Professional Documents

Culture Documents

Wilroy7 16

Uploaded by

rudrakrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wilroy7 16

Uploaded by

rudrakrCopyright:

Available Formats

CONTROLLER SUPPLY / EXHAUST PORT

PNEUMATIC DRIVE CYLINDER

RETURN SPRING PNEUMATIC PISTON / PLUNGER ASSEMBLY FILL / VENT PLUG

HYDRAULIC OIL RESERVOIR

DISCHARGE CHECK VALVE

REMOVABLE BORE CARTRIDGE

HYDRAULIC CHAMBER BARBED FLUID BLEEDER

GYLON TFE DIAPHRAGM

MICROMETER VOLUMETRIC ADJUSTMENT CARTRIDGE

FLUID CHAMBER

INTEGRAL RELIEF VALVE

MOUNTING BASE SUCTION CHECK VALVE

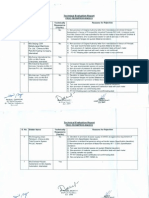

PART MODEL NUMBER

WRA 1 - 11 2M NN SE BB

Model Construction Control Method Base NN: None Selection BB: Base Connections SE: NPT

Note: 2M=1/4" NPT (F) Discharge, 1/4" NPT (M) Suction 5M=1/4" NPT (F) Discharge, 1/2" NPT (M) Suction

WRA 1: 316 SS

NN: None 11: MK XIIA

2N: .250" plunger, no stroke adjuster 5N: .500" plunger, no stroke adjuster 2M: .250" plunger with 316 SS micrometer knob 5M: .500" plunger with 316 SS micrometer knob

Plunger Configuration

Diaphragm NN: None Rupture Detection C5: Rupture Detection Bracket & Gauge SN: Rupture Detection Gauge & Nema 4 switch S7: Rupture Detection Gauge & Nema 7 switch

Williams and Milton Roy have combined technologies to design a pump blending the proven mRoy hydraulic by-pass diaphragm design with the Williams V Series pump. The result is the low volume, high turndown characteristics of a pneumatic drive coupled with the chemical containment and high pressure capabilities of a hydraulically actuated diaphragm. The WILROY is a hydraulically actuated diaphragm pump which delivers chemical containment, low maintenance, overpressurization protection with unsurpassed accuracy and repeatability. We invite you to look at how we can meet your chemical injection needs with proven solutions from Williams Milton Roy.

The Best of Both Worlds

Features 316 SS exposure Integral relief valve Low maintenance robust design Two sizes in one housing Field reconfigurable Compact size for ease of installation Gylon diaphragm for diverse compatibility Centralized design for ease of maintenance & operation Optimum chemical containment Operation

The WILROY Pump comes with either a 1/4"(WILROY 2M) or 1/2" (WILROY 5M) plunger. Operated by controller or solenoid, the pump is manufactured with a totally sealed hydraulic chamber, removable bore cartridge and integral air bleed mechanism. Along with a serviceable diaphragm, the pump's design assures relatively simple maintenance and operation. The WILROYs amplification ratio allows the pump to inject chemical against process fluids much greater than the air/gas supply pressure. The plunger displaces the hydraulic fluid in the intermediate chamber that in turn displaces the diaphragm. The diaphragm displaces the chemical and injects a precise amount of chemical into the process.

Optional Diaphragm Rupture Detection

The WILROY diaphragm liquid ends are, by design, leakproof and durable. In some applications however, added assurance is desired to protect the pump internals from extremely hostile chemicals, or protect the process from potential contamination by hydraulic fluids, or to provide additional containment of the chemicals from being released to the environment.

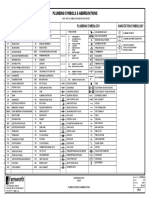

dimensions

All measurements are inches / millimeters unless otherwise noted.

typical installation

FlowTracking Controller Configuration

Standard Pneumatic Controller Configuration

performance specifications

Model

Maximum Volume @500PSI GPH / LPH

Volume Per Stroke CC

Stroke Length INCH

Strokes Per Minute (Range)

