Professional Documents

Culture Documents

Crane Pedestral Design

Uploaded by

gautham21brickOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Pedestral Design

Uploaded by

gautham21brickCopyright:

Available Formats

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN DR 352 Rev 0 L MAY 1991

John Brown Engineers & Constructors Limited

20 Eastbourne Terrace, London W2 6LE

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L

CONTENTS 1. 2. 3. 3.1 3.2 3.3 3.4 3.5 3.6 4. 4.1 4.2 4.3 4.4 5. 5.1 5.2 5.3 6. 7. OBJECTIVE DEFINITION DESIGN SPECIFICATION CRANE SPECIFICATION DUTY FACTOR CRANE UTILISATION STATE OF LOADING LIFT-IMPACT FACTOR API-RP2A RECOMMENDATIONS MAXIMUM LOADING FOR DESIGN LLOYDS'S METHOD AN INDEPENDENT METHOD COMPARISON OF THE METHODS RECOMMENDATION FATIGUE DESIGN CONVENTIONAL FATIGUE ANALYSIS COMMENTARY CRANE VIBRATIONS ACCIDENTAL LOAD REFERENCES

FIGURES AND TABLES REV 0 ISSUED PREPARED BY: OFFSHORE STRUCTURES MAY 1991

APPROVED BY: ........................... K. LOGENDRA, ASSOCIATE DIRECTOR OFFSHORE STRUCTURES

AUTHORISED BY: ................... H. THIRKELL, DIRECTOR OF ENGINEERING

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 1 OF 17

OBJECTIVE The objective of the Design Practice is to give detailed guidance on the static and fatigue design of the pedestal structures of offshore platform cranes. An offshore crane is subject to significant shockloading which should be addressed in an adequate manner in the design of the crane pedestal.

DEFINITION The crane pedestal is, in general, a vertical tubular structure spanning at least two topside deck levels (see Fig. 1-3). In some cases this tubular is also used for diesel storage. However, the safety aspect of diesel storage must be addressed as part of a Formal Safety Assessment. The slew ring of the revolving crane is mounted onto the top of the tubular with or without a transition cone called the pedestal adoption. The definitions of the symbols used in this Design Practice are given immediately after their introduction in design equations.

DESIGN SPECIFICATION For the design of the crane pedestal two loading conditions will have to be considered: the maximum loading and the fatigue loading. No specific guidance on crane pedestals is given in the DEn Guidance Notes (Ref.1) despite the fact that a series of crane accidents occurred in the early 80's. The section on the design of the crane supporting structure can make effective use of API-RP2A (Ref. 2) as will be discussed in Section 4.2. It is also worth noting that some interesting field data on offshore crane behaviour are reported in Ref. 3. It is common practice in John Brown to use a combination of the Lloyd's Code on Lifting Appliances in a Marine Environment, Chapter 3, Sect. 3 on offshore cranes (Ref. 4), and the British Standard on rules for the design of cranes (Ref. 5). This Design Practice will review the adequacy of this method and will bring it in line with the Guidance Notes and API-RP2A (Ref. 1 and 2) as applied to other parts of the topsides and substructure design.

3.1

CRANE SPECIFICATION The following crane specific information is required: a crane capacity curve (see Fig. 4) seastate dependent crane derating coefficients the weight of the boom and the hook

In some cases (e.g. Bruce) there is also an accidental load requirement which stipulates that the pedestal must be stronger than the crane strength. In that case the vendor supplied data should also contain a crane failure envelope.

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 2 OF 17

3.2

DUTY FACTOR According to Lloyd's Register it is logical and reasonable to reflect the harsh duty of an offshore pedestal crane by a Duty Factor (DF) = 1.2 This factor is to be applied to the lift-load only and in combination with Lloyd's dynamic amplification factors (see Ref 4 Ch. 3 Sect 2.3.1).

