Professional Documents

Culture Documents

PCT 301T Modeling

Uploaded by

Portia ShilengeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCT 301T Modeling

Uploaded by

Portia ShilengeCopyright:

Available Formats

Page 1 of 21

PCT 301T

MODELING

Modelling is used to study the dynamic behaviour, process design,

model-based control, optimization and predictions of the processes.

Modelling principles

Dynamics models of chemical processes consist of ODE (ordinary

differential equations) and / partial differential equations (PDE), plus

related algebraic equations.

For process control problems, dynamic models are derived using

unsteady state conservation laws.

Page 2 of 21

A systematic approach for developing dynamic models

1. State the modelling objectives and the end use of the model.

2. Draw the schematic diagram of the process and label all

process variables.

3. List all the assumptions involved in developing the model.

4. Write appropriate conservation equation (mass, component,

energy, and so forth).

5. Introduce equilibrium relation and other algebraic equation

(from thermodynamics, transport phenomena, chemical kinetics

etc).

6. Perform degree of freedom.

7. Simplify the model. (Grouping of like terms).

8. Classify the inputs as the disturbance or manipulated

variables.

Page 3 of 21

Conservation laws

Theoretical models of chemical processes are based on

conservation laws such as the conservation of mass and energy.

Conservation of Mass

Rate of mass accumulation = rate of mass in rate of mass out

Conservation of Component i

Rate of = rate of rate of + rate of

mass mass in mass out mass

accumulation component i produced

Page 4 of 21

Conservation of Energy

Rate of = rate of rate of + net rate of

energy energy in by energy out by heat addition

accumulation convection convection to the system

+ net rate of work performed on the system

by the surrounding

Page 5 of 21

Uses of Mathematical Modeling

To improve understanding of the process

To optimize process design/operating conditions

To design a control strategy for the process

To train operating personnel

Page 6 of 21

Development of Dynamic Models

Illustrative Example: A Blending Process

FIRST ORDER SYSTEM RESPONSE FOR UNSTEADY STATE

PROCESS

Example 1

Liquid - level system (Mass storage)

Objective is to measure the height level (h) of the system and

determine the transfer function.

Page 7 of 21

Assumption made: out flow (Q

0

) is linearly related to the hydrostatic

head of the liquid level through the resistant (R)

Conservation equation: Mass

Accumulation = Input - output

Degree of freedom analysis: 4 -3 = 1

2 input and 2 output

Q

0

h(t)

R

h

Q

i

x(t)

Page 8 of 21

Accumulation = Input output

out in

m m

dt

dM

- -

=

...Eq(1)

0

) (

- -

= Q Q

dt

Ah d

i

..Eg(2)

R

h

Q

dt

Adh

i

=

-

. ...Eq(3)

( ) ( ) R Q h

dt

dh

RA

i

-

= +

..Eq(4)

Page 9 of 21

Apply Laplace transformation in Eq (4)

And find the transfer function.

1 1 ) (

) (

+

=

+

=

s

K

RAs

R

s X

s H

p

t

...Eq(5)

Apply the inverse to determine the process response

DO EXAMPLE (B) FROM YOUR NOTES

Process Gain (K

p

)

Process time

(tau)

Page 10 of 21

Example 2

Consider a perfectly mixed stirred-tank heater; with a single feed

streams and a single product stream, as shown below. Assuming that

the flow rate and temperature of the inlet streams can vary, that the

tank is perfectly insulated, and the rate of heat, Q added per unit time

can vary, heat losses are negligible, density and heat capacity of the

liquid are assumed to be constant. Develop a mathematical model to

find the tank liquid temperature as a function of time and its time

response when the inputs are subjected to the step change.

Page 11 of 21

Fig: 1 Stirred tank heating process with constant volume.

Objective is to measure the temperature (T) of the system and

determine the transfer function.

Page 12 of 21

Assumption made: the outlet and the inlet flow are equal, volume,

density and the heat capacity of the liquid are constant and heat losses

are negligible.

