Professional Documents

Culture Documents

Performance of Differential Unit

Uploaded by

Murali KrishnanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance of Differential Unit

Uploaded by

Murali KrishnanCopyright:

Available Formats

PERFORMANCE OF DIFFERENTIAL UNIT

TORSION DIFFERENTIAL PERFORMANCE The Torsion design makes important contributions to vehicle performance,

especially with respect to the concerns of traction management. These contributions may be better understood with respect to familiar vehicle operating conditions which give rise to problems of traction management.

VEHICLE TRAVEL ON STRAIGHT ROADS On smooth, dry, straight road surfaces, with no apparent traction management problem, Torsion differential performance is virtually undetectable from that of an open differential. However, on slippery road surfaces where one of the drive wheels does not have adequate traction to support at least one-half of the applied engine torque to the differential housing, the Torsion differential delivers an increased amount of the applied torque to the drive wheel having better traction. The amount of additional torque which can be delivered to the wheel having better traction is limited only by the bias ratio or the amount of traction available to that wheel.

Of course, it is never possible to deliver more torque to the drive wheels than the torque which combined traction of the drive wheels will support. However, a Torsion differential designed with an appropriate bias ratio assures that, for most vehicle operating conditions, the vehicle can deliver all of the torque which combined traction of the drive wheels will support.

VEHICLE TRAVEL THROUGH TURNS In turning situations, the outside wheels of a vehicle travel over more distance than the inside wheels. Accordingly, the inside and outside drive wheels must rotate at slightly different speeds (i.e., differentiate) to maintain rolling traction with the road. A torque division between drive axles at the bias ratio is a precondition for differentiation under all circumstances of operation. Essentially, in order for one drive wheel to rotate faster than the other, the drive wheel having greater resistance to rotation slows with respect to the differential case and transfers torque to the other wheel contributing to its faster rotation. The Torsion differential resists transfers of torque between drive wheels in proportion to the torque applied to the differential housing, and these results in a larger proportion of the applied torque being delivered to the slower rotating drive wheel. Therefore, bias ratio should be selected to provide the maximum traction advantage that will still allow both drive wheels to deliver significant portions of engine torque in turns. However, even in turning situations, the Torsion differential enhances traction management.

Since torque is already distributed in increased proportion to the inside drive wheel, it is exceedingly unlikely that the outside drive wheel will ever exceed available traction and 'spin up'. Alternatively, should the torque of the inside wheel exceed available traction in a turn, it is equally unlikely for this wheel to 'spin up' since such a 'spin up' would still require a difference in traction between drive wheels which exceeds the bias ratio. Ordinarily, when the inside wheel exceeds available traction, differentiation ceases and torque is divided in more even proportion between drive axles determined by the maximum torque that can be sustained by the inside drive wheel. Thus, in all directions of travel, the Torsion differential will resist 'spin up' of either drive wheel by instantly dividing torque between drive axles in proportions up to the bias ratio to match prevailing traction conditions.

CENTER BOX APPLICATION Although the differential has been mostly described with respect to its use between drive axles, it should be understood that analogous performance can be expected from use of the differential as an operative connection between drive shafts to the front and rear axles. For example, traction management is enhanced in such 'center box' applications by assuring that more of the traction of the front and rear drive wheels is available for use.

CONCLUSION The Torsion differential exhibits a torque biasing characteristic which matches available engine power to changing traction conditions.

In particular, Index gearing provides special design opportunities to match different biasing characteristics with different vehicle applications and conditions of use to best accommodate traction considerations in each instance. Gleason's applied engineering can provide optimal Torsion differential designs to meet a wide variety of traction management requirements.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Exam RIS500 2014h Sol1Document10 pagesExam RIS500 2014h Sol1Murali KrishnanNo ratings yet

- Boiler Efficiency 3hriwhel 'Document27 pagesBoiler Efficiency 3hriwhel 'Murali KrishnanNo ratings yet

- SINTEF Petroleum Research: Co NDDocument2 pagesSINTEF Petroleum Research: Co NDMurali KrishnanNo ratings yet

- Energy Annual10 LRDocument28 pagesEnergy Annual10 LRMurali KrishnanNo ratings yet

- Master of Science in PhysicsDocument8 pagesMaster of Science in PhysicsMurali KrishnanNo ratings yet

