Professional Documents

Culture Documents

Steel Ball MFG Process

Uploaded by

Ravi Sharma M POriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Ball MFG Process

Uploaded by

Ravi Sharma M PCopyright:

Available Formats

Gmail - Fw: ball mfg process

https://mail.google.com/mail/?ui=2&ik=db8fff3f41&view=pt&search=...

Ravi Sharma M P <mpautobe@gmail.com>

Fw: ball mfg process

1 message Ravisharma.MP@brakesindia.co.in <Ravisharma.MP@brakesindia.co.in> To: mpautobe@gmail.com

----- Forwarded by MP Ravisharma/QA/CORP/BIL on 02/07/2012 04:33 PM ----From: G Rajavel/QA/CORP/BIL

Tue, Feb 7, 2012 at 4:33 PM

To: R Sajeesh/QA/CORP/BIL@brakesindia.co.in Cc: AP Sakthivel/QA/CORP/BIL@brakesindia.co.in, IT Santhosh/QA/CORP/BIL@brakesindia.co.in, MP Ravisharma/QA/CORP/BIL@ brakesindia.co.in, NK_Ashokkumaran@brakesindia.co.in, S Balamurugan/QA/CORP/BIL@brakesindia.co.in, S Nithyanandham/QA/CORP/BIL@ brakesindia.co.in, V Kandaswamy/QA/CORP/BIL@brakesindia.co.in Date: 09/30/2011 01:17 PM Subject: Re: ball mfg process

This is another PFD for ball mfg.

Thanks & Regards, Rajavel G Corporate Quality Assurance - SQA Brakes India Ltd.,Padi, Chennai 600050 Ph.: +91-44-26526478 Mobile:+91-9786964984 Web : www.brakesindia.com

E-Mail: rajavel.g@brakesindia.co.in

From: N Chandrasekaran/QA/CORP/BIL To: V Kandaswamy/QA/CORP/BIL@brakesindia.co.in, NK_Ashokkumaran@brakesindia.co.in, G Rajavel/QA/CORP/BIL@brakesindia.co.in, MP Ravisharma/QA/CORP/BIL@brakesindia.co.in, AP Sakthivel/QA/CORP/BIL@brakesindia.co.in, IT Santhosh/QA/CORP/BIL@brakesindia.co.in, S Nithyanandham/QA/CORP/BIL@brakesindia.co.in, S Balamurugan/QA/CORP/BIL@brakesindia.co.in Date: 09/30/2011 01:12 PM Subject: ball mfg process

Manufacturing

1 of 3

07-02-2012 21:54

Gmail - Fw: ball mfg process

https://mail.google.com/mail/?ui=2&ik=db8fff3f41&view=pt&search=...

Abbott manufactures over five billion balls each year in a range of sizes and materials. Most are of stainless or carbon steel, while the rest are from brass, aluminum, chrome steel, precious metals, and offers glass and plastic. Abbott has a special department devoted to the manufacture of precious metal balls, including gold, silver, platinum, palladium, titanium and specialized alloys, for uses such as electrical contacts, switches, relays, brazing and jewelry. Each material has unique production requirements, but the process is generally similar and has been refined over decades for efficiency and uniform quality. All Abbott processes and policies are designed for maximum quality. Defects are so rare that we measure them in parts per million, and we won't be satisfied until we find none. Every ball passes through exacting inspections that automatically detect and remove off-spec balls. A significant number of random samples is tested for hardness and examined microscopically for structure and finish. Only when we know that customers will be satisfied do we impart the Abbott Ball name to our products. Abbott's high standards for quality and value also apply to the extensive line of metal burnishing media that we manufacture.

How a Ball is Made

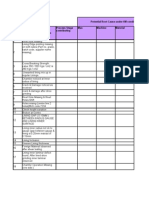

Heading: In the first step, heading machines cut wire into short lengths and form it into spherical shapes between dies.

2 of 3

07-02-2012 21:54

Gmail - Fw: ball mfg process

https://mail.google.com/mail/?ui=2&ik=db8fff3f41&view=pt&search=...

Deflashing: The flash line, a ridge left by the forming dies, is removed as balls roll between heavy, cast iron plates. Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision. Heat-treating: Carbon steel balls are next carburized and hardened. Heat treatment imparts the desired hardness and case depth. Descaling: This step removes the residues and by-products from the heat-treating process. Hard Grinding: Slow, meticulous grinding assures proper sizing and sphericity, with tolerances as close as .0001". Lapping: Several proprietary lapping processes can bring balls to the requirements of ISO 3290 Grade 10 - 48. Finishing: Proprietary chemical and mechanical processes give the balls their final microsmoothed finish, for increased wear resistance and product longevity. Inspection: All products pass through at least two 100% inspection stages, using proprietary, automated inspection processes.

