Professional Documents

Culture Documents

QA QC Plan ACL PQP 02

Uploaded by

isukuruOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA QC Plan ACL PQP 02

Uploaded by

isukuruCopyright:

Available Formats

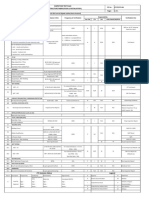

QUALITY ASSURANCE / QUALITY CONTROL PLAN

ATS-QA/QC-PLAN ACL-PQP-02/01

Rev.

Date

ATS

Contr.

Client

01 ATS Signature: Name: Date:

For presentation Contractor Signature: Name: Date:

Client Signature: Name: Date:

Page 1 of 7

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 2 of 7

CONSTRUCTION QUALITY ASSURANCE / QUALITY COTROL PLAN

One of the main priorities of AKKILA COMPANY LIMITED is to maintain high quality of the works and to improve continuously the Quality System. The present manual covers all construction quality assurance and quality control procedures, practices and documentation, as follows: 1. 2. 3. 4. Preparation and updating of Construction QA/QC plan including: Description of procedures and standard practices, QA/QC responsibility matrices and document flow, Inspection report forms, Preparation and qualification of welding procedures. Qualification of welders. Field quality control, including: Traceability during fabrication and erection works, Control of compliance with relevant procedures, Visual inspection, Radiographic inspection, Ultrasonic inspection, Magnetic particle inspection, Liquid penetrant inspection, Preparation of welding books and welding inspection reports, Supervision of pipeline/flow line pigging and gauging, Supervision of hydrostatic testing, Completion of the documentation, PROCEDURES AND STANDARD PRACTICES In order to provide the assurance of the quality, the following procedures and standard practices are applied: Standard practice for visual examination, Standard practice for radiography, Standard practice for liquid penetration examination, Standard practice for magnetic particle inspection, Standard practice for ultrasonic testing, Standard practice for bending,

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 3 of 7

Hydrotesting procedure, Standard practice for surface preparation and painting inspection Standard practice for tank and vessel cleaning; Standard practice for lowering pipe into trench, trench padding and backfilling, Standard practice for tank construction & erection Welding procedures,

All these documents are based on the applicable codes and standards, such as ASME Section V, ASME Section VIII, ASME Section IX, ANSI/ASME B31.3, B31.4, B31.8, API Standard 1104, etc., as well as on the schedules and specifications of Client. The procedures and standard practices are included in Part I of the Construction QA/QC plan.

RESPONSIBILITY MATRICES AND DOCUMENT FLOW

The responsibility matrices and document flow tables are included in Part II of the Plan. They are the following: Pipeline / flowline Responsibility Matrix and Document Flow.

The Responsibility Matrix (Mat 01-PL) shows the responsibilities of the QA/QC staff, pipeline engineers, foremen, and material men in the quality control process during all stages of construction, namely: Right of way, Stringing, Bending, Trenching, Welding NDT/NDE, Coating, Lowering-in, Backfilling, Hydrostatic testing, Reinstatement. The Document Flow Table (Doc 01-PL) shows the way of preparation, signing, and distribution of the QA/QC documents, related to the process, namely: visual, dye-pen and radiographic inspection reports, trench inspection, joint insulation, lowering and backfilling reports, report for welding defects, orders for repair, pigging and hydrotesting reports. In-plant piping Responsibility Matrix and Document Flow.

The Responsibility Matrix (Mat 02-in) shows the responsibility of the QA/QC staff, piping engineers, foremen, and material men in the quality control process during all in-plant piping fabrication and erection, namely: sorting of materials (material dedication), preparation for prefabrication, welding, NDT/NDE sandblasting, painting, erection (incl. Field welding), hydrostatic testing and reinstatement.

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 4 of 7

The Document Flow Table (Doc 02-in) shows the way of preparation, signing and distribution of the following documents related to prefabrication and erection of the plant piping: visual, dye- pen. and radiographic reports, coating reports, progress reports, welding inspection reports, hydrotesting reports.

