Professional Documents

Culture Documents

Turbine Glands

Uploaded by

Kiran KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbine Glands

Uploaded by

Kiran KumarCopyright:

Available Formats

Turbine Glands

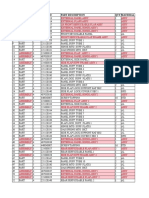

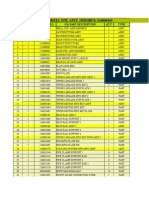

GLAND STEAM SYSTEM

The purpose of the gland steam system is to reduce steam leakage to a minimum and to prevent air ingress. Steam leakage leads to the requirement for increased make up; this increases the load on the feed and boiler water treatment chemicals and to a deterioration of the working environment surrounding the power plant. Air ingress leads to a loss of vacuum and hence reduction in plant efficiency , and causes problems of thermal stressing around the gland as well as increases oxygen content of the exhaust steam. System The system consists of a set of glands fitted to the turbine, and a steam supply and exhaust system to service them.

The system above shows the two means of controlling the gland receiver pressure; the first is by having a dump in split range with the make-up valve, the second is the use of a pressure regulating valve which dumps excess pressure to the exhaust line. The normal operating pressure is around 0.1 to 0.2 bar. Gland steam condenser The gland steam condenser is cooled by the condensate extracted from the main condenser and so acting as a feed heater.The gland steam often shares its condenser with the air ejector reducing the cost of having two units A fan is fitted to induce a flow through the system without incurring a negative pressure in the final pocket as this would allow the ingress of air. This is ensured by the fitting on valves to the exhaust line from the glands so enabling the back pressure to be set. Miscellaneous A vapour hood is sometimes fitted with extraction at negative pressure reducing leakage still further. The turbine rotor is shaped to prevent oil which leaks from the bearing traveling down the rotor and entering the gland

Schematic of pockets on inlet end of HP turbine

There are two pockets in the glands fitted to all the ends of the turbine; the inner pocket is connected to the gland steam supply and the outer to the exhaust line . The HP turbine has to further inner pockets due to it having to deal with steam at higher pressures and hence increased leakage. The innermost pocket simply passes leakage steam back to the casing a few stages downstream, the next pocket passes the leakage steam to the HP turbine exhaust. When the engine is stopped the gland steam make-up supplies the system requirements. When the engine is in use the flow of steam to the supply pocket of the inlet end to the HP end reverses and the gland starts to supply the system reducing the quantity the makeup has to provide. At full power the only gland requiring steam will be the exhaust end of the LP turbine, the other will be either supplying the system or supplying themselves sufficiently to not require steam from the system.In this condition the make-up would be shut and the pressure regulated by the dump opening.

Principle of the Labyrinth Gland

The leakage of steam is reduced by the use of labyrinths, these provide a tortuous path for the steam to follow to exit the turbine reducing the pressure across a series of fine clearances to a level that can easily be managed by the gland steam system.

With in the cavity where the flow is turbulent, the velocity of the steam is increased with an associated drop in pressure. The kinetic energy is then dissipated by the change in direction, turbulence and eddy currents.fugal action. Very small heads can deal with large pressure drops

Materials

A typical clearance between the rotor and the fixed gland is about 0.25 to 0.38mm, hence with very little rotor distortion the possibility of rub occurs. This has led to the use of soft, self lubricating materials for the gland segments. The simplest form of gland consists of carbon rings held on to the shaft by the use of garter springs. Carbon Dioxide is formed with contact with superheated steam making this material only suitable for low temperature requirements. Brass and Copper led alloys have been found suitable with an alloy of Lead, Copper and Nickel being suitable up to 520oC.

Shaft Rub

Should the rotor bend, say due to carry over the area of rub on the gland will be over a small arc. With successive revolutions the heat generated will increase bend. This increases the area of contact and magnifies the condition by the increased generation of heat. Plastic flow occurs when the material yields under compression to reduce the stress and on cooling a permanent set occurs. One side of the gland, typically the stationary part is made up of thinned sections thereby reducing the contact area to a minimum. Spring loaded glands prevent this from happening by giving under contact with the rotor , limiting the heat generated and giving time for the rotor to recover its shape. Spring backed gland

The minimum clearance for a spring backed gland ranges from 0.3 mm fot eh HP inlet to 0.63 mm for the Astern turbine. For fixed glands the minimum is 0.5 mm. With the smaller clearances there is an increase in efficiency

Hydrostatic Gland

A wheel forged on the rotor ends runs in a water bath. This water is flung out by centrifugal action. The gland only needs to be small as large pressure drops require little head. The system cannot be used on reversible sets as the seal effect is lost at reduced revolutions. It is more likely to be seen on turbo-alternators.

