Professional Documents

Culture Documents

Training Report

Uploaded by

pcpathikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Report

Uploaded by

pcpathikCopyright:

Available Formats

INTRODUCTION

It was established in 1973 , comprising of 2 units of each of capacity 110 MW. It is located at the left bank of the CHAMBAL River at the upstream of KOTA BAIRAJ. 1st & 2nd units are of 110 MW each. 3rd ,4th &5th units are of 210 MW . 6th & 7 unit of 195 MW. Total generation capacity (110+110+210+210+210+195+195) =1240 MW Favorable condition Abundant quantity of clean cooling water. Good transport facility Concentration of load in Kota region due to large number of industries.

Wagon unloading system Unload the coal from wagon to hopper. Hopper allows to pass coal pieces 200mm From hopper coal fall on vibrator which is supported by roller. Crushing system CRUSHER HOUSE:- Its main function to crush the coal to 20mm Two types Primary crusher Rail crusher Rotary breaker Secondary crusher Boiler

It is a closed vessel in which water under pressure is convert into steam. Hot water or steam used to transfer heat to a process. A boiler is always designed to absorb max amount of heat released in process of combustion. Furnace:- It is primary part of boiler where the fuel is burnt to liberate the heat energy.

INTRODUCTION The KOTA SUPER THERMAL POWER STATION is ideally located on the left bank of Chambal River at the upstream of KOTA BARRAGE. Thermal power station to produce electrical power for supply undertakings K.S.T.P.S. is designed for ultimate capacity of 1045 MW. First two units of 110MW each, another three units of 210MW each and further the sixth unit of 195MW have been completed.

The state Rajasthan is predominantly rural and agricultural .While Rajasthan mineral sources are immense, its sources for power generation werent commensurable with its requirements. The large expense of water, stored by the barrage provides, as efficient direct circulation cooling system for the power station thus avoiding installation of cooling towers. For bringing in coal for power station and machinery and equipment etc. a 15Km long private siding from the Gurla Railway Station on Delhi-Bombay broad gauge line has been laid-up to the power station. GENERATOR Generator is the main part of thermal power station or any power plant. A generator is a machine which converts mechanical energy into electrical energy. The generator has gas cooling construction enclosing the stator winding, core and hydrogen coolers .The cooling medium hydrogen is contained within the frame and circulation by fans mounted on either ends of the rotor .The generator is driven by directly coupled steam turbine at a speed of 3000 rpm. Provision has been made for circulating the cooling water in order to maintain a constant temperature of the coolant i.e. H2 as measured at the fan section side which is in touch with the temperature of the winding, core and other parts as per load. Each of the 2 units under stage-1 have been provided with BHEL make 3-phase turbo generator rated 137.5 MVA, 11KV, 0.8 pf, 7220 Amp, 3000 rpm and 50 cycles/sec .The generator has closed loop of hydrogen gas system for cooling of the stator and rotor at a pressure of 2.0 atm. is filled in a gas tight outer casing of the generator. H2 gas circulates inside the casing by two single stage rotor mounted fans on either side of the rotor .The heated H2 is in turn cooled by six surface type water coolers axially mounted inside the generator casing .The cooling water is supplied to H2 coolers from the BCW over head tank. Each generator has terminal led out of its casing and a star point is formed by sorting the neutral side terminals by a sorting bar. The neutral is grounded by a 1-phase 11000/220V, 37.5 KVA. Neutral grounding transformer, whose secondary coil is laminated by laminated strip with mechanical ventilating holes, is connected across a 650V, class 0.4 ohm, 50 kW neutral grounding resistors and relays for protection of generator against stator earth faults and stator in turn faults (rating 1 amp). The H2 gas inside the generator casing is prevented from leaking in between the rotor and shields, by a continuous oil film maintained between the rotor and

sealing rings .The shaft sealing system have two independent oil sources associated pumps, regulators, coolers filters, electrical controls and alarm system. Two independent oil sources are provided for air side and H2 side sealing rings. The oil circuit of the H2 side of the shaft seal is closed and the oil is vacuum treated. DESCRIPTION OF THE GENERATOR PARTS:1. STATOR BODY:Armature of a generator formed of laminations having slots on its inner periphery to accommodate armature conductors and is known as stator .The stator body is a totally enclosed gas tight fabricated structure suitably internally to rigidity . The function of stator frame is to contain and support the stator core winding , hydrogen coolers and also path for distribution of cooling hydrogen through the generator . 2. STATOR CORE:The rotating magnetic field flow with the core .In order to reduce the magnetizing (eddy) current losses in the active portion of the stator core due to rotation of field structure in between the stator the entire core is built up of thin laminations .The segments are stamped out from CRGO .The core contain several pockets separated by steel spaces for radial cooling of the core by hydrogen. 3. STATOR WINDING:The stator has 3 phase double layer, short pitched and bar type of winding having two parallel paths .Each slot accommodates two bars .The lower and upper bars are displaced from each other by one winding pitch and connected at their ends so as to form coil groups .Each bar consists of solid as well as hollow conductors with cooling water passing through the later alternator 4. DISTILLATE HEADER:Ring type header, made up of copper are provided separately for distillated inlet and outlet min the stator of turbine side .The headers are support on insulator and insulated from stator body .At turbine side each individual bar is connected with inlet/outlet header .The vent pipe connection are at the top of the both inlet and outlet header .The vent pipes are connected to gas trap desire to measure the extent of hydrogen leakage into water circuit. 5. TERMINAL BUSHING:Three phases and six neutral terminals are brought out from the stator through bushings which are capable of withstanding high voltage and provided with gas tight joints .The bushing is assembled and tested for flow, leakage to ensure tightness and continuous flow of water. 6. END SHIELD:-

