Professional Documents

Culture Documents

Belajar B. Inggris

Uploaded by

Mario HanamiciOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belajar B. Inggris

Uploaded by

Mario HanamiciCopyright:

Available Formats

2010 SECTION V

ARTICLE 2

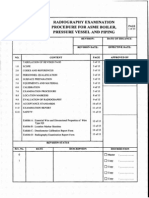

A R T I C L E 2 RADIOGRAPHIC EXAMINATION

T-210

SCOPE

The radiographic method described in this Article for examination of materials including castings and welds shall be used together with Article 1, General Requirements. Definitions of terms used in this Article are in Mandatory Appendix V of this Article. Certain product-specific, technique-specific, and application-specific requirements are also given in other Mandatory Appendices of this Article, as listed in the table of contents. These additional requirements shall also be complied with when an Appendix is applicable to the radiographic or radioscopic examination being conducted. T-220 T-221 GENERAL REQUIREMENTS Procedure Requirements

A lead symbol "B," with minimum dimensions of % in. (13 mm) in height and 1/16 in. (1.5 mm) in thickness, shall be attached to the back of each film holder during each exposure to determine if backscatter radiation is exposing the film. T-224 System of Identification

A system shall be used to produce permanent identification on the radiograph traceable to the contract, component, weld or weld seam, or part numbers, as appropriate. In addition, the Manufacturer's symbol or name and the date of the radiograph shall be plainly and permanently included on the radiograph. This identification system does not necessarily require that the information appear as radiographic images. In any case, this information shall not obscure the area of interest. T-225 Monitoring Density Limitations of Radiographs

T-221.1 Written Procedure. Radiographic examination shall be performed in accordance with a written procedure. Each procedure shall include at least the following information, as applicable: (a) material type and thickness range (b) isotope or maximum X-ray voltage used (c) source-to-object distance (D in T-274.1) (d) distance from source side of object to film (d in T274.1) (e) source size (F in T-274.1) (a) film brand and designation (f) screens used T-221.2 Procedure Demonstration. Demonstration of the density and image quality indicator (IQT) image requirements of the written procedure on production or technique radiographs shall be considered satisfactory evidence of compliance with that procedure. T-222 Surface Preparation

Either a densitometer or step wedge comparison film shall be used for judging film density. T-226 Extent of Examination

The extent of radiographic examination shall be as specified by the referencing Code Section. T-230 EQUIPMENT AND MATERIALS

T-231 Film T-231.1 Selection. Radiographs shall be made using industrial radiographic film.

T-222.1 Materials Including Castings. Surfaces shall satisfy the requirements of the applicable materials specification or referencing Code Section, with additional conditioning, if necessary, by any suitable process to such a degree that the images of surface irregularities cannot mask or be confused with the image of any discontinuity on the resulting radiograph. 7 T-222.2 Welds. The weld ripples or weld surface irregularities on both the inside (where accessible) and outside shall be removed by any suitable process to such a degree that the images of surface irregularities cannot mask or be confused with the image of any discontinuity on the resulting radiograph. The finished surface of all butt-welded joints may be flush with the base material or may have reasonably uniform crowns, with reinforcement not to exceed that specified in the referencing Code Section. T-223 Backscatter Radiation

You might also like

- Asme Sec V A-2-2004 PDFDocument39 pagesAsme Sec V A-2-2004 PDFjaire esparzaNo ratings yet

- ASME Section V Art 2 SpanishDocument8 pagesASME Section V Art 2 SpanishScribdTranslationsNo ratings yet

- RT Asme VDocument9 pagesRT Asme Vhernando gelvesNo ratings yet

- Lim - Asme VDocument7 pagesLim - Asme VGilang AdiNo ratings yet

- NDT - RADIOGRAPHDocument12 pagesNDT - RADIOGRAPHDedy TriandaNo ratings yet

- LADWER ASME V April 2017Document7 pagesLADWER ASME V April 2017Luthfi ArdiansyahNo ratings yet

- RT ASME Art 2Document39 pagesRT ASME Art 2Florin TrNo ratings yet

- Radiographic Testing ProcedureDocument8 pagesRadiographic Testing ProcedureRai Singh MalhiNo ratings yet

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureJake SparrowNo ratings yet

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDocument15 pagesRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Lloyd S Register Sec V 2017 Edition Key ChangesDocument27 pagesLloyd S Register Sec V 2017 Edition Key ChangesDilip VaradharajanNo ratings yet

- RT-procedure SampleDocument19 pagesRT-procedure Sampleneelapu mahesh reddyNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Mandatory Appendix Ii - Asme VDocument2 pagesMandatory Appendix Ii - Asme VAngelTinocoNo ratings yet

- Kie TP R297Document35 pagesKie TP R297Muhamad Dahlan STNo ratings yet

- ASME Section V - NDE Requirements: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Document25 pagesASME Section V - NDE Requirements: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Anbarasan PerumalNo ratings yet

