Professional Documents

Culture Documents

Terra Construction Plan Rev0

Uploaded by

hasan_676489616Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terra Construction Plan Rev0

Uploaded by

hasan_676489616Copyright:

Available Formats

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.

: 4686-011 Date: 7/28/09 Page: 1 of 45

Terra International UAN Expansion Project Woodward, OK

CONSTRUCTION EXECUTION PLAN

Rev No: 0 Issue Purpose Date By Approved Owner Approval

A

Issue for Comment

B Issue for Approval

1 Issue for Construction

2 Issue for Construction

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 2 of 45

TABLE OF CONTENTS

I GENERAL.....................................................................................................................................3 A.Constructability and Preconstruction Activities........................................................................3 C. Major Subcontracts ..................................................................................................................5 1. General 5 a.Construction Manager (CM)......................................................................................................29 b. General Superintendent (GS)....................................................................................................30 c. Superintendents...........................................................................................................................30 d. Project Controls Manager (PCM) ...........................................................................................30 e. Field Project Engineer (FPE)....................................................................................................31 f. Site HSE Manager (SHSEM)......................................................................................................31 g. Site Quality Assurance Manager (SQM)..................................................................................31 h. Site Subcontracts Manager (SSM)............................................................................................32 7. Health, Safety, and Environment Site Plan............................................................................32 a. HSE Plan......................................................................................................................................34 b. Environmental.............................................................................................................................34 c. Security.........................................................................................................................................34 d. General Lifting Requirements...................................................................................................35 8. Local Labor Conditions.............................................................................................................37 10. Mechanical Completion ..........................................................................................................38 11. Construction Communications...............................................................................................39 a. Communications.......................................................................................................................39

II. TEMPORARY FACILITIES...............................................................................................................40

A. Mobilization of Temporary Facilities to the site.....................................................................40 B. Telecommunications...................................................................................................................41

III. PERMITS.............................................................................................................................................41

A. Owner Permits...........................................................................................................................41 B. Ventech Permits.........................................................................................................................42

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 3 of 45

GENERAL

The Woodward Expansion Project consists of a new 1,500 STPD UAN Solution Plant (UAN-II) to be built at Terras Woodward, Oklahoma Plant. The new UAN Plant is an integrated facility consisting of the following production units: Nominal 535 STPD Urea Plant Nominal 525 STPD Nitric Acid Plant Nominal 665 STPD Ammonium Nitrate Plant The integrated facility will produce two products for Terra: UAN Solution, and Urea Liquor (UL). Provisions will be made in the layout and design for the future addition of Ammonium Nitrate Solution (ANS) as a third product. Weatherly will provide all the required basic and detailed engineering for the ISBL facility. Terra will provide the procurement for the ISBL facility per Weatherlys specifications. Weatherly will provide the process technology (specifications, detailed drawings and contract documents). Ventech will provide the construction of the ISBL facilities. The ISBL facilities will require CO2 and Ammonia, which will be obtained by tie-in to the existing Woodward Ammonia Plant. Utilities required by the ISBL facilities include 350 psig steam, 600 psig steam, potable water, plant air, instrument air, demineralized water, cooling water, firewater, and boiler feed water. Firewater, demineralized water, potable water, 350 psig steam, and 600 psig steam will be obtained by tie-in to the existing Woodward Plant supply systems. Plant air, instrument air, boiler feed water, cooling water, and process water for UAN dilution will be supplied by new OSBL facilities. A. Constructability and Preconstruction Activities

Ventechs construction implementation strategy includes a strong pre-construction effort with the participation of the key construction management personnel in the engineering office during the early phases of the engineering and procurement cycle. During this pre-construction phase, the construction team will: 1. Participate with project scope review; 2. Develop site specific procedures, work methods, and inspection and test plans; 3. Develop plans for the construction temporary facilities;

3

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 4 of 45

4. 5. 6. 7.

Provide input to schedules and estimates for detailed construction activities, Participate in the first project planning and start up planning processes; Develop Systems Turnover philosophy, identification, and sequencing; Providing general construction input to the engineering, material management and procurement activities.

Ventech will initiate the pre-construction effort with a comprehensive constructability checklist that includes details for a division of responsibilities matrix between the engineering/procurement and construction organizations. This standardized approach will facilitate a smooth transition from the engineering office to the early field construction activities and provide the framework for field construction. B. Ventech Construction Subcontracting Strategy

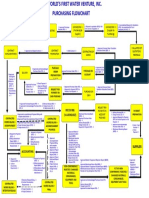

Work will be contracted by Ventech in support of the overall project execution. It is anticipated that work performed on a subcontracted basis will include: 1. Civil Subcontractors a. b. c. d. e. a. b. c. d. e. f. g. 3. Site preparation and development Installation of auger cast pilings for foundations Installation of foundations for equipment and structure Final grading and finish grading and concrete paving Underground piping and electrical installation Temporary facility installation and maintenance Installation of aboveground piping components & systems X-ray and N.D.E. requirements for piping components & systems Installation of steel for structure, pipe rack, etc Installation of rotating and static equipment Painting / Insulation for piping components and equipment Installation of the main power systems and utilities

2. Mechanical Subcontractors

I&E Subcontractors a. Installation of the power and control cabling systems b. Installation of the control devices & systems c. Heavy Haul Transport / Lifting for Specialized Equipment

4. Miscellaneous - Subcontractors a. Cooling Tower Installation b. Field Installed Firewater System For the portion of the work being subcontracted by Ventech, the use of local subcontractors for specific work packages is expected, depending on the work scope, subcontractor

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 5 of 45

capabilities, and approval by the client. All subcontracted work will be preformed under subcontract terms and conditions that are established for the project and which are consistent with the primary EPC contract. These terms and conditions will provide for coordination with the work of others and compliance to the technical, safety, quality, industrial relations, cost, and schedule objectives that are established for the project. C. Major Subcontracts

As a basis of the EPCM estimate and the current construction execution plan, Ventech has considered the following subcontract work scopes: .a Civil Package Piping Underground Site Preparation Auger Cast Piles Foundations .b Mechanical Package Structural Steel Setting Major Equipment Piping Above Ground .c Instrument .d Electrical 1. General a. b. 2. Construction Manager to ensure work released by QC at each stage. Subs must redline drawings as changes in filed are made and maintain a set in the office.

Civil Package a. Piping (Underground) The Subcontractor will ensure that installation of iron and carbon steel underground piping systems (including fire protection U/G piping) is accomplished in compliance with project specifications, applicable codes, and contract requirements. 1) Procedure a) Welding and Nondestructive Examination (NDE) shall be accomplished in accordance with Reference 2.1 (CQP A15) form and or their equivalent in addition to the requirements of this CQP. b) Fabrication and installation of underground carbon steel piping shall be supervised and controlled by the Subcontractor as piping is fabricated and installed.