Conservation equation: Energy

Rate of = rate of rate of + net rate of

energy energy in by energy out by heat addition

accumulation convection convection to the system

+ net rate of work performed on the system

by the surrounding

Page 13 of 21

( ) ( ) W Q T fC T fC

dt

dH

p i p

+ =

.Eq(1)

( ) ( ) Q T T fC

dt

dT

C V

i p p

+ =

...Eq(2)

( ) Q T fC fCpT

dt

dT

C V

i p p

+ = +

.Eq(3)

Q

f C

T T

dt

dT

f C

C V

p

i

p

p

1

+ = +

|

|

.

|

\

|

...Eq(4)

Page 14 of 21

( ) Q

f C

T T

dt

dT

f C

C V

p

i

p

p

|

|

.

|

\

|

+ = +

|

|

.

|

\

|

1

1

Apply the Laplace transformation and find the transfer function

So,

Q

s

f

V

f C

s T

s

f

V

s T

p

i

1

1

) (

1

1

) (

+

|

|

.

|

\

|

+

+

|

|

.

|

\

|

=

...Eq(5)

Process time

(tau)

Process Gain (K

p2

)

Process Gain (K

p1

)

Page 15 of 21

) (

1

) (

1

) (

2 1

s Q

s

K

s T

s

K

s T

p

i

p

+

+

+

=

t t

...Eq(6)

Two transfer functions

T.F 1

1 ) (

) (

1

+

=

s

K

s T

s T

p

i

t

T.F 2

1 ) (

) (

2

+

=

s

K

s Q

s T

p

t

Page 16 of 21

An unsteady-state mass balance for the blending system:

rate of accumulation rate of rate of

(2-1)

of mass in the tank mass in mass out

=

` ` `

) ) )

( )

1 2

(2-2)

d V

w w w

dt

= +

Page 17 of 21

The corresponding steady-state model

The Blending Process Revisited

For constant density:

1 2

1 1 2 2

0 (2-4)

0 (2-5)

w w w

w x w x wx

= +

= +

Page 18 of 21

Equation 2-7 can be simplified by expanding the accumulation term using the

chain rule for differentiation of a product:

Substitution of (2-7) into (2-8) gives:

Substitution of the mass balance in (2-6) for in (2-9) gives:

Page 19 of 21

After canceling common terms and rearranging (2-6) and (2-10), a more

convenient model form is obtained:

Page 20 of 21

Typical question

A stirred-tank heating process described by

) (

1

1

) ( '

1

/ 1

) ( '

'

s T

s

w

m

s Q

s

w

m

wC

s T

i

+

+

+

=

, is used to

preheat a reactant containing a suspended solid catalyst at a constant flow rate of 1000

kg/h. the volume in the tank is 2 m

3

, and the density and specific heat of the suspended

mixture are, respectively, 900 kg/m

3

and 1 cal/g

0

C. The process initially is operating

with inlet and outlet temperature of 100 and 130

0

C. The following questions concerning

process operations are posed:

Page 21 of 21

(a) What is the heater input at the initial steady state and the value of K and

TAU?

(b) If the heater input is increased by 30%, how long will it take for the tank

temperature to achieve 99% of the final temperature change?

Assume the tank is at its initial steady state. If the inlet temperature in increased

suddenly from 100 to 120

0

C, how long will it take before the outlet temperature

changes from 130 to 135

0

C.

You might also like

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Factorization of Boundary Value Problems Using the Invariant Embedding MethodFrom EverandFactorization of Boundary Value Problems Using the Invariant Embedding MethodNo ratings yet

- Chapter 2simulation Process ControlDocument43 pagesChapter 2simulation Process ControlAudrey Patrick KallaNo ratings yet

- (Ebook) Multivariable Control, An Introduction PDFDocument14 pages(Ebook) Multivariable Control, An Introduction PDFCaterine Feria RamirezNo ratings yet

- Illustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending SystemDocument22 pagesIllustrative Example: A Blending Process: An Unsteady-State Mass Balance For The Blending SystemHermes Yesser Pantoja CarhuavilcaNo ratings yet

- Theoretical Models of Chemical Processes: PTT355 Process Control & DynamicsDocument27 pagesTheoretical Models of Chemical Processes: PTT355 Process Control & DynamicsKALESMI A/P AMARALATHAN STUDENTNo ratings yet

