Professional Documents

Culture Documents

Cip400 800

Uploaded by

Hatem AbdelrahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cip400 800

Uploaded by

Hatem AbdelrahmanCopyright:

Available Formats

Alfa Laval CIP 400 and Alfa Laval CIP 800

Cleaning in Place unit for heat exchangers

A problem frequently encountered in almost all applications is the build-up of deposits on heat transfer surfaces. Alfa Laval supplies a wide range of cleaning agents suitable for removing most of these troublesome deposits and restoring performance to optimal levels. The time-consuming work of opening plate heat exchangers can thus often be avoided by using an Alfa Laval Cleaning in Place (CIP) unit. Alfa Laval CIP units are available in a wide range of standard sizes, with optional extras that include reversible flow and explosion-proof capabilities. Alfa Laval CIP units can be used for all types of heat exchangers, including spiral heat exchangers, shell-and-tube heat exchangers and gasketed, welded and brazed plate heat exchangers. Concept Alfa Laval CIP units are simplicity itself: Connect the Alfa Laval CIP unit to the heat exchanger Mix the cleaning agent with water in the tank and heat it up Circulate the cleaning solution a couple of hours Drain and rinse Disconnect the CIP unit The heat exchanger is back to full performance capacity**

Alfa Laval CIP units are a cost-effective way to achieve better performance, and the cleaning agents used are, of course, environmentally friendly. In addition to boosting the performance of all kinds of heat exchangers, Alfa Laval cleaning agents extend the operating time between cleaning cycles as well as prolonging the overall lifetime of the heat exchangers, without damaging the plates or gaskets.** Features & benefits Connected directly to inlet and outlet. This avoids any need to open the heat exchanger, which in turn minimizes downtime and prolongs the working life of the gasket. All wetted parts in the operating unit, as well as the pump and valves, are made of AISI 316 stainless steel to ensure maximum working life. High-quality equipment that is CE marked and manufactured according to ISO 9001 standards. Rapid cleaning at optimal temperatures, due to built-in heater (standard equipment) operating on electricity or steam, as required. Valve arrangement for reversible flow direction. This makes it possible to remove the solid particles rapidly, and is easy to operate without needing to rearrange the connection hoses.

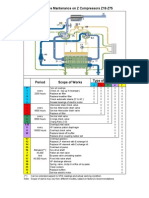

Technical specifications Pump * Voltage Alfa Laval CIP 400 Centrifugal, ALC1/150 400 V/3 phase/50 Hz 440 V/3 phase/60 Hz 460 V/3 phase/60 Hz 480 V/3 phase/60 Hz 500 V/3 phase/50 Hz 12 kW 70C (158F) 400 litres (106 US gallons) 125 kg 1880 mm 900 mm 1088 mm 2 5m NR DIN 11851/DIN 405 DN 50 AISI 316 (stainless steel) NBR EPDM On request Alfa Laval CIP 800 Centrifugal, ALC1/150 400 V/3 phase/50 Hz 440 V/3 phase/60 Hz 460 V/3 phase/60 Hz 480 V/3 phase/60 Hz 500 V/3 phase/50 Hz 12 kW 70C (158F) 800 litres (211 US gallons) 145 kg 2080 mm 900 mm 1275 mm 2 5m NR DIN 11851/DIN 405 DN 50 AISI 316 (stainless steel) NBR EPDM On request

Total heating power Max. operating temp Volume Weight Length Width Height Number of hoses Hose length Hose material Connection standard and size Material for wetted parts Pump gaskets Hose connection gaskets Eexd (explosion-proof)

* See pump curve for flow rate and pumping head ** Only if the cleaning take place in regular intervals, a circulation in the channels is possible in order for the cleaning agents to remove the deposits.

Pump curve for 50 Hz. Impeller dimensions 150.

Pump curve for 60 Hz. Impeller dimensions 150.

