Professional Documents

Culture Documents

Design and Simulation of Low Speed Axial Flux Permanent Magnet (AFPM) Machine

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Simulation of Low Speed Axial Flux Permanent Magnet (AFPM) Machine

Copyright:

Available Formats

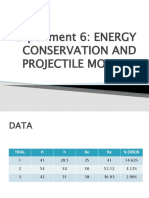

13

International Journal of

Science and Engineering Investigations vol. 1, issue 3, April 2012

ISSN: 2251-8843

Design and Simulation of Low Speed Axial Flux Permanent

Magnet (AFPM) Machine

Hassan Moradi

1

, Ahmad Darabi

2

1

Faculty of Electrical & Robotic Engineering, Shahrood University of Technology

2

Faculty of Electrical & Robotic Engineering, Shahrood University of Technology

(

1

hassanmoradi333@yahoo.com,

2

Darabi_Ahmad@hotmail.com)

Abstract-In this paper presented initial design of Low Speed

Axial Flux Permanent Magnet (AFPM) Machine with Non-

Slotted TORUS topology type by use of certain algorithm

(Appendix). Validation of design algorithm studied by means

of selected data of an initial prototype machine. Analytically

design calculation carried out by means of design algorithm

and obtained results compared with results of Finite Element

Method (FEM).

Keywords- Axial Flux Permanent Magnet (AFPM) Machine;

Design Algorithm;, Finite Element Method (FEM); TORUS.

I. INTRODUCTION

The first work focused on PM disc machines was

performed in late 70s and early 80s. Disc type axial flux PM

machines have found growing interests in the last decade

especially in the 90s and have been increasingly used in both

naval and domestic applications as an attractive alternative to

conventional radial flux machines due to its pancake shape,

compact construction and high power density [1], [2].

AFPM motors are particularly suitable for electrical

vehicles, pumps, fans, valve control, centrifuges, machine

tools, robots and industrial equipment. AFPM machines can

also operate as small to medium power generators. Since a

large number of poles can be accommodated, these machines

are ideal for low speed applications, as for example,

electromechanical traction drives hoists or wind generators.

Moreover, AFPM have been today widely investigated in a

large number of applications such as: submarine propulsion,

airplane propulsion systems, wind energy, paper industry. The

unique disc-type profile of the rotor and stator of AFPM

machines makes it possible to generate diverse and

interchangeable designs. AFPM machines can be designed as

single air gap or multiple air gaps machines, with slotted, non-

slotted or even totally ironless armature [1], [3], [4], [5].

II. MACHINE STRUCTURE OF CASE STUDY

AFPM machine topology that presented in this paper is

Non-slotted TORUS machine (TORUS-NS). An idealized

version of the machine structure is shown in Figure 1. The

TORUS machine is a non-slotted, toroidal-stator, double-sided,

axial-flux, disc-type, permanent magnet, brushless machine.

Figure 1 shows the basic layout. A simple toroidal strip-

wound laminated stator core carries a slot less toroidal

winding which may have any chosen number of phases.

The rotor comprises two mild steel discs, one on each side of

the stator, carrying axially-polarized magnets [6]. Use of the

high-field permanent-magnet material Neodymium-Iron-

Boron (NdFeB) for excitation enable quite high flux density

to be achieved in the relatively large air-gap associated with

the slotless winding [7]. The active conductor lengths are the

radial portions facing the magnets. It is seen that the machine

effectively comprises two independent halves, lying either

side of the radial centreline. The name Torus was adopted

to indicate the toroidal nature of both the stator core and

the stator winding [6]. The geometry of the TORUS-NS

machine is described in Figure 2 [8]. The three phase winding

arrangement, magnet polarities and flux paths in the magnetic

circuit in average diameter of the TORUS-NS machine are

shown in Figure 3 [1].

Figure 1. Axial flux TORUS type non-slotted surface mounted PM machine

configuration (TORUS-NS).