REPORT FORMS

The report forms are included in Part III of the plan, divided into 5 topics: Welding, NDT, Hydrotest. Pipeline / Flowing / In-Plant. Mechanical. Civil. Instrumentation.

The forms were prepared on the grounds of the recommendations given by related codes and standards, and in compliance with the good field practice.

PREPARATION AND QUALIFICATION OF WELDING PROCEDURES

The preparation and qualification of the welding procedures is carried out by Welding /NDE (Non-Destructive Evaluation) Group (see fig.1) in accordance with the requirements of ASME IX, API Standard 1104, ANSI/ASME B31.3, B31.4, B31.8, AWS D1.1, etc. There are 10 welding procedures covering most of the pipeline and in-plant piping construction activities. These procedures are prepared by AKKILA COMPANY LIMITED QA/QC engineers and qualified under the supervision of RWTUV. They are included in Part I of the Plan. Any further qualification of a procedure that may appear necessary for a job will be prepared by experienced welding engineers and submitted to the Client for approval. After being approved by the Client, the procedure will be carried out in the fabrication yard by experienced welders under the supervision of welding inspectors from both AKKILA COMPANY LIMITED QA/QC Department and the Client, Certified materials and consumables shall be used. The mechanical testing will take place in authorized laboratory, approved by the Client.

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 5 of 7

QUALIFICATION OF WELDERS

The welders testing and qualification is carried out by the Welding/ NDE Group (see fig.1). The qualification of welders under the qualified welding procedures is carried out according to the requirements of ASME IX API Standard 1104, ANSI/ASME B31.3, B31.4, B31.8, AWS D1.1, etc The testing takes place in the fabrication yard under the supervision of welding inspectors from both AKKILA COMPANY LIMITED Group and the Client. Certified materials and consumables are used. Welders Performance Test Record is prepared and signed for the successful welders. The welders are provided with ID cards for the duration of the works.

FIELD QUALITY CONTROL

The field quality control is carried out by the Field Inspection Group (see fig.1). The following activities take place: Preparation and updating of welding maps. Tracing prefabrication, blasting, priming, and painting. Visual inspection of welding, blasting, priming, and painting. Checking paint thickness. Monitoring work compliance with the relevant procedures. Checking skid assembly. Checking vessels. Checking rotating equipment. Checking earthworks. Concrete pour checking. Grouting checking. Checking instrument installation. Preparation of mechanical, civil, electrical and instrumentation checklists.

The following documents are related to the field quality control: Visual Inspection Report Workshop/Erection Welding Report Trench Inspection Report Joint Insulation Inspection Report Lowering and Backfilling Report

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 6 of 7

In-plant Piping Coating Report Skid Assembly Report Vessel Inspection and Closing Report Rotating Equipment Report Mechanical Equipment Checklist Mechanical Completion Checklist Earthwork checklist Backfilling checklist Concrete Pour Checklist Instrument Installation Record

RADIOGRAPHY AND OTHER NON-DESTRUCTIVE METHODS

The non-destructive testing is carried out by NDT Group (see fig.1). Appropriate NDT equipment and materials are provided: Gamma-ray sources, Films and chemicals, Image quality indicators, Viewers and pentameters, Photo-laboratory equipment, MOI equipment, Ultrasonic equipment, Dye penetration testing chemicals, Field hardness testing equipment (if necessary).

The evaluation of the results is performed by Welding/NDE Group (see fig.1). The staff is properly qualified. The minimum qualification required is Level II. The following documents are related to the NDT/NDE: Liquid Penetration test Report Radiographic Examination Report Magnetic Particle Test Record Ultrasonic Test Record

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

REV.1 CONSTRUCTION QA/QC-Plan QUALITY ASSURANCE / QUALITY CONTROL PLAN Page 7 of 7

PREPARATION OF WELDING BOOKS AND WELDING INSPECTION REPORTS

The welding book (W008) for the pipelines, and the welding inspection report (W005) for the in plant piping, are final documents summarizing all welding and NDT carried out. They contain welding history and reference to all reports related to the welding of a pipeline or in-plant piping element. The preparation of these documents is a continuous processes during the execution the words. The completion of such document takes place after the line or spool obtains status of NDT clear. The welding book/welding inspection report, together with all related inspe ction reports, form the Test Package, which is to be completed before the hydrostatic testing. Examples are shown in part IV: Test package example Hydrotesting documentation example Welding book

The examples represent real cases taken from the field practice of AKKILA COMPANY LIMITED.