3.3

CRANE UTILISATION According to BS 2573 (Ref. 5) the crane operating life is reflected by two parameters (see Tables 1 and 2): the Class of Utilisation (U1-U9) the State of Loading (Q1-Q4)

Historically the following utilisations have been used: U3 for unmanned installations (N = 125,000 cycles) U5 for drilling/production platform (N = 500,000 cycles) The class can be revised based on Client supplied data. 3.4 STATE OF LOADING The previous sections only addressed the general working environment and the number of lifts in the course of the crane useful operating life. The aim of the parameter Q in BS 2573 is to reflect the average severity of the loading as a percentage of the maximum crane loading for the crane pedestal fatigue analysis. The State of Loading of offshore cranes is best reflected by Q2 - moderate state of loading In the fatigue analysis the state of loading is incorporated by a parameter Kp which is called the load spectrum factor. Its value is dependent on the state of loading and the value of Kp associated with Q2 is Kp = 0.63 It is a multiplication factor for the total pedestal bending moment. Following Section 2.3.2.1 of BS 2573 it could be derived independently based on Client supplied data but it is questionable if these additional calculations would effectively improve the accuracy of the fatigue analysis.

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 3 OF 17

Note 1:

The recommended value of m = 3 in the expression for Kp (see Sect. 2.3.2.1 in Ref. 5) corresponds to the slope of the DEn-SN curve in a log-log scale. According to the expressions in Ref.5 a utilisation of 10, 60, 30% of the lifts at 100, 60, 40% of the crane capacity corresponds with a Kp = 0.63 equal to Kp for the Q2 state of loading.

Note 2:

3.5

LIFT IMPACT FACTOR The most onerous loading condition for an offshore crane will be experienced during the offloading of a supply boat. Since the hook-speed of the main hoist will be low in comparison with the supply boat heave motion there will be a significant impact on the crane when the load comes free from the supply boat for the first time. This impact factor can also be called dynamic amplification factor (DAF); it is a random variable because it will depend on the actual heave motion of the supply boat at the point of lift-off. The specific values for the DAF in a crane analysis can be derived from the equations in Ref 4, Ch. 3 Sect. 3.3.2; some specific numbers are given in Sect. 4.1. The DAF can also be found from computer simulations or from field measurements and can be as high as 3.0.

3.6

API-RP2A RECOMMENDATIONS API-RP2A Sect. 7.3.1 summarised the guidance on the crane supporting structures as follows: "7.3.1 Static Design. The supporting structure should be designed for the dead load of the crane plus a minimum of 2.0 times the static rated load as defined in API Spec. 2C and the stresses compared to the Par. 3.1.1 allowables with no increase." In the light of the discussion and analysis of Chapter 4 this design condition is significantly lighter than the recommendation of this DR. Therefore the API recommendations should not be used for crane pedestal design except for Gulf of Mexico type environmental conditions.

MAXIMUM LOADING FOR DESIGN The maximum loading governing the design of the crane pedestal will be in accordance to the Lloyds's code on Lifting Appliances (Ref. 4), Ch. 3, Sect. 2.16.2. More specifically the governing load condition will be Case 2 for the crane in operating mode with wind. In particular the maximum moment in the pedestal will be governing. For this case the effects of the horizontal loads on the crane boom (which is so important for the crane design itself) can be ignored.

4.1

DR352.WP5

LLOYD'S METHOD

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 4 OF 17

According to Ref. 4, Ch. 3 the design load for the pedestal will require the incorporation of a duty factor (DF) and a dynamic amplification factor (DAF) on the hook load. More specifically the following values can be obtained from Ref. 4, Chapter 3: Duty Factor (DF) = 1.2 (Sect. 2.3.1) DAF (for Hs = 1.6m) = 1.61 (Sect. 3.3.2) DAF (for Hs = 3.9m) = 2.07 (Sect. 3.3.2) Using these factors together with the vendor supplied data and after inclusion of the static moment due to the weight of the hook and the boom the most unfavourable moment for the design of the crane pedestal is: Mmax = Mhook + Mboom + DF * DAF * Mhookload The maximum stress as a result of this moment is to be compared with the allowable bending stress pa: pb = 0.57 py (Sect. 5.3.2) 4.2 AN INDEPENDENT METHOD It was noted in Sect. 3.2 that the maximum DAF on the hook load can be as high as 3.0. This value will be used in the independent method. Secondly the pedestal is a thin-walled tubular structure which should be designed in accordance to API-RP2A Section 3.2.3. The one-third increase in allowable stresses should not be applied to the crane pedestal. For py = 340 MPa and D/t = 75 the allowable bending stress according to API-RP2A is: pb = 0.65 py For values of D/t and py different from D/t = 75 and py = 340 MPa the equation for pb in API-RP2A Sect. 3.2.3 should be used. This value of pbis to be combined with a dynamic amplification factor for the hookload equal to DAF = 3.0 Finally pb is to be obtained from the following equations for Mmax

