Professional Documents

Culture Documents

Concrete Technology

Uploaded by

Kaushal KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Technology

Uploaded by

Kaushal KumarCopyright:

Available Formats

31Jul13

31Jul13

Kinetics of cement hydration

The progress of cement hydration depends on: Rate of dissolution of the involved phases (in the initial stages and at later stages) Rate of nucleation and crystal growth of hydrates Rate of diffusion of water and dissolved ions through the hydrated materials already formed

1

Factors affecting the kinetics of hydration

The phase composition of cement The amount and form of gypsum in the cement Fineness of cement w/c of mix Curing conditions Hydration temperature Presence of chemical admixtures

2

Several theories proposed

Dormant period

Stages in Cement Hydration

3. Acceleration stage (3 12 hours after mixing): Nucleation and growth of C-S-H (often termed as the second-stage CSH) and CH occurs. C2S also starts hydrating substantially. Ca2+ concentration in the liquid phase declines as CH starts precipitating. SO42- concentration starts to decline with increasing AFt formation, and adsorption of SO42on C-S-H.

6

Formation of an impermeable hydrate layer (CSH) on the surface of the C3S particle precludes the further dissolution of C3S. The hydrate layer has a lower C/S ratio compared to C3S. As a result Ca2+ is released into the liquid phase (which contains OH-), and a silica rich layer forms on the surface of the C3S particle. This electrical double layer thus formed prevents any reaction to form CSH by impeding the passage of ions. Liquid phase gets supersaturated with respect to CH. As a result CH starts precipitating and this stops the further dissolution of C3S.

End of the dormant period can come about in many ways:

The barrier can weaken due to ageing. Diffusion of ions can occur across the barrier by osmosis. A gradual weakening of the electrical double layer may occur. Nucleation of CH can get slowed down when the nuclei 5 start approaching their critical size.

Stages in Cement Hydration

1. Pre-induction period (first few minutes):

Rapid dissolution of ionic species (alkali sulphates contribute K+, Na+, and SO42-; CaSO4 dissolves until saturation, contributing Ca2+ and SO42-) C3A dissolves, and reacts with SO4 to form ettringite (AFt), which forms a surface barrier. C4AF also reacts to form AFt.

2-

Stages in Cement Hydration

2. Induction (dormant) period (first few hours):

Formation of electrical double layer, and the precipitation of Calcium hydroxide (CH) leads to the dormant period

Stages in Cement Hydration

4. Post-acceleration period: Slow down due to decline in non-reacted material, and because the process becomes diffusion controlled. The contribution of C2S increases steadily, leading to a decline in the rate of formation of CH. Consumption of SO42- leads to a conversion of ettringite to Monosulphate.

7

Evolution of hydration (Normal Setting)

C-S-H forms on the surface of dissolving C3S. C/S of CS-H is lesser than of C3S, thus an increase of the Ca2+ concentration in the liquid phase occurs. Only very small % of C2S reacts at this stage. 3

The concentration of SO42- remains constant as the amount consumed due to AFt formation is balanced by the amount dissolved from gypsum.

Young et al. 1998

IndianInstituteofTechnologyBombay

IndianInstituteofTechnologyBombay

31Jul13

Evolution of hydration products

Some more points on Hydration mechanism

In the first few minutes, about 2 10 % of C3S hydrates, and a significant fraction is consumed within 28 days. On the other hand, 5 25% of C3A reacts in the first few minutes of hydration. With an increase in the amount of SO3, the C3S reaction becomes faster. However, beyond a limit, SO3 can start causing retardation. The initial reactivity depends on the quantity and quality of alkalis present (K+ increases reactivity, while Na+ decreases it). The reactivity of C4AF is dependent on the A/F of the cement. The method of grinding cement may also influence the hydration kinetics.