You might also like

- Zsec 1Document2 pagesZsec 1Kiran KumarNo ratings yet

- Technical Guide Edition 2.0 Gas Spring MountingDocument23 pagesTechnical Guide Edition 2.0 Gas Spring Mountingcrashnburn4uNo ratings yet

- Daily ScheduleDocument6 pagesDaily ScheduleKiran KumarNo ratings yet

- Plot No 117 - 118Document28 pagesPlot No 117 - 118Kiran KumarNo ratings yet

- Goldstone Infratech Limited: E-Bus Division HyderabadDocument1 pageGoldstone Infratech Limited: E-Bus Division HyderabadKiran KumarNo ratings yet

- Daily ScheduleDocument6 pagesDaily ScheduleKiran KumarNo ratings yet

- c9 Panelling Concept1 Final BomDocument10 pagesc9 Panelling Concept1 Final BomKiran KumarNo ratings yet

- 6template For An Agreement of Sale of Immovable Property PDFDocument2 pages6template For An Agreement of Sale of Immovable Property PDFKiran KumarNo ratings yet

- UP Design Guide v1.2Document20 pagesUP Design Guide v1.2Kiran KumarNo ratings yet

- Dullapalli Plot 235 SQ - YardDocument14 pagesDullapalli Plot 235 SQ - YardKiran KumarNo ratings yet

- Cooling System in An AutomobileDocument13 pagesCooling System in An AutomobileKiran KumarNo ratings yet

- Department Design Sheet ReviewDocument4 pagesDepartment Design Sheet ReviewKiran KumarNo ratings yet

- Shell Structure Assembly Parts List for MinibusDocument4 pagesShell Structure Assembly Parts List for MinibusKiran KumarNo ratings yet

- Olectra Greentech Limited: Description: Remarks Size Material QTY Description Part No SL NoDocument1 pageOlectra Greentech Limited: Description: Remarks Size Material QTY Description Part No SL NoKiran KumarNo ratings yet

- Z Sec Radiator Flaps LH RHDocument1 pageZ Sec Radiator Flaps LH RHKiran KumarNo ratings yet

- Invoice Copy Employee Contribution - ESIC & EPFO. Attendance Sheet ESIC Challan EPFO ChallanDocument1 pageInvoice Copy Employee Contribution - ESIC & EPFO. Attendance Sheet ESIC Challan EPFO ChallanKiran KumarNo ratings yet

- Goldstone Infratech Limited: E-Bus Division HyderabadDocument1 pageGoldstone Infratech Limited: E-Bus Division HyderabadKiran KumarNo ratings yet

- Seat Layout k6Document1 pageSeat Layout k6Kiran KumarNo ratings yet

- New Drawing Release 09/03/18 DIM 1296 WAS 923 & 460 WAS 905 13/09/18Document1 pageNew Drawing Release 09/03/18 DIM 1296 WAS 923 & 460 WAS 905 13/09/18Kiran KumarNo ratings yet

- Projects, Assignments & Task Sheet - Review Department Design Sl. No. Project Assignment TaskDocument3 pagesProjects, Assignments & Task Sheet - Review Department Design Sl. No. Project Assignment TaskKiran KumarNo ratings yet

- Pen Table FilesDocument4 pagesPen Table FilesAnonymous TG3lMENo ratings yet

- June 2019 Employee Attendance ReportDocument4 pagesJune 2019 Employee Attendance ReportKiran KumarNo ratings yet

- c9 Panelling Concept1 Final BomDocument10 pagesc9 Panelling Concept1 Final BomKiran KumarNo ratings yet

- Aug 18Document6 pagesAug 18Kiran KumarNo ratings yet

- External Panel Parts List and AssembliesDocument10 pagesExternal Panel Parts List and AssembliesKiran KumarNo ratings yet

- NocDocument1 pageNocKiran KumarNo ratings yet

- New Drawing Release 09/03/18 DIM 795 WAS 523 & 1102 WAS 515 13/09/18Document1 pageNew Drawing Release 09/03/18 DIM 795 WAS 523 & 1102 WAS 515 13/09/18Kiran KumarNo ratings yet

- Module - 7Document64 pagesModule - 7Kiran KumarNo ratings yet

- ESI Form2Document2 pagesESI Form2Jay NayakNo ratings yet

- Guntur Break UpDocument1 pageGuntur Break UpKiran KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012Document100 pages2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012ferrerick100% (3)

- ROLLS ROYCE Gasturbines - tcm92-4977Document20 pagesROLLS ROYCE Gasturbines - tcm92-4977Vipin Thathiriyat100% (3)