- 2 - Mathematical Modelling PDFDocument20 pages2 - Mathematical Modelling PDFErfinaFebriantiNo ratings yet

- Fluid Mixing Lab ReportDocument20 pagesFluid Mixing Lab ReportbasharalhawarnaNo ratings yet

- Problem Set 5Document6 pagesProblem Set 5PeaceNo ratings yet

- Chapter 5 - Energy Analysis For Open Systems Compatibility ModeDocument35 pagesChapter 5 - Energy Analysis For Open Systems Compatibility ModekhameesmarwanNo ratings yet

- Introduction To Process Control & Mathematical Modelling 1.0 What Is A Control System?Document11 pagesIntroduction To Process Control & Mathematical Modelling 1.0 What Is A Control System?gongweejieNo ratings yet

- Theoretical Models of Chemical ProcessesDocument21 pagesTheoretical Models of Chemical Processesstup_30100% (2)

- Oupa Nhambe - Control Project Part 2Document19 pagesOupa Nhambe - Control Project Part 2Oupa100% (4)

- Thermodynamics, Fluid Dynamics, and Heat TransferDocument20 pagesThermodynamics, Fluid Dynamics, and Heat TransferDhia EmpayarNo ratings yet

- Exam Pas IwebDocument26 pagesExam Pas IwebcoolvatNo ratings yet

- Exam Pan American Advanced Studies Institute Program On Process Systems EngineeringDocument26 pagesExam Pan American Advanced Studies Institute Program On Process Systems EngineeringRashadafaneh0% (1)

- ModellingDocument18 pagesModellingPortia ShilengeNo ratings yet

- Module - 1 - Models in Engineering and Equation FormsDocument29 pagesModule - 1 - Models in Engineering and Equation FormsG MahendraNo ratings yet

- The Influences of Air Temperature On The Intake Process by Numerical SimulationDocument4 pagesThe Influences of Air Temperature On The Intake Process by Numerical SimulationmaniNo ratings yet

- Optimization of Combined Cycle Power Plant ReportDocument14 pagesOptimization of Combined Cycle Power Plant ReportbasharalhawarnaNo ratings yet

- Process Control InstrumentationDocument200 pagesProcess Control InstrumentationJaneesh VayalilakathNo ratings yet

- 35proci2012 VII6 PDFDocument6 pages35proci2012 VII6 PDFcallsignNo ratings yet

- Research Article: Analysis of Process Variables Via CFD To Evaluate The Performance of A FCC RiserDocument14 pagesResearch Article: Analysis of Process Variables Via CFD To Evaluate The Performance of A FCC RiserDanut RaduNo ratings yet

- Combustion in IC EnginesDocument25 pagesCombustion in IC EnginesVirendra SinghNo ratings yet

- Lecture Notes On Numerical Analysis Part I: Mathematical Models in Chemical EngineeringDocument20 pagesLecture Notes On Numerical Analysis Part I: Mathematical Models in Chemical EngineeringchandrahasNo ratings yet

- Mathematical Modeling of Chemical ProcessesDocument43 pagesMathematical Modeling of Chemical ProcessesInnocent ShetaanNo ratings yet

- Modeling of The Modified Quadruple-Tank Process: A. Numsomran, V. Tipsuwanporn, K. TirasesthDocument6 pagesModeling of The Modified Quadruple-Tank Process: A. Numsomran, V. Tipsuwanporn, K. Tirasesthanon_369320474No ratings yet

- CFD Theory Ansys FluentDocument52 pagesCFD Theory Ansys FluentVatsalya SharmaNo ratings yet

- Mathematical ModelDocument16 pagesMathematical ModelRichard ObinnaNo ratings yet

- III Dynamic Process ModelDocument26 pagesIII Dynamic Process ModelIshita BhattacharyyaNo ratings yet

- Draft Issue: Dynamic Simulation Otis P. ArmstrongDocument23 pagesDraft Issue: Dynamic Simulation Otis P. Armstrongotis-a100% (1)

- CFD NotesDocument68 pagesCFD NotesPraveen P JoseNo ratings yet

- Computational Fluid Dynamics: Course NotesDocument68 pagesComputational Fluid Dynamics: Course NotesPankaj GuptaNo ratings yet

