Professional Documents

Culture Documents

Cnews 41 en Web

Uploaded by

rudrakrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cnews 41 en Web

Uploaded by

rudrakrCopyright:

Available Formats

CPL CONCORDIA Group Newsletter

n.

41

Year XI - Issue n.2 June 2013

Postal subscription with special rates for periodicals issued more than twice a year and no more than 70% advertising content. Business Sales Management Department. Modena

CPL CONCORDIA lands in the United States with the services of electrical maintenance and metering for the Empire State Building in New York and 40 other buildings in the Big Apple

NEW HORIZONS FOR ENERGY EFFICIENCY

BIOGAS, IDEAL SOLUTION FOR AGRICULTURE AND ENVIRONMENT Biogengas cogeneration to take all the opportunities of Fifth Energy Act CPL DESIGNS THE SMART CITIES OF THE FUTURE Made in Italy technologies and software for the smart cities

Following a restyling, a fresh, new C-News goes international!

Our house organ has recently celebrated 10 years of publication and, as often happens in these cases, while basking in the glow of satisfaction brought by this accomplishment, we began thinking about what to do next, as pros. During this time of reflection, it was the company that came to our rescue, with the restructuring decided on in 2012. With its strong emphasis on international markets and the development of new services and products, the reorganisation had thrown us an unprecedented challenge. We would have to nurture our newsletter, bringing out a whole new feel in terms of content and communication style. So we launched the English version of C-news (this issue will be available in English in July), with a view to opening up a direct line of communication with the various foreign markets in which we are increasingly active, in Europe, Asia, Africa, and the Americas. But, in order to fully convey CPL Groups new internationalised approach, we have also opted for a new look for our magazine. The new format is based on the magazine design adopted in the English-speaking world (such as the US Letter paper size, of which American weekly Time is a prime example) so that it can be printed using any printer - a necessity given the increasing use of PDF files accessible online. The communication style is innovative and includes the introduction of informative graphics, alongside the photographs, which are designed to intrigue, explain, and further illustrate the solutions and designs offered to customers. But the new magazine was also created to be more accessible and interconnected with new technologies. With a layout that is much more readable Editor-in-Chief Francesco Manicardi when using tablets and smartphones, we have also chosen to include QR codes (two-dimensional barcodes like the one in the bottom left-hand corner of this page), which will allow readers to find out more about the issues explored, through links to our new site (www.cpl.it) and its numerous videos, brochures, and photo galleries. Now, as always, its time to hand over to the C-news readers, whether they are members of the cooperative or customers, business owners or trade unions representatives, Italian companies or foreign multinationals. We look forward to hearing your suggestions, criticisms, and compliments, which you can send to the usual address: redazione@cpl.it. Welcome to C-news!

CPL CONCORDIA is associated with

Partner

Editors GABRIELE BATTISTI SAURO CORSI MARCO DAL DOSSO MARIO GUARNIERI EMANUELE MALAVASI The quarterly newsletter brought to you by CPL CONCORDIA Group Year XI - Issue n. 2 June 2013 Registered with the Court of Modena on 26.05.2003 under n. 1673 Editor-in-chief FRANCESCO MANICARDI E-mail: redazione@cpl.it Design and layout Gabriele Greco - Ufficio Comunicazione CPL CONCORDIA Marco Maini - KINA SNC

Have contributed to this issue: ANDREA BARBIERI MATTEO BARUTTA LUCIANO CAPODICASA ROBERTO CASARI SARA CAVAZZA TERESA DIAZZI FEDERICO DI ROBERTO ALESSANDRO FONTANESI ALESSANDRO GAGGINI MIRKO GALLORINI DIEGO GANZERLA MICHELE GAVIOLI TANJA GAVIOLI VIRNA IODICE ANDREA MANNI OMAR MAZZUCHELLI

ANDREA ODDOLINI UGO PAGANIN DIEGO PEGORARI RICCARDO POLESEL Published by CPL CONCORDIA Soc. Coop. Via A. Grandi, 39 41033 Concordia s/Secchia (MO) Tel. 0535.616.111 Fax 0535.616.300 Website: www.cpl.it Mail: info@cpl.it

CNews online - http://en.cpl.it/cnews

Get free access to C-News contents from the CPL Concordia website by downloading the QR Code Reader!

This periodical is printed on environmentally friendly paper

Leading article

At the age of 114, the Americans are telling us were sexy!

CPL Group is working towards the exportation to the U.S of young managers and new technologies in the groups core energy business activities, through the incorporation of a new company, CPL CONCORDIA USA, due to be based in New York.

by President Obama in his second term. Unsurprisingly - given todays rapidly changing geopolitical situation - the desire not to depend on energy supplies from overseas has led the U.S. administration to look into resuming exploitation of its own oil fields and consider more streamlined power uses. Anyone who has visited the States will know about the unrestrained use of air conditioning and electrical waste there, both of which are encouraged by the low fuel costs. Now the Americans are pushing for measures to encourage businesses that are committed to energy efficiency. CPL could play a major role within this framework, providing appropriate technologies and personnel, backed by over 50 years experience in an industry that spans building energy audits, consumption, and the design and application of plants (new or upgraded) that allow users to save money without reducing comfort. Young managers for export Our strategy is to export know-how through young managers that are homegrown, with love. We want to raise a generation of technicians and engineers with the ability to take the knowledge and skills acquired on the job, in relation to the plants handled by CPL Group, and to export this expertise abroad. It is our aim to produce managers who can not only follow orders, but also spot opportunities implied by customers for the diversification of services, from CHP to public lighting and from management software to energy metering tools. In New York, we have incorporated CPL CONCORDIA USA in a 50/50 partnership with a local business. We already have contracts for 40 buildings, the most important being the Empire State Building, the tallest skyscraper in New York and perhaps the most renowned the world over. But how can we improve the energy efficiency of such a colossal structure? By taking the same approach as we would for a city, albeit one that

Roberto Casari -

rcasari@cpl.it

Chairman, CPL CONCORDIA

The re-discovery of America Once upon a time, not so long ago, CPL CONCORDIA had contacts and partners in the North American continent. On a recent trip back to the United States, CPL Industrials sales director Mr Crivellari and I came across a variety of businesses and organisations and - after the presentation of CPL - something we often heard back was CPL is very sexy. What those meeting us found attractive was our business longevity, our medium-to-long term rationale (including our aversion to the here today, gone tomorrow style, preferring, instead, to build our worth for the members/shareholders and stakeholders over time), as well as our ability to offer up new ideas in all areas of the energy and power market, and our willingness to field-test new technologies and rapidly turn them into offerings for the customer. All these factors in our favour are greatly appreciated in the States. We encountered considerable interest in energy saving and energy efficiency, also due to the agenda laid down