Figure 2. Definition of the geometrical parameters for the TORUS-NS

AFPM machines [8]

International Journal of Science and Engineering Investigations, Volume 1, Issue 3, April 2012 14

www.IJSEI.com Paper ID: 10312-03 ISSN: 2251-8843

U -V -W V W -U U -V -W

V W -U U -V -W V W -U

S

N

S

N

S

N

N

S

N

S

N

S

Figure 3. Three-phase winding, PM polarities and magnetic flux paths of a

TORUS-NS machine [1].

III. INITIAL DESIGN OF TORUS-NS MACHINE

In this section performed initial design of TORUS-NS

machine by use of certain algorithm. The selected values of

principal design details are given in Table I. The overall

specification for the direct-drive generator was 5 kW nominal

demanded Power, 200 R.P.M nominal speeds [9].

TABLE I. SELECTED VALUES OF PRINCIPAL DESIGN DETAILS

Symbol Quantity Value Unit

PR Nominal power 5000 [W]

m Number of phase 3 -

VDC DC Voltage 210 [V]

f frequency 46.67 [Hz]

n Nominal speed 200 [rpm]

connection wye

TABLE II. ANALYTICALLY DESIGNED PARAMETER OF TORUS-NS

AFPM MACHINE

Symbol Quantity Value Unit

VL Line Voltage 219.05 [V]

VP Phase Voltage 126.47 [V]

p Number of pole pair 14 -

A Electrical Loading 10500 [A/m]

J Current Density 7.8 [A/mm

2

]

aP Number of parallel path 7 -

Bg Air-gap peak flux density 0.74 [T]

Diameter ratio 0.5745 -

Kp Electrical power waveform factor 0.777 -

Ki Current waveform factor 0.134 -

Ke EMF factor t

-

Kcu Copper fill factor 0.33 -

rPM Magnetic recoil permeability 1.05 -

Br residual flux density of the PM material 1.17 [T]

Bcr Flux density in the rotor core 1.17 [T]

Kd Leakage flux factor 0.533 -

Bu Specific magnetic loading 1.125 [T]

Efficiency 0.81 -

Do Outer Diameter 0.470 [m]

Di Inner Diameter 0.270 [m]

Dg Average Diameter 0.370 [m]

g Air-gap length (magnet to the winding) 0.0015 [m]

Bcs Flux density in the stator core 1.245 [T]

Lcs Axial length of the stator core 0.020 [m]

Wcui Winding thickness at inner diameter 0.0055 [m]

Wcuo Winding thickness at outer diameter 0.0032 [m]

Wcu Winding thickness at inner diameter 0.0043 [m]

Ls axial length of the stator 0.0288 [m]

Lcr axial length of the rotor core 0.020 [m]

LPM PM length 0.0127 [m]

i magnet widthtopole pitch ratio 0.72 -

wPMg Magnet width in average diameter 0.0299 [m]

Lr axial length of the rotor 0.0327 [m]

Le axial length of the machine 0.097 [m]

Nt number of turns per phase 160 turn

Irms RMS phase current 12.71 [A]

lw axial thickness of the winding 0.0044 [m]

sa cross-section of a conductor 0.329 [m2]

dstr Strand wire diameter 0.71 [m]

Li effective length of the stack 0.1 [m]

L1av Average length of the armature turn 0.2576 [m]

IV. SIMULATION OF TORUS-NS MACHINE

In this section simulated TORUS-NS machine by means of

FEM with mentioned parameter in table I and II. As mentioned

before it is seen that the machine effectively comprises two

independent halves, lying either side of the radial

centerline. Measured view of TORUS-NS machine model for

simulation is shown in Figure 4.

After drawing the model for simulation of TORUS-NS

machine and attribution of the material for component of

machine carry out mesh generation. Meshing of machine is

shown in Figure 5.

U -V -W V W -U

S

N

N

S

83.02

20

12.7

10

4.4

1.5

29.9 11.61

Figure 4. View of model for simulation of TORUS-NS machine.