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 5 OF 17

Mmax = Mhook + Mboom + DAF * Mhookload 4.3 COMPARISON OF THE METHODS Two comparisons between the two methods will be made base on the static part and the dynamic part of the crane loading. Using the equations in Sect. 4.1 and 4.2 and by setting the hookload equal to zero a direct comparison can be made between the allowable static bending stresses. The Lloyd's method (stat) pb = 0.57 py The alternative method (stat) pb = 0.65 py Using the equations in Sect. 4.1 and 4.2 and by setting the boom weight and the hook weight equal to zero a direct comparison can be made between the allowable dynamic bending stress in the pedestal due to the hook-load. By dividing the maximum allowable bending stresses by the Duty Factor and DAF the following values are obtained. The Lloyd's method (dyn) pb = 0.23 py The alternative method (dyn) pb = 0.22 py (These numbers are found as follows: 0.23=0.57/(1.2 x 2.07);0.22 = 0.65/3.0) 4.4 RECOMMENDATION The alternative method incorporates a well recognised model to accommodate the bending strength reduction for thin-walled tubulars. In addition the allowable static stress in the alternative method has been found to be 10% higher (using industry accepted practices) than the Lloyd's method. Therefore it is recommended to apply the alternative method of Section 4.2 for the ultimate design of pedestals for offshore cranes. 5 FATIGUE The assessment of the fatigue strength of crane components should address the following load histories: the lift-off of a load from a supply boat the dynamics in the crane system as a result of the impact forces during lift off the setting-down of the load on the platform

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 6 OF 17

From a review of methods and consequences it is concluded that the BS 2573/Lloyd's procedure considering each lift-off and setting-down as a fatigue cycle is governing for the crane pedestal. This procedure will be further addressed in Sect. 4.1. It is noted that the API-RP2A recommendation on crane pedestal fatigue should not be used for North Sea conditions; it may form a simple basis for light cranes on platforms operating in Gulf of Mexico conditions. The crane vibrations will be discussed in Sect. 5.3. They are the result of impact forces during lift-off from a supply boat and forms a governing fatigue loading on many crane components. For the crane pedestal its inclusion leads to a small correction which can be disregarded within the accuracy of its overall fatigue analysis. 5.1 CONVENTIONAL CRANE FATIGUE ANALYSIS From the crane specific data the following is required for the fatigue analysis. Class of utilisation (U3 - U5) representing the number of lifts during the lifetime of the crane. (See Sect. 3.3) State of loading as reflected in Q2 = 2 and Kp = 0.63. (See Sect. 3.4)

The maximum stresses in the crane pedestal will directly depend on the bending moment and we are specifically interested in the maximum positive and negative bending moment. 5.1.1 The Maximum and Minimum Moment for Fatigue The lift-off moment to be considered for the fatigue analysis is : Mmax = Kp * (Mhook + Mboom + DF x DAF x Mhookload) This moment should be checked for the following conditions and seastates: (a) (b) (i) (ii) maximum reach associated to maximum load maximum load at the maximum associated reach seastate 2-3 (Hs = 1.6m) with a DAF = 1.61 seastate 4-6 (Hs = 3.9m) with a DAF = 2.07

This leads to four cases (a-i, a-ii, b-i, b-ii). The opposite sign to the lift-off moment will occur during placing of the load on the platform. This moment is similar to the lift-off moment with one exception that the operation is seastate independent which can be reflected by a DAF = 1.0 or : Mmin = Kp * (Mhook + Mboom + DF x Mhookload) Comment 1: If the crane is optimally designed using Lloyd's recommendation for the DAF