PPS00014EN 0303

Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval Contact details for all countries are continually updated on our web site. Please visit www.alfalaval.com to access the information direct.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Field Balancing Large Rotating MachineryDocument26 pagesField Balancing Large Rotating MachineryShantanu SamajdarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Dynamic Stresses Hydro Power Plant RKAggarwalDocument22 pagesDynamic Stresses Hydro Power Plant RKAggarwalDheeraj DhimanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 19 KKKKKKKKKKKKKKKKKKDocument4 pages19 KKKKKKKKKKKKKKKKKKHatem Abdelrahman100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Magnetic Center Finding Using Vibrating Wire TechniqueDocument6 pagesThe Magnetic Center Finding Using Vibrating Wire TechniqueHatem AbdelrahmanNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- WEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishDocument40 pagesWEG HGF Low and High Voltage High Performance Electric Motor Range Broa017 Brochure EnglishHatem AbdelrahmanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Practical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetDocument2 pagesPractical Solutions To Machinery and Maintenance Vibration Problems Chapter 7, Misalignment Section 4, Machinery Soft FeetHatem AbdelrahmanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Understandingamp - Phaseinrotatingmachineryvibinst 07 20pgsDocument20 pagesUnderstandingamp - Phaseinrotatingmachineryvibinst 07 20pgsHatem Abdelrahman100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Huang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDDocument130 pagesHuang Xianghui 20050fdggggggggggggggggggggggggggggggggggggggggggggggg5 PHDHatem AbdelrahmanNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Fault Zone - : Air GapDocument0 pagesFault Zone - : Air GapHatem AbdelrahmanNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Icmtech435435 345435 43543Document63 pagesIcmtech435435 345435 43543Hatem Abdelrahman100% (1)

- Gei 100351Document32 pagesGei 100351Hatem Abdelrahman100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Prec Maint March 2007Document9 pagesPrec Maint March 2007Hatem AbdelrahmanNo ratings yet

- Article 6hy JytjuytDocument7 pagesArticle 6hy JytjuytHatem AbdelrahmanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- V106 Relative Motion Record FormDocument0 pagesV106 Relative Motion Record FormHatem Abdelrahman100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 1q07 Beat Freq Back To BasicsDocument3 pages1q07 Beat Freq Back To BasicsHatem AbdelrahmanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDocument46 pagesEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- Don't Get Soft: Cover Series: Installation Best PracticesDocument6 pagesDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Vibrations NotesDocument43 pagesVibrations NotesNicolas LuchmunNo ratings yet

- Best Practices: Asset Condition ManagementDocument2 pagesBest Practices: Asset Condition ManagementHatem AbdelrahmanNo ratings yet

- Article 6hy JytjuytDocument7 pagesArticle 6hy JytjuytHatem AbdelrahmanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- EM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYDocument46 pagesEM10 - Electric Motor Vibrations - Eshleman - 06051 (2) TRYTRYHatem Abdelrahman100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Kingsbury Leg ComponentsDocument3 pagesKingsbury Leg ComponentsHatem Abdelrahman100% (1)

- Customer Application Centers: Global Accessibility To Our TechnologyDocument1 pageCustomer Application Centers: Global Accessibility To Our TechnologyHatem AbdelrahmanNo ratings yet

- Preventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsDocument1 pagePreventive Mantenance On Z Compressors Z18-Z75: Take All ReadingsHatem AbdelrahmanNo ratings yet

- 1q03 3500 22mDocument4 pages1q03 3500 22mscribdkhatnNo ratings yet

- Helping You ... : Fourth Quarter 1999 Vol. 20 No. 4Document1 pageHelping You ... : Fourth Quarter 1999 Vol. 20 No. 4Hatem AbdelrahmanNo ratings yet

- Why Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsDocument2 pagesWhy Upgrades Are Important - : Some Lessons Learned With Older Monitoring SystemsHatem AbdelrahmanNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- IBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsDocument4 pagesIBERDROLA's Center For Monitoring, Diagnostic and Simulation (CMDS) of Combined-Cycle Power PlantsHatem AbdelrahmanNo ratings yet

- Ontario Power Generation's Nanticoke Power PlantDocument3 pagesOntario Power Generation's Nanticoke Power PlantHatem AbdelrahmanNo ratings yet