- Job-Seeking in Norway (Faktaark Engelsk)Document1 pageJob-Seeking in Norway (Faktaark Engelsk)Murali KrishnanNo ratings yet

- Advanced Model For Drilling and Well OperationsDocument2 pagesAdvanced Model For Drilling and Well OperationsMurali KrishnanNo ratings yet

- Hatred, Lies, and ViolenceDocument360 pagesHatred, Lies, and ViolenceMurali Krishnan100% (1)

- Ormen Lange Hfhewkn IDocument8 pagesOrmen Lange Hfhewkn IMurali KrishnanNo ratings yet

- 01 Basin ModellingDocument2 pages01 Basin ModellingMurali KrishnanNo ratings yet

- BIGCCS Centre 2009 Annual Report SummaryDocument28 pagesBIGCCS Centre 2009 Annual Report SummaryMurali KrishnanNo ratings yet

- Sintef Faktaark 2012 EDocument2 pagesSintef Faktaark 2012 EMurali KrishnanNo ratings yet

- AKSO ITP Tri-Fold Leaflet v5Document2 pagesAKSO ITP Tri-Fold Leaflet v5Murali KrishnanNo ratings yet

- WORKING IN NORWAY'S OIL AND GAS SECTORDocument3 pagesWORKING IN NORWAY'S OIL AND GAS SECTORMurali KrishnanNo ratings yet

- KTH Alumni Network HT11Document1 pageKTH Alumni Network HT11Murali KrishnanNo ratings yet

- 2009 Gudmundson Serden SvergieDocument9 pages2009 Gudmundson Serden SvergieMurali KrishnanNo ratings yet

- Digital Design and Manufacturing - Revised - 2Document13 pagesDigital Design and Manufacturing - Revised - 2ProSISTEM Consulting (Ionut Michiu)No ratings yet

- Brukerundersøkelsen På EngelskDocument43 pagesBrukerundersøkelsen På EngelskMurali KrishnanNo ratings yet

- BG Databook 2013 IndiaDocument1 pageBG Databook 2013 IndiaMurali KrishnanNo ratings yet

- Standard Budget For Consumer ExpendituresDocument4 pagesStandard Budget For Consumer ExpendituresMurali KrishnanNo ratings yet

- Consulting-Ten Commandments of Small Business (Lesson)Document1 pageConsulting-Ten Commandments of Small Business (Lesson)nenu_100No ratings yet

- 2013 Services NorwayDocument4 pages2013 Services NorwayMurali KrishnanNo ratings yet

- PHD Håndbok2013 - WebDocument9 pagesPHD Håndbok2013 - WebMurali KrishnanNo ratings yet

- Checklist For Applications For A Residence Permit As A TraineeDocument1 pageChecklist For Applications For A Residence Permit As A TraineeMurali KrishnanNo ratings yet

- Nice To Know 2012-2013Document16 pagesNice To Know 2012-2013Murali KrishnanNo ratings yet

- Achilles Fast Facts FFNQ Niughgbc BQDocument2 pagesAchilles Fast Facts FFNQ Niughgbc BQMurali KrishnanNo ratings yet

- Annual Report 2008: Gas Technology Centre NTNU - SINTEFDocument9 pagesAnnual Report 2008: Gas Technology Centre NTNU - SINTEFMurali KrishnanNo ratings yet

- Stavanger, Norway: Guide T ODocument2 pagesStavanger, Norway: Guide T OMurali KrishnanNo ratings yet

- Extending Value-Through Field RedevelopmentDocument6 pagesExtending Value-Through Field RedevelopmentMurali KrishnanNo ratings yet

- AVEVA Graduate BrochureDocument6 pagesAVEVA Graduate BrochureMurali KrishnanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manual de Partes Excavadora 324DDocument676 pagesManual de Partes Excavadora 324DOswaldo Andrade100% (2)

- Electric Rickshaw & Battery Rickshaw in DelhiDocument14 pagesElectric Rickshaw & Battery Rickshaw in DelhiNanyaNo ratings yet

- BMW OBD-II Diagnostic Interface PinoutDocument5 pagesBMW OBD-II Diagnostic Interface PinoutAngel Julian HernandezNo ratings yet

- F10 Chassis DynamicsDocument66 pagesF10 Chassis Dynamicsnimametal100% (3)