Figure 5. Meshing of TORUS-NS machine.

The magnetic flux lines for no-load condition are depicted in

Figure 6.

Figure 6. Magnetic flux lines for no-load condition of TORUS-NS machine.

International Journal of Science and Engineering Investigations, Volume 1, Issue 3, April 2012 15

www.IJSEI.com Paper ID: 10312-03 ISSN: 2251-8843

The flux density distribution by means of vectors and

direction of flux for no-load condition is depicted in Figure 7.

Figure 7. Flux density distribution by means of vectors and direction of flux

for no-load condition.

The flux density distribution for no-load condition is

depicted in Figure 8.

Figure 8. Flux density distribution for no-load condition of TORUS-NS

machine.

Figure 9 shows the air-gap flux density over one pole using

FEA. It can be seen from this curve that the maximum air-gap

flux density is roughly 0.748 T and the average air-gap flux

density was determined to be 0.61 T.

A flux density comparison between the sizing analysis

results and FEA results on various parts of the TORUS-NS

machine at no load is tabulated in Table III.

0 5 10 15 20 25 30 35 40

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Distance (mm)

A

i

r

g

a

p

F

l

u

x

D

e

n

s

i

t

y

(

T

e

s

l

a

)

Figure 9. No load air-gap flux density of the TORUS-NS (at average

diameter Dg= (Di +Do)/2).

TABLE III. FLUX DENSITY COMPARISON OF TORUS-NS MACHINE AT NO

LOAD

Flux Density Bcs-max Bcr-max Bg-max Bcs-avg

FEM 1.123 1.09 0.748 0.61

Sizing eq. 1.245 1.17 0.748 0.60

It is seen that the FEA results are consistent with the results

obtained from the sizing analysis except for the fact that

maximum value of the stator flux density is a little lower than

the value obtained from sizing analysis. The reason for this

discrepancy is that the leakage flux is a bit higher because of

the large air-gap which results in lower flux density in the

stator core [10].

The magnetic flux density in the x (tangential) and y

(normal) directions are shown in Figure 10.

0 5 10 15 20 25 30 35 40

-0.4

-0.2

0

0.2

0.4

0.6

0.8

Distance (mm)

B

x

,

B

y

(

T

e

s

l

a

)

Bx

By

Figure 10. Magnetic flux density in the x (tangential) and y (normal)

directions of TORUS-NS machine.

V. CONCLUSION

In this paper with selected values of principal design details

Designed by use of a certain algorithm Parameter of TORUS-

NS AFPM Machine. Then machine simulated by use of Finite

Element Method (FEM). The FEA results are consistent with

the results obtained from the sizing analysis that validates high

precision of design algorithm studied in this paper.

APPENDIX

Equation of initial design algorithm:

1) Outer Diameter:

3

1

2

)

) 1 )( 1 (

4

(

q t +

=

f A B K K K N

P p

D

g p i e stator

R

o

] [m

2) Inner diameter:

o i

D D = ] [m

3) Average air-gap diameter:

o g

D D

2

1 +

=

] [m

4) Flux density in the stator core

32 . 0

47 . 5

= f B

cs

] [T

5) Axial length of the stator core

p B

D B

L

cs

o g

cs

4

) 1 ( t +

=

] [m

International Journal of Science and Engineering Investigations, Volume 1, Issue 3, April 2012 16

www.IJSEI.com Paper ID: 10312-03 ISSN: 2251-8843

6) Winding thickness at inner diameter

2

4

2

i

s cu

g s

i

cui

D

J K

D A

D

W

+

=

] [m

7) Winding thickness at outer diameter

2

4

2

o

s cu

g s

o

cuo

D

J K

D A

D

W

+

=

] [m

8) Axial length of the stator

cui cs s

W L L 6 . 1 + = ] [m

9) Axial length of the rotor core

p B

D B

L

cr

o u

cr

8

) 1 ( t +

=

] [m

10) Permanent Magnet axial length

| | m W g

B

K

K

B

B

L

cu

g

d

f

r

g rPM

PM

) ( +

=

11) Axial length of the rotor

PM cr r

L L L + = ] [m

12) Axial length of the machine

g L L L

r s e

2 2 + + = ] [m

REFERENCES

[1] Jacek F. Gieras, Rong-Jie Wang and Maarten J. Kamper, "Axial Flux

Permanent Magnet Brushless Machines", Publisher: Springer; Second

edition, 2008.