Taylor, 1968

10

Heat evolution during cement hydration

11

IndianInstituteofTechnologyBombay

You might also like

- Sl. No. Enrollment No Name Attendance AssesmentDocument4 pagesSl. No. Enrollment No Name Attendance AssesmentKaushal KumarNo ratings yet

- Assignment 4Document2 pagesAssignment 4Kaushal KumarNo ratings yet

- Faculty and Lab Staff Duty Roster: Sr. NO. Name Designation Department RemarksDocument3 pagesFaculty and Lab Staff Duty Roster: Sr. NO. Name Designation Department RemarksKaushal KumarNo ratings yet

- Capstone Projects PDFDocument3 pagesCapstone Projects PDFKaushal KumarNo ratings yet

- Sl. No. Name Roll No. Mobile No. Recovery Email IDDocument24 pagesSl. No. Name Roll No. Mobile No. Recovery Email IDKaushal KumarNo ratings yet

- L2 - MRCS - Embedded Metal Corrosion - 2Document35 pagesL2 - MRCS - Embedded Metal Corrosion - 2Kaushal KumarNo ratings yet

- Chhattisgarh Mains Paper V Section IIIDocument24 pagesChhattisgarh Mains Paper V Section IIIKaushal KumarNo ratings yet

- Chapter 1 - IntroductionDocument4 pagesChapter 1 - IntroductionKaushal KumarNo ratings yet

- Assignment 8 PDFDocument1 pageAssignment 8 PDFKaushal KumarNo ratings yet

- L1 - MRCS - Embedded Metal Corrosion - 1Document30 pagesL1 - MRCS - Embedded Metal Corrosion - 1Kaushal Kumar100% (1)

- Duty Chart t1 Sep2018Document34 pagesDuty Chart t1 Sep2018Kaushal KumarNo ratings yet

- BBS IntroDocument15 pagesBBS IntroKaushal KumarNo ratings yet

- Lec 67Document8 pagesLec 67Kaushal KumarNo ratings yet

- Assignment 1 CTM2019Document2 pagesAssignment 1 CTM2019Kaushal KumarNo ratings yet

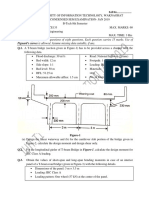

- Bridge Engineering Final Examination PaperDocument3 pagesBridge Engineering Final Examination PaperKaushal KumarNo ratings yet

- CE (ESE Paper-II) Mixed Subjects TestsDocument1 pageCE (ESE Paper-II) Mixed Subjects TestsKaushal KumarNo ratings yet

- Assignment 4 (Crashing)Document1 pageAssignment 4 (Crashing)Kaushal KumarNo ratings yet

- A Mid - Term Presentation Submitted in Fulfillment of The Requirements For The Degree ofDocument11 pagesA Mid - Term Presentation Submitted in Fulfillment of The Requirements For The Degree ofKaushal KumarNo ratings yet

- Analysis of Structures Above Ground Surface For Blast LoadingDocument1 pageAnalysis of Structures Above Ground Surface For Blast LoadingKaushal KumarNo ratings yet

- Fig. A1: Peak Incident Pressure Versus The Ratio of Normal Reflected Pressure/Incidence Pressure For A Free Air BurstDocument5 pagesFig. A1: Peak Incident Pressure Versus The Ratio of Normal Reflected Pressure/Incidence Pressure For A Free Air BurstKaushal KumarNo ratings yet

- Overview of Smart Structure MaterialDocument36 pagesOverview of Smart Structure MaterialKaushal Kumar100% (1)

- Cement Composition and Special Cements - Part 2Document14 pagesCement Composition and Special Cements - Part 2Kaushal KumarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Smeaton ProjectDocument18 pagesSmeaton ProjectNemesisRepublic@blogspot.comNo ratings yet

- Marketing Innovation Project by GRP 6Document7 pagesMarketing Innovation Project by GRP 6muskaan bhadadaNo ratings yet

- Technical Seminar On Fly Ash For Cement ConcreteDocument30 pagesTechnical Seminar On Fly Ash For Cement Concretesantkabir100% (1)