CNews n. 41 - June 2013

extends vertically rather than horizontally. This vertical city experiences heat and electricity losses that can be monitored by our remote monitoring systems. In general, then, these are large complexes that can be upgraded using trigeneration, i.e. combined power, heat, and cooling plants, with our modules which offer 95% efficiency over several years of operation. We have already put these technologies into use without a hitch, for example, at Milans Linate Airport, in the Telecom Italia head offices, and at the Sassuolo Hospital, in Modena, Italy. There are considerable opportunities for improvement everywhere, since CPL can handle energy purchase agreements directly and we can offer our internal maintenance service throughout Italy (guaranteeing within-the-hour intervention following fault reporting thanks to the network of 10 branches located throughout the country), and also as a result of our ongoing pursuit of new technologies. The indispensable nature of R&D Within this perspective, research and development are fundamental activities for us. In our case, we have over 150 young developers working on solutions, i.e. forward-thinking products and services. For example, our head of ICT, Mr Bandini, is based at the CPL plant in Mirandola, Modena, where he is responsible for coordinating information and technology projects (with funding from the European Union and the Italian Ministry of Education, University and Research) oriented towards the creation of smart cities, wherein every aspect of energy use and management is handled with a smart approach. To achieve this, we need energy meters, specific renewable power sources, such as off-grid photovoltaic power systems or geothermal energy, and smart meters for gas and water that help monitor consumption. In addition to the smart cities, we are also studying the large-scale use of LNG, the liquefied natural gas that will enable us to reduce production and management costs. During our trip to the States, we visited Texas to attend the Houston International Festival on LNG, where our view that this is a rapidly developing market was confirmed. Our fleet of specially equipped vehicles means we can transport LNG at -161 and soon we will have the chance to put it to use, alongside our co-generation and tri-generation plants, in city grids that are not linked to gas pipelines, offering considerable savings in areas such as Sardinia. Realism and commitment in the face of economic crisis its time to stop blaming the market The competitive edge offered by our know-how is one of the few factors that can still save us within the global marketplace, in which Italy (and possibly Europe) is destined to play an increasingly marginal role. These harsh economic times will not be shortlived. Italy is currently gripped by a political impasse that is affecting the countrys economy, while the world of finance continues to live off its earnings. The self-referential bureaucracy spawned by the Bassanini reform (which has

granted excessive power to the technocrats) and delays in the payment by the public sector of debts to businesses are determining factors in the gradual decline of our country. I do not think that governments should need specially devised laws for them to make good their debts - it has been a Christian duty for over 2000 years... At this moment, with citizens overburdened by taxes and creditors of the state taking their own lives, we are rightfully embittered and may well be justified in thinking that acts of this kind should be considered by certain others who are failing to uphold their commitments. We need to be aware that our country has to rediscover principles such as honesty and loyalty, applying them to its actions, rather than causing obstructions - as some public officials do (whether for reasons of incompetence or ignorance) every day, when they prevent others from working simply because they have noone to answer to and will receive their monthly pay cheque whatever happens. We cannot pussyfoot around when it comes to the problems that are arising every day. Expert measures are needed to address and solve them and if youre not up to this, then youd better change jobs. I rate a good road sweeper much higher than a bad engineer. Despite all this, we are trying to keep our sights on the future, working with realism and commitment. Damn market! may be the reaction, but the market cant be an excuse. In the same way that a lifeguard who wants to work has to know all the strokes and be able to swim in all conditions, so too must we be able to face the changing market, adapting our organisation according to trends and learning from whatever is going on in the world. In the same way that, after all its misadventures, the ugly duckling grew into a swan, in our 114 years of life, CPL has never been stopped, neither by the world wars, or the economic and oil crises, nor by the earthquake of 2012. On the contrary, it came out stronger on each occasion. So with the future firmly in our minds, we forge ahead, empowered by the strength of our 800 members and the combined abilities of the 1,700 employees (with an average age of 38) working with us, in Italy and abroad. We will continue to look for new pathways, both to increase the number of employees (as part of our corporate mission, alongside the pursuit of profit and innovation) and to contribute to sustainable development, which - for us - means a combination of conventional and renewable energy sources, managed with efficiency and savings in mind. Over the next 10 years, we have set ourselves some challenging goals, with a view to ensuring foreign contracts reach 30% of the CPL Group turnover. In 2013, we expect to exceed 470 million, but I am hoping the figure will be nearer the 500 million mark. This year, the net equity of CPL Group (reported at 98 million in 2007) is set to reach over 164 million - a solid foundation on which to continue to build for the future.

CNews n. 41 June 2013

In this issue

BUSINESS AREA

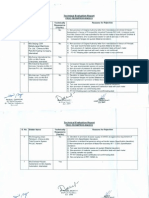

06 08 10 12 14 16 19 20 22 24 25 26 28 30 32 From the Empire State Building, the view is infinite From smart campuses to smart cities - an intelligent leap forwards! Why SMART? Gas meters of the future? CPL is researching them in Reggio Emilia Biogengas - a biogas system manufacturer shares its experience Energy recovery for pharmaceuticals company Angelini Tuscany - two flood-proof cogeneration units! In Triveneto, Ferservizi facilities run on CPL power Efficient energy at the Pontifical Lateran University Four centuries of history and students from 105 nations Udine discovers the comfort offered by district heating After-sales service makes all the difference in the market The new Biogas Maintenance & Cogeneration After-Sales Department JOKA CPL Polska steams ahead in the Polish cogeneration industry Managing documents and processes within a 34

secure, integrated system When Italian-designed technology is applied to Tunisian gas wells...

MARKETING

36 Romes Auditorium - taken as model by masters degree course at La Sapienza University Recognition for global service at public authority event Forum PA 2013 The future of gas? Liquefied and transportable New smart meters make their debut Solarexpo 2013 goes exclusive

38 39 40 41

BUSINESS NEWS

42 43 44 45 Training in Concordia put into practice in Romania In search of young engineers BEST award acknowledges financial statements New spotlights on sport after the Emilia earthquake

CSR

46 CSR at CPL CONCORDIA now SA8000certified

From the Empire State Building, the view is infinite

CPL CONCORDIA USA puts down roots in Manhattan offices. The new member of the CPL CONCORDIA group holds maintenance contracts for 40 tall buildings, including the world-famous Empire State Building.

New York City, view of Manhattan Empire State Building, Wall of Fame: (from the left) Head of Foreign Sales, CPL Industrial, Michele Crivellari, Chairman of CPL CONCORDIA Roberto Casari, General Manager of ESB, Joseph Bellina.

Francesco Manicardi -

fmanicardi@cpl.it

Head of Press Office

PL CONCORDIA Group is joining the U.S. market with the merger of two major acquisitions, to form the new Manhattan-based company, CPL CONCORDIA USA. The new business, which is 50% owned by the U.S. partner G Three Partners, currently employs 21 staff members and already holds management contracts with 40 large buildings for system engineering and maintenance activities, in addition to metering, engineering and technical services, monitoring, and fuel billing. One of these great buildings served by CPL CONCORDIA USA is the Empire State Building, the most renowned skyscrapers in New York - and perhaps the world. Forecasts for the U.S. market indicate a turnover of over $50 million over the next five years. CPL CONCORDIA USA is now sole shareholder of the New York Electric Maintenance & Data Corp. - an enterprise, formerly owned by G Three Partners, that specialises in system engineering and maintenance - and fully controls CPL Energy Management Service Group Inc., which was created following the acquisition of assets from Archangel Energy Group Inc. CPL EMS Group will handle metering, engineering and technical services, monitoring, and fuel billing. Our short-to-medium-term development in foreign markets includes North and Central America, Eastern Europe, the Gulf area and some African nations, said Michele Crivellari, Managing Director, CPL Industrial. As part of these internationalisation activities, finding qualified industrial partners is fundamental. We need businesses who recognise the high level of technology and expertise that CPL offers and which can be combined with their activities to win over new market shares together. In the United States, market demand for alternative energy and the services associated therewith is growing exponentially, stated Dario Gristina, President & CEO of CPL CONCORDIA USA Inc. Our decades of experience in this U.S. market sector, pooled with the extensive know-how offered by CPL CONCORDIA Group, provide exciting opportunities for a rapid

launch within a market estimated to be worth hundreds of billions of dollars. We are very pleased with the new company, with CPL CONCORDIA and its workers, and we are confident that we can achieve outstanding results both in the short term and in the years to come. These operations are just some of the tools that CPL CONCORDIA Group will be using as part of its development strategy within Europe and other markets. The group has recently approved the Industrial Plan for 2013 to 2015. Our goal for the next three years is to continue the growth we have experienced over the last five years, maintaining a proper balance between income and assets/liabilities - explains Roberto Casari, Chairman of CPL CONCORDIA Group - Penetration of foreign markets - whether those in which CPL is already operating or in other nations worldwide - is one of the main goals the Group

has set itself for the next three years. According to the plans, in 2015, the company is expected to turn over 80 million outside the conventional domestic market.

