Professional Documents

Culture Documents

Follower Rest

Uploaded by

Arun SfrhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Follower Rest

Uploaded by

Arun SfrhCopyright:

Available Formats

SHERLINE

PRODUCTS

INCORPORATED 1974

FOLLOWER REST

P/N 1090

THE PURPOSE OF A FOLLOWER REST The reason this tool is called a follower is because the brass supports actually move along with or follow the cutter. It is used to support a piece of round stock while it is still being machined to keep the part from deflecting away from the tool. In a normal setup, the Sherline follower rest will lead the tool. (See Figures 1 and 4.)

BRASS PAD

TOOL

PART

HOLD DOWN BLOCK KEEPS DOWNWARD PRESSURE ON FOLLOWER REST.

FIGURE 2Cutting forces on a part and how they are countered by the follower rest supports. When using a center to support the free end, newer Sherline lathes manufactured after mid-1996 have a cutout in the tailstock to allow it to overlap the table. Older machines may require the use of a tailstock spindle extension (P/N 1220) for clearance. If you are using a tailstock center, the pads should be set by moving the rest as close to the tailstock as possible, tightening and returning to cutting position. MOUNTING THE FOLLOWER REST TO THE SADDLE The Sherline follower rest attaches to the lathe saddle with a flat ended set screw. Push down on the follower rest as you tighten this screw so it is clamped flat on the bed. The small block which mounts by means of the crosslide T-slot is positioned so that the nylon tip set screw pushes down on the machined top surface of the body of the follower rest.

NYLON TIP ON SET SCREW FOLLOWER REST BODY ATTACHMENT SET SCREW HOLD DOWN BLOCK CROSSLIDE SADDLE

SET SCREW TIGHTENS ON SADDLE

FIGURE 1Follower rest installed on lathe. (Tool post removed for clarity.) A follower rest works because it counters the two main forces applied by the tool. When a tool is cutting, the stock wants to climb up on the tool as well as be pushed away. The top brass pad will keep the stock from climbing up, and the brass pad in the rear will keep the stock from being pushed away. The stock will then be cut concentric with the outside diameter because that is where it is supported. It isnt necessary to have the free end of the stock supported by a center when using a follower, but it does make for a better setup, especially for larger diameters.

FIGURE 3Follower hold down block in position.

SHERLINE PRODUCTS INC. 2350 Oak Ridge Way Vista California 92083-8345 FAX: (760) 727-7857 Toll Free Order Line: (800) 541-0735 International/Local/Tech. Assistance: (760) 727-5857 Internet: www.sherline.com

7/29/98

This screw holds down the follower rest to counter lifting forces, and its nylon face can also slide on the flat surface so the crosslide can be moved. In actual use, the tool post should be positioned so only a very small adjustment of the crosslide is required to get the part to finished size.

finish on the part will cause excessive wear on the pads. This in turn can cause your part to taper. To minimize wear, always lubricate the pads with oil when cutting. It would be wise to set up with a piece of scrap of the same material and diameter as your actual stock. When using a follower of this type, you will usually cut to the finished diameter in one pass. If you need a close tolerance part, it may be easier to turn it slightly oversize, bring it to size with a good, flat mill file and polish it with 320 grit wet/dry paper. If you have a lot of pieces to make, it pays to spend a little extra time getting the setup just right. MAKING THE CUT Run the follower rest down the part until the pads are near the end and the tool is just off the end. Dial in the desired depth of cut. If the end of the part is not supported by a center, the part may tend to spring away from the pads a little when not being pressed on by the tool. If the part isn't running perfectly true, it could cause a problem at the start of the cut because the part isnt in constant contact with the brass pads. If this is the case, slip a loop of paper around the part and pull back lightly until the part rests against the pads.

FIGURE 4Follower rest set up in normal position with pads leading the cutting tool. SETTING THE POSITION OF THE SUPPORT PADS To set the pad position, put the round piece you plan to machine in the collet or chuck you will be using. Turn the spindle by hand to make sure the part runs reasonably true. Move the saddle (with the follower rest attached) close to the spindle. Loosen the pad clamping screws, bring the brass pads in contact with the part and retighten the screws to lock them in place. Then move the follower rest back to the position required for the cut and the pads will be aligned with the headstock end of the stock. If you are dealing with very small diameter part, it may be necessary to modify the pad to assure contact. (See Figure 5.)

