Professional Documents

Culture Documents

Ultraviolet Photo-Detective Characteristics of Al/LPD-Oxide/n-type GaN With Photo-Electro-Chemical Wet Etching-Based Rough GaN

Uploaded by

SEP-PublisherOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultraviolet Photo-Detective Characteristics of Al/LPD-Oxide/n-type GaN With Photo-Electro-Chemical Wet Etching-Based Rough GaN

Uploaded by

SEP-PublisherCopyright:

Available Formats

www.seipub.

org/eer

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

Ultraviolet Photo-detective Characteristics of Al/LPD-Oxide/n-type GaN with Photo-electro-chemical Wet Etching-based Rough GaN

Gow- Huei Yang*1,2, Jun-Dar Hwang*3,Yu-Hung Chen*4, Chien-Mao Chan5, Nai-Wei Xu5,You-Xin Guo5

1 2 3 4

Department of Electronic Engineering, Chung Chou University of Science and Technology, Yuan-Lin 510, Taiwan Graduate School of Materials, National Yunling University of Science Technology, Douliou 640, Taiwan Department of Electrophysics, National ChiaYi University, ChiaYi 600, Taiwan Photovoltaic Technology Division, Green Energy & Environment Research Laboratories, Industrial Technology

Research Institute, Hsinchu 31040, Taiwan

5

Department of Electrical Engineering, Da-Yeh University, Da-Tsuen, Changhua 515, Taiwan

*1gwohuei@dragon.ccut.edu.tw; *3jundar@mail.ncyu.edu.tw; *4YHChen@itri.org.tw

Abstract A room-temperature anisotropic photo-electro-chemical etching process for n-type GaN films using a potassium hydroxide (KOH, pH=1.09~1.39) and phosphoric acid (H3PO4, pH=12.60~12.90) in the stirrer solution and Deuterium lamp illumination is described. The process provides anisotropic etch profiles and high etch rates >240 nm/ min at moderate light intensities ~17.3 mW/cm2 @237 nm in the H3PO4 (pH=1.09) solution. The etch rate and photocurrent are characterized as a concentration of the stirred solutions. In this work, two types of metal-oxide-semiconductor (MOS) structures were fabricated. One is the semiconductor layer with as-grown n-GaN (Sample B), and the other is the n-GaN surface with photo-electro-chemical etching (Sample A). The oxide layer for both these devices were fabricated using silicon dioxide insulator grown by a low-temperature (30-40) and reliable method of liquid phase deposition (LPD). For an incident light wavelength of 366 nm with an intensity of 4.15 mW/cm2 and a 6 V reverse bias, it was found that the photo to dark current ratio was around 31 and 26 for sample A and B, respectively. The photo to dark current ratio of sample A increases 19.2% compares with sample B.

applied in high-power or high-frequency optoelectronic devices, such as p-i-n and p--n photodiode[Monroy et al.,(1999), Monroy et al. (1997)]. The ultraviolet (UV) rays photo-detectors have been the subject of a vast body of the research work[Hwang et al. (2005)]. Obviously, the fundamental step in any devicesis the transfer of patterns onto the surface of the semiconductor by etching. The removal of surface material is a fundamental device processing step, and the most successful etching of GaN has been accomplished using dry etching methods, including reactive ion etching (RIE), inductively coupled plasma (ICP), electron cyclotron resonance (ECR) [Youtesy et al.(1997), Hwang et al.(2004)]. Dry etching techniques generally utilize a strong physical etch component, which can lead to ion-induced damage of the semiconductor. To improve the performance of such devices, their structures must be fabricated with damage-free from etching. Wet chemical etching is an important complement to dry etching methods by providing low damage etching, low cost and selective etching of different materials. A photo-electro-chemical (PEC) etching was considered to etch with slight damage for the fabrication of GaN devices, rather than ion sputtering that inevitably causes surface damage.