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 6 of 45

c) The Subcontractor shall assure that underground carbon steel piping conforms to the engineering drawings and sketches, specifications, and applicable codes and standards. d) Engineering drawings and sketches shall be used to confirm, in detail, the location, orientation and dimensions of underground piping, valves, and accessories. e) Engineering drawings and specifications shall define the requirements for materials, construction practice and testing. f) Verify ditch excavation (route, depth, width, grade, and shoring) and verify sand or other required bedding in ditch. g) Verify installed pipe materials are the correct diameter, wall thickness and material type and grade. h) Verify line slopes are in accordance with approved drawings and branches, vents, drains and reducers are installed correctly. i) Verify valves are installed correctly (item number, flow direction, bypass, and extensions). j) Verify gaskets and bolting are correct (materials & installation) and piping and valves are adequately supported and anchored. k) Verify thrust blocks are installed where required by the engineering design, each designated test section or total system has been pressure tested, exterior coatings are correctly applied and before backfill, that the cathodic protection system is installed, when required. l) Subcontractor shall ensure documentation is correct and complete to meet project requirements. m) Wrapped and coated pipe shall be holiday tested, where applicable, by a spark or holiday tester of appropriate voltage for the coating system being tested and recorded in accordance with Reference 2.5 (CQP B21.02) Coating Underground Piping form and or their equivalent. 2) Records and Documentation a) One set of drawings shall be kept by the Construction Manager/Field Engineer for inspection and testing records. They will be marked-up to indicate which parts of a piping system have been tested, inspected and found to be in accordance with the specifications, codes, standards, and drawings. b) Completed documentation will be forwarded to the Field Engineer or Construction Site Quality Control Manager for review and retention in site files. When applicable, "as built" data shall be recorded for all routing installation changes, the "as built" data must be included in the piping test package.

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 7 of 45

3)

CQP Forms for Reference: (if applicable) a) CQP B04.01A - Pipe Pre-Test Checklist (Steel/Iron Underground Pipe) b) CQP B21.02 A- Coating Underground Piping

b.

Site Preparation

Due to the relatively small ISBL area of proposed construction, the installation of pilings, foundations, underground piping and electrical boxes and conduits will need to be coordinated so that construction begins with deep installations. It will be necessary to over excavate the ISBL area and backfill with a structural fill material (locally referred to as red select) to facilitate trenching in lower parts of the excavation. Conceptual sequence of Scope of Work is recommended as follows: a) b) Excavate area to Elevation 90-0 (see drwg.) # 4686-SK-1017 Rev A Backfill lower one half with structural fill (red select) Elevation 95-0. Area backfill to be compacted to 90% modified Proctor density where as backfill placed directly under foundations to be compacted in accordance with project earthwork specifications. Install test pilings for load testing within the ISBL area and conduct necessary load tests to verify design depths and piling capacities prior to installation of permanent pilings. Proceed with installation of permanent pilings and pile caps. Proceed with the excavation and trenching scope of work for installation of cable boxes, conduit and underground piping.

c) d) e) 1)

Procedure

The Construction Manager/Field Engineer shall direct earthwork activities in accordance with project specifications, applicable codes, and contract requirements. The results of Field Density Test Record shall be documented on an, Form B02.01B The Field Engineer shall assure "Dig Safe" permits are obtained as required by local regulations. Inspection and documentation shall be provided as required for each phase of earthwork construction activity, including: a) b) c) d) e) Cofferdams Excavations Line and grade Backfill and compaction Roads and storage areas

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 8 of 45

f) g) h) i) j) k) 2) 3)

Aggregate production Dewatering Tie-backs and anchors Gradations Proctor Moisture content

Field Density test(s) shall be performed by a qualified specialist. The results of the test(s) will be recorded on a Field Density Test Record,Form B02.01B, or approved third party documentation. Completed Earthwork Inspection Daily Reports, shall be submitted to the Construction Site Quality Control Manager or Resident Engineer for review and retention. The Construction Site Quality Control Manager shall perform sufficient monitoring of in-process work to assure compliance with the engineering design. Auger Cast Pile Installation

4)

c.

This specialty subcontract will be required for the installation of the (200) Auger Cast Piles associated with the equipment foundations and structure. This work will be performed only after soil test have been tested and (six) test piles have been installed. Test piles must be approved for suitability of equipment, techniques and source of materials by a qualified Inspector. Documentation must be completed and signed by the Inspector and witnessed by Client or their designee. Potential subcontractors for this specialty work will most likely be from outside the local area. This work is foreseen to be on the critical path of the project schedule. It will be critical that this subcontract is placed and field activities are scheduled to start as soon as permits are set in place. d. Foundations

Formwork will be constructed to the shape, form, line and grade required; and shall be maintained sufficiently rigid to prevent deformation under load. Unless otherwise specified, formwork and details shall conform to ACI 318. All exposed concrete edges shall be chamfered x 45 degree. Exposed form surfaces will be coated with form oil before placing reinforcement. Unexposed surfaces may be wetted in lieu of form oil, except in freezing conditions. Formwork design and construction will be in accordance to ACI 347 and the responsibility of the Subcontractor.

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 9 of 45

Reinforcing Steel will be free of oil, mud, loose rust or other loose coatings, and will be properly secured in position by concrete blocks or metal chairs and by spacers. The details of design and construction for reinforced concrete, including the bending, splicing and placing of reinforcing steel will conform to ACI 318. Concrete protection over steel reinforcement will not be less than 3 inches between steel and ground footing; 2 inches for exposed concrete aboveground and for columns, beams, girders and inch for slabs and walls not on ground or exposed to weather. 1) Procedure a) Prior to initial delivery of concrete, and at intervals as noted on CQP Form B08.01A, Batch Plant Inspection Report, current NRMCA Certification or local regulatory certifications of Ready Mixed Concrete Product Facilities (see Reference 2.1) shall be on file at the batch plant. Prior to initial delivery, and at intervals as noted on the Batch Plant Inspection Report, the batching process shall be inspected to ensure that it is in compliance with project specifications and Reference 2.2, if referenced by applicable project specifications. Prior to initial delivery, inspection will be performed to verify that the plant scales, volumetric water batching device, and volumetric admixture dispenser have been calibrated and the results recorded. Prior to initial delivery, an inspection will be performed to verify the batch plant is using an acceptable Concrete Delivery (Batch) Ticket system and concrete delivery trucks are serviceable and meet contract requirements. Prior to initial delivery and at intervals established in project specifications, verify that materials meet the specification and originate from acceptable supplies. Documentation of verifications will be via Form B08.01A, Batch Plant Inspection Report, with copies of batch plant supplied documentation attached. The completed reports shall be forwarded to the Resident Engineer for review and retention in site files.

b)

c) d)

e) f) g)

Anchor bolts to be checked for diameter to projection. Concrete will be proportioned and mixed to achieve minimum compression strength of 4000 psi after 28 days. Batch mix must be approved by Ventech. Concrete Forms: Pour Cords, Form and rebar checks.