Max Discharge Pressure PSIG / BARG

Max Air Consumption @100 @6.9 PSIG BAR SCF SCM Per Day Per Day

Weight lbs/Kg

WILROY 2M WILROY 5M

.54 / 2.04 2.25 / 8.51

.8 3.2

1 1

1-45 1-45

3000 / 207 3000 / 207

2100 2100

59 59

27 / 12.2 27 / 12.2

performance charts

Flow Performance Graph for Wilroy 2M

STROKE ADJUSTER 100% PLUNGER SPEED: 45 SPM

Flow Performance Graph for Wilroy 5M

STROKE ADJUSTER 100% PLUNGER SPEED: 45 SPM

0.60 0.50 FLOW - GPH 0.40 0.30 0.20 0.10 0 0 500 1000 1500 2000 2500 DISCHARGE PRESSURE - PSIG 3000

MA XF L

2.50 2.25

OW

100

MAX

FLOW

2.00 FLOW - GPH

@A IR/ GA

80 70 60 50 40 35 30 20 10 0

1.75

S 35 PS IG

1.50 1.25 1.00 0.75 0.50 0.25 0.00 0 500 1000 1500 2000 2500 DISCHARGE PRESSURE - PSIG 3000

Oscillamatic

PNEUMATIC CONTROLLERS

Featuring our latest addition to the Williams line the MK XIIA controller which combines the corrosion resistance of 316 SS with the diaphragm-style spool design for ease of maintenance. The Williams Oscillamatic controllers are unique and precise pneumatic instruments. These units are designed to operate any pneumatic metering pumps or instrument requiring pilot pulses. The controllers accept a constant supply of air or gas pressure which produces pneumatic output pulses. The output signal is manually adjusted by a control rate valve. The controller, installed on the metering pump, provides the most accurate and reliable pneumatic control available today.

MODELS

SUPPLY RANGE PSI BAR

BODY MATERIAL

STROKE SPM

ELASTOMERS AVAILABLE

SPOOL STYLE

MK XIIA

30-100

2.0-6.9

316 SS

1-45

NEOPRENE

DIAPHRAGM

MK XIIA

AIR/GAS PRESSURE PSIG

@ AIR /G

90

AS = 100 PSIG

pump accessories

WFS6704

Explosion Proof Class I, Division 1&2, Groups A, B, C, D Class II, Division 1&2, Groups E, F, G Fully Field Adjustable

MICRO FLOW SWITCH

For Detecting Increases & Decreases in Flow Rates

Miniature Compact Size Operating Temperature -40 F to +300 F (-40 C to +150 C) Operating Pressure 3000 PSIG (207 bar) Corrosion Resistant 316 Stainless Steel Shock & Vibration Resistant 1/4 NPT Connections

Operates in Any Orientation

DRUM GAUGES Liquid Level/Injection Rate Gauge MODELS C779WS C779WS-V C779WS-SS C779WS-SS-V 30216-CS-V-GPD-S 30216-S6-V-GPD-S MATERIALS Carbon Steel Carbon Steel - Vented Stainless Steel Stainless Steel - Vented Carbon Steel Stainless Steel SENSITIVITY 0.1 PSI 0.689kPa

PCV125 AL Pressure Regulator FLOW RATES 20SCFM .566m3/min MAX. PRESSURE 250 PSI 1724 kPa

AIR OR GAS DRYER-FILTERS Complete with Manual Drain Valve MODELS J-150 FLOW RATES 40SCFM 40SCFM MAX. PRESSURE 150 PSI 500 PSI

LIQUID CHEMICAL FILTERS 316 Stainless Steel MODELS LCF-10-25 LCF-15-25 CONNECTION FILTER ELEMENT 1/4 NPT 25 micron, Std 1/2 NPT 25 micron, Std OPTIONAL FILTER ELEMENT 1, 2, 8 microns or 100 mesh stainless steel screen

J-500

AUTOMATIC DUMP VALVES Used with the Air or Gas Dryer-Filters MODELS ADV-150-A ADV-250-A BOWL Plastic Steel MAX. PRESSURE 150 PSI 250 PSI

PENNSYLVANIA: 201 Ivyland Road Ivyland, PA 18974-0577 TEL: (800) 235-3421 (215) 293-0415 FAX: (215) 293-0498 E-mail: info@williamspumps.com CANADA: 9357 45th Avenue Edmonton, Alberta T6E 5Z7 TEL: (800) 331-2674 (780) 434-9471 FAX: (780) 435-6560 E-mail: edmonton@williamspumps.com SINGAPORE: 18 Bedok Road South Singapore 469276 TEL: (65) 242-9182 FAX: (65) 243-4249 E-mail: singapore@williamspumps.com www.williamspumps.com