CNews n. 41 - June 2013

From smart campuses to smart cities - an intelligent leap forwards!

ACCUS, RIGERS, SUPERAIN: the first CPL CONCORDIA research projects, backed by European Union and national funding.

Emanuele Malavasi Gabriele Flandoli emalavasi@cpl.it gflandoli@cpl.it Project manager, ICT sector International standards and projects, ICT sector

The beginning o clock in the afternoon, on 5th July 2012. Work had just been completed on the Smart Campus (set up at the CPL head office in Mirandola to allow operations to resume following the earthquakes that had hit the area just over a month earlier) when engineer Pietro Andreotti, chairman of ICIE (Italian acronym for this cooperative institute for innovation) and architect Valerio Nannini met in the conference room in Container 18. Armed with a proposal for Mario Guarnieri (deputy chairman), Giuseppe Bandini (head of ICT), and myself, they suggested CPL join them in a research project on smart cities. The project, titled ACCUS, would be funded by the European Parliaments Seventh Framework Programme, whose ambitious goal is to make Europe world leader in research and innovation, part of the reasoning being to encourage economic growth and better social and environmental wellbeing. To be honest, CPL had already received various invitations to actively participate in this type of project in the past but - as almost happened again this time - the idea had always been rejected. According to our calculations, the effort it would take to organise the project (without being certain of success), as well as managing the relations with the other Italian and European partners (including meetings and, obviously, drafting the paperwork in English) and the various bureaucratic

and reporting aspects, plus the task of sharing the results with the other partners, would all add up to far more than the financial backing we could count on (approximately 50% more). This time, though, we tried to look at it from a different angle. All those costly activities could be seen as opportunities to try out a new work approach. It would also be a chance to become familiar with and get ourselves known by important actors, such as universities and European businesses. Last but not least, it would mean investing resources with others and attempting to establish an enterprise network. The three projects underway: ACCUS (Adaptive Cooperative Control in Urban Subsystems). Approved by the European Union on 5th April 2013, ACCUS envisages the construction of an integrated platform for the various urban subsystems (transport, energy, public lighting) and the development of an architecture for the adaptive, co-operative control of these subsystems in order to optimise their performance. The testing will be conducted in Poland. The initial project also included trials in Cagliari and was therefore far more ambitious for CPL too, but a reduction in funds from the MIUR (Italian ministry of education, university and research) meant that this part was no longer feasible. Our company has planned to invest 165,000 and the main partners in the project are ICIE, Inabensa (Spain), HI-Iberia (Spain), AccionaInfrastructures (Spain) Tecnalia (Spain), Gdansk University of Technology (Poland), and Joef Stefan Institute (Slovenia). RIGERS: RIGEneration of the city - Smart buildings and grids.

The city of Modena - one of the local authorities involved in the RIGERS project testing.

In response to a nationwide call for tender dated 5th July 2012, concerning design ideas for smart cities and communities and social innovation, our group passed the first selection phase with flying colours (scoring 91/100). The aim of the working design, submitted on 30th April 2013, was to produce a model of a smart city based on existing buildings and situations, developing methodologies, protocols, and procedures for data collection and diagnostics/ auditing purposes, as well as to draw up a plan of action, involving a series of innovative technological solutions, to enhance energy, environmental, and seismic facilities within an integrated approach. This project is particular significant for CPL as it envisages the design and testing of new devices such as smart meters for household gas, a multi-service data acquisition unit, and an integrated smart public lighting and urban security system. The testing will be performed in a number of pilot districts throughout Italy, working in conjunction with local authorities in Modena, Bologna, Ravenna, Forl, Cesena, Latina, and the Unione dei Comuni Modenesi dellArea Nord (a union of local councils from the northern area of the province of Modena). CPL will be investing 2.5 million over 30 months and will be supported in the project by the following partners: ICIE, SACMI, CMC, SPES, SATA, ICT-CNR, UNIBO, (DEI, DICAM, DA). SUPERAIN: Sustainable Urban Planning to improve rainwater management and use. The project, which has been submitted and is currently under review by the European Commission (Seventh Framework Programme), envisages the development and testing of an ICT tool (SDSS - Spatial Decision Support System) to help in the planning of rainwater management infrastructures within a smart urban environment and the real-time management thereof so as to provide multiple services, such as storage of water for nonpotable uses and management of sewerage and water drainage networks to prevent flooding events and allow pollution monitoring.

The testing - which is always conducted on a transnational scale will take place in Germany (Berlin), Spain, and Italy (in certain towns in the north Modena area). CPL plans to invest 161,000 and will be supported by the following main partners: GESP (Italy), Ambiente Italia (Italy), Politecnico di Milano (Italy), Fraunhofer IGD (Germany), and Aguas de Terrassa (Spain). But we wont be stopping there. Right now, Europe and Italy are bubbling with enthusiasm for and interest in projects of this kind, which explore the possibilities of smart cities, in search of solutions aimed at curbing energy use and improving efficiency. Aware of this, CPL CONCORDIA has already obtained ESCO certification (Energy Service Company) and can now offer energy management services and projects, all the while researching, designing, and implementing new equipment, software tools, and processes. Only in this way can we provide innovative solutions and services that will enable us to overcome national barriers and tackle todays increasingly complex and competitive world market.

FOCUS ON

Why SMART?

Every day now, we hear talk of smart buildings, smart grids, smart cities, but what exactly do these expressions mean?

very day now, we hear talk of smart buildings, smart grids, smart cities, but what exactly do these expressions mean? A building, grid, or city is called smart when certain aspects thereof are managed in an intelligent manner and certain standards are met. 1. Energy. All energy carriers (gas, electricity, water) are used to the fullest and in synergy - i.e. in an optimal manner in terms of costs and atmospheric emissions; maximum use is made of renewable sources (photovoltaic, solar thermal, wind, geothermal, etc.); systems are centralised, remote-monitored, and energy-optimised; the aim is to prevent wastage and losses by making everyone pay for what they actually use. 2. Environment. Unsorted waste is pared down to a minimum, pollution is monitored and every possible effort is made to counter it, misuse of drinking water is reduced, and rainwater is utilised instead wherever possible. 3. Services provided to tenants/ residents/users. Efficiency levels of communal services are

always maintained and ancillary energy services are provided, such as chargers for cars, natural gas fuel pumps for cars, centralised laundry/ironing services, communal gyms, centralised/communal demineralised drinking water supplies (carbonated or still). 4. Transport/Mobility. A sufficient number of parking spaces are provided for cars, motorcycles, and bikes, with parking availability information supplied to the inhabitants; the public transport network is well connected and integrated with the traffic-light network; there are charging points (electricity, natural gas, etc..) available for cars and motorbikes that are either electricpowered or use low-polluting fuels. 5. Comfort and health. The temperatures and moisture levels in public and private rooms meet the standards laid down by the ministry of health; in public and private rooms, the air is monitored and meets hygiene standards, as is sanitary water; the buildings are low-energy and have appropriate safety measures for emergencies, and there are local and remote-monitored security systems/devices for the protection of people and environments (against thefts,

burglaries, robberies, etc.). 6. Mass telecommunications. Telephone, television, Internet, etc. allow interactivity and can be found in all rooms/spaces (public and private). 7. Notices/Information aimed at inhabitants/users/visitors. Detailed information is provided regarding costs (energy, maintenance, ancillary services, etc..) and facilities; incentives are provided to encourage positive use of energy, environmental, security, and safety facilities etc; mobility information is provided continuously for public and private means of transport. Obviously, in order to be smart (and therefore to be able to do all the planning and make the right decisions), first and foremost... you have to know the facts! The diagram on the next page, taken from the RIGERS project, summarises the analyses required at building, grid, or city level, in order to gather all the data that will be entered and managed using interoperable platform technology. This will allow us to obtain a full picture of the current situation, and subsequently plan and design - via various simulations - the optimum solution.