Attachments:

Pipeline/Flowline Responsibility Matrix In-Plant Piping Responsibility Matrix Pipeline/Flowline Document Flow In-Plant Piping Document Flow Construction QA/QC Plan Fig.01

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

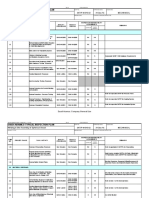

Quality Assurance / Quality Control PIPELINE / FLOWLINE RESPONSIBILITY MATRIX

Unit JOB R. O. W Check truck Loads Collect Mill Certificates Material Man Pipeline Engineer Complete check Complete check Foreman QA/QC Unit Complete check Complete check

Stringing

Bending

Trenching

Complete check Draw scheme For Welding Book Complete check Prepare L001 Check Consumables Measure pipe length Write on pipes Length, pipe # Weld #

Gauging (Roundness check) Complete check Issue L001 100% inspection, Issue W001 Fill in W008 Issue W010 Radiography Dye Pen Evaluate Radiographs Issue W002. W003 Order repair(W017) Complete Check Issue L002 Complete check Issue L003 Issue W008 Collect Related documents Complete Test pack Collect Documents Issue L004 Issue W004 Complete Test pack Complete Check

Welding

NDT

Check Consumables

Coating Lowering-in / Backfilling

Check consumables Collect certificates

Complete check Prepare L002

Complete check Prepare L003

Test Pack Preparation

Hydrotest

Complete Check Prepare L004 Complete Check

Reinstatement

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

MAT01 PL. xls

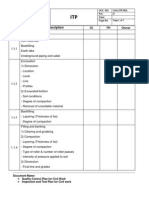

Quality Assurance / Quality Control IN-PLANT PIPING PESPONSIBILITY MATRIX

Unit JOB Storage piping, fittings, flanges Sort materials As per isometrics Preparation for Prefabrication Prefabrication fitting And tack welding Welding Complete check Material Man Complete check Collect mill certificates List of discrepancies Issue materials As per requisitions Pipeline Engineer Foreman QA/QC Unit Complete check Complete check Check Requisitions Complete check Issue W011 Mark weld #, Welder # Check classes, Dimensions, schedules Issue requisitions

Complete check Schedule Preparation as Per test pack priorities Complete check 100% visual inspection, Issue W001 Radiography Dye pen, Issue W002 Evaluate radiographs Issue W009 Issue W010 Order repair (W017) Complete check Issue L005

NDT

Check consumables

Sandblasting, Priming, Painting

Check consumables Collect certificates

Complete check Prepare L005 All NDT Activities for field welding

Erection

Issue W011

Test Pack

Hydrotest

Complete check

Issue W009 Issue W010 Issue W009 Prepare W004 Collect related documents Complete pack Complete check Issue W004 Complete Test Pack

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

Reinstatement

Complete check

Complete check

MAT 02 IN. xls

Quality Assurance / Quality Control PIPELINE / FLOWLINE DOCUMENT FLOW

Index W001 W002 Description Visual inspection Report Liquid Penetration Test Report Radiographic Examination Report Prepared by QA / AC QA / QC Signed by QA / AC Client Inspector QA / AC Client Inspector QA / AC Client Inspector Copies 2 2 Distribution Client QA / QC Client QA / QC Client QA / QC Pipeline Engineer Welding Foreman Client QA / QC Pipeline engineer Construction Manager Client QA / QC Pipeline Engineer Client QA / QC Pipeline Engineer Client QA / QC Pipeline Engineer Client QA / QC Pipeline Engineer Client QA / QC Pipeline Engineer Client QA / QC Pipeline Engineer Client QA / QC Material Man Client QA / QC Material Man