PULL PAPER LOOP TO KEEP PART AGAINST PADS UNTIL CUTTING

CENTERLINES OF BRASS PADS

FIGURE 5Remove the corners of the pad tips to allow them to come closer together for small parts. With a small diameter rod held in the a chuck or collet, transfer the center of the part to the side of each pad using a scribe. Because of tolerance buildup, the line may not fall on the exact center of the pad, but that will not effect the function of the follower. TIPS FOR USING THE FOLLOWER REST The round stock you use with this attachment should be very round and have a good finish. If the stock is not round, the finished part will have the same shape because the part rotates supported by its outside diameter. A poor surface

FIGURE 6Supporting a long part with a paper loop. Now run the lathe at about 200 RPM and keep the part in position with the paper loop until you begin cutting. If you don't do this, it could cause a problem if the cutter starts to cut and the end of the stock is bouncing around because it isn't running straight or is bent. Take a heavy enough cut to keep the stock firmly against the pads but still larger than the final dimension. Cut about 1/8" (4mm) of length, stop and measure the amount of error and then adjust the crosslide accordingly. (The tool will move but the follower will not.) If the diameter is correct, cut the distance required. By cutting only 1/8" the pads are still supporting the part if you take another cut.

1090 pg. 2 of 3

The part size may vary as the pads seat in. Remember to keep them oiled. Keep the RPM down and the feed rate up. A slight radius on the tool tip will improve the finish. When you stop cutting you may have to hold the stock against the pads to prevent undercutting as pressure from the tool is released. TURNING STOCK OTHER THAN ROUND If you need to turn a round end on material that isn't round (like hex or square stock), the tool must lead the pads so that the pads are running on the round surface cut by the tool. The tool can be mounted almost parallel with the bed to accomplish this. (See Figure 7.) Take your initial (starting) cut with the end of the part held close to the chuck for support. Then move it out into position where the follower rest pads are supporting the newly machined round surface of the part and cut to size. I have found it best to always start with a piece of scrap material identical to your final part for experimentation with the setup. This accessory is not hard to use, but you really need to turn a practice part first to get your speed and feed rates correct. Joe Martin, President and Owner SHERLINE Products

BRASS PAD

CROSSLIDE HOLD DOWN BLOCK

DIRECTION OF FEED

HEX OR SQUARE STOCK FOLLOWER REST BODY

TOOL POST AND TOOL

FIGURE 7Cutting non-round stock.

EXPLODED VIEW PARTS DIAGRAM

3 1 4 5 6 7

REF. NO. 1 2 3 4 5 6 7 8 9 PART NO. 1087 4060 1088 4066 4051 1094 4077 1089 3056

FOLLOWER REST PARTS LIST DESCRIPTION Follower rest body Flat Point set screw, 10-32 x 1/4" Brass pad (2) #10 Flat washer (2) Skt. hd. cap screw, 10-32 x 3/8" (2) Set Screw w/ nylon head, 10-32 x 3/8" Skt. hd. cap screw, 10-32 x 5/16" Follower hold down block Tee nut, 10-32 (Replacements available as set of 4)

8 9 2

1090 pg. 3 of 3

You might also like

- Boring Head: For P/N 3049, Metric VersionDocument2 pagesBoring Head: For P/N 3049, Metric VersionMd. Alam HasnatNo ratings yet

- Jointer Planer: Quarter 2 - Activity 5Document18 pagesJointer Planer: Quarter 2 - Activity 5YY SamaNo ratings yet

- Type CMR, Instalacion.Document4 pagesType CMR, Instalacion.Mario MarquezNo ratings yet

- Dfs-230 Assault GliderDocument1 pageDfs-230 Assault GliderCARMEN JUANA CRUZ CONDEMAITANo ratings yet

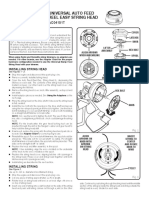

- Universal Auto Feed Reel Easy String Head: WarningDocument6 pagesUniversal Auto Feed Reel Easy String Head: WarningElena CMNo ratings yet

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGNo ratings yet

- DW 9500 ManualDocument2 pagesDW 9500 ManualCesarNo ratings yet

- Mill Vise: InstructionsDocument1 pageMill Vise: InstructionsJF LuisNo ratings yet

- 1911 Auto Schuemann Barrels InstructionsDocument2 pages1911 Auto Schuemann Barrels InstructionsDale WadeNo ratings yet

- MN4027 PDFDocument4 pagesMN4027 PDFAntonio Juan AntonioNo ratings yet

- Manual Pulidora1Document34 pagesManual Pulidora1Warner BenavidesNo ratings yet

- Atlas 4350 Hacksaw ManualDocument6 pagesAtlas 4350 Hacksaw Manualf4d711No ratings yet

- Penta ProDocument28 pagesPenta ProMarzio ScurattiNo ratings yet

- ScrollSaw 572.24700Document6 pagesScrollSaw 572.24700Doug HigelNo ratings yet

- This Manual Should Only Be Used For Elite 3.5-21x50 & 4.5-30x50 Tactical Riflescopes With These Reticle DesignsDocument32 pagesThis Manual Should Only Be Used For Elite 3.5-21x50 & 4.5-30x50 Tactical Riflescopes With These Reticle DesignsEph EweNo ratings yet