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 10 of 45

Note: ISBL foundations specifications are Engineered by Weatherly Inc. (see Civil Engineering Documentation) Ref.# 3.5.1-01 3. a. Mechanical Package Structural 1) Procedure The Subcontractor shall erect structural steel in accordance with the engineering design and construction practices. As a minimum, this shall include the following: a) Subcontractor shall verify that base plates are set level, at the proper elevation, and on the proper location and that concrete is properly cured before setting steel. b) Drawings shall be marked to record readings, dates, and approvals and be kept as a permanent record. Sub shall verify latest revision with drawings in office. c) Subcontractor shall monitor and report erection progress on a daily basis to ensure that the type and grade of structural steel installed and that installation activities are in compliance with project specifications and applicable codes. d) Subcontractor shall also verify daily and report that the erected structure is left in a guyed stable condition. e) Subcontractor and the Construction Site QA/QC Manager shall verify that erection torque wrenches are currently calibrated prior to use. f) Bolt tightening methods shall be as specified in the project procedures. If none are specified, the Field Engineer, in concurrence with the client, shall designate the "turn of the nut" method. g) Subcontractor and the Construction Site QA/QC Manager shall check connections including; bolts, nuts, washers are the correct type, grade, size and finish, bolting tightening practice. h) Bolting inspections and checks shall be noted on a record set of erection or design drawings indicating satisfactory or unsatisfactory, date, month and piece mark number and the Subcontractors and the Construction Site QA/QC Manager initials for each connection checked. Mark inspected bolts? Line across nut and bolt. i) Subcontractor and the Construction Site QA/QC Manager will verify structural steel welding is in accordance with project welding requirements. j) Subcontractor and the Construction Site QA/QC Manager verify the plumbness of erected columns, ladders, platforms (grating), stairs and handrails are correct and complete as directed in the specification. k) `At final inspection, incomplete items or items requiring rework will be documented on CQP Form B12.01A, Structural Steel Punch List.

10

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 11 of 45

l) Upon completion of the structure, pipe rack or area, etc., CQP Form B12.01B, Structural Steel Inspection Record shall be completed. Completed documentation shall be forwarded to the Field Engineer for review and retention in site files. b. 1) 2) c. 1) CQP Forms for Reference: (if applicable) Form B12.01A, Structural Steel Punch List Form B12.01B, Structural Steel Inspection Record Major Equipment Setting Procedure - Fixed Fixed and specialty equipment (exchangers, reactors, drums, tanks, towers, fin fans, heat-recovery-steam-generators, fire protection/safety systems and similar types of fixed equipment) are installed in accordance with applicable specifications and drawings. As a minimum, this shall include the following: a) b) c) d) e) f) g) h) i) j) k) l) m) n) o) Verify correct personnel equipment and materials are in place for the installation. Lifting plans required for loads in excess of 20,000 lbs. Verify foundation or structure is completed and released for setting equipment (anchor bolt holes confirmed to match anchor bolts). Verify Anchor bolt holes in baseplate match foundation before lifting. Verify elevation is correct. Verification of correct orientation. Verify foundation scrabbled and correct shims sets are correct elevation. Ensure correct plumbness and anchor bolts tightened. Verify Grouting Correct. Verify internal and external components and attachments are correct Verify required grounding is installed. Verify protective coatings, insulation and fireproofing. Verify any special process work (welding/NDE) is correct and complete (if required) Verify ASME Code work, if applicable, is correct, complete and signed off by the Authorized Inspector (apply appropriate ASME QC manual requirements). Verify CQP, General Fixed Equipment Installation and or the specific verification subcontractors form is completed for each installed component. Verify CQP, Mechanical Equipment Closing Authorization is completed for opened components and or the specific verification subcontractors form.

d.

Equipment Completion and Release shall include the following:

11

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 12 of 45

1)

2) 3) 4) 5)

The appropriate CQP forms and or their equivalent shall be prepared for each piece of major fixed equipment as listed on the project equipment list and for any piece of major fixed equipment being reinstalled in a different or relocated service. In such cases, the record should reflect complete information associated with the change. Additions or changes to existing CQP forms and or their equivalent may be necessary to address the specific inspection requirements associated certain types of special fixed equipment. Each record shall be originated by the Quality Control Manager or his/her designee, who shall complete the applicable portions of the record once the equipment is released to the field for installation. The Construction Manager, in coordination with the Field Engineer and/or the Construction Site Quality Control Manager will ensure that each item of work is signed and released prior to allowing the next step to begin. Completed records will be forwarded to the Field Engineer or Construction Site Quality Control Manager for review. The Field Engineer or Construction Site Quality Control Manager shall be responsible for storing documents in Project Data for retention, with a copy to the home office QC department. Completed CQP forms will provide the following information:

e. 1) 2) 3) 4) 5) f. 1)

A record of each piece of equipment, its manufacturer, and its characteristics. Signatures indicating that the equipment has been properly set, assembled, connected, tested, and accepted. Information required by the materials management and project controls groups for completion of required records and reports. Permanent, complete equipment record for the Owner's operations and maintenance organizations. Attached test and inspection reports including any construction related documents required by the equipment manufacturer's representative. Quality Records will provide the following information: The applicable test & inspection records / CQP forms and or their equivalent shall be completed by the Construction Site Quality Manager or designee for each piece of fixed mechanical equipment identified in the project equipment list. These forms can be found in the CQP manual. The completed reports will be forwarded to the Field Engineer or Construction Site Quality Control Manager for review and retention.

2)

12

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 13 of 45

g. 1)

Records Retention: Copies of proprietary forms required by equipment suppliers/erectors shall be obtained by the Construction Manager/Engineer and forwarded to the Field Engineer or Construction Site Quality Control Manager for review and retention. Completed documentation shall be retained by the Field Engineer or Construction Site Quality Control Manager in site files.

2)

h. CQP Forms for Reference: (if applicable) 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16) 17) 18) 19) Form B25.01A, Exchanger Installation Checklist Form B25.01B, Mechanical Equipment Closing Authorization Report Form B25.01C, Air Cooler Installation Checklist Form B25.01D, General Fixed Equipment Installation Checklist Form B25.01E, Tower Tray Installation Checklist Form B25.01F, Pressure Vessel/Tank Installation Checklist Form B25.01G, Fired Heater Installation Checklist Form B25.01H, Packaged Unit Installation Checklist Form B25.01I, C02/Deluge/Sprinkler Valve Skid Installation Checklist Form B25.01J, Safety Shower/Eyewash Installation Checklist Form B25.02A Coupling Alignment Report (pages 1 of 3) Form B25.02B General Rotating Equipment Installation Checklist Form B25.02C Chain/Belt Driven Alignment Report Form B25.02.D Laser Alignment Report Form B25.02 E Fan/Cooler Alignment Report Form B25.02 F Mixers/Agitators Installation Checklist Form B25.02 G Diesel Engine Installation Form B25.02 H Compressor Installation Checklist Form B25.02 I Gas Turbine Installation Checklist page 1 of 3

i. Mechanical Acceptance Requirements 1) Procedure - Rotating

The subcontractor will assure that rotating mechanical equipment is installed and tested in accordance with applicable specifications and drawings. As a minimum, this shall include the following: a) Verify proper identification of equipment. b) Verify equipment base is prepared for grouting and shop applied coating (if not removed) is compatible with the proposed grout to be used. c) Verify foundation or structure is complete and released for setting equipment (anchor bolt holes confirmed to match anchor bolts and foundation surface is prepared for grout).

13

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 14 of 45

d) e) f) g) h) i) j) k) l) j.

Verify correct shimming, orientation and elevation is correct. Verify driver and driven coupling hub run out acceptable. Verify grouting is correct and complete. Verify piping is appropriately cleaned and inspected before being connected to equipment (inspection point). Verify piping is connected to equipment without stress. Verify driver and driven final aligned. Verify soft foot checked and accepted, seal oil system cleaned and operable and seals installed. Verify driver direction of rotation correct and driver run-in complete (vibration and temperature acceptable). Verify coupling guard installed, suction screens installed, electrical and instrumentation connections are complete; including grounding.