DR352.WP5 UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 7 OF 17

then the maximum moment in the crane pedestal will be independent of the seastate. Comment 2: Due to the effect of the boom weight on the pedestal moment it is expected that the maximum pedestal moment will be concurrent with the maximum reach. Comment 3: Since the minimum pedestal moment (occurring while placing the load on the platform) is seastate independent it can be demonstrated that the minimum pedestal moment reaches its (absolute) extreme value for the highest load (i.e lowest seastate) and for the maximum reach. These three comments should be verified for the fatigue analysis. If confirmed then they form the immediate basis for obtaining the maximum and minimum moment to be used in the fatigue analysis of the crane pedestal as follows: Mmax = Kp * (Wh + 0.5 Wb + DF x DAF * Wl) *rmax Mmin = Kp * (Wh + 0.5 Wb + DF x Wl) *rmax where Kp = 0.63 (see Sect. 3.3) Wh = weight of the hook Wb = weight of the boom Wl = weight of the hookload DF = 1.2 (see Sect. 3.2) DAF = 1.61 (see Sect. 4.1) rmax = maximum reach 5.1.2 The Allowable Stress The maximum and minimum moments also give the corresponding R-value which is defined as: R = Mmin./Mmax. = min. stress/max. stress For crane pedestals the class F welding detail should be used. The corresponding table from BS 2573 for class-F welding details is copied as Table 3 in this DR. Using the R-value calculated above and the number of cycles in accordance to the class of utilisation (U3 - U5) the corresponding maximum allowable fatigue (tension or compressive) stress can be read directly from Table 3. The maximum stress together with the maximum pedestal moment determines the section modules or (if the diameter is specified) the material thickness of the pedestal.

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 8 OF 17

5.2

COMMENTARY Fatigue in the UK sector of the North Sea is in general addressed using the DEn Guidance Notes (Ref. 1) and therefore it is useful to make some comparative remarks on the procedure of Sect. 5.1. The only difference will be in the selection of the SN curve; all other aspects (the number of cycles, the F curve, the Kp - value) are found to be identical using the information contained in the Guidance Notes. The two differences between Ref. 1 and BS 2573 (Ref. 5) in the fatigue curves are: DEn do not recognise the R-dependency for R = -1 (fatigue with a zero mean) the allowable stress is different.

This is reflected in the following data for the maximum stress-amplitude in MPa at U5 (500,000 cycles). In this table, for completeness, the API-RP2A fatigue allowables have been included as well. Stress in MPa R = -1.0 R = -0.7 BS 2570 62 71 DEnGN 54 64 API-X 69 81 API-X' 57 67

This difference between BS 2573 and the Guidance Notes is significant from a design point of view. But it should be noted that their difference is equivalent to doubling the estimated failure rate, (failure = through thickness crack) from 2% to 4% in the lifetime of the crane. Because of the ease of inspection of a crane pedestal as compared with underwater parts of the structure it is recommended to apply the slightly less conservative BS 2573 data. 5.3 CRANE VIBRATIONS The impact due to supply-boat offloading will result in vibrations in the crane system and these vibration gradually reduce in magnitude until the equilibrium condition is reached. The amplitude of the fatigue loading is governed by (DAF - 1.0) * hook-load and the total stress range is twice this amplitude; secondly the number of active cycles will depend on the system damping In general the damping of structural systems is small; for example a value of 2% of critical damping seems realistic implying that in 5 cycles the amplitude of the oscillations is reduced to 50%. It can then be demonstrated that for these conditions (with this damping) using Ref. 1 information the fatigue damage in the crane pedestal due to crane dynamics can be ignored. This is contrary to the findings of Ref. 3. It should be noted, though, that crane vibrations form an important aspect in the design of the crane boom and other components in the pedestal crane. 6 ACCIDENTAL LOAD

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 9 OF 17

For the design of the Bruce pedestal crane the following accidental load scenario was stipulated. "The crane pedestal, and supporting structure, will be analysed to demonstrate a minimum factor of safety against collapse of 1.5. The applied loading for this case shall be determined from crane failure envelopes supplied by the crane vendor. For this case, allowable stresses will be limited to the yield stress of the pedestal material." The accidental load scenario may well be governing for the design of the crane pedestal and its supporting steel work. The main reason for this scenario is the occurrence of accidents like the hook snatching the supply boat causing pedestal failure and fatalities in the early 80's. Without further data the following two changes are recommended for incorporation in the above description. a) b) safety against collapse to be reduced from 1.5 to 1.3 yield stress to be replaced by allowable stress with a one-third increase.