To make the stator body air tight the end shield are fitted .Gas tightness is achieved by putting a rubber sealing cord .The end shields are made3 in two halves convenience during erection and installation. 7. ROTOR:The field structure is the largest & heaviest component of generator and is called the rotor. The rotor houses the static excitation winding and the exciting current is supplied to the rotor through the slip rings & brushes. The rotor shaft is a single piece forging the longitudinal slot for inserting the field winding. The slots are distributed over the circumference so that two field solid poles are obtained . 8. BEARINGS:The generator bearings are of pedestal type with spherical seating. It allows self alignment and is supported on a separate pedestal on slip ring side. The bearing has a provision of hydraulic shaft lifting during start up and turning gear operation to eliminate shaft current. Shaft bearing and its pipes are insulated from earth. 9. BRUSH GEAR:The current carrying gear assembly is rigidly fixed on the extent part of the bearing pedestal on the exciter side. There are two brushes gear stand for (+) ive and (-) ive supply. The field to stator wdg. Provide the brush gear. The designs of brushes during normal operation condition have low coefficient of friction and are self lubricating. CONCLUSION The first phase of Practical Training has proved to be quite fruitful. It provides an opportunity for encounter with such huge machines like wagon tippler, 110MW & 210MW Turbines and Generators. The architecture of the power plant, the way various units are linked and the way working of whole plant is controlled make the student realize that engineering is not just learning the structure description and working of various machine but the great part is of planning proper management. It also provides an opportunity to lean low technology used at proper place and time can cave a lot of labor e.g. Wagon tippler (CHP). But there are few factors that require special mention. Training is not carried to its true spirit. It is recommended that there should be some project specially meant for students where presence of authority should be ensured. There should be strict monitoring of the performance of students and system of grading be improved on basis of work done.

However training has proved to be quite fruitful. It has allowed an opportunity to get an exposure of the practical implementation to theoretical fundamentals.

ADVANTAGES OF CHOOSING KOTA FOR THERMAL PLANT SETUP :

Availability of large amount of clean cooling water required for the station. Location of station on broad gauge main Delhi-Bombay Railway line. Concentration of load in Kota city and Kota region. Constant power supply. Proximity to M.P. Coal fields. Transmission and Grid substation are quite nearer to the site.

TURBINE :Turbine is a machine in which a shaft is rotated steadily by impact of steam it converts heat energy into mechanical energy.

TURBO GENERATOR :-

Designed for continuous operation at the rated output. Driven by directly coupled steam turbine at a speed of 3000 r.p.m. Have two main parts: Rotor Stator A temperature detector is provided to maintain the temperature. Temperature of windings is maintain by H2 coolant.

Stator Frame: Welded steel frame construction. Withstand the thermal gas pressure. It is used for holding the armature stampings and windings in position.

Stator Core: Built up of special sheet laminations to minimize eddy current losses . The laminations are stamped out and after that each lamination is varnished on both side.

Stator Bars: Manufactured as half bars. Made in strips to reduce skin effect. Semi-conductor coating is also applied to a part of overhung to reduce eddy currents to minimum.

Stator Windings: Double star layers, lap wound, three phase, short pitch type(to reduce losses). Complete arrangement of winding circuit is viewed from turbine end of generator.

The basic energy cycle involved in the plant is as follows : Chemical Energy ---> Mechanical Energy ---> Electrical Energy Turbine Turbine converts the heat energy of the steam into mechanical energy. The super heated steam works on the blades of the turbine and hence the blades starts rotating to produce the mechanical energy. 1) High pressure turbine. 2) Intermediate Pressure turbine. 3) Low pressure turbine.

INTRODUCTION

For the power generation with 2x110 MW and 3x210 MW of K.T.P.S. authorities are required to be operative to active full operation. The auxiliaries are basically operation either on L.T. System i.e. 415 V 3 ? power supply is made available to the system after providing the station transformer of 3x50 MVA capacity with voltage 220 KV/ 7.2/7.2 KV & different service transformers of capacity 1.0 MVA , 1.5 MVA , 2.0 MVA , which are located near the load centre as

the transformer having the voltage of 6.6 KV /415 V. The 6.6 KV power is distributed through 6.6 KV interconnected Bus System for all the five units with a control through DC of 220 V. The 415 V power supply is done through a L.T. SWGR (Switchgear) which are located nearby the distribution transformer as well as the load centers. The all in -comers, which are breaker controlled , are having the control the L.T. SWGR are having the control system on 110/ 220 V AC. The 6.6 KV power supply which are either MOCB (Minimum Oil Circuit Breaker) of JYOTI MAKE or Air Circuit Breakers.

The 6.6 KV power supply to various draining equipment?s i.e. more is made through breakers which are either MOCB of Jyoti make air circuit breaker which are either of voltage makers as well as SF 6 of NGEF make. The LT supply is also controlled through air break circuit breaker which are either L&T make or English Electric Company of India. The various H.T. motors are switched on / started through on direct ON line (DOL) in order to inverse the availability of equipment at full efficiency without time gap. Further , the 6.6 KV system which is normally in delta configuration and terms as an unearthed system so also to keep the running motor complete in operating condition in case of any one .phase of motor winding is earthed due to any one reason. Earthling is detected by an protection system with alarm facility to take remedial measures immediately and at the same time to maintain the generation level in the same condition, prior to occurring the earth fault the single phase earth fault is detected in due course till the motor is not earthed to other or another phase. ? PUBLIC ADDRESS SYSTEM? is available through in area of each unit which helps in fast communication for prompt remedial measure.

Soot Blowers are there in the boiler area on the furnace side or Zone which helps in blowing the soot / ash deposition regularly of the furnace wall / economizer tubes to keep heat transfer at the required parameter.

In April 1973, Central Electricity Authority prepared a Project Report for power station comprising of the two units of each of capacity 110 MW for RSEB subsequently in September., 1975 this was revised by the Consultant Thermal Design Organization , Central Electricity Authority for invention of 2x110 MW units being manufactured by BHEL, Hyderabad in 1st Stage. The planning commission cleared the project report in Sept., 1976 for installation of two units each of 110 MW in first estimated cost of Rs. 143 Crores. K.T.P.S. IS DESISIGNED IN FOUR STAGES I 2x110 MW STAGE II 2X210 MW STAGE III 1X210 MW STAGE IV 1X195 MW * Total Power Generation 1045 MW * To be commissioned shortly in August, 2003.