Equipment Completion and Release

The appropriate CQP Forms and or their equivalent shall be prepared for each piece of major rotating equipment as listed on the project equipment list and for any piece of major fixed equipment being reinstalled in a different or relocated service. In such cases, the record should reflect complete information associated with the change. 1) 2) 3) 4) k. Each record shall be originated by the subcontractor, who shall complete the applicable portions of the record once the equipment is released to the field for installation. The record shall be maintained during the course of installation and testing, properly signed and dated by the respective responsible person. The Construction Manager, in coordination with the Field Engineer and/or the Construction Site Quality Control Manager will ensure that each item of work is signed and released prior to allowing the next step to begin. Completed records will be forwarded to the Field Engineer or Construction Site Quality Control Manager for review and retention. Mechanical Equipment

Although the equipment for the Terra UAN Expansion Project is identified in the Equipment List, the majority of the mechanical equipment includes:

Columns Drums Vessels Reactors Exchangers Cold Boxes Compressors / Fans / Turbines 2 4 35 2 41 0 3

14

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 15 of 45

Heaters / Boilers Pumps Storage Tanks PSA Unit Ejectors Injection Package Units Filters Cooling Tower Cells Reactor Valves / Hydraulic System Miscellaneous Equipment

2 68 3 0 1 3 11 3 0 19

4.

Piping (Aboveground)

The Subcontractor will ensure that field fabrication and installation of aboveground piping is accomplished in compliance with project specifications, applicable codes, and contract requirements. a. 1) 2) Procedure Activities within the scope of the ASME Boiler and Pressure Vessel Code or National Board Inspection Code (NBIC) shall be accomplished in accordance with the appropriate ASME Quality Control Systems Manual. Piping systems shall be inspected by the Subcontractor & Construction Site Quality Control Manager as they are fabricated and installed, to assure that the system conforms to the engineering drawings and sketches, specifications, and applicable codes and standards. Isometrics or P&ID's and Piping Plans may be the controlling documents dependent on the engineering design. They are utilized to inspect for proper general arrangement of the piping, valves, instruments, equipment, and accessories. Engineering drawings and specifications shall be used to inspect the work for conformance to designated materials, equipment, supports and hangers, and tests. Piping and associated components shall be visually inspected for the following: Piping - class, size, and identification, valves - Class, identification, orientation, equipment - identification, compliance with specifications and manufacturers' drawings. Pipe supports and hangers - Identification, compliance with specifications and manufacturer's drawings, and a completed marked-up set of engineering drawings showing as-built locations. Fabrication and installation verification of above grade pipe systems shall be carried out by the Subcontractor in accordance with, but not limited to CQP Form B17.01A, Pipe Pre-Test Check-List. Installation errors shall be reported on CQP Form B17.01D and or their equivalent.

15

3)

4)

b. 1) 2) 3)

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 16 of 45

4) 5) 6)

7)

Subcontractor will assure the work is completed and signed off accordingly by qualified Inspector. Final pipe test completion shall be documented in accordance with CQP Form B17.01E Pipe Test Completion Checklist. Welding, post weld heat treatment (PWHT) and nondestructive examination (NDE) of piping systems shall be performed in accordance with specification and applicable codes and standards. Project specific pressure test procedure shall be developed and approved prior to pressure testing that addresses modifications required, release system configuration, valve line-up, vents, restoration, pneumatic concerns, flush requirements, etc. Subcontractor shall complete CQP Form B17.01A, Pre-Pipe Test Record. Attached to the Pre-Pipe Test report will be CQP Form B17.01B, Pipe Test Record, and marked-up P&ID/Isometrics to indicate pressure test boundaries that identifies every line and equipment item tested. These forms will be used as a support documents for the subsequent release of piping for insulation and/or painting. Records and Documentation

c. 1)

2) 3) 4)

One set of drawings shall be kept by the Construction Manager/Field Engineer for inspection and testing records. They will be marked-up to indicate which parts of a piping system have been tested, inspected and found to be in accordance with the specifications, codes and standards, and drawings. Other notes pertaining to the piping system may be included on the P&ID's. Test packages shall be prepared and controlled by the Construction Site Quality Control Manager. When a subcontractor prepares Test packages, The Construction Site Quality Control Manager shall verify that the activity meets the intent of this Plan. Completed documentation will be forwarded to the Field Engineer or Construction Site Quality Control Manager for review and retention in site files. Test Package Content

d.

Subcontractor will generate a piping test package for each piping system segment to be pressure tested, including trim on fixed equipment. Each package will contain pertinent information appropriate to the test. 1) Typical test package contents include: a) Colored set of P&ID's and ISO's (approved for construction) illustrating test boundaries. b) Applicable CQP Forms and or their equivalent, including punch-lists, with signature acceptance from all responsible parties. c) Deviation documentation including any RFI's and "red-lined" drawings

16

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 17 of 45

d) Cleaning / flushing information, if applicable. e) Welding sign-off to confirm completion of welding, PWHT, N.D.E., weld tracking and mapping. f) Reference to any support drawings, or piping specifications. g) Required pressure gauge calibrations. h) Location of piping test blinds and indication of blinds to remain in the line after the test (verify test blind material and thickness with the Field Engineer). i) Location and description of items to be removed from the line for the test. j) Location and description of machinery or equipment to be tested through (verify with the Field Engineer). Although turnover of welding and NDE records as a stand-alone package is preferred, certain projects may contractually require inclusion of applicable welding and NDE documentation into each test pack. This should be confirmed at the start of the project and test packs must be assembled accordingly. e. Test Package Development and Test Control

The Construction Manager shall assure the development of test packs occurs as early as practical in the project. This should begin following final systems definition and mark-up on P&ID's. 1) 2) 3) 4) 5) 6) 7) Test boundaries shall be laid out on P&IDS and ISO's to logically manage testing within each defined turnover system boundary. Test package drawings will be highlighted in color to define test limits. The same color should be used throughout the test package. The Subcontractor will control test package distribution. Usually, two (2) sets of test packages are assembled. One set for field use and one master set that remains in the site QA office file. Field test packages will be signed out to the Subcontractor as the piping to be tested is completed. The test packages must be returned and signed in at the end of each work shift. Office test packages remain in the Quality Control office and shall not be signed out by anyone other than the Construction Site Quality Control Manager. Office test packages are the official sign off documents and bear all original acceptance signatures. Signatures in black ink are preferred. Signatures in pencil are unacceptable. As each piping test segment becomes complete, the Construction Manager must request the quality control department provide a welding and NDE clearance. A pre-test punch (inspection) will be performed before involving the owner. All deficiencies shall be noted and a pre-punch list shall be generated. After all pre-test punch list items have been completed; the punch list must be

17

8)

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 18 of 45

9) 10)

11) 12) 13) f. 1) 2) 3) 4) 5) 5. a.