2001 Williams Milton Roy. All Rights Reserved. WILROY PRODUCT BROCHURE - 7/01 PD3720

You might also like

- CPL Business Exhibit PDFDocument18 pagesCPL Business Exhibit PDFrudrakrNo ratings yet

- CPL Business Exhibit PDFDocument18 pagesCPL Business Exhibit PDFrudrakrNo ratings yet

- Rfq-Safety Equipment - 20141031 - 141247 PDFDocument13 pagesRfq-Safety Equipment - 20141031 - 141247 PDFrudrakrNo ratings yet

- En1555 1Document18 pagesEn1555 1rudrakrNo ratings yet

- Mses 20141103 110854 PDFDocument2 pagesMses 20141103 110854 PDFrudrakrNo ratings yet

- 5 Steam Star Super PlusDocument26 pages5 Steam Star Super PlusrudrakrNo ratings yet

- Tender 20141114 170200 PDFDocument117 pagesTender 20141114 170200 PDFrudrakrNo ratings yet

- Biogas Cogenerazione - India PDFDocument8 pagesBiogas Cogenerazione - India PDFrudrakrNo ratings yet

- 535 2Document5 pages535 2rudrakrNo ratings yet

- Tender For Cathodic Protection - 20141103 - 110356 PDFDocument42 pagesTender For Cathodic Protection - 20141103 - 110356 PDFrudrakrNo ratings yet

- EN334Document108 pagesEN334rudrakr100% (1)

- En 12186gas Pressure Regulating Stations For Transmission and Distribution - Functional RequirementsDocument26 pagesEn 12186gas Pressure Regulating Stations For Transmission and Distribution - Functional RequirementsMartijn Groot100% (7)

- Let Me Explain Issues Related To LNG in Question and Answer FormDocument23 pagesLet Me Explain Issues Related To LNG in Question and Answer Formashdimri100% (6)

- Piping-Design - Basis Rev 1Document50 pagesPiping-Design - Basis Rev 1Anurag Sinha100% (2)

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- Projects Undertaken: Integrated Operations & Maintenance Solutions For Oil & Gas InstallationsDocument5 pagesProjects Undertaken: Integrated Operations & Maintenance Solutions For Oil & Gas InstallationsrudrakrNo ratings yet

- The Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913Document5 pagesThe Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913rudrakrNo ratings yet

- Contact details for oil & gas suppliersDocument1 pageContact details for oil & gas suppliersrudrakrNo ratings yet

- 2011 Lisowski Czyzycki Transport and StorageDocument9 pages2011 Lisowski Czyzycki Transport and StoragerudrakrNo ratings yet

- Piping Questionnaire - Piping StudyDocument14 pagesPiping Questionnaire - Piping Studyrudrakr0% (1)

- Hydrostatic Test Pressure Formula GuideDocument26 pagesHydrostatic Test Pressure Formula Guiderudrakr0% (1)

- Hazardous Clasification PDFDocument8 pagesHazardous Clasification PDFkip2008No ratings yet

- BIOGASIITAUG13Document42 pagesBIOGASIITAUG13rudrakrNo ratings yet

- BL Procam Metering PumpsDocument7 pagesBL Procam Metering PumpsrudrakrNo ratings yet

- 2011 Lisowski Czyzycki Transport and StorageDocument9 pages2011 Lisowski Czyzycki Transport and StoragerudrakrNo ratings yet

- TE MeterDocument2 pagesTE MeterrudrakrNo ratings yet

- Factory Acceptance Testing Guideline Process - NoRestrictionDocument16 pagesFactory Acceptance Testing Guideline Process - NoRestrictionhamed51060No ratings yet

- The Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913Document5 pagesThe Measurement of Dry Film Thickness of Coatings On Structural Steelwork (Abrasive Blast Cleaned) TP913rudrakrNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- 2011 Lisowski Czyzycki Transport and StorageDocument9 pages2011 Lisowski Czyzycki Transport and StoragerudrakrNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Exhaust Gas Cleaning System Technical DocumentsDocument3 pagesExhaust Gas Cleaning System Technical DocumentsvinodNo ratings yet