LOCATION The Kota Thermal Power Station is ideally on the left bank of Chambal River at Up Stream of Kota Barrage . The large expanse of water reached by the barrage provides an efficient direct circulation of cooling system for the power station. The 220 KV GSS is within ? Kms. from the power station.

LAND

Land measuring approx. 250 hectares was required for the project in 1976, For disposal of ash tank very near to power station is acquired which the ash in slurry form is disposed off through ash and slurry disposal plants. COAL Coal India limited owns and operates all the major coal fields in India through its coal producing subsidiary companies viz. Eastern Coal Fields Limited, Western Coal Fields Limited/ Coal India limited is supply coal from its coal mines of coal producing subsidiaries BCCL, SECL & ECL to Kota Thermal Power Station through railway wagons. The average distances of SECL, ECL & BCCL are 800, 950 and 1350 Kms. respectively.

INTRODUCTION

The KOTA SUPER THERMAL POWER STATION is ideally located on the left bank of Chambal River at the upstream of KOTA BARRAGE. Thermal power station to produce electrical power for supply undertakings K.S.T.P.S. is designed for ultimate capacity of 1045 MW. First two unit of 110MW each, another three units of 210MW each and further the sixth unit of 195MW has been completed. The state Rajasthan is predominantly rural and agricultural .While Rajasthan mineral sources are immense, its sources for power generation werent commensurable with its requirements. The large expense of water, stored by the barrage provides, as efficient direct circulation cooling system for the power station thus avoiding installation of cooling towers. For bringing in coal for power station and machinery and equipment etc. a 15Km long private siding from the Gurla Railway Station on Delhi-Bombay broad gauge line has been laid-up to the power station. Keeping in view the higher demands of power, it was decided to house initially a 2 x 200 MW thermal power station at Kota on techno-economical reasons as follows Availability of clean water required for station. Location of station on Broad gauge main railway line. Proximity to Madhya Pradesh Coal fields. Concentration of load in Kota region due to large No. of industries located.

The coal linkage for the power station is brought from Dudhichua mines of Singrauli coal field which is about 800 km from Kota. The source of Water (cooling for the P.S.) is the reservoir formed by Kota Barrage on the Chambal River. The water is drawn from this reservoir and after use released near the left main canal of the barrage. The comparative use of water from barrage by the P.S. is 2.75 cusec for each 110 MW unit. A single chimney of 180 Meters height with two separate flues for the two units each of 110 MW is provided. Similarly another chimney with three separate flues is also provided for another three units of 210 MW each. The disposal for fifth unit till now is also through the second chimney.

For Thermal power station the other advantage for choosing Kota are: Availability of station amount of clean cooling water required for the station. Location of station on broad gauge main Delhi- Bombay Railway line. Concentration of load in Kota city and Kota region. Constant power supply. Proximity to M.P. coal fields. Transmission and Grid substation quite nearer to the site. INSTALLATION AND COMMISSIONING OF UNITS:Construction work for stage-I started in 1977 and first unit of 110 MW was commissioned on 17th Jan. 1983.The second 110 MW unit was firstly synchronized in July 1983. The second stage units are synchronized in 1989. The second unit of second stage was commissioned in Oct. 1989. After that unit of 210 Mw was started in April 11, 1984. The commencement of unit VI, in Stage IV started in July, 2001 and the synchronization of the unit was done in July, 2003. Thus the units in K.S.T.P.S. are as: Stage I - (Two units each of 110 MW) Stage II- (Two units each of 210 MW) Stage III- (one unit of 210 MW) Stage IV- (one unit of 195 MW) NEED FOR POWER STATION:Rajasthan is the largest state in the country. About 30% population lives in villages which are local point of development while Rajasthan mineral resources are immense. But its resources for power station generation not upto requirements.Moreover the state government has drawn up a rural electrification program

with a large demand on agricultural load with rapid adoption & modern method of agricultural and industrialization of towns. The mode of living of people in rural and urban areas is changing rapidly with requirement of more power. The hydro potential available on the Chambal has already has nested fully by the construction of Gandhi Sagar Dam, Rana Pratap Sagar Dam, Jawahar Sagar Hydro P.S. It is because lack of adequate resources for power development that a Nuclear Power Plant has been established at Rana Pratap Sagar Dam for meeting the anticipated demands of Rajasthan. The feasibility report for K.S.T.P.S. was prepared by central Electrical authority, in April 73, envisaged an installed Capacity of 2 x 210 MW units and 1 x 200 MW units. The planning commission declared the project in Sep 76 for installation of 2 x 110 units at estimated cost of Rs. 8160 Lakhs. In Aug. 77 M/C Design (New Delhi) Pvt. Ltd., were appointed as consultants for carrying out designing and detailed Engineering of project. Land measuring 235.5 Hct. was required for the project in 1976-77 for disposal of the ash; a tank very near to power station measuring 157.26 Hct has been acquired, where ash in slurry form is disposed through ash disposal pipe lines. Rajasthan State Electricity Board (RSEB)completed the construction which is done by Raj. Bridge construction corporation (RBCC) and other auxiliaries are supplied by Bharat Heavy Electrical Limited (BHEL) & Instrumentation Limited (IL), Kota.

ENERGY GENERATED IN KSTPS Total generation Capacity = (2 x 210+2 x 210+1 x 210+ 1 x 195) = 1045MW Total generated Electricity (in one hour) = 1045MW x 1=10.45Lakh units Total generated Electricity (in 24hours) = 10.45 x 24= 250.8 Lakhs units Amount of Coal required (per day) in KTPS is = 0.5 x 250.8 x 100000 Kg. = 125.4 x 100000Kg. = 125.4 million Kg. This amount of coal is supplied by 5 trains of coal. GENERATOR Generator is the main part of thermal power station or any power plant. A generator is a machine which converts mechanical energy into electrical energy.