Pt. 1 can be further reduced after review of the vendor data supporting the crane failure envelope. Pt. 2 is a reflection of API-RP2A on thin walled tubulars in line with the comments in Sect. 4.2. 7 REFERENCES a) Department of Energy; Offshore Installations: Guidance on Design, Construction and Certification (Fourth Edition) 1990. API-RP2A API Recommended Practice for Planning, Designing and Construction Fixed Offshore Platforms 1989 (18th Edition). Shauschausen, J. and Gran, S. Supply Boat Motions; Dynamic Response and Fatigue of Offshore Cranes OTC 3795, 1980. Code for Lifting Appliances in a Marine Environment, Lloyd's Register of Shipping, Jan. 1987. BS 2573 Rules for the Design of Cranes Part 1: Specification for the Classification Stress Calculations and Design Criteria for Structures 1983.

b)

c)

d)

e)

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 10 OF 17

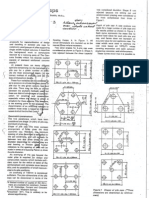

FIGURE 1. A TYPICAL CRANE PEDESTAL SUPPORT

STANDARDS\DR\DR352\FIG-1.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 11 OF 17

FIGURE 2a. PRIMARY STEEL ARBROATH DECK

STANDARDS\DR\DR352\FIG-2.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 12 OF 17

FIGURE 2b. PRIMARY STEEL ARBROATH DECK

STANDARDS\DR\DR352\FIG-3.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 13 OF 17

FIGURE 3. DETAILS OF THE CRANE PEDESTAL

STANDARDS\DR\DR352\FIG-4.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 14 OF 17

FIGURE 4. CRANE LOAD CAPACITY CURVE

STANDARDS\DR\DR352\FIG-5.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 15 OF 17

STANDARDS\DR\DR352\FIG-6.WPG

STANDARDS\DR\DR352\FIG-7.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

Engineering & Construction Sector

DESIGN REFERENCE OFFSHORE STRUCTURES CRANE PEDESTAL DESIGN

DR 352/0 L PAGE 16 OF 17

STANDARDS\DR\DR352\FIG-8.WPG

DR352.WP5

UNCONTROLLED COPY. DOCUMENT VIEWED ON THE NETWORK TAKES PRECEDENCE.

You might also like

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- PP00011 Pdi DS Cal 00007 - C03Document96 pagesPP00011 Pdi DS Cal 00007 - C03Olanrewaju Tope100% (1)

- 05 Melcal Crane SpecificationDocument21 pages05 Melcal Crane SpecificationGabriel Cujia QuinteroNo ratings yet

- LIFTECH - Container Crane DesignDocument49 pagesLIFTECH - Container Crane Designaiyubi2100% (1)

- Lifting BEAMSDocument90 pagesLifting BEAMSGogyNo ratings yet

- Design Criterions For Crane PedestalsDocument5 pagesDesign Criterions For Crane PedestalsRPDeshNo ratings yet

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDocument6 pagesFEA and Optimization of Telescopic Boom of Mobiles Hydraulic Cranenpd1986100% (2)

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Calculation PadeyeDocument6 pagesCalculation PadeyeAddy Sumoharjo ST100% (1)

- Lifting Sets Calculation - API RP 2ADocument11 pagesLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Technical Spec P-8781-1 Rev 00Document45 pagesTechnical Spec P-8781-1 Rev 00Wong Yew Wei0% (2)

- Sea FasteningDocument48 pagesSea FasteningJack Lee Kean Heng100% (1)

- New EN 13852-1 Offshore Cranes Edition 2013Document33 pagesNew EN 13852-1 Offshore Cranes Edition 2013kazdano100% (3)

- 01 Horizontal Angle CalculationDocument3 pages01 Horizontal Angle CalculationMbalekelwa MpembeNo ratings yet