- Procedure Radiography - QU - RT - ASME B31.3 - 2014Document20 pagesProcedure Radiography - QU - RT - ASME B31.3 - 2014papathsheila100% (1)

- RT Procedure Rev.01Document30 pagesRT Procedure Rev.01shivanshsovNo ratings yet

- Procedure: R E A (P) LDocument19 pagesProcedure: R E A (P) LPramod GrNo ratings yet

- Procedure For Radiography TestingDocument9 pagesProcedure For Radiography TestingKarrar TalibNo ratings yet

- RT Procedures For WeldDocument19 pagesRT Procedures For WeldABHIJIT GIRINo ratings yet

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- Radiographic Test ProcedureDocument10 pagesRadiographic Test ProcedureNoor A AlamNo ratings yet

- Ut ProcedureDocument12 pagesUt ProcedurerohithNo ratings yet

- Sop RTDocument9 pagesSop RTEddy Dwi CahyonoNo ratings yet

- RT ProcedureDocument14 pagesRT ProcedureEngEslam7100% (4)

- MIL-STD-883H - 2012 - X-Ray of Semiconductor and Hybrid DevicesDocument16 pagesMIL-STD-883H - 2012 - X-Ray of Semiconductor and Hybrid DevicesJo BloomNo ratings yet

- Sicc-Rt-01 Asme Rev 01Document29 pagesSicc-Rt-01 Asme Rev 01Enrique Campos Cannavaro100% (1)

- Radiography Test Inspection Free NDT Sample Procedure 1 4Document5 pagesRadiography Test Inspection Free NDT Sample Procedure 1 4Alam MD SazidNo ratings yet

- Code Case - 2235-10Document10 pagesCode Case - 2235-10Nilesh Pathare0% (1)

- Article 16 Magnetic Flux Leakage (MFL) ExaminationDocument5 pagesArticle 16 Magnetic Flux Leakage (MFL) ExaminationleonciomavarezNo ratings yet

- RT Proceure Gas Pipeline Abu Humos/ El Nobaria 42" Diameter & 65 KM LengthDocument14 pagesRT Proceure Gas Pipeline Abu Humos/ El Nobaria 42" Diameter & 65 KM LengtharavindanNo ratings yet

- RT ProcDocument14 pagesRT ProcaravindanNo ratings yet

- RT Procedure GeneralDocument18 pagesRT Procedure GeneralvsnaiduqcNo ratings yet

- Acceptance CriteriaDocument11 pagesAcceptance Criteriarajali798890% (10)

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- General Procedure For Radiographic Examination: PAE - RT-001 Rev.0Document13 pagesGeneral Procedure For Radiographic Examination: PAE - RT-001 Rev.0NguyenThanhdung100% (1)

- RT ProcedureDocument26 pagesRT ProcedureKoshala Balasuriya100% (1)

- Mandatory Appendix Ix - Asme VDocument3 pagesMandatory Appendix Ix - Asme VAngelTinocoNo ratings yet

- Rediographic Examination ProcedureDocument6 pagesRediographic Examination ProcedureAbank RoonyNo ratings yet

- Codigo ASME (Arrastrado)Document3 pagesCodigo ASME (Arrastrado)Mou RmzNo ratings yet

- RadiographyDocument5 pagesRadiographyAman KumarNo ratings yet

- Casting Procedure PDFDocument14 pagesCasting Procedure PDFShailendra Bhadoria100% (1)

- Apendice Mandatorio I - ASME VDocument3 pagesApendice Mandatorio I - ASME VAngelTinocoNo ratings yet

- Ultrasonic Testing Procedure: 1. ScopeDocument10 pagesUltrasonic Testing Procedure: 1. ScopePrashant PuriNo ratings yet

- RTDocument14 pagesRTaravindanNo ratings yet

- NDT-OPR-011-31 Rad of Welds ASME V Article 2Document16 pagesNDT-OPR-011-31 Rad of Welds ASME V Article 2diaccessltd_17172961100% (1)

- Procedimiento de RadiografiaDocument40 pagesProcedimiento de Radiografiajose10001No ratings yet

- Guidelines For The Use of Digital Detector Arrays and Computed Radiology For Aerospace Casting InspectionsDocument32 pagesGuidelines For The Use of Digital Detector Arrays and Computed Radiology For Aerospace Casting InspectionsFabien Faucher100% (2)

- OPGW Cables SpecDocument45 pagesOPGW Cables SpecOffshre Eng-Solutions100% (1)

- Job Procedure For RadiographyDocument12 pagesJob Procedure For RadiographyMecon HyderabadNo ratings yet