- Aspen Hysys Dynamics Modelling of Differential Pressure (DP) Transmitter For Flow ControlDocument3 pagesAspen Hysys Dynamics Modelling of Differential Pressure (DP) Transmitter For Flow ControlMayurShindeNo ratings yet

- FMHM GTU Study Material E-Notes Unit-1 06042020040340PMDocument21 pagesFMHM GTU Study Material E-Notes Unit-1 06042020040340PMIas IfsNo ratings yet

- Types of FlowsDocument24 pagesTypes of FlowsSyed MuneebNo ratings yet

- NACA 0012 Airfoil Analysis PDFDocument11 pagesNACA 0012 Airfoil Analysis PDFMiliani AhmedNo ratings yet

- GIW Pump Curves PDFDocument126 pagesGIW Pump Curves PDFmushava nyoka0% (1)

- A Review of Tesla ValveDocument33 pagesA Review of Tesla ValveMogambo Khushua100% (1)

- Problem 2: First and Second Law of Thermodynamics Thermodynamics Coursechemical Engineering DepartmentDocument17 pagesProblem 2: First and Second Law of Thermodynamics Thermodynamics Coursechemical Engineering DepartmentTita Ari UtamiNo ratings yet

- Expanded Air Valve Program 1Document8 pagesExpanded Air Valve Program 1Capital Diesel SASNo ratings yet

- Process Fired Heaters Training PresentationDocument108 pagesProcess Fired Heaters Training Presentations_m_kumar100% (4)

- Effect of Lean Amine Temperature on Gas SweeteningDocument5 pagesEffect of Lean Amine Temperature on Gas SweeteningYorman Zambrano SilvaNo ratings yet

- Hydrostatic Pressure Lab ReportDocument12 pagesHydrostatic Pressure Lab ReportKan Shao JieNo ratings yet

- R.1.47.01 Atlas Rupture DiscDocument2 pagesR.1.47.01 Atlas Rupture DiscSmita RojatkarNo ratings yet

- CH 5 Cls VIIA ChemistryDocument3 pagesCH 5 Cls VIIA ChemistryTrixxy CarterNo ratings yet

- Cold Room Unit PDFDocument3 pagesCold Room Unit PDFSyed Izad redzaNo ratings yet

- Kel 3Document13 pagesKel 3satrio wekaNo ratings yet

- Sublimation of CaffeineDocument3 pagesSublimation of CaffeineNabil ShaikhNo ratings yet

- 750-94 CB CBLE 400-800 HP 96inchDocument194 pages750-94 CB CBLE 400-800 HP 96inchRenato GilbonioNo ratings yet

- Pressure Gauge and Transmitter GuideDocument35 pagesPressure Gauge and Transmitter GuideTHEOPHILUS ATO FLETCHERNo ratings yet

- pb3-06 510series Broc QX PDFDocument8 pagespb3-06 510series Broc QX PDFJaime LondoñoNo ratings yet

- Plumbing Symbols & AbbreviationsDocument8 pagesPlumbing Symbols & AbbreviationsThel Cruz100% (1)

- Prelab Membrane FiltrationDocument14 pagesPrelab Membrane FiltrationHANISNo ratings yet

- Compressible Flow Acoustic EquationsDocument22 pagesCompressible Flow Acoustic EquationsNitish AryaNo ratings yet

- Fluid Mechanics (4th Year)Document2 pagesFluid Mechanics (4th Year)Jaypee Calamba100% (1)

- Dwg-001 - D Almacenamiento Arcilla CalcinadaDocument1 pageDwg-001 - D Almacenamiento Arcilla CalcinadaCarlos Andrade GómezNo ratings yet

- Aqua Silencer Report 2Document25 pagesAqua Silencer Report 2avikashNo ratings yet

- Crane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Document2 pagesCrane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Septiana DamayantiNo ratings yet

- Fluid Mechanics Lab ReportDocument35 pagesFluid Mechanics Lab ReportBilal Akhundzada0% (1)

- Calculator - Saturated Steam Table by Temperature - TLVDocument2 pagesCalculator - Saturated Steam Table by Temperature - TLVhej hejNo ratings yet