Keywords

Wet Etching; Photo-detective;GaN; Liquid Phase Deposition

Introduction In recent years, wide direct bandgap semiconductor gallium nitride (GaN) and its ternary alloys were

28

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

www.seipub.org/eer

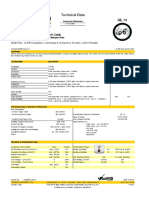

Minsky et al have reported localized electrochemical etching of unintentionally n-type GaN layers using HeCd laser illuminations (325 nm) and KOH solutions[Peng et al.(1998)]. By controlling the etching parameters, such as electrolyte concentration, illumination intensity, photocurrent, which affect the morphology of the etched surface and the etch rate can be obtained. A detailed description of the PEC system and wet etching process has been reported elsewhere [Rotter et al. (2000), Riedl et al (2003)]. Experiment Details In this paper, we report a series of PEC etching experiments on the n-type GaN in which we have used deep ultraviolet (=237 nm) illumination to study the wet etching process in electrolytes of different concentrations KOH and H3PO4stirrer solutions. A 30W Deuterium lamp (Oriel) was used as UV light source. Further, GaN MOS ultraviolet photo-detector were fabricated using silicon dioxide insulator grown at a low-temperature (30-40 ) and reliable method of liquid phase deposition (LPD). The etch depth and the profile of the illuminated spots were characterized by a Tencor Alpha-step 500 profilometer and by an atomic force microscope (AFM). Material and electrical properties of LPD-SiO2 on GaN were investigated by using energy dispersive X-rays (EDX). An ultraviolet Xe lamp at wavelengths of 366 and 254 nm was used as an optical source and the current-voltage (I-V) behavior was measured using an HP 4155B analyzer. Results and Discussion The n-GaN layer was grown on a c-face sapphire substrate by a metalorganic chemical vapor deposition (MOCVD) system with a horizontal reactor. Detail growth method has been reported previously [Hwang et al.(2005)]. In our study, GaN was obtained with a carrier concentration of ~2x1017 cm-3 and a mobility of ~250 cm2/V-s. Next, the n-type GaN sample was cleaned by being dipped into an HCl:H2O (1:1) solution for 5 min and a Ti layer (100nm) was deposited by Joule evaporation. The pattern of the metallization was defined by standard metal lift-off techniques. Subsequent annealing in N2 ambient at 850 for 3.5 min is applied to form ohmicTiN contacts. The Ti served to provide electrical contact to the sample as well as an etch mask. FIG.1 shows the experimental apparatus used in this work.

FIG. 1SCHEMATIC OF ETCTING APPARATU

The samples were clipped to a Teflon base using a nickel washer. A Pt wire was used as the system cathode. No bias was applied between the sample and the Pt cathode. An ammeter was used to monitor the current flowing within the electrochemical cell. A positive lens is to be used as a light beam converges, andthe sample is placed at the focal plane of the positive lens. Using an aperture stop (pinhole) determines the amount of light reaching the sample. An unfiltered Deuterium lamp provided uniform illumination over the entire surface of the sample with an intensity of ~17.3mW/cm2 at the wavelength of 237 nm. Precautions were taken to refrain from the UV induced absorption in the electrolytes by utilizing a short optical path about 1.5 mm in liquid. The electrolyte consisted of dilute aqueous solutions of KOH and H3PO4with concentrations in the range of pH=1.09~1.39 and pH=12.60~12.90, respectively. The solutions were magnetically stirred during the etching. UV illumination was used to generate electron-hole pairs at the semiconductor surface, which enhanced the oxidation and reduction reactions within an electrochemical cell. As the electron-hole pairs have generated, it is important that holes are transported to the semiconductor surface weakening the chemical bonds, thus encouraging dissolution, and additionally the electrons are swept to the cathode to avoid subsequent recombination with the holes at the surface. The resultant photocurrent is therefore proportional to the reaction rate of the hole-assisted etching at the semiconductor-electrolyteinterface[Youtsey et al. (1998)]. The PEC process, the UV excited hot carriers at the GaN/electrolyte interface have excess energy to access the H+/H2 and OH-/O2 redox levels in the water and to enhance the oxidation process. The oxide layer is subsequently dissolved in acids or bases of suitable low concentration[Penga et al. (1998)]. Youtsey et al, has postulated that the following both reactions

29

www.seipub.org/eer

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

(oxidation and oxide dissolution) are responsible for the decomposition of GaN. Thus, 2GaN + 6h+ + 6OH- Ga2O3 + 3H2O + N2 Ga2O3+ 6OH- 2GaO 3-+3H2O (1) (2)