- Porsche Stradali OBDII 100 EngDocument9 pagesPorsche Stradali OBDII 100 EngJoseph TogoNo ratings yet

- Agt Tractor Broshure English enDocument6 pagesAgt Tractor Broshure English enLuciusNo ratings yet

- Anulador Del NeutralizadorDocument3 pagesAnulador Del NeutralizadormartinaguilarespinoNo ratings yet

- Vehicle registration recordsDocument188 pagesVehicle registration recordsINDU NAIK GUGULOTHNo ratings yet

- BMW Coding Parameters - F10 - For 5 and 6 SeriesDocument7 pagesBMW Coding Parameters - F10 - For 5 and 6 SeriesJB100% (3)

- Indian Automotive IndustryDocument19 pagesIndian Automotive IndustryAbhishek SinghNo ratings yet

- Cushman Shuttle6 82284-G2 0113Document6 pagesCushman Shuttle6 82284-G2 0113Forklift Systems IncorporatedNo ratings yet

- Wiring DiagramsDocument9 pagesWiring DiagramsjulienfranceNo ratings yet

- Chassis: Ram GELCOAT: 963-WK-305Document9 pagesChassis: Ram GELCOAT: 963-WK-305Alan TrejoNo ratings yet

- Freightliner Fld120 PDFDocument19 pagesFreightliner Fld120 PDFCopyMaster2No ratings yet

- Hangcha 10TNDocument2 pagesHangcha 10TNFreddy AndresNo ratings yet

- Mitsubishi Mirage 1994Document40 pagesMitsubishi Mirage 1994Jhordan Torres100% (1)

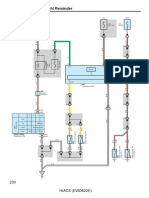

- HIACE Electrical System OverviewDocument2 pagesHIACE Electrical System OverviewDanielNo ratings yet

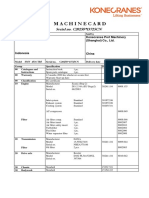

- Machinecard: Serial No. C20258 13725CNDocument3 pagesMachinecard: Serial No. C20258 13725CNAbas AbasariNo ratings yet

- Products Truck VT Hd45 Cargo SpecDocument5 pagesProducts Truck VT Hd45 Cargo SpecAbdulhamid ElgasaierNo ratings yet

- Section Iv: Correct Names of Rim/Wheel Components and Attaching PartsDocument4 pagesSection Iv: Correct Names of Rim/Wheel Components and Attaching PartsanilstarNo ratings yet

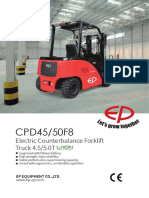

- CPD4550F8 Li Ion en Brochure 1Document4 pagesCPD4550F8 Li Ion en Brochure 1Bersanz Srl100% (1)

- Fuses and Relays Box Diagram Opel - Vauxhall Astra HDocument15 pagesFuses and Relays Box Diagram Opel - Vauxhall Astra HStegeran CiprianNo ratings yet

- VCDS Log Analyzer - Multiple Faults FoundDocument7 pagesVCDS Log Analyzer - Multiple Faults FoundAdrianNo ratings yet

- Production Parts Press Line Coverage ReportDocument34 pagesProduction Parts Press Line Coverage ReportAjayNo ratings yet

- Proposal MAHINDRA FORD PDFDocument8 pagesProposal MAHINDRA FORD PDFPromo OtomotifNo ratings yet

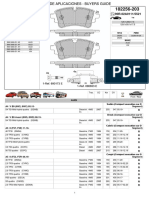

- 8EMEKRD Cacbgb+: O.E.M. MakeDocument6 pages8EMEKRD Cacbgb+: O.E.M. MakeDiego LópezNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- Owner'S Manual: WWW - Vwt4Camper - Info - A Useful Website For Owners and Enthusiasts of VW T4 Transporter CampervansDocument243 pagesOwner'S Manual: WWW - Vwt4Camper - Info - A Useful Website For Owners and Enthusiasts of VW T4 Transporter CampervansrcriganNo ratings yet

- Jan CSD LIST WITH DELHI REGDocument16 pagesJan CSD LIST WITH DELHI REGDeepak SuyalNo ratings yet

- T40180 TeleskopDocument2 pagesT40180 TeleskopAhmed El-AdawyNo ratings yet