluids ReportalyssaNo ratings yet

- YSI Model 55: Handheld Dissolved Oxygen and Temperature SystemDocument26 pagesYSI Model 55: Handheld Dissolved Oxygen and Temperature Systemdwisdt9044No ratings yet

- How The Concept of The Element Evolved From Ancient Greek To The PresentDocument23 pagesHow The Concept of The Element Evolved From Ancient Greek To The PresentPineda, Sean AlfredNo ratings yet

- Analysis of Hard WaterDocument3 pagesAnalysis of Hard WaterPankaj Patel100% (4)

- ApplicationNote PH Measurement JamJellies EN 30538204Document4 pagesApplicationNote PH Measurement JamJellies EN 30538204MarcinNo ratings yet

- Ramesh Kumar Guduru CV and Research ProfileDocument8 pagesRamesh Kumar Guduru CV and Research ProfileAnonymous v9cXHdjNo ratings yet

- Roof Drainage DesignDocument9 pagesRoof Drainage DesignarbiNo ratings yet

- Chapter 1 - Introduction EDMDocument5 pagesChapter 1 - Introduction EDMPraveen RnNo ratings yet