The holes drift to the semiconductor surface, where they oxidize the gallium nitride, thus producing N2 bubbles that have been observed and Ga2O3 that dissolvesaway[Youtesy et al. (1997)]. During the overall photo-assisted electrochemical process, the etching of n-type GaN results when the rate of dissolution of oxidized products is faster than that of the oxide formation. FIG.2 shows the photo-current conducted through the electrochemical cell during a 60 min etch. The onset of illumination corresponded with an approximately exponentially decrease in photo-current flow within 20 min. According to Faradays law of electrolysis, the photo-current flow between anode (GaN sample) and cathode (Pt) is proportional to the reaction rate at the semiconductor/electrolyte interface. We suggest the total reaction rate is limited by diffusion.

FIG.3 shows a AFM images of a n-type GaN surface obtained a uniform and smooth etched surface was obtained with a root-mean-square (RMS) roughness 23.7 nm in the stirrer solution (pH=12.9 KOH) with aperture stop.FIG.4 shows a AFM images of a n-type GaN surface obtained a uniform and smooth etched surface was obtained with a root-mean-square (RMS) roughness 15.1 nm in the stirrer solution (pH=1.09H3PO4) with aperture stop. FIG.5 shows an instantaneous measure of the etch rate of the semiconductor. The etch rate gradually decreases due to the decrease in photo-current flow within 15 min. We believe the oxide dissolution rate equals the oxidation rate of the underlying n-type GaN film, andthe photocurrent levels out within 43~60 min, as shown in FIG.2. We have presented the applicability of PEC etching to the surface of n-type GaN at room temperature. The process provides highly anisotropic etch profiles and high etch rates >240 nm/min at moderate light intensities ~17.3mW/cm2 @237 nm by Deuterium lamp in the H3PO4 (pH=1.09) solution.

FIG. 2 PLOT OF TIME EVOLUTION OF PHOTOCURRENT

FIG. 4 AFM IMAGES OF A GaN SURFACE (H3PO4 pH=12.9) WITH APERTURE STOP 1.83m ETCH DEPTH 60 MIN ETCH TIME ROUGHNESS 15.1 nm.

FIG. 3 AFM IMAGES OF A GaN SURFACE (KOHPh=12.9) WITH APERTURE STOP 0.7m ETCHDEPTH 60 MIN ETCH TIME ROUGHNESS 23.7 nm.

FIG.5 SHOWS AN INSTANEOUS MEASURE OF THE ETCH RATE OF THE SENICONDUCTOR

30

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

www.seipub.org/eer

The ultraviolet photo-detector Al/LPD-Oxide/n-type GaN with photo- electro-chemical wet etching-based rough GaN (sample A) and Al/LPD-Oxide/as grew n-type GaN (sample B),which were fabricated using silicon dioxide insulator grown by a low-temperature (30-40) and reliable method of liquid phase deposition (LPD). The LPD process uses a supersaturated acid aqueous solution of hydrofluosilicic (H2SiF6) as a source liquid and an aqueous solution of boric acid (H3BO3) as a deposition rate controller, which has been described in detail elsewhere [Yang et al.(2011)12]. The chemical reaction of LPD process can be expressed in the following.

H 2 SiF6 + 2 H 2O + H 6 HF + SiO2 H 3 BO3 + 4 HF BF + H 3O + 2 H 2O (4)

+

(3)

In this study, the different concentrations of H2SiF6 and H3BO3 variedfrom 0.3 to 1M and 0.005 to 0.01M, respectively. Al/LPD-SiO2/n-type GaN MOS photo-detectors were fabricated by using standard lithography and lift-off technique. Ohmic contact of Ti/n-GaN metals and the gate electrode of Al were formed into a SiO2 film by evaporation. FIG.6 shows the fabricated ultraviolet photo-detector structure of Al/LPD-Oxide/n-type GaN(sample A and B). The thickness of silicon dioxide film, measured by ellipsometry and derived by assuming the silicon dioxide refractive index of 1.43, ranged from 30 to 55 nm. In FIG.7 the element analysis of LPD-SiO2, deposited into n-type GaN, is investigated by using EDX. In addition to Ga and N peaks, the Si and O peaks are found in our LPD-SiO2 films, demonstrating the SiO2 was grown into GaN layer successfully. For photocurrent measurements, a Xe lamp and a mono-chromator emitting at 366 and 254 nm were used, as the optical source with an intensity of 4.15 mW/cm2.

