Professional Documents

Culture Documents

Aft Tme Case Study

Uploaded by

pca97Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aft Tme Case Study

Uploaded by

pca97Copyright:

Available Formats

Case Study

Campus Chill Water System Design and Operation Improved Through Hydraulic Modeling with AFT Fathom

TM

Company: Address: Telephone: Fax:

TME Energy Services Division TME, Inc. 5800 Evergreen Drive, Suite A Little Rock, AR 72205-1757 501-666-6776 501-663-8888

To answer these questions a model of the district cooling system was developed within AFT Fathom. In addition to the ability to model complex and large networks (the model contains over 3,400 pipes and junctions), unique capabilities provided by AFT Fathom were critical to the success of the study. Air conditioning load calculations were developed for average and peak demand periods during winter and summer. Cooling load data was then converted into flow demands for the many heat exchangers in the system. Modifying the input for 358 pumps and control valves over the many different load cases studied was greatly TM facilitated by using AFT Fathom's Excel data import capability. As James Hess, TME Energy Engineer comments, "Now that we had a method for quickly making changes to the models, the real fun began." A series of runs were made with varying loads, operating configurations, pump characteristics and piping changes. In the end, the hydraulic model and results achieved by the study were viewed very favorably by the University. Benefits derived from the hydraulic modeling include: Instill confidence in the method as the baseline model accurately reflected key operating characteristics of the actual system. Confirm selection of the pumps for the Main Plant retrofit. Evaluated piping changes in various buildings to achieve significantly improved delta-T thereby lowering required flow rates. Verify the energy savings benefit that would result from the "Low Flow/High Delta T" project. Identify potential bottlenecks to target areas of improvement. Determine that operation of the steam turbine driven North Chiller plant as a 'booster' pump could be eliminated realizing substantial energy savings. Provide the University insight into how to best operate the plants from a pumping energy consumption standpoint. Annual energy savings of 1.9 million KWHr and $67,000 in pumping power, and $1,200,000 in annual chiller electrical and gas energy savings. "Overall, we were quite pleased with what we were able to accomplish using the AFT Fathom software in this project." stated Mr. Hess.

TME, Inc. is a full service mechanical, electrical and energy engineering firm located in Little Rock, with branch offices in Tulsa and Tucson and provides services to clients in over 25 states. TME Energy Services Division provides a wide assortment of energy related services including utility rate analysis, energy audits, wholesale purchasing of natural gas and electricity, and commissioning. Reducing energy costs is an increasingly important consideration for plant Annual energy owner/operators with an excellent example being the savings of 1.9 million energy intensive district KWHr and $67,000 in cooling system serving the pumping power, and University of Arkansas at Fayetteville. This campus $1,200,000 in annual wide system provides air chiller electrical and conditioning for 59 buildings gas energy savings. along with refrigeration heat rejection for laboratories and laser systems cooling. Classified as a primary/secondary/tertiary pump system, the primary circuit circulates water within the chiller plants, the secondary system distributes cooling water from the plants to the buildings and other users and the tertiary system consists of pumps within the various buildings. With a total connected load of 13,600 cooling tons, the system includes a Main Chiller Plant with a pumping capacity of 15,000 gpm, a Southwest Chiller Plant with 9,000 gpm capacity and a North Chiller Plant with a capacity of 6,000 gpm. As is the case with many growing universities, UAF was undergoing significant changes that would greatly impact the district cooling system. In addition to campus load growth, it was desired to evaluate changes to reduce pumping energy costs that would result from supplying colder chilled water to the campus buildings, converting the buildings to variable flow using variable speed pump drives and eliminating the 'decoupler' at each building allowing it to take advantage of available differential pressure in the secondary system. These changes were cumulatively referred to as the "Low Flow/High Delta-T" project. Finally, an operating strategy for the chiller plants to minimize pumping energy was developed. No mean feat given the complexity of this system.

Applied Flow Technology 2955 Professional Place, Suite 301, Colorado Springs, CO 80904 USA www.aft.com

Typical Building with circulating pump, heat exchanger and flow control valves.

Main Chiller Plant

University of Arkansas at Fayetteville Chilled Water System

Southwest Chiller Plant

Applied Flow Technology 2955 Professional Place, Suite 301, Colorado Springs, CO 80904 USA www.aft.com

You might also like

- Lesson Plan Class VII (Acids, Bases and Salts)Document3 pagesLesson Plan Class VII (Acids, Bases and Salts)Pushpa Kumari83% (35)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- ExxonMobil G-EMS Initiatives BOP Final Ex NotesDocument12 pagesExxonMobil G-EMS Initiatives BOP Final Ex NotesSrihari KodimelaNo ratings yet

- Sabp A 009Document208 pagesSabp A 009sethu1091100% (2)