Regards R.sajeesh

20110930131354931.pdf 100K

3 of 3

07-02-2012 21:54

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Paraff 1 - Plating TestDocument4 pagesParaff 1 - Plating TestRavi Sharma M PNo ratings yet

- 3 Metal StampingDocument2 pages3 Metal StampingRavi Sharma M PNo ratings yet

- Failure ModesDocument9 pagesFailure ModesRavi Sharma M PNo ratings yet

- SGSYDocument7 pagesSGSYnifa_lko8420No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Materials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraDocument80 pagesMaterials of Construction and Selection: Faculty of Chemical Engineering Universiti Teknologi MaraAisyah Addia AzizanNo ratings yet

- Roe - 086 - 20200325 PDFDocument11 pagesRoe - 086 - 20200325 PDFAnkit SrivastavaNo ratings yet

- Comparison of The Use of Rutile and Cellulosic Electrodes - TWIDocument11 pagesComparison of The Use of Rutile and Cellulosic Electrodes - TWISumantaNo ratings yet

- Assay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDocument3 pagesAssay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDinesh ThakkarNo ratings yet

- Technical Datasheet: LDPE 2101TN00WDocument16 pagesTechnical Datasheet: LDPE 2101TN00WjavadmohammadiNo ratings yet

- CATALOG Uniweld-Products TYPE17-2Document13 pagesCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungNo ratings yet

- Filter DataDocument6 pagesFilter DataJohnNo ratings yet

- ECE 6401: MEMS Design & Micromachining: Working Principle of MicrosystemsDocument11 pagesECE 6401: MEMS Design & Micromachining: Working Principle of MicrosystemsAbcNo ratings yet

- 2 Tutorial Pressure Sept19Document7 pages2 Tutorial Pressure Sept19hairinnisaNo ratings yet

- Epoxy Curing Agents and ModifiersDocument3 pagesEpoxy Curing Agents and ModifiersNissim Hazar CasanovaNo ratings yet

- WellLock Resin Rigless Micro Channel Remediation H011331Document1 pageWellLock Resin Rigless Micro Channel Remediation H011331bagus918No ratings yet

- Properties of Fluids PDFDocument24 pagesProperties of Fluids PDFAnthony Leire MontealtoNo ratings yet

- Jarit CV Catalog NS1888 04 08 PDFDocument285 pagesJarit CV Catalog NS1888 04 08 PDFFabian Andres GiraldoNo ratings yet

- Polywithe® - 8000 CLDocument1 pagePolywithe® - 8000 CLsébastien cardinaleNo ratings yet

- 263 269 JMTR Oct16Document7 pages263 269 JMTR Oct16Taniadi SuriaNo ratings yet

- Chemical Dimension of TasteDocument31 pagesChemical Dimension of Tastemaithili joshiNo ratings yet

- Manufacture of RadiopharmaceuticalsDocument9 pagesManufacture of RadiopharmaceuticalsRainMan75No ratings yet

- Catalogue CSM PDFDocument4 pagesCatalogue CSM PDFFran IgledominguezNo ratings yet

- AWS A5.7-84 Specification For Copper and Copper Alloy Bare Welding Rods and Electrodes R (1991)Document17 pagesAWS A5.7-84 Specification For Copper and Copper Alloy Bare Welding Rods and Electrodes R (1991)HenryNo ratings yet

- Naval Reactor Handbook Vol 3Document523 pagesNaval Reactor Handbook Vol 3Peter AngeloNo ratings yet

- Pneumatic Bench Vice Project-Report PDFDocument30 pagesPneumatic Bench Vice Project-Report PDFrahul bhatt100% (4)

- Ga Enu PDFDocument185 pagesGa Enu PDFFebriyono Ade PutraNo ratings yet

- UntitledDocument27 pagesUntitledapi-256504985No ratings yet

- ECE OLED TechnologyDocument22 pagesECE OLED Technologygourav VermaNo ratings yet

- Double Replacement Cep Lesson PlanDocument8 pagesDouble Replacement Cep Lesson Planapi-666239354No ratings yet

- Solar Refrigeration ReportDocument21 pagesSolar Refrigeration ReportCj MoLanoNo ratings yet

- Development and Validation of RP-HPLC Method For The Estimation of Trimetazidine in Bulk and Pharmaceutical Dosage FormDocument10 pagesDevelopment and Validation of RP-HPLC Method For The Estimation of Trimetazidine in Bulk and Pharmaceutical Dosage FormAshish TapadiyaNo ratings yet

- Chapter 4. Condensation PolymerizationDocument51 pagesChapter 4. Condensation PolymerizationSaifuddin AzizNo ratings yet

- Science Reviewer 3rd GradingDocument7 pagesScience Reviewer 3rd GradingSean Irvin MirandaNo ratings yet

- How Do I Layer The Ordinary Skincare ProductsDocument3 pagesHow Do I Layer The Ordinary Skincare Productsdiana fenichiuNo ratings yet