FIG. 7 ELEMENT ANALYSIS OF LPD-SiO2 BY USING EDX

FIG.8 shows the current densities vs different reverse bias for dark and photo-illuminated MOS photo-detector with LPD-SiO2 insulator. We attribute the current transport in our device to defect-assisted tunneling. The band diagram is for which shown in FIG.9. For an incident light wavelength of 366 nm with an intensity of 4.15 mW/cm2 and a 6 V reverse bias, it was found that the photo to dark current ratio was around 31 and 26 for sample A and B, respectively. The photo to dark current ratio of sample A increases 19.2% compared with the sample B. We suppose the photo-electro-chemical wet etching-based rough GaN which was applied in photo-detector structures as an anti-reflection coating. The surface of rough GaN substantially reduces reflection losses and increases absorption probability in the device; however, for an incident light wavelength of 254 nm with an intensity of 4.15 mW/cm2 and a 6 V reverse bias, it was found that the photo to dark current ratio was around 11 and 15 for sample A and B, respectively. The photo to dark current ratio of sample A is even smaller than that of sample B This behavior can be attributed to absorption in the metal gate layer or SiO2 insulator layer, because the penetration depth is very shallow a wavelength of 254 nm. Thus, only few 254 nm photons are absorbed in the depletion layer where photocurrent is generated. FIG.10 shows an incident light wavelength of 366 nm with an intensity of 4.15 mW/cm2 and a 6 V reverse bias, and it was found that the measured responsivity was around 0.145 and 0.116 A/W for sample A and B, respectively. We have demonstrated the

31

FIG. 6 THE FABRICATED MOS PHOTO-DETECTOR STRUCTURE (A) Al/LPD-OXIDE/N-TYPE GaN WITH PHOTO-ELECTRO-CHMICAL WET ETCHING-BASED ROUGH GaN (SAMPLE A ) (B) Al/LPD-OXIDE/AS GROWN N-TYPE GaN (SAMPLE B)

www.seipub.org/eer

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

photo-electro-chemical wet etching-based rough GaN which was applied UV photo-detector MOS structures as an anti-reflection coating.

in the H3PO4, solution. The sample A is the n-GaN surface with photo-electro-chemical etchingin which the photo to dark current ratio increases 19.2%.

ACKNOWLEDGMENT

This research was supported in part by Chung Chou University of Science and Technology under contract number CCUT-101-EE02

REFERENCES

Hwang, J. D., Yang, G. H. and Chang, W. T. et al,A novel transparent ohmic contact of indium tin oxide to n-type GaN, Microelectron. Eng. Vol.77, 2000, pp. 71-75

FIG.8 THE CURRENT DENSITIES VS DIFFERENT REVERSE BIAS FOR DARK AND PHOTO-ILLUMINATED MOS PHOTO-DETECTORS

Hwang, J. D., Yang, G. H. and Yang, Y. Y., et al.,Nitride-based UV metal-insulator-semiconductor photodetector with liquid-phase-deposition oxide, Jpn. J. Appl. Phys.,2005, pp. 7913-7915 Hwang, Z. H., Hwang, J. M., Hwang, H. L. and Hung, W. H. Electrodeless wet etching of GaN assisted with chopped ultraviolet light. Appl. Phys. Lett, Vol.84, 2004, pp.3759-3761. Monroy, A., Gangopadhyay, S., and Gaska., R. et al.,Low noise p--n GaN ultraviolet photodetectors , Appl. Phys. Lett.,Vol.71, 1997, pp.2334-2336 Monroy, E., Hamiton, M., and Walker., D. et al., High-quality visible-blind AlGaN p-i-n photodiodes, Appl. Phys. Lett.,Vol. 74 1999,pp.1171-1173 Penga, L. H., Chuang, C. -W, Ho, J. -K and Huang, C. N. et al,Deep ultraviolet enhanced wet chemical etching of gallium nitride,Appl. Phys. Lett, Vol.72 ,1998, pp.939-941. Riedl, T., Hitzeland, F., Hangleiter, A. et al,Revealing the Defect Structure in Laterally Overgrown GaN Stripes Utilizing Photoelectrochemical Etching Techniques, Jpn. J. Appl. Phys. Part 1, Vol.42 ,2003, pp.3381-3382 Yang, G. H., Chang, W. T. and Hwang, J. D. et al., Effect of N2-annealing on n-type Si Metal-Insulator-Semiconductor