0%

COOPERATIVE INTEROPERABLE PLATFORM

BUILDINGS

25%

Tertiary Business Residential Public buildings

Monitoring smart buildings Energy, environmental, seismic auditing Technological solution packages with energy performance analysis LCCA Cost/benefit analysis Building chips

50%

GRIDS

Water supply grid Electricity grid District heating Public lighting

Grid monitoring Smart metering Optimisation and rationalisation of grids and consumption Data transmission Maximisation of RES LCCA of water supply grids

75%

WebGIS mapping of real conditions and simulations

Energy consumption CO2 emissions LCCA of building envelope Energy grid Water supply grid

REPRESENTATIONS

Urban comfort Seismic vulnerability Seismic risk Pain points/Potential

100%

PLANNING

Building- and urban-scale planning scenarios

New criteria for urban planning Urban-scale tender procedures Interventions to reduce consumption/emissions

Incentive schemes and planning Building monitoring/audits Use of RES Smart grids and micro-smart grids

CNews n. 41 - June 2013

Gas meters of the future? CPL is researching them in Reggio Emilia

Andrea Barbieri anbarbieri@cpl.it

A natural gas sector project is underway to design an electronic household meter offering accurate consumption measurement for billing customers. With the introduction of completely new data transmission systems, combined electricity, water, and gas readings will be possible using a single telecommunications infrastructure.

Natural gas sector

008 heralded the beginning of a positive revolution in the world of gas. In the space of a few years, a series of resolutions and regulations will be bringing new gas meters into our homes, as has already happened in the electricity market. What were talking about are electronic meters that can transmit fuel consumption data to a control centre and also feature an automatic shutoff valve. With these new devices, users will no longer have to read their own meters or allow meter readers into their homes or businesses, while bills will be based on actual usage, instead of estimates, calculated according to TOD (timeof-day) rates. Providers will also be able to cut off supplies in the event of payment arrears. However, in order to meet these targets, we need to look more closely at how data can be sent to the control centres. The transmission process will involve dual radio technology, i.e. a) an ad hoc radio technology for data transmission from each household meter to a data collection device (concentrator) and b) a standard cellular technology for data transmission from the concentrator to the control centre. CPL CONCORDIA, which already has considerable expertise in the latter technology, is working on the design and testing of the former, in association with the Enzo Ferrari Department of Engineering at the University of Modena, as well as the multiutility company IREN, based in Reggio Emilia, and Sedicom, in Rome (www.sedicomtech.it), which will be providing a specific

software package for designing data transmission networks. This is an extremely intricate project, for which there is no technical literature and no experience of this type of networks to work from. We need to examine how the radio signal propagates under certain conditions and how it reaches all the meters. The concentrator will first collect the readings from thousands of meters in its vicinity, via the radio frequency section of the connection, and then transmit the data to the control centre. This first section of the system - between the concentrator and the meters - is the most critical point, which is why we are currently running signal propagation tests in the city of Reggio Emilia, in association with IREN. This propagation testing will provide information as to the ranges that can be covered within an urban environment, depending on population density in the various areas, as well as building heights and sizes. One key element of the system is the meter antenna, which will have to be able to transmit the signal at very low power and in very complex environments in telecommunications terms (e.g., through alcoves or from inside buildings and, in some cases, even underground). Following on from this, a series of pilot projects will be launched with the gas grid in use, which will involve thousands of meters being read. The telecommunication infrastructure planned could also be used to read meters employed by other utility providers (e.g. water, electricity, and district heating) through an additional radio link between two neighbouring meters, thereby offering multiservice features, as hoped for by the AEEG, Italys electricity and gas authority.

The CPL staff (all born and bred within the natural gas sector) expect to complete the propagation test and start the first pilot tests during 2013, and then move on to trials to establish whether the Italian and European markets are ready for the system developed.

TRIALLING

13

Biogengas, a biogas system manufacturer shares its experience

From Cremonesi S.p.As building expertise in biomass cogeneration plants to the reliability of the engines and assistance offered by CPL CONCORDIA, theres a new approach in the industry to the earning opportunities offered by the Fifth Energy Act.

The introduction of smaller systems (75/99/299/599 kW) has brought about a significant change in demand. The end customers are the livestock breeders and rather than viewing investments in biogas as an alternative to their business, they look on them as an opportunity to keep on working better.

PLANTS and SYSTEMS

The biogas cogeneration plant at the Locatelli farm, in Soresina (province of Cremona) An example of a containerised CHP unit located between the digesters and farm facilities.

Cesare Cremonesi -

cesare.cremonesi@biogengas.it

Chairman of Biogengas

iogengas S.r.l., which was established in December 2012, is a new business venture that comes from a successful partnership between CPL CONCORDIA and Brevetti Francesco Cremonesi S.p.A., a long-running company and leading name in the creation of modern breeding farms for dairy cows, whose mission envisages the sale of complete biogas plants fuelled by livestock waste. The Fifth Energy Act has revolutionised returns on investments in renewable energy as a whole, and for biogas plants, the new tariff plan has drastically shifted the axis of returns away from power plants fuelled with noble biomass (maize silage) towards those fuelled mainly with livestock waste and biomass derived from agribusiness processes (including whey, husks, and waste from fruit, vegetables, and slaughtering etc.). This new way of thinking is based on the belief that it promotes more worthy ends, i.e. offering an additional source of income for farmers while bringing benefits to the environment. This is because, as well as lowering CO2 emissions, using digestate as an organic fertiliser for forage crops also means a decrease in the use of chemical fertilisers and a drastic reduction in the unpleasant odours caused by conventional organic fertilisation. This new approach has led to a significant change in demand, moving it towards small and medium-sized systems and plants (75/99/299/599 kW), which are being bought by livestock breeders. As mentioned earlier, these customers are no longer considering investments in biogas as an alternative to their core business, but as a means of continuation and improvement. Initial significant contacts with major foreign markets (Cuba, Mexico, Argentina) have further confirmed our

belief that the approach is meeting with success abroad, and not just in Italy. Biogengas is confident that it can rely on the knowhow offered by Cremonesi S.p.A., which has grown independently over the years and can produce complete, high-efficiency biogas plants, fuelled solely by livestock waste. Not only that, Cremonesi can guarantee a loyal customer base consisting of the hundreds of Italian breeders it has won over in its more than fifty years of business. With its supply of CHP units to Biogengas, CPL CONCORDIA is doing its part by providing the construction know-how and ensuring an extensive, efficient maintenance service through its specialised support network. To date,

Biogengas has secured contracts for the construction of three plants (two 99 kW plants and one 500 kW version) and is at an advanced stage in a substantial number of negotiations in Italy and abroad, which means we can be more than optimistic about reaching the target of seven/ten plants by the end of 2013.

15

CNews n. 41 - June 2013

Energy recovery for pharmaceuticals company Angelini

CPL CONCORDIA oversees creation of new cogeneration plant serving Angelini chemical plant in Ancona - analysis of existing systems and needs leads to tailor-made design proposal for processing and air handling.