- Padeye Calculator (Shackle Compatibility & Design Capacity) : ApplicationsDocument8 pagesPadeye Calculator (Shackle Compatibility & Design Capacity) : ApplicationsBayari ArNo ratings yet

- 13.15 B - Presentation - Forces Experienced by Winch Drums and Reels Systems PDFDocument26 pages13.15 B - Presentation - Forces Experienced by Winch Drums and Reels Systems PDFarturomNo ratings yet

- Heavy Lift Installation Study of Offshore Structure 2004Document203 pagesHeavy Lift Installation Study of Offshore Structure 2004Quang-derer75% (4)

- Spec. For Pedestal CraneDocument18 pagesSpec. For Pedestal Craneronny_fernandes363No ratings yet

- APPEA Guidelines For Lifting Equipment APPENDICIESDocument60 pagesAPPEA Guidelines For Lifting Equipment APPENDICIESIsye Ruis100% (3)

- Bridon Crane Rope CatalogueDocument80 pagesBridon Crane Rope CataloguePete Swift100% (1)

- SC-292 - Lift Point DesignDocument39 pagesSC-292 - Lift Point DesignSantanu100% (2)

- Marine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102Document22 pagesMarine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102leelarama100% (1)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- 3423Document12 pages3423Tran Van DaiNo ratings yet

- SC-211 - Dual Crane Lift SystemsDocument46 pagesSC-211 - Dual Crane Lift SystemsSantanu100% (1)

- Wave Scatter DiagramDocument8 pagesWave Scatter Diagramcr231181No ratings yet

- Miscellaneous Calculations: 1 Sea Transport Forces On CargoDocument4 pagesMiscellaneous Calculations: 1 Sea Transport Forces On CargoAgarry EmmanuelNo ratings yet

- Spreader Bar With LugsDocument15 pagesSpreader Bar With LugsvamsiNo ratings yet

- DNV Standard 2-22 - Lifting AppliancesDocument92 pagesDNV Standard 2-22 - Lifting Appliancesdomsoneng100% (6)

- CALCULATIONS Pad Eye DesignDocument5 pagesCALCULATIONS Pad Eye DesignVijay Verma100% (1)

- LGS Seafastening Design - Revision 3Document2 pagesLGS Seafastening Design - Revision 3ksangeeth2000No ratings yet

- 1.3 - Tubular Member Design ConsiderationsDocument27 pages1.3 - Tubular Member Design ConsiderationsDanNo ratings yet

- Pedestal Crane Student ManualDocument25 pagesPedestal Crane Student ManualDangtrinh Nguyen100% (1)

- Har-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Document12 pagesHar-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Damar Budi LaksonoNo ratings yet

- EC3 - Offshore Padeye DesignDocument4 pagesEC3 - Offshore Padeye Designscaricatutto100% (1)

- Comparison Between Lattice Boom and Knuckle BoomDocument2 pagesComparison Between Lattice Boom and Knuckle BoomG.SWAMI100% (2)

- Design Calculation LiftingDocument19 pagesDesign Calculation LiftingAbu Al Sayyid100% (1)

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- Smit Singapore Pte LTD: Peter Zhang 1 of 1Document8 pagesSmit Singapore Pte LTD: Peter Zhang 1 of 1Myatmyat SwewinNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Offshore Latticed Structures - Analysis of The Lattice Crane BoomDocument1 pageOffshore Latticed Structures - Analysis of The Lattice Crane BoomGogyNo ratings yet

- Padeye Design CheekDocument3 pagesPadeye Design CheekBolarinwa89% (9)

- RC-Pier LRFD 3 Column Frame Pier ExampleDocument160 pagesRC-Pier LRFD 3 Column Frame Pier ExampleMTCLS100% (2)

- QN E121.00003 000 PDFDocument33 pagesQN E121.00003 000 PDFAditya JainNo ratings yet

- Design Report For 395Document228 pagesDesign Report For 395Saurabh PandeyNo ratings yet

- SDA Primary Structure of Passenger Ships-Guidance On Direct Calculations PDFDocument48 pagesSDA Primary Structure of Passenger Ships-Guidance On Direct Calculations PDFhiginio.moro6182No ratings yet

- Design Criteria (Based On BS)Document23 pagesDesign Criteria (Based On BS)Sebastian Eron DavidNo ratings yet