FIG. 9 BAND DIAGRAM FOR DEFECT-ASSISTED TUNNELING. THE HOLES TUNNEL THROUGH DONOR-LIKE DEFECTS IN LPD-SiO2 TOWARD THE METAL GATE ELECTRODE

FIG. 10 THE RESPONSIVITY VS DIFFERENT APPLIED BIAS FOR PHOTO-ILLUMINAYED MOS PHOTO-DETECTOR

Capacitors by Using Liquid-Phase-Deposition SiO2 Micro & Nano Letters Vol.6, 2011, PP. 944-946 Youtesy, C., Adesida, I. and Bulman, G.:Highly anisotropic photoenhanced wet etching of n-type GaN, Appl. Phys. Lett., Vol.71 ,1997, pp. 2151-2153 Youtsey, C., Adesidaand, I., Bulman, G., Gallium nitride whiskers formed by selective photoenhanced wet etching of dislocations, Appl. Phys. LettVol.73 ,1998, pp.797-799.

Conclusions We report a study of the deep ultraviolet irradiation effects on the wet chemical etching of n-typeGaN. The process provides highly anisotropic etch profiles and high etch rates >240 nm/min at moderate light intensities ~17.3mW/cm2 @237 nm by Deuterium lamp

32

Electrical Engineering Research (EER) Volume 1 Issue 2, April 2013

www.seipub.org/eer

Gwo-Huei Yang received the B. S. and M. S. degrees from theDepartment of PhysicsTam Kang University, Tamsui, Taiwan, in 1984 and 1989, respectively and the Ph. D. degrees from the Department ofElectrical Engineering, Day Eh University , Changhua County, Taiwan, in 2007. Currently, he is Assosiate Professor with Department of Electronic Engineering, Chung Chou University of Science and Technology, Yuan-Lin, Taiwan and Graduate School of Materials, National Yunling University of Science Technology, Douliou, Taiwan. His research interests include LASER devices, optical signal processing, nonlinear optics, semiconductor physics and optoelectronic devices, nano devices. Jun-Dar Hwang received the B. S. degree from the Department of Electrical Engineering, National Taiwan University of Science and Technology, Taipei, Taiwan, in 1986 and the M. S.

and Ph. D. degrees from the Department of Microelectronic Engineering, National Cheng Kung University, Tainan, Taiwan, in 1980 and 1985, respectively. Currently, he is a Professor with the Department of Electrophysics, National Chiayi University, Chiayi, Taiwan. His research interests include optoelectronic semiconductor devices, solar cell, photodetector, semiconductor material processing and nano devices. Yu-Hung Chen received his Ph.D. in electrical engineering from National Chung Hsing University, Taichung, Taiwan, in 2009. He is currently a researcher at the Photovoltaic Technology Division, Green Energy & Environment Research Laboratories, Industrial Technology Research Institute (ITRI), Hsinchu, Taiwan. Dr. Chen research interests are in high efficiency silicon thin film, heterojunction silicon crystalline solar cells and photodetectors. He has published more than 50 research papers in reputable international journals and conferences.

33

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mill's Critique of Bentham's UtilitarianismDocument9 pagesMill's Critique of Bentham's UtilitarianismSEP-PublisherNo ratings yet

- Base BentlyNevadaDocument308 pagesBase BentlyNevadaZuriel Salim Gonzalez Lopez100% (1)

- Marine power and energy management control systemsDocument51 pagesMarine power and energy management control systemssj_hecklers67% (3)

- LCD MikroCDocument7 pagesLCD MikroCXoqqo Rollinng MightNo ratings yet

- Contact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentDocument7 pagesContact Characteristics of Metallic Materials in Conditions of Heavy Loading by Friction or by Electric CurrentSEP-PublisherNo ratings yet

- Improving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesDocument5 pagesImproving of Motor and Tractor's Reliability by The Use of Metalorganic Lubricant AdditivesSEP-PublisherNo ratings yet