Andrea Manni amanni@cpl.it afontanesi@cpl.it Project Manager, Fano area Alessandro Fontanesi Engineering sector

he chemical industry is another industry on the lookout for new technology to improve energy efficiency in production facilities and to curb emissions. To achieve this, ANGELINI hired Italian multi-utility company CPL CONCORDIA, with 30 years of experience in cogeneration systems to its name, as well as 450 plants up and running throughout Italy, entrusting it with the task of designing and building a new CHP plant for the ANGELINI facilities in Ancona. First of all, a study was carried out on the ANGELINI facilities to establish the type of manufacturing systems located there and the type of existing users. At the same time, the plants electricity, heating, and cooling needs were analysed. This enabled us to identify and develop a proposal for the client including the most economically advantageous size and most convenient location for the cogeneration plant. It also envisaged the ways of recovering the energy supplied by the plant within the manufacturing facility in order to offer the best guarantees to allow extension of the CHP operation to the highest possible number of hours over the year. Throughout the year, the facility uses continuous thermal energy (supplied by steam generators) for its industrial processes and partly also (in the form of hot water) for heating and air conditioning in certain areas, during the summer and winter months.

The amount of thermal energy required for processing and climate control and the constant, substantial electricity requirements, in addition to the continuous use thereof, have made it cost effective to introduce a CHP plant which can run at maximum load for a good number of hours over the year. The location chosen for the cogeneration plant corresponds, in terms of centre of gravity, with the area dedicated to the engineering systems serving the facility. The work carried out for the construction of the new CHP plant is outlined below: building works; installation of the Jenbacher 612 natural-gas-fuelled internal combustion engine featuring: a total input power of 4,586 kWt, 2.019 kWe of usable medium-voltage electrical power generated, 1,268 kWt of thermal power generated in the form of hot water (90 C), and 654 kWt (1,000 kg/h) in the form of saturated steam (8 bar). construction of a freestanding outdoor enclosure consisting of metal structural work which is suitably soundproofed to allow the gradual reduction of noise emissions towards the exterior

The Jenbacher 612 natural-gaspowered internal combustion engine, featuring: a total input power of 4,586 kWt, 2,019 kWe of usable medium-voltage electrical power generated, 1,268 kWt of thermal power generated in the form of hot water (90 C), and 654 kWt (1,000 kg/h) in the form of saturated steam (8 bar).

THE ENGINE

17

CNews n. 41 - June 2013

and is divided into separate areas to house, respectively, the cogeneration unit, the auxiliary mechanical systems for fluid pumping, and the ancillary electrical systems; installation of electrical equipment (panels) and mechanical equipment inside the enclosure; on-roof installation of equipment including the steam generator and the economiser for heat recovery from the flue gases, water/ air electrical dissipation devices, silencing systems and systems for the abatement of pollutant emissions caused by combustion gases in the atmosphere; ground-level installation of a 15 m high flue, complete with steel trellis and overhead work station for emission sampling; installation of plate heat exchangers (water/water), in the substations of the halls, to house the user devices that have been identified as suitable for recovering the thermal power originating from the CHP in the form of hot water (previously powered by a dedicated steam heat exchanger); pipelines laid to carry hot water from the CHP plant to the existing heating substations identified as suitable for the recovery of medium-temperature heat; pipelines laid to carry the condensate and steam generated by the recovery of thermal power from the CHP plant flue gases to the existing main steam storage tank; installation of a natural gas supply network connecting the existing main manifold at the facility to the CHP plant; electrical lines laid for the electrical connection between the CHP plant and the facilitys existing electrical system and booster transformer installed to allow use of the electricity generated; control and supervision system. Special note should be made of the atmospheric emissions of the plant built, which fall within the strict values prescribed by regional law. We were able to reach the NOx limit through the application of carburisation control to an engine already designed to reach full load with minimum emission values. The limit value for carbon monoxide (CO) was reached by adopting a catalytic conversion system for special applications which currently ensures emission values within the required limits.

Maintenance staff working on cogeneration units A stage in the construction of the 15 m high flue

Tuscany - two flood-proof cogeneration units!

Two Tuscan farms - one called Valdichiana, located in Sinalunga, Siena, the other Colline Senesi, located in Cortona, Arezzo - where two biogas CHP plants are running at full capacity. All thanks to the CPL maintenance service and its skill in restoring plant operation even following an exceptional weather event.

Mirko Gallorini mgallorini@cpl.it

Project Manager, Tuscany area

t the end of 2012, CPL CONCORDIA completed work on the construction of two 999 kW biogas cogeneration plants and their connection to the ENEL grid, the first commissioned by the Val di Chiana farm, in Sinalunga (Siena), and the second by the Colline Senesi farm situated in Cortona (Arezzo). Both plants are powered by biogas produced from the anaerobic digestion of waste from livestock and crop farming, which means less greenhouse gases and also the possibility of recovering the thermal energy produced by the engine as it runs. Once all the necessary permits and approvals had been obtained, the jobs went smoothly and all the deadlines were met, allowing commissioning in time to obtain the allinclusive feed-in tariff for 2012. The tariff, which will remain valid for 15 years, will ensure the farms investments are repaid as scheduled in the approved business plan. The plants are currently operating at full capacity under the watchful eye of the CPL CONCORDIA monitoring systems. Our maintenance service, with its nationwide coverage, offers support and maintenance operations performed by highly specialised staff, to ensure the number of hours of operation required to meet electricity production requirements are always guaranteed. Special credit goes to the maintenance engineers, whose professionalism during a particularly devastating climatic event

demonstrated their worth and that of CPL. On 12th November 2012, continuous, heavy rain caused rivers and streams to overflow, leading to the flooding of several hectares of the Val di Chiana areas in Arezzo and Siena. As a result, the stretch of the A1 motorway running from the Val di Chiana junction to the Chiusi junction was closed off for several hours. At that time, the plant on the Valdichiana farm was literally awash and our engineers working on the site were forced to leave the area,

helped out by local fire brigade tractors. Fortunately, the waters failed to reach the area where the engine was located, stopping - instead - just a coupled of metres away. This meant that when the waters receded a few hours later, the same engineers were quickly able to get the plant back up and running and the preset maximum power threshold was quickly restored.

19

In Triveneto, Ferservizi facilities run on CPL power

Thanks to its extensive coverage, CPL CONCORDIA guarantees maintenance and emergency services for the properties owned by the Italian state railways, from the Ferrotel railway workers lodgings in the town of Brenner to the case Cantoniere houses, and other buildings in the cities of Trieste, Venice and Verona.

Palazzo Tiepolo in Mestre, known by railway workers as il Pirellino The main railway building in Trieste, facade and interior