The generator has gas cooling construction enclosing the stator winding, core and hydrogen coolers .The cooling medium hydrogen is contained within the frame and circulation by fans mounted on either ends of the rotor .The generator is driven by directly coupled steam turbine at a speed of 3000 rpm. Provision has been made for circulating the cooling water in order to maintain a constant temperature of the coolant i.e. H2 as measured at the fan section side which is in touch with the temperature of the winding, core and other parts as per load. Each of the 2 units under stage-1 have been provided with BHEL make 3-phase turbo generator rated 137.5 MVA, 11KV, 0.8 pf, 7220 Amp, 3000 rpm and 50 cycles/sec .The generator has closed loop of hydrogen gas system for cooling of the stator and rotor at a pressure of 2.0 atm. is filled in a gas tight outer casing of the generator. H2 gas circulates inside the casing by two single stage rotor mounted fans on either side of the rotor .The heated H2 is in turn cooled by six surface type water coolers axially mounted inside the generator casing .The cooling water is supplied to H2 coolers from the BCW over head tank. Each generator has terminal led out of its casing and a star point is formed by sorting the neutral side terminals by a sorting bar. The neutral is grounded by a 1-phase 11000/220V, 37.5 KVA. Neutral grounding transformer, whose secondary coil is laminated by laminated strip with mechanical ventilating holes, is connected across a 650V, class 0.4 ohm, 50 kW neutral grounding resistors and relays for protection of generator against stator earth faults and stator in turn faults (rating 1 amp). The H2 gas inside the generator casing is prevented from leaking in between the rotor and shields, by a continuous oil film maintained between the rotor and sealing rings .The shaft sealing system have two independent oil sources associated pumps, regulators, coolers filters, electrical controls and alarm system. Two independent oil sources are provided for air side and H2 side sealing rings. The oil circuit of the H2 side of the shaft seal is closed and the oil is vacuum treated.

TURBO GENERATOR SPECIFICATIONS:-

(a)

STAGE I

Make Russian Manufacturer BHEL Type T.G.P. Apparent Output 137.5MVA Active Output 110 MW Power factor 0.8 lagging Rated voltage 11 KV Rated current 7200 Amp. Rated speed 3000 rpm Frequency 50 Hz Phase connections Double gen. star No. of generator terminals 6 Max. Output with air cooling 68.75MVA Excitation voltage 230V

(b)

STAGE II & III

Make KWVC Craftworks,Germany Manufacturer BHEL Rated capacity 247 MVA Rated Output 210 MW Rated current 9050 Amp. Rated terminal voltage 15.75 KV Rated speed 3000 rpm Power factor 0.8 lagging Excitation voltage 310V Phase sequence Double star Insulation class B No. of turns per phase/pole 10 Short circuit ratio 0.49

STAGE IV

Make KWVC Craftworks,German Manufacturer BHEL Rated Capacity 247 MVA Rated Output 210 MW Rated Current 9050 Amp. Rated Terminal Voltage 15.75 KV Rated Speed 3000 Rpm Power Factor 0.8 Lagging

Excitation Voltage 310 V Phase Sequence Double Star Insulation Class B No. of Turns per Phase/Pole 10 Short Circuit Ratio 0.49

CHAPTER -1 INTRODUCTION For the power generation with 2x110 MW and 3x210 MW of K.S.T.P.S. authorities are required to be operative to active full operation. The auxiliaries are basically operation either on L.T. System i.e. 415 V 3- power supply is made available to the system after providing the station transformer of 3x50 MVA capacity with voltage 220 KV/ 7.2/7.2 KV & different service transformers of capacity 1.0 MVA, 1.5 MVA, 2.0 MVA, which are located near the load centre as the transformer having the voltage of 6.6 KV /415 V. The 6.6 KV power is distributed through 6.6 KV interconnected Bus System for all the five units with a control through DC of 220 V. The 415 V power supply is done through a L.T. SWGR (Switchgear) which are located nearby the distribution transformer as well as the load centers. The all incomers, which are breaker controlled , are having the control the L.T. SWGR are having the control system on 110/ 220 V AC. The 6.6 KV power supply which are either MOCB (Minimum Oil Circuit Breaker) of JYOTI MAKE or Air Circuit Breakers. The 6.6 KV power supply to various draining equipments i.e. more is made through breakers which are either MOCB of Jyoti make air circuit breaker which are either of voltage makers as well as SF 6 of NGEF make. The LT supply is also controlled through air break circuit breaker which are either L&T make or English Electric Company of India. The various H.T. motors are switched on started through on direct ON line (DOL) in order to inverse the availability of equipment at full efficiency without time gap. Further , the 6.6 KV system which is normally in delta configuration and terms as an unearthed system so also to keep the running motor complete in operating condition in case of any one .phase of motor winding is earthed due to any one reason. Earthling is detected by an protection system with alarm facility to