W003

QA / QC

W010

Defective Welding Rate

QA / QC

QA / QC

L001

Trench Inspection Report

P/L Engineer QA / QC P/L Engineer QA / QC P/L Engineer QA / QC P/L Engineer QA / QC QA / QC P/L Engineer QA / QC Vendor

QA / QC Client Inspector QA / QC Client Inspector QA / QC Client Inspector QA / QC Client Inspector QA / QC Client QA / QC Client Vendor

L002

Coating Inspection Report

L003

Lowering-in & Backfilling Report

L004

Pigging Report

W008

Welding Book

Hydrotest Report

Pipe and Fitting Mill Certificate

Coating Certificate

Vendor

Vendor

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

DOC 01 IN. xls

Quality Assurance / Quality Control IN-PLANT PIPING DOCUMENT FLOW

Index W001 Description Visual inspection Report Workshop/ Erection Welding Report Prepared by QA / AC Piping Engineer Signed by QA / AC Client Inspector Piping Engineer Copies 2 Distribution Client QA / QC Construction Manager QA / QC Piping Engineer Client QA / QC Piping Engineer Welding Foreman Client QA / QC Client QA / QC Piping Engineer Client QA / QC Piping Engineer Construction Manager Client QA / QC Piping Engineer Client QA / QC Client QA / QC Client QA / QC Material Man Client QA / QC Material Man

W011

W012

Order For X - ray

QA / QC

QA / AC QA / AC Client Inspector QA / AC Client Inspector

W002 W003

Liquid Penetration Test Report Radiographic Examination Report

QA / QC QA / QC

2 4

W009

In-Plant Welding Progress Report

QA / QC

QA / QC

L005 W005

In-plant Piping Coating Report Welding Inspection Report Hydrotest Report Pipe and Fitting Mill Certificate

Piping Engineer QA / QC QA / QC QA / QC Vendor

QA / QC Client Inspector QA / QC QA / QC Client Inspector Vendor

3 2 2 3

Coating Certificate

Vendor

Vendor

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

DOC 02 IN.xls CONSTRUCTION QA/QC PLAN FIGURE 1

QUALITY ASSURANCE/QUALITY CONTROL ORGANIZATION

QA/QC MANAGER

Field Inspection Group Material Compliance Pipelines In-Plant Piping Civil Mechanical/Vessels Instrumentation/Electrical

NDT Group Radiography Ultrasonic MPI Liquid Penetration

Construction / Welding Group Welding procedures Welders qualification Fabrication & Rolling Tank Erection / Construction NDT Planning Evaluation NDT results Hydrotesting Repair planning & control Precommissioning

P.O. Box 54711, Abu Dhabi, United Arab Emirates Tel. #: +9712 6745040, Fax: + 971 2 6746080, E-mail: a_t_s@emirates.net.ae

You might also like

- QA/QC Procedure for FabricationDocument7 pagesQA/QC Procedure for FabricationRajesh K Pillai100% (6)

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNo ratings yet

- Proposed Quality Control PlanDocument3 pagesProposed Quality Control PlanMohamad Rafik50% (2)

- Itp Bored Pile Rev 1Document10 pagesItp Bored Pile Rev 1Pandar HasibuhanNo ratings yet

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocument81 pages30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- JK Pipeline Welding & Installation Traceability Procedure CoDocument1 pageJK Pipeline Welding & Installation Traceability Procedure Cogst ajahNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- Annexure C3.23 - Quality Management PlanDocument23 pagesAnnexure C3.23 - Quality Management Planifansusanto100% (1)

- 2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Document30 pages2.2.16 - QPR-RHE-002 RLC Waste Management 2 (220205)Lyle KorytarNo ratings yet

- Quality Plan for GPL Construction ProjectDocument23 pagesQuality Plan for GPL Construction Projectmayank dixitNo ratings yet

- ELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingDocument11 pagesELT-01-CQ-PC-XXXX Welding Consumables Receiving, Storage and HandlingjorgekarlosprNo ratings yet

- Quality Control Procedure Index) - Rev.2Document3 pagesQuality Control Procedure Index) - Rev.2valent aviolandaNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- Quality Record Control ProcedureDocument5 pagesQuality Record Control ProcedureGomathyselviNo ratings yet

- Contract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectDocument44 pagesContract Welding and Inspection Plan for Pulang Pisau Power Plant ProjectSamid MidmidNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- Rapid P0030 CPP Qac PRC 0001 0024 - A CCDocument14 pagesRapid P0030 CPP Qac PRC 0001 0024 - A CCAtuk SafizNo ratings yet

- Khulud Gas Development Project FabricationDocument5 pagesKhulud Gas Development Project FabricationRana AsifNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- Inspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDocument2 pagesInspection and Test Plan - In-Situ Puf Insulation To Valvesflanges Froth PakDinesh100% (1)

- O252-PI-SP-0126 - C04 - Specification For PaintingDocument26 pagesO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- Material Inspection ReportDocument2 pagesMaterial Inspection ReportReza AchmalyadiNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- Pipeline repair inspection and test planDocument4 pagesPipeline repair inspection and test planAhmedNo ratings yet

- Membrane Purification System (MPS) Project Chemical Cleaning ReportDocument8 pagesMembrane Purification System (MPS) Project Chemical Cleaning ReportEdy Iswanto0% (1)

- Quality Management PlanDocument9 pagesQuality Management Planmurtada kamilNo ratings yet

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- QP-018, Quality Manual Procedure For Coupon and Probes MonitoringDocument12 pagesQP-018, Quality Manual Procedure For Coupon and Probes MonitoringIksan Adityo MulyoNo ratings yet

- QC Construction ProceduresDocument24 pagesQC Construction ProceduresRahmat Hidayat100% (1)

- B170 Aq SPC 70000 - 2Document41 pagesB170 Aq SPC 70000 - 2Mingyu Song100% (1)

- Att#11 - A - Painting ProcedureDocument14 pagesAtt#11 - A - Painting ProcedureClémentNo ratings yet

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Qa-Qc Quality PDFDocument60 pagesQa-Qc Quality PDFNaveed Ahmed Get-InfoNo ratings yet

- Approved ITP 06012023 For WT6Document1 pageApproved ITP 06012023 For WT6mohamed irsath100% (1)

- Quality InductionDocument15 pagesQuality InductionaleemmurtazaNo ratings yet

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- Inspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CDocument1 pageInspection and Testing Plan (Itp) : Tiling Works: C China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- On - Plot HydrotestingDocument14 pagesOn - Plot HydrotestingarunmirandaNo ratings yet

- QCP 12 Project Inspection Record (Zuluf Water Supply Facilities B.I. No. 10-12322)Document6 pagesQCP 12 Project Inspection Record (Zuluf Water Supply Facilities B.I. No. 10-12322)RAMAKRISHNANo ratings yet

- Field Civil Inspection & Test PlanDocument9 pagesField Civil Inspection & Test PlanChristian Albert Sinaga RumajarNo ratings yet

- 1.5 Assurance ProcessDocument9 pages1.5 Assurance Processaswar100% (1)

- MIP17-MS-2012 Method Statement For Fabrication and Installation of PipingDocument23 pagesMIP17-MS-2012 Method Statement For Fabrication and Installation of PipingAmeerHamzaWarraichNo ratings yet

- Curriculum Vitae - Paul Joseph Sebastian..Document4 pagesCurriculum Vitae - Paul Joseph Sebastian..Abdullah AnsariNo ratings yet

- CV 2023Document5 pagesCV 2023AmitNo ratings yet

- Mechanical Engineer With 4.6 Years QA/QC Experience Seeks New OpportunityDocument5 pagesMechanical Engineer With 4.6 Years QA/QC Experience Seeks New Opportunityvishal bailur100% (1)