[2] M. Aydin, S. Huang and T. A. Lipo, Axial Flux Permanent Magnet

Disc Machines: A Review, Research Report, University of Wisconsin-

Madison 2004.

[3] A. Bellara, Y. Amara, G. Barakat and P. Reghem , Analytical Modeling

of the Magnetic Field in Axial Flux Permanent Magnet Machines with

Semi-Closed Slots at No Load XIX International Conference on

Electrical Machines - ICEM 2010, Rome

[4] Fabrizio Marignetti, Giovanni Tomassi, Piergiacomo Cancelliere,

Vincenzo Delli Colli,Roberto Di Stefano, Maurizio Scarano ,

Electromagnetic and Mechanical design of a Fractional-slot-windings

Axial-flux PM synchronous machine with Soft Magnetic Compound

Stator , IEEE 2006.

[5] A. Parviainen, J. Pyrhnen, M. Niemel, AXIAL FLUX INTERIOR

PERMANENT MAGNET SYNCHRONOUS MOTOR WITH

SINUSOIDALLY SHAPED MAGNETS ISEF 2001 - 10th

International Symposium on Electromagnetic Fields in Electrical

Engineering Cracow, Poland, September 20-22, 2001.

[6] B.J. Chalmers, Wu Wei, E. Spooner, "An Axial-Flux Permanent-Magnet

Generator for a Gearless Wind Energy System", IEEE Int. Conf. on

Power Electronics, Drives and Energy Systems for Industrial

Growth,PEDESP6, New Delhi, pp. 610-616.

[7] E. SPOONER, B.J. CHALMERS, M.M. El Missiry, WU WEI and A.C.

RENFREW, MOTORING PERFORMANCE OF THE TOROIDAL

PERMANENT MAGNET MACHINE "TORUS", University of

Manchester Institute of Science and Technology, UK University of

Zimbabwe, Zimbabwe.

[8] F. Libert, Design, Optimization and Comparison of Permanent Magnet

Motors for a Low-Speed Direct-Driven Mixer, Licentiate Thesis, Royal

Institute of Technology, Stockholm 2004.

[9] F. Caricchi, B.J. Chalmers, F. Crescimbmi, E. Spooner Advances in the

Design of TORUS Machines, IEEE, pp. 516-522 Vol. 2, 1-3 Dec.1998.

[10] M. Aydin, S. Huang and T. A. Lipo, Design and 3D Electromagnetic

Field Analysis of Non-slotted and Slotted TORUS Type Axial Ftux

Surface Mounted Permanent Magnet Disc Machines, International

Electrical Machines and Drives Conference, IEEE 2001, Boston.

Hassan Moradi received the B.Sc. degree in

electrical engineering from Shahid Rajaee

University, Tehran, Iran, in 2001 and the M.Sc.

degree in the same field from Shahrood University

of Technology in 2012.

His research activities are mostly on design and

modeling of electrical machines.

Ahmad Darabi received the B.Sc. degree in

electrical engineering from the University of

Tehran, Tehran, Iran, in 1989 and the M.Sc. degree

in the same field from Ferdowsi University,

Mashhad, Iran, in 1992. He obtained the Ph.D.

degree with the Electrical Machine Group,

Queens University, Belfast, U.K., in 2002.