signed off by the Construction Manager or his/her designee and turned over to the quality control department. The punch list items will be inspected and signed off by the Construction Site Quality Control Manager. The quality control department must then notify the owner for a pre-test approval. All test gauges will be stored and issued in the designated control location and will be visually inspected before and after each use, test gauges must have calibration certifications and be re-calibrated per job specifications. Once the test segment has been reinstated, a post walk down will be performed. All deficiencies shall be noted and a post-punch list shall be generated. After all punch list items have been completed, the punch list must be signed off by the Construction Manager or his/her designee and turned over to the quality control department. The quality control department will then notify the owner for a post-test walk-down. Completed, signed off test packages shall be retained in the project files until turnover to the owner. The Field Engineer or the Construction Manager shall control retention and turnover of test packages to the owner CQP forms for Reference: (if applicable) Form B17.01A, Form B17.01B, Form B17.01C, Form B17.01D, Form B17.01E, Pipe Pre-Test Checklist Pipe Test Record Pipe Test Inclusion Record Pipe Test Punch List Pipe Test Completion Checklist

Instrumentation and Electrical Electrical (Underground)

The Subcontractor is responsible for issuance of cable/termination tickets (or liaison with the project engineering organization when engineering issues the cable/termination tickets), and for maintaining site files for retention of required documentation. 1) Prerequisites a) Prior to the start of duct-bank installation activities, requirements for coordination of inspections and verifications, and associated documentation, shall be established. b) A site procedure should be established for the routing, filing, and retention of completed Inspection Reports, as-built drawings, and other documentation as required by project procedures, specifications, and the CQP for the project.

18

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 19 of 45

c) The Subcontractor will be responsible for generating and maintaining the forms and inter-discipline interface necessary to coordinate the combined electrical and civil activities appropriate to duct-bank installations. 2) Procedure

The Subcontractor shall direct the installation of duct-banks and associated cable pulls in compliance with engineering specifications and drawings and applicable procedures. The progress of duct-bank installation activities shall be maintained by markingup installation drawings or a log in a manner that indicates the following status. Status may be included in Systems Turnover and Reporting (Reference CQP A16) and or equivalent. a) b) Duct-bank work in progress, duct-bank nearly complete, inspected, and ready for cable pull or duct-bank (including cable pull) complete, inspected, and accepted. The Subcontractor and Construction Site QA/QC Manager shall verify the completion and conformance of duct-bank installation activities and document acceptance of the work via signature on the corresponding CQP Forms and or equivalents.

3)

Duct-bank Installation a) b) c) d) The Subcontractor shall direct the installation of the duct-bank in compliance with engineering specifications and drawings and applicable procedures. Form B03.02A, Duct-bank Installation Checklist shall be prepared for each duct-bank installation to identify pertinent data concerning the installation. Duct-bank installations shall be accomplished in accordance with the engineering requirements. The Subcontractor and Construction Site QA/QC Manager shall verify completion and compliance of duct-bank installation activities to engineering requirements and document acceptance of the work via signature on Form B03.02A and or equivalent. Duct-bank Installation Checklist.

e) 4)

Cable Installation

The Construction Supervisor/Engineer shall direct the installation and termination of electrical cables in compliance with engineering specifications, applicable procedures and CQP B18.01 and or equivalent.

19

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 20 of 45

The Subcontractor and Construction Site QA/QC Manager shall assure the following: a) b) c) d) e) f) g) h) i) j) k) l) m) n) o) 5) Verify inter-discipline coordination (Civil & Electrical). Verify correct conduit and associated materials (correct size and type). Verify trench depth and routing per drawings and specifications (trench elevation, location, dimensions and forming). Check for conflicts with other underground construction and ensure trench free of debris. Check conduit sizes, types, location and ensure conduits are properly sloped. Verify rigid steel elbows used for all stub-ups, including PVC runs when required as well as conduit fittings and seals are installed per the engineering design. Verify that the conduit position will allow minimum concrete coverage on all sides of the conduits and conduit spacing, supports and tie downs correct. Verify stub-up dimensions and locations, field bend radius correct per the engineering design and bends free of deformities. Verify caps on conduit ends prior to release for concrete pour and conduit connections tightly made. Confirm all field changes recorded on as-built drawings. Concrete pour report completed to release duct bank for pour (CQP Form B08.02B) and or equivalent. Check that pulling wires are in place, stub-ups have not moved during pour and cable pull rigging is adequate to handle cable. Verify cable reel assignments, cable voltage rating, minimum pulling temperature and pulling compound is compatible with cable to be pulled. Inspect cables for jacket damage before pull and verify direction of pull and method of pulling. Verify the trench is backfilled with the correct material free of stones and debris, to the correct depth and required compaction tests performed.

CQP Forms for Reference: (if applicable) a) Form B03.02A Duct-bank Installation Checklist

20

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 21 of 45

b. 1)

Electrical (Grounding below Grade) Procedure a) The Subcontractor Construction Site QA/QC Manager shall verify completion and compliance of grounding below grade installation and testing activities and indicate acceptance of the work via signature on Form B03.03A, Grounding Below Grade Installation Checklist and Form B03.03B, Ground Rod Installation Checklist. ITO forms shall be signed off as appropriate to indicate acceptance of ITO activities.

b) 2)

Inspection and Verification

The Construction Site QA/QC Manager or qualified designee shall assure the following meet the requirements of project drawings and specifications: a) b) c) d) e) f) g) h) 3) Check ground grid loop cable (correct size and type) and verify proper identification, grounding cable depth and routing per drawings. Check for conflicts with other planned underground construction and connection (thermal/compression). Verify ground well/rod locations and installation per the engineering design and confirm ground rod connections correct. Perform and record continuity test of ground grid per the engineering design. Verify ground rod resistance-to-earth checked and recorded per project requirements. Measure resistance between grounded equipment and nearby known ground after connection to ground grid. Perform as required by the engineering design. Assure grounding excavations are backfilled with the correct material and backfill to the correct elevation and required compaction tests performed. Assure any required grounding markers are in place.

Subcontracted Work

During grounding below grade installation and testing activities, Field Engineer/Construction Site QA/QC Manager shall monitor and verify the subcontractor's work for compliance with engineering requirements and applicable procedures. As a minimum, this shall include: a) b) When subcontractors are working to this Construction Plan, compliance shall be maintained to the applicable sections of this manual, as required by the contract. When subcontractors implement their own program for control of the

21

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 22 of 45

work, the Construction Site QA/QC Manager or designee shall verify compliance with that program. Installation, verification and testing activities shall be documented in accordance with this plan or the subcontractors own program for control of the work as required by contract. The Construction Site QA/QC Manager shall assure the implementation of this program consistent with the engineering design and the contract. 4) a. b. c. 1) CQP Forms for Reference: (if applicable) Form B03.03A Grounding below Grade Installation Checklist Form B03.03B Ground Rod Installation Checklist Electrical (General Electrical Equipment Installation) Procedure

The Electrical Subcontractor shall assure that electrical equipment is installed in accordance with applicable specifications and drawings. As a minimum, this shall include the following: a) Verification that equipment installations and tests are in accordance with applicable project drawings, specifications and applicable vendor requirements. Documentation of inspection activities shall be in accordance with applicable CQP, Vendor Manuals, and applicable Commissioning/ Startup Procedures. When required, verification that equipment conforms to manufacturers' drawings. Ensuring that preventative maintenance is performed in accordance with (CQP A14) and or equivalent. Resolution of any nonconforming items or conditions in accordance with (CQP A06) and or equivalent. Assuring that foundation or structure is released for setting equipment.

b) c) d) e) 2)

Equipment Completion and Release a) CQP Form B18.02A, General Electrical Equipment Installation Checklist shall be prepared for each piece of major electrical equipment as listed on the project equipment list and for any piece of major electrical equipment which is being reinstalled in a different or relocated service. In such cases, the record should reflect complete information associated with the change. Additions or changes to existing CQP forms may be necessary to address

b)

22

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 23 of 45

c)

the specific inspection requirements associated certain types of major electrical equipment. Changes shall be accomplished in accordance with (CQP A08). Each record shall be originated by the Subcontractor, who shall complete the applicable portions of the record once the equipment is released to the field for installation. The record shall be maintained during the course of installation, properly signed and dated by the respective responsible person. The Subcontractor, in coordination with the Field Engineer and/or the Construction Site QA/QC Manager will ensure that each item of work is signed and released prior to allowing the next step to begin. Completed records will be forwarded to the Field Engineer or Construction Site QA/QC Manager for review and retention.