take remedial measures immediately and at the same time to maintain the generation level in the same condition, prior to occurring the earth fault the single phase earth fault is detected in due course till the motor is not earthed to other or another phase. PUBLIC ADDRESS SYSTEM is available through in area of each unit which helps in fast communication for prompt remedial measure. Soot Blowers are there in the boiler area on the furnace side or Zone which helps in blowing the soot / ash deposition regularly of the furnace wall / economizer tubes to keep heat transfer at the required parameter. In April 1973, Central Electricity Authority prepared a Project Report for power station comprising of the two units of each of capacity 110 MW for RSEB subsequently in September. 1975 this was revised by the Consultant Thermal Design Organization , Central Electricity Authority for invention of 2x110 MW units being manufactured by BHEL, Hyderabad in 1st Stage. The planning commission cleared the project report in Sept., 1976 for installation of two units each of 110 MW in first estimated cost of Rs. 143 Crores. The KSTPS has four stage & six unit power station. In first stage there is 2 unit of 110 MW, in second stage 2 unit of 210 MW. In third & fourth stage, there each having 210MW &195 MW units respectively. The construction of fifth stage Of 195 MW is under construction and may be possibly completed up to sept. 2008. The total power generated in KSTPS is 1045 MW. K.S.T.P.S. IS DESISIGNED IN FOLLOWING STAGES:STAGE I 2x110 MW STAGE II 2X210 MW STAGE III 1X210 MW STAGE IV 1X195 MW STAGE V 1X195MW * * Stage V is to be commissioned shortly in Sept. 2008. LOCATION:The Kota Thermal Power Station is ideally on the left bank of Chambal River at Up Stream of Kota Barrage. The large expanse of water reached by the barrage provides an efficient direct circulation of cooling system for the power station. The 220 KV GSS is within Kms. from the power station. LAND:Land measuring approx. 250 hectares was required for the project in 1976, For disposal of ash tank very near to power station is acquired which the ash in slurry form is disposed off through ash and slurry disposal plants. COAL:Coal India limited owns and operates all the major coal fields in India through its coal producing subsidiary companies viz. Eastern Coal Fields Limited,

Western Coal Fields Limited/Coal India limited is supply coal from its coal mines of coal producing subsidiaries BCCL, SECL & ECL to Kota Thermal Power Station through railway wagons. The average distances of SECL, ECL & BCCL are 800, 950 and 1350 Kms. respectively. WATER:The source of water for power station is reservoir formed by Kota Barrage on the Chambal River. In case of large capacity plants huge quantities of coal and water is required. The cost of transporting coal and water is particularly high. Therefore, as far as possible, the plant must be located near the pit rather than at load centre for load above 200 MW and 375 MW. The transportation of electrical energy is more economical as compared to the transportation of coal. DESIGN FEATURES:The satisfactory design consists of the flowing steps. Estimation of cost. Selection of site. Capacity of Power Station. Selection of Boiler & Turbine. Selection of Condensing Unit. Selection of Electrical Generator. Selection of Cooling System. Design of Control and instrumentation system. The design of steam power station requires wide experience as the subsequent operation and maintenance are greatly affected by its design. The most efficient design consist of properly sized component designed to operate safely and conveniently along with its auxiliaries and installation. CHAPTER -2 General Layout & Basic Idea A control system of station basically works on Rankin Cycle. Steam is produced in Boiler is exported in prime mover and is condensed in condenser to be fed into the boiler again. In practice of good number of modifications are affected so as to have heat economy and to increase the thermal efficiency of plant. The Kota Thermal Power Station is divided into four main circuits : Fuel and Ash Circuit. Air and Gas Circuit. Feed water and Steam Circuit. Cooling Water Circuit. Fuel & Ash Circuit:Fuel from the storage is fed to the boiler through fuel handling device. The fuel used in KSTPS is coal, which on combustion in the boiler produced the ash. The quantity of ash produced is approximately 35-40% of coal used. This ash is collected at the back of the boiler and removed to ash storage tank through ash disposal equipment. Air and Gas Circuit:-

Air from the atmosphere is supplied to the combustion chamber of Boiler through the action of forced draft fan and induced draft fan. The flue gas gases are first pass around the boiler tubes and super heated tubes in the furnace, next through dust collector (ESP) & then economizer. Finally, they are exhausted to the atmosphere through fans. Feed Water and Steam Circuit:The condensate leaving the condenser is first heated in low pressure (LP) heaters through extracted steam from the lower pressure extraction of the turbine. Then its goes to dearator where extra air and non-condensable gases are removed from the hot water to avoid pitting / oxidation. From deaerator it goes to boiler feed pump which increases the pressure of the water. From the BFP it passes through the high pressure heaters. A small part of water and steam is lost while passing through different components therefore water is added in hot well. This water is called the make up water. Thereafter, feed water enters into the boiler drum through economizer. In boiler tubes water circulates because of density difference in lower and higher temperature section of the boiler. The wet steam passes through superheated. From superheated it goes into the HP turbine after expanding in the HP turbine. The low pressure steam called the cold reheat steam (CRH) goes to the reheater (boiler). From reheater it goes to IP turbine and then to the LP turbine and then exhausted through the condenser into hot well. Cooling Water Circuit:A large quantity of cooling water is required to condense the steam in condenser and marinating low pressure in it. The water is drawn from reservoir and after use it is drained into the river. COAL HANDLING PLANT INTRODUCTION:It can be called the heart of thermal power plant because it provided the fuel for combustion in boiler. The coal is brought to the KSTPS through rails there are fourteen tracks in all for transportation of coal through rails. The main coal sources for KSTPS are SECL (South Eastern Coalfields Limited), ECL (Eastern Coalfield Limited) and BCCL (Bharat Coking Coal Limited). Everyday 3 to 4 trains of coal are unloaded at KSTPS. Each train consists of 58 wagons and each wagons consists of 50 tonnes of coal. The approximate per day consumption at KSTPS is about 1400 metric tones. It costs approximate 2 crores of rupees