- Varying ViewsDocument5 pagesVarying Viewsforevertay2000No ratings yet

- Peerless Pump Tech BulletinsDocument176 pagesPeerless Pump Tech BulletinsWilhelm ThorleyNo ratings yet

- Industrial PumpingDocument59 pagesIndustrial Pumpingpca97100% (1)

- Keystone Fig. AR1-AR2 Butterfly ValveDocument4 pagesKeystone Fig. AR1-AR2 Butterfly Valvepca97No ratings yet

- Climate Change & Crop ProductionDocument312 pagesClimate Change & Crop ProductionGary Bhullar75% (4)

- Wicker Riverside Action Plan 20071Document46 pagesWicker Riverside Action Plan 20071Tony CarrollNo ratings yet

- EESC 1101 - Lab 4 - Brooklyn College Building Stone PDFDocument13 pagesEESC 1101 - Lab 4 - Brooklyn College Building Stone PDFLorenzo YapNo ratings yet

- How High Can You Go?: New Approaches For Cooling System EfficiencyDocument4 pagesHow High Can You Go?: New Approaches For Cooling System EfficiencyagnieasNo ratings yet

- Air Cooled Condenser - Kratki OpisDocument47 pagesAir Cooled Condenser - Kratki Opisbaca88No ratings yet

- Performance Improvement of ACCDocument46 pagesPerformance Improvement of ACCLekhamani YadavNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Evolving Design Chiller PlantDocument7 pagesEvolving Design Chiller PlantMohsin KhanNo ratings yet

- Air-Cooled vs. Water-Cooled ChillersDocument11 pagesAir-Cooled vs. Water-Cooled Chillersmnt6176100% (2)

- HVAC Softwares ManualDocument6 pagesHVAC Softwares ManualAbhyuday GhoshNo ratings yet

- Feasibility Report About: Steam Power PlantDocument13 pagesFeasibility Report About: Steam Power Plantjsmith84No ratings yet

- Article Hydrocarbon Processing April 2007Document4 pagesArticle Hydrocarbon Processing April 2007btjajadiNo ratings yet

- Aspen Utility OptimiserDocument17 pagesAspen Utility OptimiserKokil JainNo ratings yet

- Pipe Network Analysis of A Complex Flow System Using Pipenet - A Case StudyDocument10 pagesPipe Network Analysis of A Complex Flow System Using Pipenet - A Case StudyIAEME PublicationNo ratings yet

- Neena ProjectDocument19 pagesNeena Projectkramarraja123No ratings yet

- Benefits of District CoolingDocument13 pagesBenefits of District CoolingsyedahmedsabirNo ratings yet

- N-Gas Compressor Stations Heat Recovery Analysis HedmanDocument30 pagesN-Gas Compressor Stations Heat Recovery Analysis Hedmanioan1946No ratings yet

- Chilled Water Systems: Figure 8-1 Shows That The Larger A Building Figure 8-2 Shows That On A SquareDocument4 pagesChilled Water Systems: Figure 8-1 Shows That The Larger A Building Figure 8-2 Shows That On A SquareWalter J Naspirán CastañedaNo ratings yet

- Back Pressure Steam Turbine GeneratorsDocument16 pagesBack Pressure Steam Turbine GeneratorsMohamed Salem100% (3)

- Ground-Coupling With Water Source Heat Pumps: NomenclatureDocument13 pagesGround-Coupling With Water Source Heat Pumps: NomenclatureStokabaNo ratings yet

- ASHRAE Journal - Optimizing Chilled Water Plant ControlsDocument12 pagesASHRAE Journal - Optimizing Chilled Water Plant ControlsAntonio LebrunNo ratings yet

- Pumping 6Document2 pagesPumping 6Foulen FouleniNo ratings yet

- Integrated Variable Speed DrivesDocument14 pagesIntegrated Variable Speed DrivesulatbookNo ratings yet

- Reducir Los Costos en Proyectos de "Revamps" Mediante La Optimización Del Diseño y Las Operaciones. (Fuente)Document4 pagesReducir Los Costos en Proyectos de "Revamps" Mediante La Optimización Del Diseño y Las Operaciones. (Fuente)Efraín VeraNo ratings yet

- DataCenter ChilledWaterSystemOptimization WhitepaperDocument4 pagesDataCenter ChilledWaterSystemOptimization WhitepaperRafael MelendezNo ratings yet

- 11 Pumped Storage Schemes (Document13 pages11 Pumped Storage Schemes (tsinghal_19No ratings yet

- Turbine Efficiency in Thermal Power PlantDocument5 pagesTurbine Efficiency in Thermal Power PlantjalukyNo ratings yet

- Pinch White Paper (Rev 3) 2012Document21 pagesPinch White Paper (Rev 3) 2012Energy_ExpertNo ratings yet