- Screenshot 2022-06-20 at 7.24.17 PMDocument14 pagesScreenshot 2022-06-20 at 7.24.17 PMNahid IslamNo ratings yet

- Analysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionDocument19 pagesAnalysis of Uncertainties in Measurement of Rotor Blade Tip Clearance in Gas Turbine Engine Under Dynamic ConditionJOSEPH TinderNo ratings yet

- CFX-Intro 14.5 Appendix A TurboDocument21 pagesCFX-Intro 14.5 Appendix A TurboShaheen S. RatnaniNo ratings yet

- Turbomachine PDFDocument93 pagesTurbomachine PDFVarun PathakNo ratings yet

- Wind Turbine DesignDocument58 pagesWind Turbine Designlogicvirus100% (1)

- Dcam PT 66 Training Module 15.1 FundamentalsDocument57 pagesDcam PT 66 Training Module 15.1 FundamentalsSThaneasMurNo ratings yet

- Turbine Control Software: ITS-Industrial Turbine Services GroupDocument19 pagesTurbine Control Software: ITS-Industrial Turbine Services GroupSyed Mohammed Hussain100% (1)

- Low Head Hydropower From Wastewater PDFDocument8 pagesLow Head Hydropower From Wastewater PDFमनीष कश्यप100% (1)

- Turbine Protection System PresentationDocument24 pagesTurbine Protection System PresentationAbhishek Bansal100% (1)

- Ocean EnergyDocument22 pagesOcean EnergyPrathamesh OmtechNo ratings yet

- 8 International Mechanical Engineering Research Conference Reaction PaperDocument3 pages8 International Mechanical Engineering Research Conference Reaction PaperEymann JalaNo ratings yet

- Dependente Operacional Vento Impacto de Vigília Turbina em Fluxo de Impulso SuperfícieDocument10 pagesDependente Operacional Vento Impacto de Vigília Turbina em Fluxo de Impulso SuperfícieEMMANUELLE CARNEIRO DE MESQUITANo ratings yet

- Gas Turbine Technology Evolution: A Designer'S Perspective: Turbovision, Inc., Palm Beach Gardens, Florida 33418Document19 pagesGas Turbine Technology Evolution: A Designer'S Perspective: Turbovision, Inc., Palm Beach Gardens, Florida 33418John Carella100% (1)

- Delhi's IPGCL and PPCL power stationsDocument9 pagesDelhi's IPGCL and PPCL power stationsKirti GuptaNo ratings yet

- (1990) On The Dynamis of Cracked Rotors, A Literature SurveyDocument5 pages(1990) On The Dynamis of Cracked Rotors, A Literature SurveyJoel Morales PerezNo ratings yet

- Tesla Turbine Simulation and Performance AnalysisDocument13 pagesTesla Turbine Simulation and Performance AnalysisAmal ShajiNo ratings yet

- A) Wind Power: Low Solidity, Low Torque - Darries Long Drive Shaft - SavoneiousDocument4 pagesA) Wind Power: Low Solidity, Low Torque - Darries Long Drive Shaft - Savoneiousaravind babuNo ratings yet

- Wave Assisted Propulsion by Lieutenant General SPC Cory A. HofstadDocument6 pagesWave Assisted Propulsion by Lieutenant General SPC Cory A. HofstadCory Andrew HofstadNo ratings yet

- Maintenance Prevention On Coal Fired Power Plant BoilerDocument5 pagesMaintenance Prevention On Coal Fired Power Plant BoilerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Installation Manual Waterjet - 7739920Document128 pagesInstallation Manual Waterjet - 7739920George Rahău100% (3)

- ME Mechanical-Engineering SyllabiDocument4 pagesME Mechanical-Engineering SyllabiAbdur RazzaqNo ratings yet

- Gas Turbine System & PropulsionDocument35 pagesGas Turbine System & PropulsionnaveedsidhuNo ratings yet

- 5 - Condensor, GSC and Ejector in Thermal Power PlantDocument36 pages5 - Condensor, GSC and Ejector in Thermal Power PlantEshwar Pawar100% (1)

- EX - NO:6 Dismantling of Jet Engine AimDocument4 pagesEX - NO:6 Dismantling of Jet Engine AimesakkimuthuNo ratings yet

- Omc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyDocument2 pagesOmc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyBala JiNo ratings yet

- Investigating Generator Pole-Slip Protection PerformanceDocument170 pagesInvestigating Generator Pole-Slip Protection PerformanceVictorNo ratings yet

- Mech 422 Problem Sets Fluid MachineriesDocument7 pagesMech 422 Problem Sets Fluid MachineriesMarvin LabajoNo ratings yet

- Seal Steam RegulatorDocument10 pagesSeal Steam RegulatorBiplab DasNo ratings yet