3)

Completed "Equipment Installation Records" will provide the following information: a) b) c) d) e) f) g) h) i) j) k) l) m) n) o) A record of each piece of equipment, its manufacturer, and its characteristics. Signatures indicating that the equipment has been properly set, assembled, connected, tested, and accepted. Information required by the materials management and project controls groups for completion of required records and reports. Permanent, complete equipment record for the Owner's operations and maintenance organizations. Attached test reports including any construction related documents required by the equipment manufacturer's representative. Check equipment nameplate details with data sheet. Verify hazardous area classification (if applicable). Inspect for mechanical damage and note all damages. Verify equipment is mounted and anchored and grounded in accordance with drawings and Mfg. Instructions. Verify all shipping stops, bracing and packing is removed, cables are correctly installed, terminated and labeled. Verify spare entries are blanked/plugged with the correct fittings. Verify Megger check or other electrical tests are accepted. Verify Unit is internally and externally clean and covers are securely fastened with all screws. Verify that equipment tagging is installed and visible, warning labels/placards are installed and visible. Verify instrumentation installation is complete and accepted

23

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 24 of 45

4)

Test Records a) The applicable test records /other pertinent CQP forms shall be completed by the Subcontractor or designee for each piece of electrical equipment identified in the project equipment list. These forms can be found in the CQP or Start-Up manuals. The completed reports will be forwarded to the Field Engineer or Construction Site QA/QC Manager for review and retention. These reports shall be filed with Form B18.02A, General Electrical Equipment Installation Checklist.

5)

Records Retention a) b) Copies of proprietary forms required by equipment suppliers/erectors shall be obtained by the Subcontractor and forwarded to the Field Engineer or Construction Site QA/QC Manager for review and retention. Completed documentation shall be retained by the Field Engineer or Construction QA/QC Manager.

6)

CQP Forms for Reference: (if applicable) a) Form B18.02A, General Electrical Equipment Installation Checklist

d. 1)

Instrumentation Responsibilities a) The Field Engineer is responsible for resolution of instrumentation installation and calibration issues with the project engineering organization, and the Startup Manager.

2)

Procedure a) The Subcontractor or designee, in coordination with the Construction Site QA/QC Manager or Field Engineer, shall verify completion and compliance of Instrumentation installation and calibration activities and indicate acceptance of the work via signature on the appropriate CQP forms as referenced in 7.0 of this procedure. Instrumentation loop checkout and testing shall be accomplished in accordance with project the appropriate Startup procedures. Installation of each instrument and loop shall be documented by the Subcontractor on Form B19.01A, Instrument Field Installation Check List and or equivalent. Each loop will be inspected for compliance with the engineering design, as the work progresses, by the Subcontractor or Construction Site QA/QC Manager. Each instrument or loop will then be calibrated as required by the engineering design. Calibration shall be

24

b) c)

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 25 of 45

documented on Forms B19.01B Instrument Pressure/Leak Test Report, B19.01C Instrumentation Punch List Record, B19.01D Instrument Calibration Report, B19.01E Control Valve Calibration Report, B19.01F Pressure Relief Valve Calibration Report and B19.01G Orifice Plate Inspection Report and or equivalent as appropriate for the activity. 3) General Instrument Installation Checks a) Verify that the proper instruments are installed, and that auxiliary equipment, e.g., solenoid valves, position switches, positioners, air sets, etc., are properly installed, flow elements properly oriented and process pressure taps piped to the correct instrument ports, in accordance with the design drawings. Instrument stands and racks are the correct type, and are properly located and secured. Instrument wiring and terminations, and/or piping, tubing, and fittings conform to specifications and instrument design. Process analyzers/transmitters are properly mounted, wired, and piped. Field run control loops are checked for proper mounting, wiring and/or piping thermowells are properly installed. Control valves are in the correct location and properly oriented. Drains, purges, vents, winterizing, and root/isolation valves are properly installed. Control wiring is properly pulled, terminated, and identified. Scales and charts are correct, as specified. Tubing is free of kinks and dimples, minimum bend radii are maintained, and proper flexibility allowed for expansion or movement. Cable and/or tube bundles are properly routed, supported, protected from damage, separated, and identified. Cutting, deburring, cleanliness, and seals for process instrument tubing are in accordance with the specification. Junction/marshalling boxes are properly fabricated and located per specifications. Valves, positioners, brackets, and stem clamps are secure. Verify that all instruments are installed to allow access for calibration and maintenance, all required test connections are properly installed, and instruments and tubing are adequately supported. Verify that all loop components have been properly and permanently installed, that all flex and conduit connections are complete and fittings are secure, that all panel and device covers are properly installed, drain lines are complete, that all equipment and cables are properly identified, and that all components are free from visual damage and contamination. Verify that the instrument primary sensing and pneumatic piping has been checked for continuity, blown down and leak tested, or perform

b) c) d) e) f) g) h) i) j) k) l) m) n) o) p)

q)

25

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 26 of 45

r) s)

these tests at this time. Verify the instrument sensing lines slope in the proper direction, in accordance with applicable installation detail. Verify that all instrument devices are identified with instrument mark number stamped on metal tags. Tags shall be attached in accordance with project requirements. Construction Tests and Calibration

4)

a) b) c) 5)

Pneumatic portion of loops are visually inspected and soap tested for leaks. Thermocouple connections are checked to ensure that similar metals are connected. Instruments are field calibrated for mechanical and electrical operation as defined by the limited scope of Construction responsibility.

Instrument Device Calibration a) Calibration shall include all plant instrumentation, all factory calibrated and factory installed skid mounted and equipment mounted instrumentation after complete installation. This includes instruments on the instrument list and any instruments added during startup. The technician shall calibrate, re-calibrate, re-zero, adjust, re-span, repair, and replace, if necessary, instruments as required to ensure all plant instruments and control loops function as designed at the time of plant turnover to the Owner. Instruments shall be bench calibrated when received and field calibrated after tubing and cables have been terminated. Best to check with GG to see if well have a bench lab set up. A clean enclosed area shall be provided complete with a calibration bench and storage shelves for test equipment and instrument storage. A records file system shall be maintained for all instrument calibration records and instrument test equipment calibration records. All instruments calibration set-points and ranges shall be obtained from the Instrument Data Sheet when available or from the manufacturer instruction manual. All instrument device calibration data (set-points/ranges) shall be recorded on the appropriate Instrument Calibration Data Sheet. After each instrument is calibrated, a calibration "sticker" shall be placed on the instrument for verification of calibration.

b) c) d)

26

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 27 of 45

6)

Instrumentation Checkout a) Startup Group or instrumentation subcontractor will typically be responsible for all checkout, configuration changes and logic verification.