per day including transportation expenses. The coal is firstly unloaded from wagon by wagon triplers then crushed by crushers and magnetic pulley and pulverized to be transformed to the boiler. The whole transportation of coal is through conveyor belt operated by 3- Induction motor. The coal handling plant can broadly be divided into three sections :1) Wagon Unloading System. 2) Crushing System. 3) Conveying System. WAGON UNLOADING SYSTEM:Wagon Tripler:It unloads the coal from wagon to hopper. The hopper, which is made of Iron , is in the form of net so that coal pieces of only equal to and less than 200 mm. size pass through it. The bigger ones are broken by the workers with the help of hammers. From the hopper coal pieces fall on the vibrator. It is a mechanical system having two rollers each at its ends. The rollers roll with the help of a rope moving on pulley operated by a slip ring induction motor with specification: Rated Output. : 71 KW. Rated Voltage. : 415 V. Rated Current. : 14.22 Amp. Rated Speed. : 975 rpm. No. of phases. : 3 Frequency. : 50 Hz. The four rollers place themselves respectively behind the first and the last pair of wheels of the wagon. When the motor operates the rollers roll in forward direction moving the wagon towards the Wagon Table. On the Wagon table a limit is specified in which wagon has to be kept otherwise the triple would not be achieved. CRUSHING SYSTEM:Crusher House:It consists of crushers which are used to crush the coal to 20 mm. size. There are mainly two type of crushers working in KSTPS:Primary Crushers i.e. i) Rail crushers or ii) Rotary breaker. Secondary Crushers. i.e. Ring granulators. Primary Crushers:Primary crushers are provided in only CHP stage 3 system, which breaking of coal in CHO Stage 1 & Stage 2 system is done at wagon tripler hopper jail up to the size (-) 250 mm. Roll Crusher:Type : 80 5 A breakers. Capacity : 1350 TPH Rates/ 1500 TPH Design. Feed material : Rom Coal. Feed size. : (-) 1200 mm. (approx.) End Product size : (-) 500 mm. Motor rating. : 2 Nos. 125 KW, 100 rpm.

Crushers. : 225. Rotary Breaker:Type : 12 x 21o Rotary Breaker. Capacity : 800 TPH Rated/ 1000 TPH Design. Feed Material. : Coal with rejects. Feed size. : (-) 0-500 mm. End product size : (-) 0-200 mm. Motor rating. : 125 HP, 1500 rpm. Secondary Crusher:Basically there are four ways to reduce material size : impact attrition , Shearing and Compression. Most of the crushers employ a combination of three crushing methods. Ring granulators crush by compressing accompanied by impact and shearing.The unique feature of this granulator is the minimum power required for tone for this type of material to be crushed compared to that of other type of crushers.

INTRODUCTION For the power generation with 2x110 MW and 3x210 MW of K.T.P.S. authorities are required to be operative to active full operation. The auxiliaries are basically operation either on L.T. System i.e. 415 V 3 power supply is made available to the system after providing the station transformer of 3x50 MVA capacity with voltage 220 KV/ 7.2/7.2 KV & different service transformers of capacity 1.0 MVA , 1.5 MVA , 2.0 MVA , which are located near the load centre as the transformer having the voltage of 6.6 KV /415 V. The 6.6 KV power is distributed through 6.6 KV interconnected Bus System for all the five units with a control through DC of 220 V. The 415 V power supply is done through a L.T. SWGR ( Switchgear) which are located nearby the distribution transformer as well as the load centers. The all in -comers, which are breaker controlled , are having the control the L.T. SWGR are having the control system on 110/ 220 V AC. The 6.6 KV power supply which are either MOCB ( Minimum Oil Circuit Breaker) of JYOTI MAKE or Air Circuit Breakers. The 6.6 KV power supply to various draining g equipments i.e. more is made through breakers which are either MOCB of Jyoti make air circuit breaker which are either of voltage makers as well as SF 6 of NGEF make. The LT supply is also controlled through air break circuit breaker which are either L&T make or English Electric Company of India. The various H.T. motors are switched on / started through on direct ON line (DOL) in order to inverse the availability of

equipment at full efficiency without time gap. Further , the 6.6 KV system which is normally in delta configuration and terms as an unearthed system so also to keep the running motor complete in operating condition in case of any one .phase of motor winding is earthed due to any one reason. Earthling is detected by an protection system with alarm facility to take remedial measures immediately and at the same time to maintain the generation level in the same condition, prior to occurring the earth fault the single phase earth fault is detected in due course till the motor is not earthed to other or another phase. PUBLIC ADDRESS SYSTEM is available through in area of each unit which helps in fast communication for prompt remedial measure. LOCATION The Kota Thermal Power Station is ideally on the left bank of Chambal River at Up Stream of Kota Barrage . The large expanse of water reached by the barrage provides an efficient direct circulation of cooling system for the power station. The 220 KV GSS is within Kms. from the power station. LAND Land measuring approx. 250 hectares was required for the project in 1976, For disposal of ash tank very near to power station is acquired which the ash in slurry form is disposed off through ash and slurry disposal plants. COAL Coal India limited owns and operates all the major coal fields in India through its coal producing subsidiary companies viz. Eastern Coal Fields Limited, Western Coal Fields Limited/ Coal India limited is supply coal from its coal mines of coal producing subsidiaries BCCL, SECL & ECL to Kota Thermal Power Station through railway wagons. The average distances of SECL, ECL & BCCL are 800, 950 and 1350 Kms. respectively. WATER : The source of water for power station is reservoir formed by Kota Barrage on the Chambal River. In case of large capacity plants huge quantities of coal and water is required. The cost of transporting coal and water is particularly high. Therefore, as far as possible, the plant must be located near the pit rather than at load centre for load above 200 MW and 375 MW . The transportation of electrical energy is more economical as compared to the transportation of coal.

Design features : The satisfactory design consists of the flowing steps. Estimation of cost. Selection of site. Capacity of Power Station. Selection of Boiler & Turbine. Selection of Condensing Unit. Selection of Electrical Generator. Selection of Cooling System. Design of Control and instrumentation system. The design of steam power station requires wide experience as the subsequent operation and maintenance are greatly affected by its design. The most efficient design consist of properly sized component designed to operate safely and conveniently along with its auxiliaries and installation. General Layout & Basic Idea : A control system of station basically works on Rankin Cycle. Steam is produced in Boiler is exported in prime mover and is condensed in condenser to be fed into the boiler again. In practice of good number of modifications are affected so as to have heat economy and to increase the thermal efficiency of plant. The Kota Thermal Power Station is divided into four main circuits : Fuel and Ash Circuit. Air and Gas Circuit. Feed water and Steam Circuit. Cooling Water Circuit. Fuel & Ash Circuit : Fuel from the storage is fed to the boiler through fuel handling device . The fuel used in KTPS is coal , which on combustion in the boiler produced the ash. The quantity of ash produced is approximately 35-40% of coal used. This ash is collected at the back of the boiler and removed to ash storage tank through ash disposal equipment. Air and Gas Circuit : Air from the atmosphere is supplied to the combustion chamber of Boiler through the action of forced draft fan and induced draft fan. The flue gas gases are first pass around the boiler tubes and super heated tubes in the furnace, next through dust collector (ESP) & then economizer. Finally, they are exhausted to the atmosphere through fans. Feed Water and Steam Circuit :