- GrowerSELECT - HS783 Fan Pulley Laser Alignment Kit Instruction ManualDocument4 pagesGrowerSELECT - HS783 Fan Pulley Laser Alignment Kit Instruction ManualOvidiu RaicovNo ratings yet

- Bearing Swaging PortableDocument13 pagesBearing Swaging PortableHemant BommidalaNo ratings yet

- Ripping and Crosscutting: A Tablesaw PrimerDocument6 pagesRipping and Crosscutting: A Tablesaw Primerpaul_fredric3173No ratings yet

- Tool Rest SVD-110: Positioning of MachineDocument5 pagesTool Rest SVD-110: Positioning of MachineLalo LeloNo ratings yet

- Quantum TrimGuide Racing AsymmetricalDocument5 pagesQuantum TrimGuide Racing AsymmetricalMarcelo MilicevickNo ratings yet

- Planed Recision Planed American ToolingDocument44 pagesPlaned Recision Planed American ToolingmeiyappannNo ratings yet

- Low-Angle and Standard Block PlanesDocument8 pagesLow-Angle and Standard Block Planesrao1307100% (1)

- Snare Bed ManualDocument8 pagesSnare Bed ManualorgqaualiaNo ratings yet

- CX200R - Mesa para TupiaDocument13 pagesCX200R - Mesa para TupiadealmeidacarlosgustavoNo ratings yet

- Naya Nangal UnitDocument24 pagesNaya Nangal UnitprabhjotbhangalNo ratings yet

- Wood PlaningDocument2 pagesWood PlaningDaniel IonNo ratings yet

- 538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualDocument4 pages538 270 Thomas Series DBZ, Sizes 50 451 Disc Couplings ManualpelakupasarNo ratings yet

- Lead Seal Casing Patches: Instruction Manual 6400Document9 pagesLead Seal Casing Patches: Instruction Manual 6400Ragui StephanosNo ratings yet

- Maximize Your M-Lok Experience With These Tips: As PackagedDocument5 pagesMaximize Your M-Lok Experience With These Tips: As PackagedlowjackNo ratings yet

- World-Wide Technical Reference Guide: Grand RegulationDocument16 pagesWorld-Wide Technical Reference Guide: Grand Regulationcjarcher1677No ratings yet

- ST 2000Document12 pagesST 2000Jorge ArbelaezNo ratings yet

- Lathe Modelling1Document4 pagesLathe Modelling1Frenchwolf420No ratings yet

- GBC USP13 ManualDocument17 pagesGBC USP13 ManualAlvaroSNo ratings yet

- Woodworking Tools and Methods NAVEDTRA 14043Document62 pagesWoodworking Tools and Methods NAVEDTRA 14043Christian Rey AbuanNo ratings yet

- 82SSJ SSJ Pulling/Running Tool Operation Manual: Design OverviewDocument3 pages82SSJ SSJ Pulling/Running Tool Operation Manual: Design Overviewsong LiNo ratings yet

- Box Profile InstallationDocument8 pagesBox Profile InstallationVarun kumarNo ratings yet

- Riflescope Instruction ManualDocument14 pagesRiflescope Instruction ManualAwal PanallNo ratings yet

- The Centre LatheDocument5 pagesThe Centre LatheShuvoVattNo ratings yet

- 8m OperationDocument3 pages8m Operationapi-469602394No ratings yet

- Series 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsDocument3 pagesSeries 13 Dir-Act 3-Piece Ball Valve Installation, Operation, and Maintenance InstructionsluchitocapoNo ratings yet

- Roof Sheet Installation GuidelinesDocument6 pagesRoof Sheet Installation Guidelinesmuzamilarshad31No ratings yet

- Ensunchadora AH-114 - SignodeDocument4 pagesEnsunchadora AH-114 - SignodeTanSoloUnMinutoNo ratings yet

- Flange Facing Operation ManualDocument4 pagesFlange Facing Operation ManualANGGUN ZURAIDNo ratings yet

- Cushion Sub: Instruction Manual 4105Document20 pagesCushion Sub: Instruction Manual 4105Foros IscNo ratings yet

- Lathe Operating InstructionsDocument24 pagesLathe Operating InstructionsJoão BraganteNo ratings yet

- Composite Spring Instructions: Please Read Instructions CarefullyDocument2 pagesComposite Spring Instructions: Please Read Instructions Carefullylaurent.lemagorouNo ratings yet

- Mountain Dulcimer History 1Document20 pagesMountain Dulcimer History 1Juli EtaNo ratings yet

- Spring Vibration Isolator Mason SLF-SLFHDocument5 pagesSpring Vibration Isolator Mason SLF-SLFHgenas7265No ratings yet