- Flat Slab ExampleDocument103 pagesFlat Slab ExampleShishir Kumar Nayak100% (3)

- LRFD Design ExampleDocument110 pagesLRFD Design ExampleJose R Birmighan SNo ratings yet

- FPSO - Technical Specification For Marine TransportationDocument11 pagesFPSO - Technical Specification For Marine Transportationdndudc100% (1)

- FRP Flexure Design MANUAL (Ver.1.2)Document9 pagesFRP Flexure Design MANUAL (Ver.1.2)Jorge MartinezNo ratings yet

- Aashto Load FactorsDocument20 pagesAashto Load FactorsRaihan MomandNo ratings yet

- Comparative Study For The Design of Single Span Bridge Using AASHTO LRFD and Indian Standard MethodDocument5 pagesComparative Study For The Design of Single Span Bridge Using AASHTO LRFD and Indian Standard MethodairpavsetNo ratings yet

- Calculation Report For Monorail and Hatch Cover REV.0Document15 pagesCalculation Report For Monorail and Hatch Cover REV.0Tran Van DaiNo ratings yet

- Load ComboDocument7 pagesLoad ComboAnonymous ya6gBBwHJFNo ratings yet

- The Role of Drag Prediction in Combat Aircraft Design and DevelopmentDocument6 pagesThe Role of Drag Prediction in Combat Aircraft Design and DevelopmentLeiser HartbeckNo ratings yet

- Seismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2Document35 pagesSeismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2jakeer7100% (2)

- Ba981 PDFDocument10 pagesBa981 PDFΔημητρηςΣαρακυρουNo ratings yet

- Model DBR February - 2015 PDFDocument23 pagesModel DBR February - 2015 PDFyogeshNo ratings yet

- Demo UdsDocument15 pagesDemo UdsvesselengineerNo ratings yet

- RC Column Design (ACI318-05)Document5 pagesRC Column Design (ACI318-05)Rizwan MirzaNo ratings yet

- The Direct Analysis Method Made Simple: CSC IncDocument73 pagesThe Direct Analysis Method Made Simple: CSC IncgayalamNo ratings yet

- BS and Russian Design Codes-1Document9 pagesBS and Russian Design Codes-1gautham21brickNo ratings yet

- Wind ProfileDocument5 pagesWind Profilegautham21brickNo ratings yet

- Design of Circular Concrete ColumnsDocument41 pagesDesign of Circular Concrete Columnsscgengineer93% (28)

- Moment Distribution MethodDocument118 pagesMoment Distribution Methodgautham21brick100% (1)

- Connection DesignDocument33 pagesConnection DesignihpeterNo ratings yet

- 05 Loadout of Offshore PlatformDocument70 pages05 Loadout of Offshore Platformardikurniawan100% (8)

- Design Guide To BS 5950Document171 pagesDesign Guide To BS 5950Benigni Butrezi NgwizinemaNo ratings yet

- Footing With Biaxial MomentsDocument8 pagesFooting With Biaxial Momentssuman33100% (1)

- Slender Column Design ProcedureDocument3 pagesSlender Column Design Proceduregautham21brickNo ratings yet

- Blast Resistant BuildingsDocument25 pagesBlast Resistant BuildingsomermmkaNo ratings yet

- Tengs Chart PDFDocument1 pageTengs Chart PDFvaram1No ratings yet

- AD286 Preloaded BoltsDocument1 pageAD286 Preloaded Boltsgautham21brickNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Crane Beam DesignDocument27 pagesCrane Beam Designyeemonzolo100% (6)

- Wave LoadingDocument13 pagesWave Loadinggautham21brickNo ratings yet

- Standard Pile CapsDocument14 pagesStandard Pile Capsgautham21brickNo ratings yet

- AD286 Preloaded BoltsDocument1 pageAD286 Preloaded Boltsgautham21brickNo ratings yet

- Ias Pre 2012 General Studies Paper II Csat Solved Question PaperDocument24 pagesIas Pre 2012 General Studies Paper II Csat Solved Question Papergirisha6666No ratings yet

- Shallow FoundationDocument49 pagesShallow Foundationgautham21brickNo ratings yet