- CH 02Document40 pagesCH 02JuliaAbdullatifNo ratings yet

- High-Speed Compressible Flow Solutions by Combined Characteristic-Based Split Method and Adaptive Meshing TechniqueDocument6 pagesHigh-Speed Compressible Flow Solutions by Combined Characteristic-Based Split Method and Adaptive Meshing TechniqueSergi C. CortadaNo ratings yet

- Adaptive Decoupling Control For Binary Distillation Column Into A 3D Virtual EnvironmentDocument13 pagesAdaptive Decoupling Control For Binary Distillation Column Into A 3D Virtual EnvironmentkbromNo ratings yet

- Optimal Control of A Hybrid Dynamical System: Two Coupled TanksDocument25 pagesOptimal Control of A Hybrid Dynamical System: Two Coupled TanksPhạm Ngọc HòaNo ratings yet

- An Adaptive Fuzzy Pid Control of Hydro-Turbine Governor: Xiao-Ying Zhang, Ming-Guang ZhangDocument5 pagesAn Adaptive Fuzzy Pid Control of Hydro-Turbine Governor: Xiao-Ying Zhang, Ming-Guang ZhangPadmo PadmundonoNo ratings yet

- Chapter 12Document91 pagesChapter 12Carmen de LeonNo ratings yet

- Tubular Reactor With Side InjectionsDocument17 pagesTubular Reactor With Side InjectionsMohamad Abou DaherNo ratings yet

- Basic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. OyarzúnDocument15 pagesBasic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. Oyarzúnñ=?!2No ratings yet

- CEIC3000 Process Modelling and Analysis Week 1 Session 1, 2012Document17 pagesCEIC3000 Process Modelling and Analysis Week 1 Session 1, 2012Ben TanNo ratings yet

- Equations of Change ChE 131Document34 pagesEquations of Change ChE 131Johanna Martinne CanlasNo ratings yet

- 4 ChapterDocument46 pages4 ChapterRama ChilpuriNo ratings yet

- Control of Integrating Processes Using Dynamic Matrix ControlDocument6 pagesControl of Integrating Processes Using Dynamic Matrix ControlManoharChintaNo ratings yet

- Chapter 16 - CFD PDFDocument28 pagesChapter 16 - CFD PDFdeepakNo ratings yet

- Process Modeling & Simulation FileDocument37 pagesProcess Modeling & Simulation FileJagjit SinghNo ratings yet

- H83PDC H83PDC H83PDC H83PDC - Process Process Process Process Dynamic & Control Dynamic & Control Dynamic & Control Dynamic & ControlDocument17 pagesH83PDC H83PDC H83PDC H83PDC - Process Process Process Process Dynamic & Control Dynamic & Control Dynamic & Control Dynamic & ControlZakariya MohamedNo ratings yet

- Matlab Ex ModelsDocument9 pagesMatlab Ex ModelsNicolas RinconNo ratings yet

- Solving Problems in Packed Absorption Using MathcadDocument10 pagesSolving Problems in Packed Absorption Using MathcadjoesuhreNo ratings yet

- Robust Iterative Learning Control of An Exothermic Semi-Batch Chemical ReactorDocument19 pagesRobust Iterative Learning Control of An Exothermic Semi-Batch Chemical ReactorFCNo ratings yet

- PIideal DecouplerDocument15 pagesPIideal Decouplerrami ramiNo ratings yet

- Energy Transport EquationDocument4 pagesEnergy Transport EquationFranklin PraveenNo ratings yet

- Heat Exchanger Process Practical 2 Feedforwrd2Document11 pagesHeat Exchanger Process Practical 2 Feedforwrd2bhavinaNo ratings yet

- Reduction of A Symmetric Matrix To Tridiagonal Form - Givens and Householder ReductionsDocument7 pagesReduction of A Symmetric Matrix To Tridiagonal Form - Givens and Householder ReductionsAntonio PeixotoNo ratings yet