- 2 Q 01 HanifanDocument2 pages2 Q 01 HanifanHatem AbdelrahmanNo ratings yet

- Materials and Processes Quiz 3Document6 pagesMaterials and Processes Quiz 3RuthNo ratings yet

- Shunyam House, Jodhpur: Presented byDocument2 pagesShunyam House, Jodhpur: Presented byManasi Sonar100% (1)

- gp700105 ComDocument44 pagesgp700105 ComShamik GhoshNo ratings yet

- Computer Application in Hydraulic Engineering-7th EditionDocument4 pagesComputer Application in Hydraulic Engineering-7th Editionkawser zaman0% (1)

- Firepro-Pipe Schedule MethodDocument191 pagesFirepro-Pipe Schedule MethodNathaniel VillanuevaNo ratings yet

- Thesis RawDocument74 pagesThesis RawBryan YuNo ratings yet

- MacadamDocument14 pagesMacadamRakesh7770No ratings yet

- Gas Pipeline Hydraulics: E. Shashi MenonDocument13 pagesGas Pipeline Hydraulics: E. Shashi Menonmostafa shahrabiNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Aircraft Electrical SystemDocument16 pagesAircraft Electrical SystemEvan TubaleNo ratings yet

- Cl80 Inrow Cooler: Data SheetDocument2 pagesCl80 Inrow Cooler: Data SheetRavi ShankarNo ratings yet

- Chapter 11: Thick-Wall Cylinders: - End Caps or Hemispherical Ends. Solution Far From End CapsDocument11 pagesChapter 11: Thick-Wall Cylinders: - End Caps or Hemispherical Ends. Solution Far From End CapsAshokNo ratings yet

- Helical Stair - CalculationDocument5 pagesHelical Stair - CalculationSuhail Ahamed0% (1)

- CorrosionX Tech Data Dec.2020Document1 pageCorrosionX Tech Data Dec.2020Aaron HeapsNo ratings yet

- 9 FencingDocument11 pages9 FencingkashifNo ratings yet

- FRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsDocument6 pagesFRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsHafiz Kamal100% (1)

- Manual Instalación Multiclin PremiumDocument70 pagesManual Instalación Multiclin PremiumnoeliaNo ratings yet

- Heater & Air Conditioning Control System: SectionDocument51 pagesHeater & Air Conditioning Control System: SectionIvan SauretNo ratings yet

- Exxon™ Bromobutyl 2255: RubberDocument2 pagesExxon™ Bromobutyl 2255: RubberMaram YasserNo ratings yet

- Natural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened StatesDocument40 pagesNatural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened Statesayat arahmanNo ratings yet

- ThermoformingDocument27 pagesThermoformingkrishnaNo ratings yet

- EN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionDocument1 pageEN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionBao Duy NguyenNo ratings yet

- Miscellaneous Bridge Components - ClassDocument86 pagesMiscellaneous Bridge Components - ClassAbhishekNo ratings yet

- Manual of 725HP 10KV MotorDocument12 pagesManual of 725HP 10KV MotorduongthetinhqbNo ratings yet

- Flax 7Document7 pagesFlax 7Rajyalakshmi MNo ratings yet

- Technical Drafting 10 SLHT Q2 WK 3 4Document9 pagesTechnical Drafting 10 SLHT Q2 WK 3 4Donna EnopiquezNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- "KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985Document7 pages"KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985rakeshamechNo ratings yet

- Heat & Mass Transfer Ex5Document2 pagesHeat & Mass Transfer Ex5mekdimNo ratings yet

- Int J Applied Ceramic Tech - 2022 - Dong - Additive Manufacturing of Silicon Nitride Ceramics A Review of Advances andDocument21 pagesInt J Applied Ceramic Tech - 2022 - Dong - Additive Manufacturing of Silicon Nitride Ceramics A Review of Advances andMatt HillocksNo ratings yet

- sch80c July12019Document12 pagessch80c July12019alif suryantoNo ratings yet

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticFrom EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticRating: 3.5 out of 5 stars3.5/5 (10)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- The Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoFrom EverandThe Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoRating: 4.5 out of 5 stars4.5/5 (6)