- Shallow FoundationDocument49 pagesShallow Foundationgautham21brickNo ratings yet

- Standard Pile CapsDocument14 pagesStandard Pile Capsgautham21brickNo ratings yet

- BCA - Worked Examples Design of Concrete BuildingDocument258 pagesBCA - Worked Examples Design of Concrete BuildingSaw Is Saw100% (27)

- FEM ExerciseDocument90 pagesFEM ExerciseSimona SavastreNo ratings yet

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 pagesNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNo ratings yet

- Grid FloorsDocument52 pagesGrid FloorsNani Tirumalasetti100% (5)

- Optimization of Bus Body StructureDocument6 pagesOptimization of Bus Body Structureharmeeksingh01No ratings yet

- Strength WorksheetDocument9 pagesStrength WorksheetHabtamu GetaNo ratings yet

- Manual de PreventoresDocument20 pagesManual de PreventoresArturo SuzanNo ratings yet

- RFA-TECH Technical Solutions Brochure 2012 LR PDFDocument32 pagesRFA-TECH Technical Solutions Brochure 2012 LR PDFZerekkuNo ratings yet

- SHAFT GoodSod Deriv07Document11 pagesSHAFT GoodSod Deriv07Leonidas FritzNo ratings yet

- To RsionDocument16 pagesTo Rsionpriodeep chowdhuryNo ratings yet

- U4 - L21 Shape Factors PDFDocument9 pagesU4 - L21 Shape Factors PDFDevesh SharmaNo ratings yet

- Nilsson 1977 Attenuation of Structure-Borne Sound in Superstructures On ShipsDocument21 pagesNilsson 1977 Attenuation of Structure-Borne Sound in Superstructures On ShipsvibroNo ratings yet

- Module4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFDocument69 pagesModule4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFEmily ShumNo ratings yet

- Timber Fitch Beam PDFDocument4 pagesTimber Fitch Beam PDFYHK3001No ratings yet

- BS EN 1295 Part 1Document38 pagesBS EN 1295 Part 1maithra333100% (1)

- Chapter 1.7Document26 pagesChapter 1.7dudescapeNo ratings yet

- Vax Consultants Pvt. LTD.Document4 pagesVax Consultants Pvt. LTD.mohana tNo ratings yet

- 0192 Design Optimization of Eot Crane BridgeDocument9 pages0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- Welding Research Council: BulletinDocument28 pagesWelding Research Council: BulletinRogerio Tropia GranjaNo ratings yet

- Twisting Moments Two Way Slabs Concrete InternationalDocument6 pagesTwisting Moments Two Way Slabs Concrete InternationalamarradoNo ratings yet

- Deflection of BeamDocument61 pagesDeflection of Beameutikol69No ratings yet

- D4761Document10 pagesD4761Nadya ChandraNo ratings yet

- Design and Analysis of Tension MemberDocument29 pagesDesign and Analysis of Tension MemberJhianne Dulpina RoqueNo ratings yet

- Irregular Beam مفيدDocument13 pagesIrregular Beam مفيدMajid AlzubadyNo ratings yet

- CP 116 (1965), Precast Concrete Code of PracticeDocument19 pagesCP 116 (1965), Precast Concrete Code of PracticeHugh Jennings100% (1)

- Mathcad - FP To UB Column Web - R0v0Document12 pagesMathcad - FP To UB Column Web - R0v0danieldumapitNo ratings yet

- Stability Analysis and Design of Steel Building Frame Using AISC 2005 Specification PDFDocument21 pagesStability Analysis and Design of Steel Building Frame Using AISC 2005 Specification PDFvrb126No ratings yet

- Aurora Place Commercial Office Tower - 88 Phillip Street, SydneyDocument27 pagesAurora Place Commercial Office Tower - 88 Phillip Street, SydneyekaapriliawatiNo ratings yet

- Tutorial No 4 TorsionDocument7 pagesTutorial No 4 TorsionwaleedkhalillahmedNo ratings yet

- Dead Lod Brige DesignDocument6 pagesDead Lod Brige DesigntizazuNo ratings yet

- Stapile 3Document29 pagesStapile 3jesusgameboyNo ratings yet