Matteo Barutta -

mbarutta@cpl.it

Project Manager, North East area

ince July 2011, the maintenance engineers from the CPL North East area have been working under a global service contract for a prestigious client, Ferservizi S.p.A. This service company is 100% owned by the FSI, Italys state railway and largest company, and has been assigned all the parent companys non-core activities, i.e. all the operations not directly linked to rail transport management. Ferservizis main corporate purpose is the management of the properties owned by the FSI group, for which it called a nationwide tender. Working as part of the CNS Consortium, CPL CONCORDIA was awarded the Phase 3 activities, which include the management and maintenance of the FSI Group properties located in Veneto, Trentino Alto Adige, and Friuli Venezia Giulia (interestingly, the area corresponds more or less with the boundaries of the CPL North East area). The most important feature of the properties managed by Ferservizi is their location, with the various facilities spread throughout the area concerned. These facilities include the Ferrotel accommodation building located in the Italian border area (Brenner and Tarvisio), hundreds of case Cantoniere (where the railway points controllers used to live before the junctions were all automated) and the office buildings in Trieste, Venice, and Verona. Because of its widespread coverage of Triveneto, CPL CONCORDIA can guarantee a prompt response to customers needs, whether linked to routine maintenance or an emergency. The main ordinary activities handled by our operating staff concern the management and maintenance of heating and air conditioning systems, as well as water and sanitation plants, electrical systems, special facilities, and building maintenance. These activities are carried out directly by Ferservizi staff or by other companies in the group, who are able to work directly on the buildings without having to clear the area of people. Trenitalia

is the main Italian company responsible for the management of passengers and freight railway transport, Italferr is the FSI Groups engineering company, which operates on the Italian and international market in the field of rail transport engineering, and RFI guarantees rail traffic safety across the network and develops system technology and materials. CPL holds maintenance contracts covering approximately 30,000 sqm of property. The most significant buildings are Palazzo Tiepolo (known by the locals as il Pirellino because of a vague resemblance to the Pirelli building in Milan), the RFI main building in Mestre, (which handles the majority of Venices rail traffic) and the main building in Trieste (a historical palazzo subject to heritage conservation regulations). Among the emergency activities, the most common operations involve ensuring properties that are no longer in use meet certain safety standards, such as the case Cantoniere houses located along the railways and the former repair centres, which often create dangerous situations for the local community or are at risk of squatting. In 2008 Ferservizi also embarked on a quality certification process for its initial operational processes and over the past year it has extended the certification to other services, including maintenance, with aspects linked to workers health and safety. Naturally, the latter process included CPL CONCORDIA, which once again proved itself to a dependable partner, not least because it holds OHSAS 18001 certification.

21

CNews n. 41 - June 2013

Efficient energy at the Pontifical Lateran University

Five-year management contract underway with prestigious university that houses exceptional items of cultural heritage and welcomes over 4,000 students from around the world

Luciano Capodicasa lcapodicasa@cpl.it Project Manager, Rome area

n my first job (in an air conditioning company), in response to customers requests, we would often quip We can do the impossible ... but miracles may take some time!. Today, ten years on, the economic - but most of all political - climate in Italy is permeated with an inability, not only to govern, but also to set objectives (it is amazing that, for a seafaring nation like the Italians, the problem is not navigating by eye - theyve been doing that for years now - its deciding the destination!). Given this situation then, it is remarkable how CPLs expertise is recognised and sought after by prestigious clients abroad, for example in the Vatican City. At the beginning of 2013, after an initial contact with the Pontifical Lateran University, we formulated an offer for the maintenance and management of all the summer and winter air handling facilities for the university buildings. Very quickly, the financial proposal was negotiated and on 15th March the contract was entered into, signed by the chairman of CPL CONCORDIA, Roberto Casari, and the rector of the university, Bishop Enrico dal Covolo. For the coming five years, CPL will be responsible for ensuring the comfort and efficiency of the various plants, systems, and facilities of a prestigious complex which houses a recently renovated library (Biblioteca Pio IX), along with the main lecture hall (Aula Magna Benedict XVI), both of which were opened in their renovated forms by Pope Benedict XVI in 2006 and awarded the prestigious national award for new builds, the IN/ARCH-ANCE, in 2009. The climate control systems

are mixed, comprising the air handling units for the primary air and a series of water-containing fan coil units that are heated in winter by two pressurised boilers and cooled in summer by two cooling units with relative cooling towers. Locally, meanwhile, there are indoor direct expansion units (of the recessed split type) connected to an impressive 13 VRV units. But the jewel in the crown of these plants is a YORK cooling unit equipped with a centrifugal compressor with magnetic levitation in which the standard bearings have been replaced with permanent magnets that eliminate friction and therefore the need for lubricating oils, thereby significantly reducing consumption and noise levels.

A set of YORK cooling units that reduce consumption and noise levels

Most of these plants are supervised by a Sauter system. The routine supervisory activities are performed by a technician, who is accompanied by a second staff member to assist in all the activities that can be tricky for safety reasons (since much of the equipment is located at heights of five or six metres). We are at the start of a new partnership and it is our duty to get CPL known, so that people are aware of how we go about tackling problems, of our commitment and dedication to our customers, and our constant pursuit of innovative solutions that optimise use of primary energy sources. We hope that this partnership will demonstrate our merits and earn us further business opportunities in this new foreign country - and maybe even a place in heaven!

23

FOCUS ON

Four centuries of history and students from 105 nations

he Pontifical Lateran University has four departments (Theology, Philosophy, Canon Law, and Law) and two institutes: The Institutum Utriusque Iuris and the Redemptor Hominis Pastoral Institute. The university is an international level institution, as both the 200 teachers and over 3,000 students on site come from over 100 countries worldwide. In 1773, Pope Clement XIV entrusted the departments of theology and philosophy of the Roman College to the clergy of Rome, thereby giving rise to the universitys history. In 1959, the university took on its current organisation, thanks to Pope John XXIII, who named the institute the Pontifical Lateran University. Since it is a university, as well as classrooms and libraries, the buildings also house a cafe and a canteen and, walking across these rooms, one cannot help but notice the internationality of the users. While no voices can be heard from the corridors during lesson times, as one approaches the canteen building, a mixture of languages can immediately by distinguished amidst the typical hum of public eating areas, including English, French, German, and sometimes even Latin.

The help desks in the Students Office The conference room in the library at the Lateran University

Udine discovers the comfort offered by district heating

A 14 km-network linking major public utilities - universities, hospitals, and schools - and private apartment buildings, with potential development of urban network in new communities too.

Ugo Paganin upaganin@cpl.it

Project Manager, North East area

fter two years of toil, in July 2012, building work finally began on the district heating network in the city of Udine. This infrastructure is part of a somewhat more complex construction and management concession which envisages the construction of a heating and engineering plant featuring a cogeneration plant, a service and workshops centre, and a series of facility tunnels for the S. Maria della Misericordia University Hospital, in Udine. The company represents both the contracts principal and one of the promoters of the activities, together with the university and the city council. The works were awarded to a temporary consortium consisting of CPL CONCORDIA, Siram, Rizzani De Eccher, and Arco Lavori, and were divided up according to the various builders areas of expertise. The same companies also incorporated Aton, the special purpose entity that will act as concession holder and manager of the work for the next 30 years. The part assigned to CPL concerns the construction of a district heating network that starts from the heating plant located inside the hospital complex and extends over the north of the city, providing over 14 km of network coverage. Thats around 28 km of piping (for the delivery and return of superheated water), linked in a loop system, including 350 mm-diameter conduits that make up 30% of the total pipelines. The concession also includes the 38 users already acquired, making a total of 38.3 MW of power, for a sum of almost 11 million, with the work to be carried out over three years. To date, the project involves the connection of major

users, such as the University of Udine, the hospital, schools, and council buildings, as well as some private apartment blocks. However, the nature of the project, as a public works concession, means that this infrastructure can also be used by any member of the public that applies to do so, and we are expecting to see considerable development in this area in the future. This district heating network, which ranks first in size in the Friuli Venezia Giulia region, seems to have been received favourably by the citys inhabitants and there are new feasibility studies underway for other urbanised areas. In our capacity as CPL North East area, we have had ongoing operations in the area since January 2007, with a local office based near Udine, which allows us

to manage the contracts acquired, working on site and extending employment opportunities in the area to local workers and subcontractors. We are delighted that hot-water-fuelled district heating has finally reached the Friuli Venezia Giulia region and are confident we can develop the project further in the years to come, providing new job opportunities and growth all round.