7)

Rework a) Items requiring rework shall be documented on Form B19.01C, Instrumentation Punch List Record. Items, which cannot be reworked within the requirements of the drawings or specifications, shall be processed for resolution in accordance with CQP A06.

8)

Subcontracted Work a) During instrumentation installation, calibration, testing and loop check activities; the Field Engineer or the Construction Site QA/QC Manager shall monitor and verify the subcontractor's construction related work for compliance with engineering requirements and applicable procedures. As a minimum, this shall include: When subcontractors are working to this Construction Plan, compliance shall be maintained to the applicable sections of this plan, as required by the contract. When subcontractors implement their own program for control of the work, the Construction Site QA/QC Manager or designee shall verify compliance with that program. Installation, calibration, and verification, shall be documented in accordance with this plan or the subcontractors own program for control of the work as required by contract. The Construction Site QA/QC Manager shall assure the implementation of this program consistent with the engineering design and the contract.

b) c) d) e) 9)

Records a) The records system as agreed with the Owner and Startup Manager shall be used and maintained to provide for the identification and correlation of installation, test and inspection records. Each instrument calibration data shall be recorded on a separate instrument calibration data sheet. Upon completion, required documentation will be submitted to the Field Engineer for review and retention in accordance with project procedures. As needed, loop check folders shall be developed in accordance with project procedures. The following are typical contents of a loop check folder: P&ID with loop identified (color highlighted). Loop Diagrams.

27

b) c) d)

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 28 of 45

e) f) g) h) i) j) k)

Instrument Data Sheets. Instrument Calibration Records. Instrument Calibration Set Points and Ranges. Appropriate CQP Forms (complete and signed). Applicable Startup Forms (complete and signed) Specific Loop-check Instructions. Instrumentation Punch list Record (complete and signed off).

10) CQP Forms for Reference: (if applicable) a) b) c) d) e) f) e. Form B19.01A, Form B19.01B, Form B19.01 C, Form B19.01 D, Form B 19.01E, Form B19.01G, Instrument Field Installation Check List Instrument Pressure / Leak Test Report Instrumentation Punch list Record Instrument Calibration Report Control Valve Calibration Report Orifice Plate Inspection Report

Scaffolding

A specialty subcontract will be utilized to provide supervision, labor, and materials for the erection and dismantling of all required construction scaffolds. The subcontractor will adhere to the Ventech and Terras safety policies. The subcontractor will provide these services in a manner, which supports the overall projects schedule. The scaffolding subcontractor will have the ability to provide engineering support as required for any scaffolds that extend higher than typical erection standards allow (i.e. scaffolds greater than 120 in height). f. Paint and Coatings

Paint will be handled as a Supply, Assemble, and Erect type subcontract, including material supply/storage, material take-off, quality application of required coating components, and supervision. Any removal from the site of generated waste as a result of painting and coating activities will be coordinated under the direction of Terra. g. Insulation

Insulation will be handled as a Supply, Assemble, and Erect type subcontract, including some phases of detailed engineering (application of the insulation specifications to project generated piping and equipment drawings), material supply/storage, and material take-off, fabrication/assembly of the insulation components, erection and supervision.

28

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 29 of 45

h.

Specialty Installation Subcontract(s)

From time to time specialty installations may be identified that will be subcontracted; these types of installations might include Cathodic Protection, Fencing, PWHT or Preheat services, Fiber Optic, etc. i. Site Service Subcontract(s)

Site Services Subcontracts or local procurement efforts may be anticipated to include the following: 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 6. Field Offices / Trailers; Geotechnical Survey & Engineering Services; Service Contracts for Civil Testing & NDE; Service Contracts for Mechanical Testing, X-Ray, & NDE; Concrete Pumping; Dump Truck Services (onsite); Authorized Inspection (AI) Services; High Voltage Electrical Testing (Hi-Pot); Specialty Instrumentation Testing or Independent Third Party Testing; Portable Sanitary Service; Equipment Tire Repair; Pipe Machining / Cutting / Bolt Torque / Hot Taps; Traffic Control if needed;

Construction Organization a. Construction Manager (CM)

The Construction Manager is responsible for coordinating all aspects of interfaces between Ventech and other interfacing parties (Major / Minor Subcontractors, Client, etc.). The Construction Manager reports directly to the Project Manager and is the senior construction representative onsite. In addition to the responsibilities associated with the Interface Coordination for the project, the CMs responsibilities will also include overseeing administration, controls, safety programs, onsite material procurement/control, subcontract administration and coordinating construction execution, along with being responsible for the final turn-over of all systems for the project to the customer. The Construction Manager will also be responsible for the oversight of all field erection activities to ensure that they support quality, safety, labor relations, productivity of the workforce, resource planning (for manpower, material, and engineering deliverables availability), work progress reporting, construction equipment planning/usage, coordination of the work between the various crafts and adherence to work plans and schedules.

29

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 30 of 45

Construction Manager reports directly to the Manager of Projects and Ventechs Construction Operations Manager. b. General Superintendent (GS)

General Superintendents are responsible for the oversight of all field subcontracted activities including erection, installation, and support including quality, safety, labor relations, productivity of the workforce, resource planning (for manpower reviews, material management, and engineering deliverables availability), work progress reporting, construction equipment planning/usage, coordination of the work between the various crafts and adherence to work plans and schedules. General Superintendents report directly to the Construction Manager. c. Superintendents

Superintendents are responsible for the overview of all discipline related field subcontracted activities including erection, installation, and support including quality, safety, labor relations, productivity of the workforce, resource planning (for manpower reviews, material management, work progress reporting, construction equipment planning/usage, coordination of the work between the various crafts and adherence to work plans and schedules. Superintendents report directly to the CM administratively and will report functional to the GS for work associated within their respective disciplines. For this project, superintendent positions are anticipated to include: 1) Mechanical Superintendent (Equipment installation and erection), 2) Piping Superintendent (underground and aboveground piping installation) 3) Electrical & Instrument Superintendent (Electrical/Instrumentation power and control systems), 4) Civil/Structural Superintendent (civil support for underground piping & electrical, foundations, dirt work, grouting), d. Project Controls Manager (PCM)

The Project Controls Manager (PCM) is responsible for the construction execution for the project, including all field controls processes at the site, such as cost monitoring, scheduling, progress measurement, and the associated reporting. This manager and his staff track cost against the field budgets, ensures that the tracking of physical progress is incorporated into the reports, predicts trends and forecast construction cost, monitors and reports progress against the schedule, ensures field schedules are prepared and advises of variances. The Project

30

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 31 of 45

Controls Manager reports directly to the Manager of Projects but will report administratively to the CM and is located at the site during construction. e. Field Project Engineer (FPE)