He is now an associated professor and has been with the Faculty of

Electrical and Robotic Engineering, Shahrood University of

Technology, Shahrood, Iran, since 1993. His research activities are

focussed mostly on design, modelling, and manufacturing of

miniature electrical machines and generating sets.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 106資優特訓班Document96 pages106資優特訓班utaNo ratings yet

- Biogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessDocument10 pagesBiogas Production From Municipal Sewage Sludge Using Ultrasound Speeding Digestion ProcessInternational Journal of Science and Engineering InvestigationsNo ratings yet

- LAS SHS PhySci MELC 7 Q2 Week-3Document10 pagesLAS SHS PhySci MELC 7 Q2 Week-3Nini VillezaNo ratings yet

- Dynamic Behavior of Materials - I - Meyers PDFDocument684 pagesDynamic Behavior of Materials - I - Meyers PDFAamir RazaNo ratings yet

- Biodiesel Production in Nigeria Using Cocoa Pod Ash As A Catalyst BaseDocument4 pagesBiodiesel Production in Nigeria Using Cocoa Pod Ash As A Catalyst BaseInternational Journal of Science and Engineering InvestigationsNo ratings yet

- A Study of The Effect of Individuals' General Indicators On The Staff Efficiency of Sistan and Baluchistan Agricultural Jihad OrganizationDocument4 pagesA Study of The Effect of Individuals' General Indicators On The Staff Efficiency of Sistan and Baluchistan Agricultural Jihad OrganizationInternational Journal of Science and Engineering InvestigationsNo ratings yet

- An Investigation of The Relationship Between Learning Management System and Learning Outcomes: Mehralborz Virtual University Case StudyDocument4 pagesAn Investigation of The Relationship Between Learning Management System and Learning Outcomes: Mehralborz Virtual University Case StudyInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Factors Affecting The Production of Drugs in Our Pharmaceutical Companies A Case Study of Ilorin MetropolisDocument4 pagesFactors Affecting The Production of Drugs in Our Pharmaceutical Companies A Case Study of Ilorin MetropolisInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Cognitive Architectures As Building Energy Management System For Future Renewable Energy Scenarios A Work in Progress ReportDocument6 pagesCognitive Architectures As Building Energy Management System For Future Renewable Energy Scenarios A Work in Progress ReportInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Projected Changes in Annual Temperature and Precipitation in Setif High Plains Region (North East of Algeria)Document4 pagesProjected Changes in Annual Temperature and Precipitation in Setif High Plains Region (North East of Algeria)International Journal of Science and Engineering InvestigationsNo ratings yet

- Employing A New Combination of The Remaining Harmonics of The Current To Detect The High Impedance Fault in Electrical Distribution NetworksDocument6 pagesEmploying A New Combination of The Remaining Harmonics of The Current To Detect The High Impedance Fault in Electrical Distribution NetworksInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Comparing Two and Three Dimensional Optimization of Turbojet Engine With Multi Target Genetic AlgorithmDocument6 pagesComparing Two and Three Dimensional Optimization of Turbojet Engine With Multi Target Genetic AlgorithmInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Application of Meta Analysis in Examination of Validity ItemsDocument5 pagesApplication of Meta Analysis in Examination of Validity ItemsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Characteristics of Some Natural Fibrous Assemblies For Efficient Oil Spill CleanupDocument8 pagesCharacteristics of Some Natural Fibrous Assemblies For Efficient Oil Spill CleanupInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Metabolic Response To Repetitive Lifting Tasks: Predetermined vs. Self-Selected PaceDocument4 pagesMetabolic Response To Repetitive Lifting Tasks: Predetermined vs. Self-Selected PaceInternational Journal of Science and Engineering InvestigationsNo ratings yet