The condensate leaving the condenser is first heated in low pressure (LP) heaters through extracted steam from the lower pressure extraction of the turbine. Then its goes to dearator where extra air and non-condensable gases are removed from the hot water to avoid pitting / oxidation. From deaerator it goes to boiler feed pump which increases the pressure of the water. From the BFP it passes through the high pressure heaters. A small part of water and steam is lost while passing through different components therefore water is added in hot well. This water is called the make up water. Thereafter, feed water enters into the boiler drum through economizer. In boiler tubes water circulates because of density difference in lower and higher temperature section of the boiler. The wet steam passes through superheated. From superheated it goes into the HP turbine after expanding in the HP turbine. The low pressure steam called the cold reheat steam (CRH) goes to the reheater( boiler). From reheater it goes to IP turbine and then to the LP turbine and then exhausted through the condenser into hotwell. ELECTRICITY GENERATOR AT K.T.P.S. Thermal power station burns the fuel and use the resultant heat to raise the steam which drives the turbo-generator. The fuel may be Fossil ( Coal , Oil and Natural Gas) whichever fuel is used the object is same to convert the heat into mechanical energy to electrical energy by rotating a magnet inside the set of winding. In a coal fired thermal power station other raw materials are air and water. The coal is brought to station by train or other means travels from the coal handling system. i) By conveyer belts to coal bunkers from where it is fed to pulverizing mills. ii) Mills grind it fine as face powder. iii) Then this powdered coal mixed with preheated air is blow into boiler by a fan known as primary air fan (PA fan). iv) When it burns more like a gas as solid in conventional domestic or industrial grate with additional amount of air called secondary air supplied by Forced Draft Fan. As the coal has been grinded so resultant ash is also as fine as powder. Some of its fine particles blinds together to form lumps which falls into the ash pit at the bottom of furnace. v) The water quenched ash from the bottom of furnace is carried out boiler to pit for subsequent disposal.

vi) Most of ash still in fine particles form is carried out to electrostatic precipitators where it is trapped by electrode charged with high voltage electricity. The dust is then conveyed to the disposal area or to bunkers for sale. vii) Now after passing through ESP few gases are discharged upto chimney by Induced Draft Fan. Meanwhile the heat reloaded from the coal has been absorbed by kilometers long tubes which lies in boiler walls inside the tubes Boiler Feed Water which is transferred into turbine blades and makes them rotate. To the end of the turbine rotor of generator is coupled, so that when turbine rotates the rotor turns with it. The rotor is housed inside the stator having coil of copper bars in which electric is produced through the movement of magnetic field created by rotor. The electricity passes from the stator winding to the transformer which steps up the voltage so that it can be transmitted effectively over the power line of grid. SWITCH YARD 220 KV System : Two 220 KV bus bars have been provided in switch yard and are inter-connected through a bus coupler. Each of the two 110 MW generator is connected to this system through a step up of 125 MVA 240/ 11 KV yard generator transformer. There are two step down transformer each feeding 6.6 KV system ( Station Switchyard ) viz. BS-IS & SB-IB. Each station transformer has two windings one secondary side and is rated for 50/25/25 mva , 270/7/7.2 kva four feeder take off from 220 switch yard, two to SKATPURA ,GSS and other to HEERAPURA , Jaipur GSS. Each of four feeder are provided with bypass isolators which is connected across line breaker and breaker isolator. By closing bus coupler between 220 KV buses and putting line feeders whose breaker required maintenance of any one bus through by pass isolators and all other line feeders whose breaker is by passed is then transformed to bus coupler breaker. A brief description of equipments of 220 KV system is as follows.

You might also like

- Today Elected Candidates of Commerce Society 2014-15Document1 pageToday Elected Candidates of Commerce Society 2014-15pcpathikNo ratings yet

- Today Notification For All I, III & V SemesterDocument1 pageToday Notification For All I, III & V SemesterpcpathikNo ratings yet

- WWW - Ieg.gov - in JKC Recruitment Stepbystep Infosys ProcessDocument11 pagesWWW - Ieg.gov - in JKC Recruitment Stepbystep Infosys ProcessAnudeep GopagoniNo ratings yet

- Water Treatment PlantDocument2 pagesWater Treatment PlantpcpathikNo ratings yet

- R 2Document50 pagesR 2pcpathikNo ratings yet

- WWW - Ieg.gov - in JKC Recruitment Stepbystep Infosys ProcessDocument11 pagesWWW - Ieg.gov - in JKC Recruitment Stepbystep Infosys ProcessAnudeep GopagoniNo ratings yet

- Research Journals Length PolicyDocument1 pageResearch Journals Length PolicypcpathikNo ratings yet

- Thermal Power PPT 1274193706 Phpapp02Document31 pagesThermal Power PPT 1274193706 Phpapp02riteshbohareNo ratings yet

- Reort On Practical Training in BhilaiDocument6 pagesReort On Practical Training in BhilaipcpathikNo ratings yet

- Requirement of Photograph For OCI RegistrationDocument4 pagesRequirement of Photograph For OCI Registrationcgrao27No ratings yet

- Presentation r5Document24 pagesPresentation r5pcpathikNo ratings yet

- Spec Pics r3Document19 pagesSpec Pics r3pcpathikNo ratings yet

- Coal r2Document9 pagesCoal r2pcpathikNo ratings yet

- KSTPS Traning ReportDocument83 pagesKSTPS Traning ReportBaldev Choudhary100% (1)