- Case Study Lathe.....Document16 pagesCase Study Lathe.....Zul AimanNo ratings yet

- Swing: Owner'S Manual and Stringing InstructionsDocument12 pagesSwing: Owner'S Manual and Stringing InstructionstopspinlobNo ratings yet

- RTL Sleevoil Instruction Manual 499970Document11 pagesRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाNo ratings yet

- BR3 002 ManualDocument10 pagesBR3 002 ManualEric LempkeNo ratings yet

- Dodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly InstructionsDocument8 pagesDodge® Sleevoil®Rtl Pillow Blocks Sizes 3-7/16" Thru 12": Pre-Assembly Instructionsjhgjhgjhgj100% (1)

- Unidad Rotacion Serie L30 PDFDocument22 pagesUnidad Rotacion Serie L30 PDFJairo BVNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- 10 kVA - PI044E PDFDocument9 pages10 kVA - PI044E PDFYogi PurchasingNo ratings yet

- Gastric Feeding TubesDocument10 pagesGastric Feeding Tubesapi-254470605No ratings yet

- Return To Sport After Surgical Management of Posterior Shoulder InstabilityDocument13 pagesReturn To Sport After Surgical Management of Posterior Shoulder InstabilityAziz CupinNo ratings yet

- Wap-3101 Um V1.0 PDFDocument34 pagesWap-3101 Um V1.0 PDFhtweakNo ratings yet

- Alter NadorDocument10 pagesAlter NadorJOSE0% (2)

- 04 IMS Technical Differences (Nokia)Document4 pages04 IMS Technical Differences (Nokia)stern_uNo ratings yet

- 3 Decomposition PDFDocument40 pages3 Decomposition PDFPyae Phyo KyawNo ratings yet

- A Project On Cost AnalysisDocument80 pagesA Project On Cost Analysisnet635193% (15)

- Quiz ErrorsDocument5 pagesQuiz Errorsanon_843459121No ratings yet

- 10.1007@s10157 020 01867 yDocument6 pages10.1007@s10157 020 01867 yGin RummyNo ratings yet

- Application Note Assessing Flow Accelerated Corrosion With Pulsed Eddy CurrentDocument2 pagesApplication Note Assessing Flow Accelerated Corrosion With Pulsed Eddy CurrentZoran TripunovskiNo ratings yet

- Chapter II Sample ThesisDocument13 pagesChapter II Sample ThesisAllen Bradley OngNo ratings yet

- Bohemian RhapsodyDocument5 pagesBohemian RhapsodyTheresia Angel WidianaNo ratings yet

- Brand Identity Aaker's ModelDocument2 pagesBrand Identity Aaker's Modelvibhaanagpal100% (1)

- Iron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystDocument19 pagesIron Ore Value-In-Use: Benchmarking and Application: Peter Hannah AnalystAnkit BansalNo ratings yet

- Training Wall Height On Convergent Stepped SpillwaysDocument10 pagesTraining Wall Height On Convergent Stepped Spillwayschutton681No ratings yet

- TestingDocument116 pagesTestingAkarsh LNo ratings yet

- Safety EducationDocument5 pagesSafety EducationOwen Silva NaldozaNo ratings yet

- Truth Beyond Paradox (Final Download)Document217 pagesTruth Beyond Paradox (Final Download)andreas waneyNo ratings yet

- Medica EasyLyte BrochureDocument6 pagesMedica EasyLyte BrochureAnderson José Carrillo NárvaezNo ratings yet

- By Engineerprof Ph/Engr. Raymart BoneteDocument1 pageBy Engineerprof Ph/Engr. Raymart BoneteNurlaila DalidigNo ratings yet

- Seed Health Testing in Field Crops Seeds........... AaaaaaaDocument37 pagesSeed Health Testing in Field Crops Seeds........... AaaaaaaJagadish GowdaNo ratings yet

- Visual Fault Locator PDFDocument2 pagesVisual Fault Locator PDFManish SoniNo ratings yet

- With Serverless ComputingDocument9 pagesWith Serverless Computingmha1375.1635No ratings yet

- ISC HydroCom ComparisonDocument22 pagesISC HydroCom Comparisonrahilshah100No ratings yet

- Module Virus Viroids PrionsDocument17 pagesModule Virus Viroids PrionsJennifer MartinNo ratings yet

- LeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFDocument2 pagesLeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFyogiprathmeshNo ratings yet

- Lecture 6 OptimizationDocument41 pagesLecture 6 Optimizationaku_la100% (2)

- MODULE 3 The Footnote and EndnoteDocument8 pagesMODULE 3 The Footnote and EndnoteJohn Robert LunaNo ratings yet

- AEM-Large Deformation AnalysisDocument37 pagesAEM-Large Deformation AnalysisPinakin GoreNo ratings yet