- A Critical Evaluation of Some Prominent Variables On Menopause in Indian WomenDocument4 pagesA Critical Evaluation of Some Prominent Variables On Menopause in Indian WomenInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Phase Frequency Detector With Delay Cells For Achieving Low Blind and Dead ZoneDocument4 pagesPhase Frequency Detector With Delay Cells For Achieving Low Blind and Dead ZoneInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Simple Matching Strategy For Surface Acoustic Wave (SAW) Delay Lines in Radio Frequency (RF) ApplicationsDocument4 pagesSimple Matching Strategy For Surface Acoustic Wave (SAW) Delay Lines in Radio Frequency (RF) ApplicationsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Evaluation of Terminal Drought Stress Tolerance of Sesamum Indicum L. Genotypes Under The Sistan Region ConditionsDocument4 pagesEvaluation of Terminal Drought Stress Tolerance of Sesamum Indicum L. Genotypes Under The Sistan Region ConditionsInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Vapour-Phase Dehydrogenation of Ethanol Using Heterogeneous Modified Kaolinite CatalystDocument3 pagesVapour-Phase Dehydrogenation of Ethanol Using Heterogeneous Modified Kaolinite CatalystInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Evaluation Methods of Limiting Switching Overvoltage During Line EnergizationDocument6 pagesEvaluation Methods of Limiting Switching Overvoltage During Line EnergizationInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Prospect of Dry Land Corn Development in South LembehDocument5 pagesProspect of Dry Land Corn Development in South LembehInternational Journal of Science and Engineering InvestigationsNo ratings yet

- High Impedance Faults Modeling in Electrical Power Distribution NetworksDocument5 pagesHigh Impedance Faults Modeling in Electrical Power Distribution NetworksInternational Journal of Science and Engineering InvestigationsNo ratings yet

- The Effects of A Back-Belt On Lumbar Disc Deformation During Stoop Type LiftingDocument10 pagesThe Effects of A Back-Belt On Lumbar Disc Deformation During Stoop Type LiftingInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Calotropis Procera: The Miracle Shrub in The Arabian PeninsulaDocument10 pagesCalotropis Procera: The Miracle Shrub in The Arabian PeninsulaInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Performance Evaluation of Petroleum Refinery Wastewater Treatment PlantDocument6 pagesPerformance Evaluation of Petroleum Refinery Wastewater Treatment PlantInternational Journal of Science and Engineering InvestigationsNo ratings yet

- The Modeling of Electric Arc in High Voltage Circuit Breakers With Use of Schavemaker Model and Negative FeedbackDocument4 pagesThe Modeling of Electric Arc in High Voltage Circuit Breakers With Use of Schavemaker Model and Negative FeedbackInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Gilbert Damping Effect On Thermally Assisted Magnetization Reversal of Perpendicular Magnetized Nano-DotDocument6 pagesGilbert Damping Effect On Thermally Assisted Magnetization Reversal of Perpendicular Magnetized Nano-DotInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Combined Memetic Algorithm in Case of Supply Chain System's Scheduling (Approach of Cost Maintenance)Document4 pagesCombined Memetic Algorithm in Case of Supply Chain System's Scheduling (Approach of Cost Maintenance)International Journal of Science and Engineering InvestigationsNo ratings yet

- A Study On A Neural Ecosystems AnalyzerDocument4 pagesA Study On A Neural Ecosystems AnalyzerInternational Journal of Science and Engineering InvestigationsNo ratings yet

- 32 Segment Display For Bengali Alphanumeric CharactersDocument6 pages32 Segment Display For Bengali Alphanumeric CharactersInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Electric Field Distributions Around Silicon Rubber Insulators in Polluted and Cleaned AreaDocument4 pagesElectric Field Distributions Around Silicon Rubber Insulators in Polluted and Cleaned AreaInternational Journal of Science and Engineering InvestigationsNo ratings yet

- The Effects of Black Hole Attack in Mobile Ad-Hoc Network Using OLSR and AODVDocument6 pagesThe Effects of Black Hole Attack in Mobile Ad-Hoc Network Using OLSR and AODVInternational Journal of Science and Engineering InvestigationsNo ratings yet