- Concrete EstimateDocument13 pagesConcrete EstimateKarl MonfortNo ratings yet

- Advanced Concrete Technology - Manu SanthanamDocument1,066 pagesAdvanced Concrete Technology - Manu SanthanamGandhi Sagar100% (2)

- WRD CSR 2019-20Document188 pagesWRD CSR 2019-20Murali GawandeNo ratings yet

- Is 269 Final Product ManualDocument14 pagesIs 269 Final Product ManualBiswajit MansinghNo ratings yet

- Jet Grouting To Construct A Soilcrete Wall Using...Document12 pagesJet Grouting To Construct A Soilcrete Wall Using...BajocarNo ratings yet

- Airfield PCCP Construction Spec Supplemental Report - Final - IPRF Aug 20Document92 pagesAirfield PCCP Construction Spec Supplemental Report - Final - IPRF Aug 20Shashank Tiwari100% (1)

- VRM OKoookuuiiiiljjjjyggyyDocument8 pagesVRM OKoookuuiiiiljjjjyggyyRakaNo ratings yet

- CIP 5 Plastic Shrinkage Cracking PDFDocument2 pagesCIP 5 Plastic Shrinkage Cracking PDFSwëêt Rãsçäl SëlvåNo ratings yet

- List of MaterialsDocument41 pagesList of MaterialsSourav BasakNo ratings yet

- Sika Concrete HandbookDocument151 pagesSika Concrete HandbookFatjon ShahaNo ratings yet

- Methods of Soil and Base StabilizationDocument82 pagesMethods of Soil and Base StabilizationSunil Bose100% (1)

- Al-Alamiah Ready Mixer Costs. K150 - K350Document1 pageAl-Alamiah Ready Mixer Costs. K150 - K350Mohammed Abd ElazizNo ratings yet

- FEASIBILTY STUDY OF ECObricksDocument19 pagesFEASIBILTY STUDY OF ECObricksMichelle Cruzado Lagumay67% (3)

- 21-Clay Bricklaying Made EasyDocument4 pages21-Clay Bricklaying Made EasyMacdonald ChikasimaNo ratings yet

- Marble Chips in ConcreteDocument6 pagesMarble Chips in ConcreteMidhun JosephNo ratings yet

- PWD SR 2018 19Document841 pagesPWD SR 2018 19Shashank SNo ratings yet

- Expanding and Plasticising Powder Grouting AdmixtureDocument2 pagesExpanding and Plasticising Powder Grouting AdmixtureYASHICA VAITTIANATHANNo ratings yet

- ITEM 200 Latest 2004Document12 pagesITEM 200 Latest 2004Marinella AbellaNo ratings yet

- Mix Designs: Appendix 2Document33 pagesMix Designs: Appendix 2BartoFreitasNo ratings yet

- Standard Codes For Concrete AdmixturesDocument2 pagesStandard Codes For Concrete AdmixturesDS20CE017Bhaskar WabhitkarNo ratings yet

- Project Proposal Enhancing The Engineering Properties of Soft Clay by Using Carpet WastesDocument7 pagesProject Proposal Enhancing The Engineering Properties of Soft Clay by Using Carpet WastesAbdullah 17-BNCIV-0931No ratings yet

- List of EStandardsDocument10 pagesList of EStandardsRetselisitsoeNo ratings yet

- Technical Seminar Report On PAPERCRETE FINALDocument8 pagesTechnical Seminar Report On PAPERCRETE FINALaditya100% (3)

- Hazem Raw Mix CompositionDocument11 pagesHazem Raw Mix CompositionHazem DiabNo ratings yet

- TDS Altius Cement Board Joint Compound CementitiousDocument2 pagesTDS Altius Cement Board Joint Compound CementitiousMoatz HamedNo ratings yet

- BAE 642-Design of Reinforce ConcreteDocument742 pagesBAE 642-Design of Reinforce ConcreteEloisa Vigonte100% (1)