25

After-sales service makes all the difference in the market

Omar Mazzuchelli -

omazzuchelli@cpl.it

Head of Biogas Maintenance & Cogeneration After-Sales

he expectations held for cogeneration and smart grids are undoubtedly an important factor in predetermining the spread of these technologies, but great professionalism is also required of the industrys operators. The risk of an emotional backlash following a betrayal of trust would be devastating for the market in the coming decade. Given the nature of the product (which is certainly neither an essential item nor a consumable good and has a repayment plan of a few years and a life cycle of twelve/fifteen years) the aftermarket is, in fact, the most important of the three key processes (1) available to the company to create value. Cogeneration, in particular, needs to stimulate the customer perceived value (2) of the investment, which is not immediately noticeable in the first two years of use, when proper power bill comparisons (i.e. with and without the CHP plant) are difficult. The Customer Relationship Management (CRM), i.e. the ability to establish and maintain relationships (obviously positive ones) with customers, is the daily tool that allows you to achieve a high degree of Customer Satisfaction (CS) and represents a valuable opportunity for the company to ensure, not only the right economic returns, but also the information needed to classify the customers needs, expectations, and behaviour, more accurately. Over time, this indomitable, competitive tool has allowed us to build up further opportunities with the same customers. In such a competitive environment, where customers have growing expectations, regarding both performance and finance and also of a psychological nature, the value factor created by the seller is constantly brought into play. A major part of the purchase will take place on a relational level. Customers have not bought a machine, they have purchased a unique item of technology, for which they hold certain expectations (cost savings, energy efficiency, corporate and social recognition, status). When properly trained, the people directly involved in these processes (service department and maintenance engineers) embody the companys competitive edge, faultlessly managing interaction with the customers during product use and demonstrating sensitivity to the needs thereof. It is not by chance that customers often prefer

to contact these staff members when it comes to the moment of truth, i.e. in the event of churn or the replacement/end-oflife repurchase of the product. Satisfied customers will buy increasingly from the same supplier and less from competitors; they will choose higher quality products, buy other products from the same supplier, and champion the product - all to the benefit of corporate advertising. Whats more, managing loyal customers costs less because they know the product better and have less need for assistance. So satisfying customers and increasing their loyalty over time boosts margins, as it lowers costs and raises revenues. If it is so simple though, you may wonder why so few companies are really gearing themselves customers and CS. I think the answer is twofold, i.e. time and excellence. Earning a customers trust requires the willingness to invest human and financial resources in the early years of that customers use of the CHP unit, understanding and supporting their needs, resolving their doubts, and guiding them towards the common goal of keeping the plant running at maximum efficiency and performance levels. Customer satisfaction is the outcome of a combination of actions within a complex system built on financial factors (purchase cost, operating cost, useful life) and performance (productivity, reliability), but also symbolic and emotional factors (status, brands), business and interpersonal relationships, and emulation of/competition with friends, colleagues, and rivals. In other words, satisfaction has to reach levels of excellence before it can significantly influence the customers choice. This is only achieved if the importance of the Customer Relationship Management is shared by the entire company. Rather than the final achievement, a sale should be perceived as the beginning of a long journey, one which will last for years and will generate further worth for the company (especially if - like CPL CONCORDIA - the company chooses an ongoing approach over a here today, gone tomorrow style). This has been the principle guiding the actions and people of the CPL service department throughout its over thirty years of cogeneration experience.

1. Namely: product & service development management (product and service innovation); supply chain management (supply chain and product and service delivery); customer relationship management (ability to build relationships with customers). 2. Value perceived by the customer: ineffective communication can make the product or service seem to be worth less than it actually is.

27

The new Biogas Maintenance & Cogeneration After-Sales Department

Scheduled routine and special maintenance Assistance and remote monitoring Increasing plant efficiency

The guarantee offered by 100 highly skilled technicians/maintenance engineers

ENGINEERS

plants throughout Italy

300+

OUR GUARANTEE

Round-the-clock service, 365 days a year

PLANT MAP www.cpl.it/mappa-degli-impianti

Udine Vicenza Milan Padua Modena Bologna Fano Arezzo Teramo Rome Naples Bari Cosenza Agrigento Nuoro

SERVICE CENTRES

Screenshot from the Pico Energy plant monitoring program

Omar Mazzuchelli -

omazzuchelli@cpl.it

Head of Biogas Maintenance & Cogeneration After-Sales

10/15 YEARS

arious factors, including the ever-increasing number of facilities, customers needs, the financial worth of the plants, and the complexity of the new engineering solutions, all contributed to CPLs decision to set up a new department. This new area offers a reliable, prompt, and competent maintenance department, manned by staff with high-level customer relations skills and abilities. The key to our success has always been our ability to understand customer needs and, at the same time, optimise the technical, financial, and organisational aspects, in order to deliver unprecedented improvements in performance. Our goal is to maximise the plants potential, continually raising the level of service quality, and eliminating waste and any other aspects that do not contribute to added value. The new organisation includes a hundred highly skilled technicians/ maintenance engineers, so that we can guarantee the various activities covered by the department at all times, all over Italy. The new department includes a new Competence Centre, which monitors the maintenance service results during service provision, from an objective perspective as regards both quality (service level indicators) and performance (technical and cost indicators). Constantly measuring customer satisfaction in relation to the service provided is key to spotting potential problems and areas for improvement. At present, the department manages over 300 cogeneration systems, with varying capacities, spread over Italy, working under standard full service agreements that have been appropriately tailored to the specific needs of each customer, thereby ensuring full, round-the-clock service, 365 days a year. Our agreements have an average term of 10/15 years and cover all aspects of post-sales services, including energy and securities marketing (green and white certificates, all-inclusive feed-in rates), directly and/or on

The average term of a CPL CONCORDIA agreement

95,8%

The number of satisfied customers who would purchase new cogeneration units from CPL CONCORDIA again

behalf of the customer. The percentage of repeat purchases for new cogeneration units at the end of a units life cycle is now 95.8%, a clear and irrefutable sign of the companys success in creating value for its customers and itself.

29

JOKA CPL Polska steams ahead in the Polish cogeneration industry

Plants, systems, and maintenance services totalling 13 MW purchased in just under a year by leading companies such as EDF and MEC Pila.

The key figures in the contract signing for the MEC Pila CHP plant The JOKA CPL Polska stand at the Poznan Fair

Michele Gavioli -

migavioli@cpl.it

Project Manager JOKA CPL Polska

he Polish-Italian consortium JOKA CPL Polska is forging ahead in the cogeneration market in Poland. The latest project acquired consists in the turnkey design and construction of a natural-gas-fuelled cogeneration plant inside a specially built substation. The plant will be located within the MEC coal-fired heating plant that provides district heating for the city of Pila, in north-western Poland. The customer, Miejska Energetyka Cieplna (MEC), founded in 1976, became the provider of district heating services for the entire city in 1991 and has been a member of ENEA, one of Polands largest electricity providers, since 2008. The agreement - including design, civil, and electromechanical works, and start-up - is worth over 7 million. The Polish market is extremely competitive but also extremely attractive for CPL in terms of cogeneration facilities and services, said Michele Crivellari, Head of Sales at CPL Industrial. This contract for the construction of 10 MW worth of plants and systems, as part of a consortium with the Polish company Joka - a result achieved through intensive teamwork - confirms our expertise on an international level. In the joint venture based in Lodz, Polish and Italian engineers are working together within JOKA CPL Polska to serve this market on a local level and very soon they will be turning their attention to public lighting and renewable energy. The electricity produced by the new cogeneration plant will be fed directly into the grid while the thermal energy will be supplied to the city through the existing district heating grid. As a result, the thermal load of the coal-fired plant will be reduced, bringing with it improvements in the level of harmful emissions in the city area. The CHP plant will be built with three GE Jenbacher engines, producing a total of 10 MWe and 9.5 MWt. The project includes all the work and services required to deliver a fully operational

cogeneration plant, including: the design, basic engineering and working design, and choice of components; the building works for the construction of the new building that will house the plant; the mechanical installation, including positioning of the engines and their accessories, as well as the refurbishment of the customers existing heating plant; the electrical work at the grid feed-in point, low- and medium-voltage panels and an auxiliary transformer, and finally, the commissioning and testing to ensure the heating plant delivered meets contractual requirements in full. Delivery of the plant is scheduled for November 2014. Alongside the design

and construction contract, CPL and JOKA have also secured the cogeneration plant maintenance agreement for the first three years of use, a contract worth over 2 million. Andrzej Drodz, chairman of JOKA, is openly satisfied: The partnership with CPL CONCORDIA has proved to be a success. In less than a year we have participated in the tender and procured cogeneration plants and service contracts from MEC Pila (10 MW) and EDF (2.7 MW). This shows that we are now recognised as a trustworthy player in the Polish market.