- MES - Construction Quality Manual - Rev - 0Document55 pagesMES - Construction Quality Manual - Rev - 0Ishaan ThakerNo ratings yet

- Business BlogsDocument58 pagesBusiness BlogsAli HajirassoulihaNo ratings yet

- CU Boulder's Student Information System Replacement Project CharterDocument91 pagesCU Boulder's Student Information System Replacement Project CharterAli HajirassoulihaNo ratings yet

- 16 Welding2Document42 pages16 Welding2Musa ÇelikNo ratings yet

- Solar Power Plant Pre-Feasibility StudyDocument100 pagesSolar Power Plant Pre-Feasibility Studyphanibhushanavula100% (21)

- How To Write A Business Plan That Really WorksDocument66 pagesHow To Write A Business Plan That Really WorksAli HajirassoulihaNo ratings yet

- Construction Safety Checklist InspectionDocument8 pagesConstruction Safety Checklist InspectionAli HajirassoulihaNo ratings yet

- Inance Ontract: Credit TermsDocument2 pagesInance Ontract: Credit TermsAli HajirassoulihaNo ratings yet

- Risk Assessment FormDocument25 pagesRisk Assessment FormAli HajirassoulihaNo ratings yet

- Acf4988 PDFDocument30 pagesAcf4988 PDFchriscivil12No ratings yet

- 16 Welding2Document42 pages16 Welding2Musa ÇelikNo ratings yet

- 16 Welding2Document42 pages16 Welding2Ali HajirassoulihaNo ratings yet

- Example Progress CalculationsDocument18 pagesExample Progress CalculationsAli HajirassoulihaNo ratings yet

- Acf4988 PDFDocument30 pagesAcf4988 PDFchriscivil12No ratings yet

- 16 Welding2Document42 pages16 Welding2Ali HajirassoulihaNo ratings yet

- Learn the Basics of PhotovoltaicsDocument21 pagesLearn the Basics of PhotovoltaicsVinay BabuNo ratings yet

- NEED SolarshortDocument25 pagesNEED SolarshortAli HajirassoulihaNo ratings yet

- Welding Cutting Published Paper PDFDocument3 pagesWelding Cutting Published Paper PDFAli HajirassoulihaNo ratings yet

- Sales Units Jan Feb Mar Apr May Jun: Cash Budget - TemplateDocument4 pagesSales Units Jan Feb Mar Apr May Jun: Cash Budget - TemplateAli HajirassoulihaNo ratings yet

- Face The FutureDocument68 pagesFace The FutureAli HajirassoulihaNo ratings yet

- Locating Field WeldDocument8 pagesLocating Field WeldRafeek ShaikhNo ratings yet

- Soft SkillsDocument117 pagesSoft SkillsAnissa Negra Akrout100% (1)

- NEED SolarshortDocument25 pagesNEED SolarshortAli HajirassoulihaNo ratings yet

- 16 Welding2Document42 pages16 Welding2Musa ÇelikNo ratings yet

- What Successful People Really Do Part 2Document69 pagesWhat Successful People Really Do Part 2Ali HajirassoulihaNo ratings yet

- Requisition: Quantity Description Estimated CostDocument1 pageRequisition: Quantity Description Estimated CostAli HajirassoulihaNo ratings yet

- Face The FutureDocument68 pagesFace The FutureAli HajirassoulihaNo ratings yet

- Capital Markets Financing for Developing InfrastructureDocument21 pagesCapital Markets Financing for Developing InfrastructureWalter ChahwetaNo ratings yet

- Best practices solar photovoltaic systemsDocument43 pagesBest practices solar photovoltaic systemsphilipnart100% (1)

- TAP Project Piping Works FlowchartDocument1 pageTAP Project Piping Works FlowchartAli HajirassoulihaNo ratings yet

- Soundsafe Safety Data Sheet EnglishDocument5 pagesSoundsafe Safety Data Sheet Englishard127No ratings yet