- Dirac of Particles: 1, On The Theory Spin and Non-Relativistic LimitDocument8 pagesDirac of Particles: 1, On The Theory Spin and Non-Relativistic LimitdanielufmaNo ratings yet

- Experiment 6: ENERGY Conservation and Projectile Motion: Group 4Document10 pagesExperiment 6: ENERGY Conservation and Projectile Motion: Group 4ParZiValNo ratings yet

- Lecture 2b - Temperature-Dependent Term of A Rate Equation PDFDocument4 pagesLecture 2b - Temperature-Dependent Term of A Rate Equation PDFPAMELA TEJADANo ratings yet

- AstronomyDocument1 pageAstronomyHITNo ratings yet

- ME 325 Final Project: May 3rdDocument3 pagesME 325 Final Project: May 3rdazeem sheikhNo ratings yet

- MCB - Miniature Circuit Breaker ConstructionDocument4 pagesMCB - Miniature Circuit Breaker ConstructionEngr. AbdullahNo ratings yet

- Gas LawsDocument63 pagesGas LawsJay-mee Claire V. DioNo ratings yet

- List of Books ScribdDocument4 pagesList of Books Scribdkultardeep0% (1)

- Fundamentals of Applied Dynamics Revised PrintingDocument1 pageFundamentals of Applied Dynamics Revised PrintingMochamad Safarudin0% (3)

- BSC Environmental Management Semester Ii, Spring Semester 2021Document22 pagesBSC Environmental Management Semester Ii, Spring Semester 2021Temphel LhendupNo ratings yet

- Vol 10 No 2 2017 9 185-194Document11 pagesVol 10 No 2 2017 9 185-194Đào Đình NamNo ratings yet

- Mis Ce2201Document2 pagesMis Ce2201Ashan ShamikaNo ratings yet

- Revision Worksheet On MotionDocument2 pagesRevision Worksheet On Motionsohil khattarNo ratings yet

- Physics - WorkDocument11 pagesPhysics - WorkMohammed HassaanNo ratings yet

- Olp Igcse Mechanics CT 4 - New - Batch 1Document5 pagesOlp Igcse Mechanics CT 4 - New - Batch 1Shabbir H. KhanNo ratings yet

- Differential Elements of Length, Surfaces, andDocument42 pagesDifferential Elements of Length, Surfaces, andKEMPNo ratings yet

- Hamiltonian Mechanics: 4.1 Hamilton's EquationsDocument9 pagesHamiltonian Mechanics: 4.1 Hamilton's EquationsRyan TraversNo ratings yet

- Armstrong-High Strain Rate Properties Int Mat. RevDocument24 pagesArmstrong-High Strain Rate Properties Int Mat. RevAnthony LeungNo ratings yet

- Phys 125 Pracexam 4Document7 pagesPhys 125 Pracexam 4Moad EloustaNo ratings yet

- Light and Architectural Lighting SystemsDocument17 pagesLight and Architectural Lighting SystemsCrystal Kaye CortezNo ratings yet

- Physics Practice Final With SolutionDocument27 pagesPhysics Practice Final With SolutionKim Jong UnNo ratings yet

- Aiko 1v1 Plan 231208Document1 pageAiko 1v1 Plan 231208Vlad RoșoiNo ratings yet

- Lab Report 1Document6 pagesLab Report 1Karla MaalihanNo ratings yet

- Ansys Maxwell Egtm IcerigiDocument2 pagesAnsys Maxwell Egtm IcerigiFeyza KaragözNo ratings yet

- Mock Board Examination Licensure Examination For Chemical Engineers (April 2006) Subject: Chemical EngineeringDocument4 pagesMock Board Examination Licensure Examination For Chemical Engineers (April 2006) Subject: Chemical EngineeringMinnie InarapmasNo ratings yet

- ElegmaDocument40 pagesElegmaNoriel_James_B_7906No ratings yet

- TOS - 3rd - Science 7Document2 pagesTOS - 3rd - Science 7Ley CanasaNo ratings yet