31

CNews n. 41 - June 2013

Executing complex projects through simple solutions. For X DataNet, a CPL CONCORDIA Group subsidiary, being global means creating unique ideas and knowing how to condense ever more efficiency, flexibility, and innovation into each product.

Managing documents and processes within a secure, integrated system

Riccardo Polesel rpolesel@xdatanet.com

Marketing and Communications Manager, X DataNet

ddition is a web application designed and developed by CPL CONCORDIA Group subsidiary X DataNet to manage business documents and processes within a secure, integrated system. More than just document management software that sorts and catalogues files, this powerful tool can automate business processes and manage any document, from creation through to final approval, within a controlled, shared environment, which is accessible to all users. These are features that convinced CPL to integrate it with SAP and allow the multi-utility company to utilise a single system for document management, making finding and using information much faster. Designed to allow maximum personalisation and teamwork, Addition can be accessed by CPL CONCORDIA employees using any browser installed on their PC (Internet Explorer, Mozilla Firefox, Chrome, etc.) safely, simply, and securely. One of CPLs main requirements was the ability to integrate the app with other existing systems in our organisation and this feature has always been one of Additions key strengths. CPL recently began employing the solution and the results were gratifying right from the start. Addition also offers users electronic record retention functions in order to directly manage CPL CONCORDIAs received and issued invoices, thereby cutting down drastically on paper use while ensuring compliance with all the legal requirements. Electronic records retention is a procedure which gives full legal validity to electronic documents, rendering them equivalent to their original paper counterparts. With the help of a company specialising in this area, X DataNet was able to devise special

functions for managing this process. X DataNet developed the software by building on experience accrued while working with a large number of medium/large Italian companies with branch locations spread over vast areas. It was just the program that CPL CONCORDIA needed, offering an integrated approach to handling payables and receivables. CPL employees now have two electronic file referencing options, either directly via SAP, or using Addition. Project managers can use Addition to work more easily, quickly, and directly. X DataNet was also responsible for the integration between the two systems. The Concordia-based cooperative is a perfect test ground for Addition. With over 200,000 documents managed each year, the company offers a challenge that will put the softwares capabilities and potential to the test. The fact, too, that a connector has been developed for integrating SAP and Addition (via ArchiveLink protocol), is definitely an extra bonus. Even now, the ongoing work between CPL CONCORDIA and X DataNet is bringing continuous improvement to Additions performance. One example of this partnership is the development of reDoc, a Windows-dedicated application, created by X DataNet, which scans and optically recognises barcodes containing bill and invoice identifiers, which is a priority stage of the process. Creating an intra-group partnership does not just mean youll be using reliable products but, more importantly, that you can grow together in terms of skills and experience, developing new ideas which may, in a short space of time, bring benefits for all involved. Joining forces is often little more than a buzzword, but in this case it laid the foundations for a development project that has created synergies that could be valuable for everyone.

33

When Italiandesigned technology is applied to Tunisian gas wells...

A water bath heater designed and made entirely in Italy, has been installed in the El Borma desert for managing just-extracted natural gas. Orders have already been placed across the Maghreb for over 40 units.

The water bath heater designed and built by CPL CONCORDIA at the El Borma well field in Tunisia

Diego Ganzerla -

dganzerla@cpl.it

Natural Gas Project Engineer

e all know how important it is for our cooperative to shift its focus onto new markets; acquiring contracts abroad and expanding the portfolio of opportunities through, among other things, new products will help us to stay competitive in the market. Given our experience in the field of natural gas plants in the Maghreb, we wanted to do more, by engineering and building equipment directly on site. While aware of the difficulties we would encounter, we were also highly prepared and motivated because it would mean getting the job done in exactly the way the customer wanted. The contract, which was procured in June 2012 and completed in early 2013, was for the supply of a water bath heater (WBH) which would be linked up directly to the natural gas extraction well located in El Borma in the south of Tunisia. The contract, worth around 270,000, was with SITEP, a Tunisian extraction company owned by ENI.

24 plants already built 7 underway 12 in the design phase

Using a 1,300 kW bi-fuel burner (natural gas/diesel), this device heats up the 20,000 Nmc/h stream of natural gas released from the wellhead at 345 bar and reduces the pressure to about 64 bar via a choke valve, a special manual valve that adjusts the pressure or flow rate of whatever comes out of the well (a mixture of various gases, water, and oil). Then the WBH goes back to

heating up the stream to prevent the formation of hydrates (ice crystals that can form due to the moisture and the components in the gases) and transfer the product to the next processing stage. The preliminary design phase was carried out quickly, with the help of a consulting firm that ensured we had the right means of tackling the tender stage. Then the staff member in charge of the project, Michele Gervasio, and I went to submit the project to the customer at their headquarters in Tunis. I think this was the most vital stage, as it meant we were able to quickly establish a direct contact which was maintained throughout the course of the work, thanks also to the staff of TIPOWER, the CPL Group member located in Tunisia. Back in Italy, we completed the detailed design, construction, and the testing (attended by a Tunisian certifier) and the final preshipment inspection with the customer; the project manager, Paolo Mambrini arranged for the recruitment and training of the staff who will be using the WBH in the well field in the middle of the desert. With the job done, we headed back to Italy with another satisfied customer under our belt, a quote request for a three-phase separator filter and the satisfaction of having produced a device in a totally new area for CPL CONCORDIA. The know-how gained on the Tunisian job has helped us tender for and win contracts for other similar jobs and now, in addition to the 24 WBHs already built, there are another seven under construction, and work about to begin on 12 more units. One non-negligible detail is that this work was begun in conjunction with the relocation of our staff to the Milan branch of CPL, following the earthquakes that occurred in May 2012. Apart from the dramatic changes this brought about in our everyday lives, we also found ourselves faced with the need to fit into the vast array of businesses and skills in the Milan area. This was not always an easy task, as certain companies underestimated the opportunities involved in working with a large company like ours and failed to give due importance to timing issues. Nevertheless, this experience within an experience meant that the bonds created between the various parties involved, including the interpersonal ties, were strengthened and a really close-knit team formed, ready to take up new and exciting challenges.

35

Romes Auditorium - taken as model by masters degree course at La Sapienza University

CPLs global service, provided over the last eight years, taken as a model of best practice in the field of Integrated Management of Real Property Assets.

Watch the case history video titled PERFECT ORCHESTRATION on energy management at the Auditorium Parco della Musica in Rome

Inside one of the rooms of the Auditorium Parco della Musica The Valle Giulia Department of Architecture at the of Romes La Sapienza University, where the masters course is held. Overleaf. A CPL employee working on the internal lighting systems at the Auditorium

Federico Di Roberto -

fdiroberto@cpl.it

Engineering department