- Influence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearDocument13 pagesInfluence of Aluminum Oxide Nanofibers Reinforcing Polyethylene Coating On The Abrasive WearSEP-PublisherNo ratings yet

- Experimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesDocument8 pagesExperimental Investigation of Friction Coefficient and Wear Rate of Stainless Steel 202 Sliding Against Smooth and Rough Stainless Steel 304 Couter-FacesSEP-PublisherNo ratings yet

- Device For Checking The Surface Finish of Substrates by Tribometry MethodDocument5 pagesDevice For Checking The Surface Finish of Substrates by Tribometry MethodSEP-PublisherNo ratings yet

- FWR008Document5 pagesFWR008sreejith2786No ratings yet

- Microstructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingDocument5 pagesMicrostructure and Wear Properties of Laser Clad NiCrBSi-MoS2 CoatingSEP-PublisherNo ratings yet

- Enhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentDocument6 pagesEnhancing Wear Resistance of En45 Spring Steel Using Cryogenic TreatmentSEP-PublisherNo ratings yet

- Effect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesDocument11 pagesEffect of Slip Velocity On The Performance of A Magnetic Fluid Based Squeeze Film in Porous Rough Infinitely Long Parallel PlatesSEP-PublisherNo ratings yet

- Reaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesDocument9 pagesReaction Between Polyol-Esters and Phosphate Esters in The Presence of Metal CarbidesSEP-PublisherNo ratings yet

- Microstructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesDocument7 pagesMicrostructural Development in Friction Welded Aluminum Alloy With Different Alumina Specimen GeometriesSEP-PublisherNo ratings yet

- Mindfulness and Happiness: The Empirical FoundationDocument7 pagesMindfulness and Happiness: The Empirical FoundationSEP-PublisherNo ratings yet

- Delightful: The Saturation Spirit Energy DistributionDocument4 pagesDelightful: The Saturation Spirit Energy DistributionSEP-PublisherNo ratings yet

- Enhanced Causation For DesignDocument14 pagesEnhanced Causation For DesignSEP-PublisherNo ratings yet

- Ontology-Based Testing System For Evaluation of Student's KnowledgeDocument8 pagesOntology-Based Testing System For Evaluation of Student's KnowledgeSEP-PublisherNo ratings yet

- Quantum Meditation: The Self-Spirit ProjectionDocument8 pagesQuantum Meditation: The Self-Spirit ProjectionSEP-PublisherNo ratings yet

- Isage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophyDocument8 pagesIsage: A Virtual Philosopher System For Learning Traditional Chinese PhilosophySEP-PublisherNo ratings yet

- Cold Mind: The Released Suffering StabilityDocument3 pagesCold Mind: The Released Suffering StabilitySEP-PublisherNo ratings yet

- A Tentative Study On The View of Marxist Philosophy of Human NatureDocument4 pagesA Tentative Study On The View of Marxist Philosophy of Human NatureSEP-PublisherNo ratings yet

- Legal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialDocument4 pagesLegal Distinctions Between Clinical Research and Clinical Investigation:Lessons From A Professional Misconduct TrialSEP-PublisherNo ratings yet

- Social Conflicts in Virtual Reality of Computer GamesDocument5 pagesSocial Conflicts in Virtual Reality of Computer GamesSEP-PublisherNo ratings yet

- Technological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsDocument9 pagesTechnological Mediation of Ontologies: The Need For Tools To Help Designers in Materializing EthicsSEP-PublisherNo ratings yet

- Architectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldDocument5 pagesArchitectural Images in Buddhist Scriptures, Buddhism Truth and Oriental Spirit WorldSEP-PublisherNo ratings yet

- Metaphysics of AdvertisingDocument10 pagesMetaphysics of AdvertisingSEP-PublisherNo ratings yet

- Computational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpDocument6 pagesComputational Fluid Dynamics Based Design of Sump of A Hydraulic Pumping System-CFD Based Design of SumpSEP-PublisherNo ratings yet

- Damage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationDocument10 pagesDamage Structures Modal Analysis Virtual Flexibility Matrix (VFM) IdentificationSEP-PublisherNo ratings yet