- CSTRDocument15 pagesCSTRVismar Campos HernándezNo ratings yet

- Dynamic Economic Dispatch Using Model Predictive Control AlgorithmDocument7 pagesDynamic Economic Dispatch Using Model Predictive Control Algorithmselaroth168No ratings yet

- Integer Optimization and its Computation in Emergency ManagementFrom EverandInteger Optimization and its Computation in Emergency ManagementNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Suitable Pumps For GasolineDocument5 pagesSuitable Pumps For GasolinePortia ShilengeNo ratings yet

- ECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Document99 pagesECO2SA W2E Facility Draft Scoping Report For PPP 30 May 2012Portia ShilengeNo ratings yet

- UOP Reforming Solutions For .Improved Profits PaperDocument32 pagesUOP Reforming Solutions For .Improved Profits PaperstevemetroNo ratings yet

- 12 Chapter3 Section4 Oil Refining Industry Page193 220Document26 pages12 Chapter3 Section4 Oil Refining Industry Page193 220Muhammad FarooqNo ratings yet

- 2011-03 Head Losses Calculations PDFDocument44 pages2011-03 Head Losses Calculations PDFAnastasia Monica KhunniegalshottestNo ratings yet

- Non Newtonian FluidsDocument12 pagesNon Newtonian FluidsPortia ShilengeNo ratings yet

- Caracteristicas Normas ASME B31Document3 pagesCaracteristicas Normas ASME B31darthneoNo ratings yet

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- Lecture 6Document42 pagesLecture 6Anonymous 9R53UyNo ratings yet

- Solved Problems Samples in Fluid Flow PDFDocument10 pagesSolved Problems Samples in Fluid Flow PDFRichard Obinna100% (1)

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- Fluid Mechanics PresentationDocument158 pagesFluid Mechanics PresentationPortia ShilengeNo ratings yet

- 4 Flow MeasurementsDocument19 pages4 Flow MeasurementsPortia ShilengeNo ratings yet

- 7 Flow of Compressible FluidsDocument27 pages7 Flow of Compressible FluidsPortia ShilengeNo ratings yet

- Cive1400 2000 01 - v2Document14 pagesCive1400 2000 01 - v2naefmubarakNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- Chapter 11Document36 pagesChapter 11Hamza FayyazNo ratings yet

- Conservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimeDocument8 pagesConservation Laws: Control-Volume Approach: M Total Mass (KG) of A Within The System at Any TimePortia ShilengeNo ratings yet

- Cive1400 200304 PDFDocument17 pagesCive1400 200304 PDFMohd Nazri SalimNo ratings yet

- Assignment 1-2013Document3 pagesAssignment 1-2013Portia ShilengeNo ratings yet

- CH 02Document32 pagesCH 02jmartinezmo100% (1)

- 2 LaminarFlowPipes&Annuli NewtonianDocument35 pages2 LaminarFlowPipes&Annuli NewtoniansyedmuhammadtariqueNo ratings yet

- 2016 Heat and Mass Transfer Practical ManualDocument8 pages2016 Heat and Mass Transfer Practical ManualPortia ShilengeNo ratings yet

- 15 Johan MullerDocument22 pages15 Johan MullerPortia ShilengeNo ratings yet

- Chapter 11Document36 pagesChapter 11Hamza FayyazNo ratings yet

- Experiment Report: Characterizing Resonant Series RLC Circuits Using LabviewDocument15 pagesExperiment Report: Characterizing Resonant Series RLC Circuits Using LabviewPortia ShilengeNo ratings yet

- 2014 Nua301t Assessment 1 - MemoDocument4 pages2014 Nua301t Assessment 1 - MemoPortia ShilengeNo ratings yet

- p2 Cyclone Eff ProjctDocument12 pagesp2 Cyclone Eff ProjctPortia ShilengeNo ratings yet

- Milling Multotec ProjectDocument15 pagesMilling Multotec ProjectPortia ShilengeNo ratings yet

- Kinematic EquationsDocument7 pagesKinematic Equationskhyun25No ratings yet

- Me 6301 Good QPDocument13 pagesMe 6301 Good QPMohanraj SubramaniNo ratings yet

- Cent Pumps PresentationDocument75 pagesCent Pumps PresentationSushma Medikonda100% (1)