- Pics r1Document11 pagesPics r1pcpathikNo ratings yet

- Kota Super Thermal Power PlantDocument29 pagesKota Super Thermal Power Plantatul mishra75% (4)

- KTPS GenerationDocument70 pagesKTPS GenerationShailendra Gautam100% (1)

- Kota Thermal Power Station Is Rajasthan's First Major Coal Power Station. Presently It Is in Operation With Installed Capacity of 1240 MWDocument7 pagesKota Thermal Power Station Is Rajasthan's First Major Coal Power Station. Presently It Is in Operation With Installed Capacity of 1240 MWpcpathikNo ratings yet

- 1 1general OverviewDocument30 pages1 1general OverviewpcpathikNo ratings yet

- 26Document65 pages26pcpathikNo ratings yet

- Electrostatic Precipitator Consists of Following PartsDocument4 pagesElectrostatic Precipitator Consists of Following PartspcpathikNo ratings yet

- Kota Super Thermal Power Station Training ReportDocument62 pagesKota Super Thermal Power Station Training ReportAman agrawal100% (1)

- Training Report Ktps-FinalDocument45 pagesTraining Report Ktps-Finalrahulj567No ratings yet

- Kota Thermal Power Station Is Rajasthan's First Major Coal Power Station. Presently It Is in Operation With Installed Capacity of 1240 MWDocument7 pagesKota Thermal Power Station Is Rajasthan's First Major Coal Power Station. Presently It Is in Operation With Installed Capacity of 1240 MWpcpathikNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GUS Vertical Axis Micro Wind TurbinesDocument1 pageGUS Vertical Axis Micro Wind TurbinesBlogKingNo ratings yet

- Amelia Putri NurhariDocument1 pageAmelia Putri NurhariReza MustofaNo ratings yet

- Unit Iv Cogeneration and Residual Heat RecoveryDocument16 pagesUnit Iv Cogeneration and Residual Heat RecoveryShanmuga SundharamNo ratings yet

- Sealeze APH Brush Seals BrochureDocument2 pagesSealeze APH Brush Seals BrochureMurilo Camisão SchwindenNo ratings yet

- First Chapter - Introduction To Applied Thermodynamic - AULA 7Document13 pagesFirst Chapter - Introduction To Applied Thermodynamic - AULA 7Gabriel SantosNo ratings yet

- Fdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning ChecklistDocument2 pagesFdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning Checklistkapster KannourNo ratings yet

- 20KW Wind TurbineDocument11 pages20KW Wind TurbineIvonei Ferreira da Silva S.No ratings yet

- Automatic Turbine Run-Up SystemDocument22 pagesAutomatic Turbine Run-Up SystemSam100% (1)

- Fans in Thermal Power PlantsDocument3 pagesFans in Thermal Power PlantsMuhammad Nadeem RazaNo ratings yet

- Solar Roof Top Roi Calculation TemplateDocument5 pagesSolar Roof Top Roi Calculation TemplateSarath Chandra VNo ratings yet

- PP Part1Document16 pagesPP Part1Kris Aileen CortezNo ratings yet

- Te 2 SyllabusDocument3 pagesTe 2 SyllabusPolireddi Gopala KrishnaNo ratings yet

- Compressor Station MallnowDocument8 pagesCompressor Station MallnowCarsten LieNo ratings yet

- Solar Refrigeration Using Peltier EffectDocument15 pagesSolar Refrigeration Using Peltier EffectSyko GamingNo ratings yet

- Power Plant Chapter 7Document25 pagesPower Plant Chapter 7Kedir MohammedNo ratings yet

- 0044 - Small - Mini and Micro Hydro Power Stations in India - Publication No.-254 - Vol-1Document372 pages0044 - Small - Mini and Micro Hydro Power Stations in India - Publication No.-254 - Vol-1RAHUL BHUSHAN AmbedkarNo ratings yet

- Heat Exchanger Sample Problems (Students)Document2 pagesHeat Exchanger Sample Problems (Students)Kakashi JuniorNo ratings yet

- Connecting Rod and Pistons (Bus) Mercedes OM 926 LA: (Europa) (Engine)Document4 pagesConnecting Rod and Pistons (Bus) Mercedes OM 926 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- Trina 400 WattDocument2 pagesTrina 400 WattSyed Umair AliNo ratings yet

- GE Aeroderivative Vietnam Sep 22 FinalDocument36 pagesGE Aeroderivative Vietnam Sep 22 Finaltuanpham100% (1)

- LawnmowerDocument2 pagesLawnmowerlili aboudNo ratings yet

- Be 2 Sem SPV - Cell Amrita - ShuklaDocument4 pagesBe 2 Sem SPV - Cell Amrita - ShuklaAnonymous gUjimJKNo ratings yet

- Outside Packed Floating HeadDocument11 pagesOutside Packed Floating HeadGurunath EpiliNo ratings yet

- Heating and Cooling With Geothermal EnergyDocument34 pagesHeating and Cooling With Geothermal EnergyJuan Carlos Sanchez FloresNo ratings yet

- Analysis and Design of Parabolic Trough PDFDocument7 pagesAnalysis and Design of Parabolic Trough PDFElZorroMexNo ratings yet

- Failure Report of 4730 GMU-30 - 14.06.2022Document3 pagesFailure Report of 4730 GMU-30 - 14.06.2022alam zebNo ratings yet

- Me1354 Power Plant EngineeringDocument16 pagesMe1354 Power Plant EngineeringAlmas BegumNo ratings yet

- Bab 8Document28 pagesBab 8Mohammad Farhan SNo ratings yet

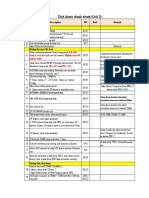

- Shutdown Check Sheet-Rev PDFDocument3 pagesShutdown Check Sheet-Rev PDFTino FerinandaNo ratings yet

- Tsee Chapter 1 & 2 MCQDocument7 pagesTsee Chapter 1 & 2 MCQPAWAR RAHULNo ratings yet