- The Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateDocument8 pagesThe Effect of Boundary Conditions On The Natural Vibration Characteristics of Deep-Hole Bulkhead GateSEP-PublisherNo ratings yet

- PLINK3 Operation Ver.0.04.2004.10Document204 pagesPLINK3 Operation Ver.0.04.2004.10Arturo Jimenez TerreroNo ratings yet

- Improving transient stability using AVR, governor and PSSDocument8 pagesImproving transient stability using AVR, governor and PSSAnas MahmoodNo ratings yet

- WagonR BrochureDocument16 pagesWagonR BrochureNijin XmxNo ratings yet

- M4 Eece425 S2020 PDFDocument60 pagesM4 Eece425 S2020 PDFYehya El hassanNo ratings yet

- Scientific Computation (Floating Point Numbers)Document4 pagesScientific Computation (Floating Point Numbers)PythonraptorNo ratings yet

- SymphoniePRO® Data Logger - 26 CH & 16 CHDocument7 pagesSymphoniePRO® Data Logger - 26 CH & 16 CHAni dwi OctaviaNo ratings yet

- Lab Report 1Document4 pagesLab Report 1sslobodan123100% (1)

- Practical 5 Aim: Low Pass Average Filter and High Pass Filter Used On An Image With Gaussian NoiseDocument1 pagePractical 5 Aim: Low Pass Average Filter and High Pass Filter Used On An Image With Gaussian Noisevaibhavmakkar54No ratings yet

- Catalogo Chekman 1Document32 pagesCatalogo Chekman 1Ramos JorgeNo ratings yet

- Autonomous Pesticide Sprayer Robot: Abstract-The Management of Pest Insects Is The CriticalDocument7 pagesAutonomous Pesticide Sprayer Robot: Abstract-The Management of Pest Insects Is The CriticalPranay SudhanNo ratings yet

- Vacumat 22 22TDocument2 pagesVacumat 22 22TSandeep ChhonkerNo ratings yet

- Digital IC DesignDocument13 pagesDigital IC DesignSteven HertzNo ratings yet

- 10 kVA - PI044E PDFDocument9 pages10 kVA - PI044E PDFYogi PurchasingNo ratings yet

- ST Unit 4 NotesDocument25 pagesST Unit 4 Notesabc fun facts100% (1)

- SpiroCard BrochureDocument2 pagesSpiroCard BrochureEdward Gustavo González MotavitaNo ratings yet

- Project Report On AirtelDocument22 pagesProject Report On AirtelSidhant AirenNo ratings yet

- Switch GearDocument6 pagesSwitch GearHari Krishna.MNo ratings yet

- Manual AURATON 2030 2030RTH en PDFDocument32 pagesManual AURATON 2030 2030RTH en PDFradomir46No ratings yet

- Universal Synchronous Asynchronous Receive/Transmit USART: MSP430 Family USART Peripheral InterfaceDocument52 pagesUniversal Synchronous Asynchronous Receive/Transmit USART: MSP430 Family USART Peripheral InterfaceEnrico W. FebriardyNo ratings yet

- Digital energy meter with serial interfaceDocument34 pagesDigital energy meter with serial interfaceMary Ann Cadena CabañasNo ratings yet

- UL13 Instrumentation Cable Technical DataDocument1 pageUL13 Instrumentation Cable Technical DataMario MejiaNo ratings yet

- Full Unbrick Solution Note 4 n910fnDocument3 pagesFull Unbrick Solution Note 4 n910fnbarzuandrei100% (1)

- Fujitsu Stylistic q584Document8 pagesFujitsu Stylistic q584conmar5mNo ratings yet

- Rotarex Centrifuge Extractor Provides Asphalt TestingDocument1 pageRotarex Centrifuge Extractor Provides Asphalt TestingRadu George Motoc100% (1)

- Cpe 242 Computer Architecture and Engineering Instruction Level ParallelismDocument46 pagesCpe 242 Computer Architecture and Engineering Instruction Level ParallelismSagar ManeNo ratings yet

- AD100 Series AC Drive Operation ManualDocument67 pagesAD100 Series AC Drive Operation ManualSegundo Tumalie100% (1)

- v22 v24 v23 - DtoDocument70 pagesv22 v24 v23 - DtoplasmapeteNo ratings yet