- Optimizing Design and Control of Chilled Water Plants PDFDocument20 pagesOptimizing Design and Control of Chilled Water Plants PDFMarli MoiseNo ratings yet

- 1 s2.0 S1359431115000368 MainDocument12 pages1 s2.0 S1359431115000368 MainJulio CésarNo ratings yet

- 2017 - Skotak A - Designing of Pump Turbine For Non Restricted Range of Operation - Hydrovision 2017, DenverDocument13 pages2017 - Skotak A - Designing of Pump Turbine For Non Restricted Range of Operation - Hydrovision 2017, DenvernamitaNo ratings yet

- Specific Allocated Energy Consumption of MSF and Med Plants: Authors: Fritz AltDocument15 pagesSpecific Allocated Energy Consumption of MSF and Med Plants: Authors: Fritz AltassurendranNo ratings yet

- Save Energy Money Ashrae Journal June 2013Document5 pagesSave Energy Money Ashrae Journal June 2013silverstaloneNo ratings yet

- Reduce Energy Use at Quarries, Mineral Processing Plants & Gravel Crushing FacilitiesDocument6 pagesReduce Energy Use at Quarries, Mineral Processing Plants & Gravel Crushing Facilitieslopi98llkj55No ratings yet

- Proposal ScriptDocument9 pagesProposal ScriptFionaNo ratings yet

- Cooling Water OptimizationDocument6 pagesCooling Water OptimizationMehdi MansourianNo ratings yet

- HVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEDocument11 pagesHVAC Design For Sustainable Lab: by Gregory R. Johnson, P.E., Member ASHRAEAu NguyenNo ratings yet

- Optimization of Startups - RTPDocument11 pagesOptimization of Startups - RTPmoh1234buk100% (1)

- Chilled Water OptimizationDocument61 pagesChilled Water Optimizationmuoi2002No ratings yet

- Steam21 Rotyutyutyutating EquipDocument2 pagesSteam21 Rotyutyutyutating EquipHatem Abdelrahman100% (1)

- 1101 The Facility FilesDocument1 page1101 The Facility FilessajuhereNo ratings yet

- Chiller Energy SavingsDocument10 pagesChiller Energy SavingsRasaNo ratings yet

- Otc 20340Document13 pagesOtc 20340Rasheed YusufNo ratings yet

- Case Study Alternatives CCDocument10 pagesCase Study Alternatives CCEvertVeNo ratings yet

- Epa Bum Ch9 HvacDocument23 pagesEpa Bum Ch9 Hvaccesar luis gonzalez rodriguezNo ratings yet

- Topic: - Power Cogeneration Plant: Term Paper OF Project ManagementDocument13 pagesTopic: - Power Cogeneration Plant: Term Paper OF Project ManagementankuaaaNo ratings yet

- Sulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationDocument8 pagesSulzer Pumps Retrofit: Increasing The Efficiency of Pumps: Technical and Economic OptimizationAri HeryadiNo ratings yet

- Presentation 3Document32 pagesPresentation 3Gopal JaiswalNo ratings yet

- ES ArticlesDocument5 pagesES ArticlesenestroNo ratings yet

- Analytical Modeling For Thermodynamic Characterization of Data Center Cooling SystemsDocument9 pagesAnalytical Modeling For Thermodynamic Characterization of Data Center Cooling SystemsJohnisking11No ratings yet

- FWC Utility System Optimisation FINALDocument12 pagesFWC Utility System Optimisation FINALrieza_fNo ratings yet

- DCS Case StudyDocument6 pagesDCS Case StudyHEI532532No ratings yet

- Compressor StudyDocument4 pagesCompressor StudytomgilmartinNo ratings yet

- Run of River Hydro SystemsDocument8 pagesRun of River Hydro Systemssabrahima100% (1)

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Chapter02-Handbook of Polyethylene PipeDocument27 pagesChapter02-Handbook of Polyethylene Pipepca97No ratings yet

- Chapter03-Handbook of Polyethylene PipeDocument61 pagesChapter03-Handbook of Polyethylene Pipepca97No ratings yet

- Forged FittingsDocument7 pagesForged Fittingspca97No ratings yet

- Cutting Costs: in Pump and Pipe SizingDocument4 pagesCutting Costs: in Pump and Pipe Sizingpca97No ratings yet

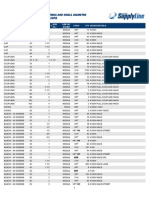

- Valve Sizing TablesDocument5 pagesValve Sizing Tablespca97No ratings yet

- AFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIDocument24 pagesAFT Evaluating Pipe Dynamic Loads Caused by Waterhammer 01-02-2013 SIpca97No ratings yet

- Goulds 3196 2x3-13 200HPDocument2 pagesGoulds 3196 2x3-13 200HPpca97No ratings yet