The Field Project Engineer (also referred to as the Field Engineer) is responsible for the planning, set up, and operation of technical data document control, interface with engineering resolution/liaison (using the Request for Information RFI) / Nonconformance Report (NCR) / Field Change Order (FCO) process), constructability, and system turnover reporting in association with the Systems Turn-Over process. The Field Project Engineer is also responsible for all field engineering, survey layout, and coordinates the vendor field representative requirements. The Field Project Engineer will also coordinate representatives from the Engineering group who may need to visit the site to provide immediate assistance and answers to technical construction issues when required. The FPE is responsible to develop and maintain as-built records for engineering follow-up. The FPE is responsible for reviewing IFC drawings and modifications to initiate the Change Tracking Process for the project. The Field Project Engineer reports directly to the CM. Responsible for developing requisitions for field required materials and verifying these have not already been procured by the home office. f. Site HSE Manager (SHSEM)

Site HSE Manager is responsible for supervising the health, safety, environmental and security programs including inspections, training and communication, corrective action follow up, incident investigations, adherence to the clients substance abuse program, MSDS procedures, and reporting for all subcontractors. The HSE Manager will be the primary contact for all safety, environmental, and security issues at the construction site for all of the subcontractors. The HSE Manager will develop HSE procedures and site-specific requirements. The HSE Manager reports directly to the Construction Manager in matters related to the administration of the HSE Program at the site and the Ventech Corporate Safety Manager. g. Site Quality Assurance Manager (SQM)

Site QA/QC Manager is responsible for managing the site quality assurance and oversight of the contractors quality control department. The QA/QC Manager oversees department staff, inspector assignments, the site quality programs, and coordinates testing (NDE) subcontract requirements. The site QA/QC staff is responsible for review of all quality control programs, quality training programs, and audit of all Ventech and Subcontractor work for compliance with standards,

31

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 32 of 45

reporting non-conformances, and assuring that all inspection documentation is in order for turnover to client. The Site QA/QC Manager reports directly to the CM in matters related to the administration of the QA/QC Program at the site and the Corporate Manager of QA/QC. h. Site Subcontracts Manager (SSM)

The Site Subcontracts Manager is responsible for the administration of all subcontracts and the coordination of subcontracted work activities. For subcontract inquiries issued in the field, the manager will prepare inquiry documents, bidder evaluations, recommendations for award, monitor subcontractors for progress, schedule, and any related HSE or Quality issues. The Site Subcontracts Manager, will be the primary contact for all contractual issues, notices, and responsibilities associated with the respective contractors. The Site Subcontracts Manager will process subcontractors billing for payments and resolve any contractual issues. The Site Subcontracts Manager reports directly to the CM in matters related to the subcontract execution at site and the Corporate Subcontracts Manager. The development of bidders list, and the respective contractual documents for all subcontracts issued for the project will be developed, inquired, evaluated and awarded based on Subcontract Procedures that are to be individualized for the EPCM contract terms and conditions. i. Materials Manager

The Materials Manager is responsible for field management of materials for the project. This manager reports directly to the CM, and is responsible for the procurement, material receiving reporting (MRR), and expediting material requirements for the subcontracted field construction forces. 7. Health, Safety, and Environment Site Plan

Ventech is committed to a goal of zero safety incidents, both in the field and in the home office. This applies to all Ventech, Subcontractors and Terra personnel, as well as any other participants in the project. The execution of the construction HSE program will be based on an established, written HSE program that has been reviewed and accepted by the Owner prior to start of activities in the field. This program will contain the Ventechs Site Specific HSE plan, policies, and procedures for implementing project requirements, and will incorporate Terra Intl facility requirements.

32

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 33 of 45

All work performed at the project site will be preformed in accordance within policies and procedures established by the project safety program and will meet or exceed any federal or local regulatory requirements. In order to obtain the best possible HSE results it is recognized that it is necessary to establish a safety culture and atmosphere where supervisors and workers are trained to analyze the tasks to be performed, identify and eliminate the hazards/risks, and communicate with each other how to perform the job safely. Supervisors will be trained to recognize and correct unsafe acts and conditions. A system will be set in place to document observations and to pro-actively track/identify trends in HSE performance. Several key or important items that will be included in the HSE program include: a. b. c. d. Ventechs Safety Procedures and Best Practices, Safety Task Analysis (STA) Pre Task Plan / Analysis Employee Based Safety (EBS / POP) Safe Behavior Observations Employee Safety Recognition Program

While a program for safety analysis and task observation is key to the success of the HSE results, the HSE Program, itself, must be based on a Site HSE Philosophy that is strictly adhered to during the construction phase. These philosophies will include the projects requirements for: a. Safety policy and objectives; b. Organizational structure and Manpower Resources with regard to safety responsibilities; c. Systems and procedures to carry out safety objectives at all stages of the project; d. Means of monitoring and reporting safety performance; e. Safety communications, meetings, and discussion on safety issues; f. Safety Audit Program(s) to be performed by the Contractors; g. Safety Orientation/Induction and Safety Training Program; and, h. Safe Work Procedures Within these project philosophies, the written HSE plan will be developed and implemented on the project. The Terra UAN Expansion Project will require a specific Site Health, Safety, Environmental Plan, which will be developed (made project specific) and implemented for the project construction site.

33

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 34 of 45

a.

HSE Plan

This written HSE Plan addresses topics and subjects as follows: 1) Health, Safety & Environmental Policy; 2) First Aid / Medical Facilities, Accident Investigation and Recordkeeping; 3) HSE Education and Training; 4) Housekeeping and Sanitation; 5) Vehicles and Equipment; 6) HSE and Health Requirements; 7) Fire Prevention / Protection; 8) Hazardous Operation and Work Permits; 9) Emergency Procedures; 10) Environmental Hazards ; Any employee, who disregards the rules, thus exposing himself and his fellow workers to major incident risk, will be subject to disciplinary actions. Furthermore, it is Ventechs policy to encourage proposals from its employees on how to maintain and improve standard of health and safety within the work environment. b. Environmental

The site construction team is responsible for adherence to and operating under all the jurisdictional environmental laws, regulations, including permitting conditions, and any owner established requirements for the construction project. The following are specific areas of concern that will have project specific procedures developed during the preconstruction phase of the project, for implementation during the construction project: 1) Pre-job Orientation Meetings

Ventech and subcontractors will be required to attend pre-job meetings to discuss environmental issues and obligations relating to the job prior to initiating work activities. c. Security

It is expected that Terra Intl will provide security personnel to maintain the integrity of the perimeter plant security. Other project security will be subcontracted to provide normal access control to the construction facility and to ensure control of construction related equipment and materials. During the preconstruction phase of the project, a security plan will be developed for the construction site which includes the following security issues, procedure, and standing orders.

34

Clients Name: Terra International Projects Name: UAN Expansion Project Project No.: 4686-011 Date: 7/28/09 Page: 35 of 45

1) Security Scope and Goals 2) Security Personnel 3) Security Patrols 4) Emergency Communication, Power and Lighting 5) Entry/Exit to/from the ISBL site 6) Entry Authorizations 7) Site Access by Visitors; 8) Material Exit Authorization 9) Site Access by Contractor Vehicles 10) Site Access by Employees 11) Site Access by Private Vehicles 12) Employee Screening for Alcohol and Drugs 13) Parking Lots & Employee Transportation 14) Warehouse & Storage areas 15) Animal & Insect Control Procedures 16) Emergency & Contingency Plans & Procedures d. General Lifting Requirements