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- Tds 071 Rev 05 Residhere Am 140 SDocument1 pageTds 071 Rev 05 Residhere Am 140 Sاحمد عدنانNo ratings yet

- Diverter Valve Wam BrochureDocument4 pagesDiverter Valve Wam BrochureEzequiel Guillermo Trejo NavasNo ratings yet

- Ecological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityDocument8 pagesEcological Effects Test Guidelines: OPPTS 850.3020 Honey Bee Acute Contact ToxicityNatalie Torres AnguloNo ratings yet

- Introduction To Drug Discovery & Development: Dr. Humair Bin MD OmerDocument9 pagesIntroduction To Drug Discovery & Development: Dr. Humair Bin MD OmerMD. RASEL MAHMUD MIMNo ratings yet

- International Abbreviations For Polymers and Polymer ProcessingDocument226 pagesInternational Abbreviations For Polymers and Polymer ProcessingTrevor J. HutleyNo ratings yet

- USP <1115> Impact on Bioburden ControlDocument65 pagesUSP <1115> Impact on Bioburden ControlBlank Backtobasic100% (1)

- Equations of StateDocument33 pagesEquations of StateDevika BharathanNo ratings yet

- 13 - Chapter 3Document32 pages13 - Chapter 3Wahab Al-QaisiNo ratings yet

- Paediatric Doses of DrugsDocument2 pagesPaediatric Doses of DrugsumapathisivanNo ratings yet

- ICIS PetrochemicalsPosterDocument2 pagesICIS PetrochemicalsPosterstavros7100% (3)

- Brochure Coating ConstructionDocument16 pagesBrochure Coating ConstructionALİ ÖRSNo ratings yet

- TGN-M-04 Weld Procedure Comparison Struc SteelDocument5 pagesTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document22 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)kiranNo ratings yet

- GSAP - Shell HelixDocument16 pagesGSAP - Shell HelixJoseph Rubyanto SudrajadNo ratings yet

- MiniProject Stage 3 - Process Dynamic & ControlDocument8 pagesMiniProject Stage 3 - Process Dynamic & ControlFarihah Eyfa100% (2)

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaNo ratings yet

- NIH Public Access: Introduction To Peptide SynthesisDocument17 pagesNIH Public Access: Introduction To Peptide SynthesisStella AguirreNo ratings yet

- 2019 Cre Ii L24-26Document32 pages2019 Cre Ii L24-26Aman PrasadNo ratings yet

- Gastroprotective Effects of Peperomia pellucida and Pachyrhizus erosus Extract CombinationDocument12 pagesGastroprotective Effects of Peperomia pellucida and Pachyrhizus erosus Extract CombinationCameliaNo ratings yet

- Using Pumps As Power Recovery TurbinesDocument4 pagesUsing Pumps As Power Recovery TurbinesKali CharanNo ratings yet

- Sensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Document7 pagesSensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Bagas Aryo SasongkoNo ratings yet

- Laboratory Corrosion Testing PDFDocument7 pagesLaboratory Corrosion Testing PDFeid elsayedNo ratings yet

- Q1 Science 9 Module 5Document28 pagesQ1 Science 9 Module 5Shiena Lou Tucasan CudadaNo ratings yet

- Pressure Gauges With Syphon PDFDocument2 pagesPressure Gauges With Syphon PDFhussamengNo ratings yet

- 10th STD Science Carbon and Its Compounds Lesson Plan Eng Version 2017-18Document5 pages10th STD Science Carbon and Its Compounds Lesson Plan Eng Version 2017-18vijos16655No ratings yet

- Smooth Finish FlangesDocument4 pagesSmooth Finish FlangessanoopvkNo ratings yet

- Module 4 - Chemical Kinetics Prelab Study GuideDocument5 pagesModule 4 - Chemical Kinetics Prelab Study GuideJustine UrbanNo ratings yet

- Precipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceDocument4 pagesPrecipitation-Hardening Bolting (UNS N07718) For High Temperature ServiceJose Anisio SilvaNo ratings yet