- Choke Flow CVDocument5 pagesChoke Flow CVpca97No ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument42 pagesPipe Stress Analysis Using CAESAR IIpca97100% (1)

- Installation of Direct Push Ground Water Monitoring Wells: Standard Guide ForDocument9 pagesInstallation of Direct Push Ground Water Monitoring Wells: Standard Guide ForEmiliano AgostiniNo ratings yet

- Industrial Design Portfolio - Johan NobisDocument47 pagesIndustrial Design Portfolio - Johan NobisJohan NobisNo ratings yet

- Act 6+14Document4 pagesAct 6+14min95No ratings yet

- White Paper The Victaulic Vortex™ Fire Suppression SystemDocument16 pagesWhite Paper The Victaulic Vortex™ Fire Suppression SystemProingmeca CANo ratings yet

- Horton Infiltration MethodDocument3 pagesHorton Infiltration MethodVictor Cordova Gonzales0% (1)

- A-Level-Chemistry Edexcel FACER Sample-Chapter PDFDocument36 pagesA-Level-Chemistry Edexcel FACER Sample-Chapter PDFahamedNo ratings yet

- Standard Operating Procedure: Vinyl Chloride (Monomer)Document6 pagesStandard Operating Procedure: Vinyl Chloride (Monomer)Ade SumitraNo ratings yet

- Pressure: Polyvinyl Chloride (PVC) and Fabricated Finings, IN. Through IN. Through 300 MM), Water DistributionDocument22 pagesPressure: Polyvinyl Chloride (PVC) and Fabricated Finings, IN. Through IN. Through 300 MM), Water DistributionJacques BlueqNo ratings yet

- Resume and Cover Letter Engr. M. Asad (Updated)Document2 pagesResume and Cover Letter Engr. M. Asad (Updated)Mian M AsadNo ratings yet

- Intake Site Selection and DesignDocument11 pagesIntake Site Selection and DesignÁnikka Quevedo GarcíaNo ratings yet

- Euler's Theorem. Diagram Illustrating How The Motion of A Continent On The Earth Can Be Described by An Angle of Rotation About A Pole of RotationDocument15 pagesEuler's Theorem. Diagram Illustrating How The Motion of A Continent On The Earth Can Be Described by An Angle of Rotation About A Pole of Rotationlorenavalderrama97No ratings yet

- Course StructureDocument28 pagesCourse Structureravi03121No ratings yet

- Didik Bahasa InggerisDocument25 pagesDidik Bahasa Inggeris大衛龍100% (1)

- Kruthumal Case Study Report - Final-Feb2014-1Document26 pagesKruthumal Case Study Report - Final-Feb2014-1Alamandha Madhan Kumar100% (1)

- SediCon Project Year 2010 Khimti Headworks Sedicon Sluicer 1Document2 pagesSediCon Project Year 2010 Khimti Headworks Sedicon Sluicer 1Balkrishna PangeniNo ratings yet

- Msds of Yellow PhosphorusDocument6 pagesMsds of Yellow PhosphorusAjesh mohanNo ratings yet

- Water Required Per AcreDocument4 pagesWater Required Per AcreSagar JssNo ratings yet

- UK MOD Requirements For Domestic Hot and Cold Fresh Water Systems - 00000300Document100 pagesUK MOD Requirements For Domestic Hot and Cold Fresh Water Systems - 00000300cervelo_6927100% (1)

- Chemgard 63 N: Chemical Resistant Epoxy Protective CoatingDocument4 pagesChemgard 63 N: Chemical Resistant Epoxy Protective CoatingghazanfarNo ratings yet

- 1.1-1.10 - Loading Direct Reduced Iron (Dri)Document9 pages1.1-1.10 - Loading Direct Reduced Iron (Dri)Yevgeniy RNo ratings yet

- Soil, Water, and Atmosphere ChemistryDocument19 pagesSoil, Water, and Atmosphere ChemistryShiela Mae VisayaNo ratings yet

- Eng - Mohamed Abdelhady Mohamed ElsayedDocument3 pagesEng - Mohamed Abdelhady Mohamed ElsayedMohamed AbdelhadyNo ratings yet

- NewsCastle - April 2012 IssueDocument18 pagesNewsCastle - April 2012 IssueU.S. Army Corps of Engineers Los Angeles DistrictNo ratings yet

- Snamprogetti Saipem Urea Process AmmoniaDocument23 pagesSnamprogetti Saipem Urea Process AmmoniaTu Hai50% (2)

- 5 Ways To Reduce COD in WastewaterDocument2 pages5 Ways To Reduce COD in WastewaterSo MriNo ratings yet

- Scientific Method SOL ReviewDocument2 pagesScientific Method SOL ReviewAlayna SheltonNo ratings yet