- UT Procedure PDFDocument23 pagesUT Procedure PDFcentaury2013No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Closed Circuit Television: CCTV Installation, Maintenance and OperationFrom EverandClosed Circuit Television: CCTV Installation, Maintenance and OperationRating: 3 out of 5 stars3/5 (2)

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Technical Properties For H-Beam & Wide Flange: Dimentional ToleranceDocument1 pageTechnical Properties For H-Beam & Wide Flange: Dimentional ToleranceMario HanamiciNo ratings yet

- Gambar 1Document10 pagesGambar 1Mario HanamiciNo ratings yet

- High Strength Hexagon Bolts (JIS B1186)Document4 pagesHigh Strength Hexagon Bolts (JIS B1186)Mario HanamiciNo ratings yet

- Hal 8Document3 pagesHal 8Mario HanamiciNo ratings yet

- Inspection Test Plan and Log: Inspection-Test by Date Forwarded To Contr. Off. RemarksDocument1 pageInspection Test Plan and Log: Inspection-Test by Date Forwarded To Contr. Off. RemarksMario HanamiciNo ratings yet

- Data Sheet 3VA2225-5HL32-0AA0: ModelDocument7 pagesData Sheet 3VA2225-5HL32-0AA0: ModelJENNYNo ratings yet

- PW160-7K S 0411Document890 pagesPW160-7K S 0411ado_22100% (3)

- Vallorbs Guide Cut Vs Rolled ThreadsDocument3 pagesVallorbs Guide Cut Vs Rolled ThreadsOrlando AriasNo ratings yet

- Lesson Plan in Mathematics Grade9Document6 pagesLesson Plan in Mathematics Grade9Abegail VillanuevaNo ratings yet

- 6-Boundary and Initial ConditionsDocument8 pages6-Boundary and Initial ConditionsqazwsxNo ratings yet

- Sternberg TheoryDocument20 pagesSternberg TheoryKhadijah ElamoreNo ratings yet

- Curriculum Vitae: Alex Gnanamani.KDocument4 pagesCurriculum Vitae: Alex Gnanamani.KDIJUNo ratings yet

- Cpu 2000 App ListDocument11 pagesCpu 2000 App ListKaiser IqbalNo ratings yet

- Coneplot (20170407)Document30 pagesConeplot (20170407)LinggaNo ratings yet

- Executive Leadership: Artificial Intelligence Primer For 2021Document10 pagesExecutive Leadership: Artificial Intelligence Primer For 2021ranga.raman100% (1)

- In Search of The Indo Europeans J P Mallory TextDocument289 pagesIn Search of The Indo Europeans J P Mallory TextHISTORY OF MUSICNo ratings yet

- MHSIR00491976Document1 pageMHSIR00491976Patan Rafiq KhanNo ratings yet

- G-10 Biology, 3rd Work Sheet On Nervous SystemDocument3 pagesG-10 Biology, 3rd Work Sheet On Nervous SystemhannahNo ratings yet

- 2010 Ue CDocument7 pages2010 Ue CLau Sze WaNo ratings yet

- ContemporaryDocument2 pagesContemporaryAlbert PaggaoNo ratings yet

- HOUSEKEEPING - WEEK 1 UpdatedDocument5 pagesHOUSEKEEPING - WEEK 1 UpdatedMaria Rizza IlaganNo ratings yet

- ARIMI Et Al-2010-Journal of Texture Studies PDFDocument21 pagesARIMI Et Al-2010-Journal of Texture Studies PDFRomaric OuetchehouNo ratings yet

- Lesson Outline: Introduction To LeadershipDocument2 pagesLesson Outline: Introduction To LeadershipAmritpal SinghNo ratings yet

- En 4j2 4fDocument71 pagesEn 4j2 4fRafael HernandezNo ratings yet

- Probability DistributionsDocument167 pagesProbability DistributionslihaiyangNo ratings yet

- Final Test 1 K 2 - KeyDocument10 pagesFinal Test 1 K 2 - KeyDuy HưngNo ratings yet

- 10D Unit-Coral Reefs PDFDocument14 pages10D Unit-Coral Reefs PDFIWAN KUNCORONo ratings yet

- Planer MachineDocument37 pagesPlaner Machinemechfame89% (9)

- Toyota Toyota+sienna+2013+manualDocument1 pageToyota Toyota+sienna+2013+manualNur Cholik Widyan Sa0% (1)

- DAA NotesDocument97 pagesDAA Notesanish.t.pNo ratings yet

- Survey of Mechanical Working: A. IntroductionDocument4 pagesSurvey of Mechanical Working: A. IntroductionAsif AhmedNo ratings yet

- Public Servants and Government ServantsDocument10 pagesPublic Servants and Government Servantsalexandra angelinaNo ratings yet

- Blue A Ks2 Test3Document6 pagesBlue A Ks2 Test3Mateo García-PumarinoNo ratings yet

- HPC Module 1Document48 pagesHPC Module 1firebazzNo ratings yet