- 020410340Document4 pages020410340Manikandan NagaNo ratings yet

- Hufenus 2006 Geotextiles GeomembranesDocument18 pagesHufenus 2006 Geotextiles Geomembranesbkollarou9632No ratings yet

- Aeroelasticity ThesisDocument5 pagesAeroelasticity Thesisb0sus1hyjaf2100% (1)

- Table 5.1. Nominal Strength Per Unit Area of BoltsDocument1 pageTable 5.1. Nominal Strength Per Unit Area of BoltsNwe OoNo ratings yet

- Einstein and Planck On Mass-EnergyDocument16 pagesEinstein and Planck On Mass-EnergyLuis GPNo ratings yet

- +1 CBSE - CHEMISTRY CDF MATERIAL (61-116) .PMD PDFDocument56 pages+1 CBSE - CHEMISTRY CDF MATERIAL (61-116) .PMD PDFcernpaul100% (1)

- Computation of Airfoils at Very Low Reynolds NumbersDocument6 pagesComputation of Airfoils at Very Low Reynolds NumbersHegespo MwanyikaNo ratings yet

- Gizmos DistancetimevelocityDocument7 pagesGizmos Distancetimevelocityapi-553234034No ratings yet

- Wave Optics QuestionDocument6 pagesWave Optics QuestionMayank KumarNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- Releasing Asset Value Sustainably: An Analysis of ISO55000xDocument7 pagesReleasing Asset Value Sustainably: An Analysis of ISO55000xFITAS MOUNIRNo ratings yet

- LS-DYNA Theory ManualDocument811 pagesLS-DYNA Theory ManualSaugatoDuttoNo ratings yet

- Lifting Sling Load EquationsDocument2 pagesLifting Sling Load EquationsFabio Okamoto100% (1)

- Cot #1 LPDocument7 pagesCot #1 LPDabe Genesis LigaligNo ratings yet

- The Laws of Motion: - Sir Isaac NewtonDocument51 pagesThe Laws of Motion: - Sir Isaac NewtonBrian NkhomaNo ratings yet

- Definitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelDocument3 pagesDefinitions - Topic 4 Mechanics and Materials - AQA Physics A-LevelLaud FumhandaNo ratings yet

- NPTEL Online Certification Course On Farm Machinery Assignment 6Document2 pagesNPTEL Online Certification Course On Farm Machinery Assignment 6Rohit AnandNo ratings yet

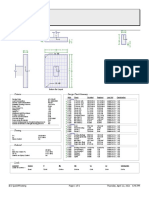

- Design Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Document6 pagesDesign Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Christian PintoNo ratings yet

- Homework Computational Mechanics 2023-1Document7 pagesHomework Computational Mechanics 2023-1George CalinNo ratings yet

- 4-Laws 2021Document36 pages4-Laws 2021Harsh SharmaNo ratings yet

- FLUENT13 Workshop XX RAE AirfoilDocument47 pagesFLUENT13 Workshop XX RAE AirfoilJosé Javier Salinas ZavalaNo ratings yet

- JEE Physics Test Series 1 PDFDocument21 pagesJEE Physics Test Series 1 PDFAkil kumarNo ratings yet

- Grade 11 Physics Study Guide / Notes For Final Exam SPH3U1Document23 pagesGrade 11 Physics Study Guide / Notes For Final Exam SPH3U1Niki79% (14)

- Biomechanics: Lichun Lu, PHD Kenton R. Kaufman, PHD, Pe Michael J. Yaszemski, MD, PHDDocument16 pagesBiomechanics: Lichun Lu, PHD Kenton R. Kaufman, PHD, Pe Michael J. Yaszemski, MD, PHDIkre19No ratings yet

- MSC NASTRAN AeroelasticityDocument2 pagesMSC NASTRAN Aeroelasticitymat2230No ratings yet

- Fema 267Document164 pagesFema 267chavico17100% (1)

- CE 212 Mechanics of Solids Sessional Lab Manual: Department of Civil EngineeringDocument87 pagesCE 212 Mechanics of Solids Sessional Lab Manual: Department of Civil Engineeringamtris406No ratings yet