Professional Documents

Culture Documents

The Migration To Higher Thrust Engines and The Effect On Control Speeds

Uploaded by

iceman737Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Migration To Higher Thrust Engines and The Effect On Control Speeds

Uploaded by

iceman737Copyright:

Available Formats

The Migration to Higher Thrust Engines and the Effect on Control Speeds Status

Steve Nelson Boeing Flight Operations Engineering

For the 777 airplane the growth in engine thrust levels has increased since the original PW4074 engine. This original engine was rated at 74000 pounds of thrust and was envisioned to grow to around 95000 pounds of thrust. The 777-200LR has a current offering of a 115000 pound thrust engine. With this engine growth the vertical tail and rudder size has remained the same. This has resulted in reduced margins between the normal operating speed and the in-air minimum control speed

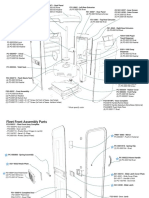

Yawing moment due to thrust asymmetry

Article 1

Large thrust commanded from operating engine

Failed engine

Yawing moment due to aerodynamic controls

This article is presented as part of the 2007 Boeing Performance and Flight Operations Engineering Conference, providing continuing support for safe and efficient flight operations.

2007 Performance and Flight Operations Engineering Conference

There is a speed below which there is a loss of directional control. This speed is defined by the inability to reliably maintain desired bank angle and/or heading at a given asymmetric thrust. This speed is always lower than the certified minimum control speed (VMCA/VMCL). FAR 25.149 states: VMC is the calibrated airspeed at which, when the critical engine is suddenly made inoperative, it is possible to maintain control of the airplane with that engine still inoperative and maintain straight flight with an angle of bank of not more than 5 degrees. Certified minimum operating speeds (V2, VREF) are always at greater than or equal to VMCA, and hence, have even greater margin to the loss of directional control speed. All models of the 777 family meet all minimum control speed regulations of all regulatory agencies where they are certified (FAA/EASA, etc). However, higher thrust asymmetry may cause the loss of directional control speed to become greater than stall warning speed at light weights. This raises the possibility that if airspeed were improperly reduced below the published operating speeds at these weights and thrust levels, the limit of full wheel and rudder control inputs could be reached prior to stick shaker activation. Flight crews following Boeing published procedures and flying recommended speeds will maintain directional control. However, loss of directional control prior to reaching stick shaker may occur after an engine failure in combination with: light weights, airspeeds lower than recommended, and higher than recommended thrust settings.

Landing Go-Around

One push of TO/GA button provides adequate thrust for most situations, and provides substantial speed margin to loss of directional control speed in the event of an engine failure. Two pushes of TO/GA button provides full G/A thrust, reducing margin to loss of control speed in the event of an engine failure.

VMCA

Loss of directional control speed (higher thrust)

Airspeed

Stick

shake

Loss of directional control speed (lower thrust)

Weight

1.2

Steve Nelson | The Migration to Higher Thrust Engines and the Effect on Control Speeds

Analysis for Probability of Violating Minimum Control Speed:

Assumptions are as follows: Engine failure is very rare Engine failure during critical takeoff phase (V1 to V2 + 15) is very rare Engine failure during go-around prior to acceleration is very rare With a fixed derate takeoff with an engine failure the pilot advances the throttle on the remaining engine to full thrust (against Boeing published procedures)

Conclusions are:

When making conservative assumptions all cases are extremely improbable (and at light weights)

The Takeoff Case:

FULL-RATED or ASSUMED TEMPERATURE METHOD (ATM) Takeoff: Full-rated takeoff V2 provides substantial speed margin to VMCA and loss of directional control speed. Assumed Temperature Method (ATM) provides same or greater margin, even if thrust is pushed (no reduction in VMC speeds assumed). FIXED DERATE Takeoff: Fixed derate takeoff limit thrust in takeoff calculations (VMC speeds are set by derated thrust level), yielding lower takeoff speeds and shorter field lengths. Pushing thrust higher upon engine failure violates procedures and reduces or eliminates margin to VMCG and VMCA, and reduces margin to loss of directional control speed Thrust levers should not be advanced beyond the fixed derate limit unless one of the following conditions apply: 1) Conditions are encountered during the takeoff where additional thrust is needed on both engines such as windshear. 2) Thrust increase following an engine failure, especially near V1, could result in a loss of directional control, and should not be accomplished unless in the opinion of the Captain, terrain contact is imminent. Flying Boeing procedures and recommended speeds will maintain directional control.

imum V2

Larg

dera e fixed

te min

Airspeed

Stick

shak

er

Loss of directional control speed

Weight

1.3

2007 Performance and Flight Operations Engineering Conference

Not following Boeing procedures and advancing thrust reduces the margin to loss of directional control speed. A V2 floor is one of the technical solutions that we are looking at. The V2 floor would maintain the larger speed margin to the loss of directional control speed that is found on the lower thrust engines.

i te m dera nimu m V2

Larg

e fix

ed

Airspeed Loss of directional control speed

Stick

shake

Weight

LANDING GO-AROUND:

If an engine fails during a go-around, an immediate loss of airspeed will occur. It is important that airspeed loss be recovered. Airspeed recovery is accomplished by following flight director guidance and Boeing recommended procedures. One push of TO/GA button provides adequate thrust for most situations, and provides substantial speed margin to loss of directional control speed in the event of an engine failure. Two pushes of TO/GA button provides full G/A thrust, reducing margin to loss of control speed in the event of an engine failure. Note: the minimum recommended approach speed is VREF + 5 knots. The 777-200LR maintains an excellent margin to loss of control speed due to a VREF speed floor. Boeing is currently evaluating speed margins for the 777-200ER at light weights to match 777-200LR methodology.

1.4

Steve Nelson | The Migration to Higher Thrust Engines and the Effect on Control Speeds

VREF (floored)

Airspeed

Stall-b

ase V REF

Loss of directional control speed

Stick

shake

Weight

The Final Effect is of minimal impact (but not zero):

Minor model 777-300/-300ER 777-200/-200ER Engine ALL PW4074, 4077, 4084 RR 877, 884 GE90-76B, -85B PW4090 RR 892 GE90-90B RR 895 GE90-94B GE90-110B1L (GE90-115BL) Exposure (loss of control speed > stick shaker speed) NONE NONE

777-200ER

Landing weights below ~365000 lb

777-200ER

Takeoff weights below ~380000 lb Landing weights below ~400000 lb Takeoff weights below ~445000 lb (Takeoff weights below ~465000 lb)

777-200LR 777 Freighter

The Plan from Here:

Boeing will revise the 777 Flight Crew Training Manual in October 2007. This revision will further clarify and emphasize the importance of following recommended crew procedures and maintaining adequate speed margins. Boeing will also publish a Flight Operations Review and an Aero Magazine article to provide additional background and clarifying information. Along with this emphasis on adhering to procedures we are also looking at technical solutions.

1.5

You might also like

- Rejected LandingDocument6 pagesRejected Landingiceman737No ratings yet

- Tailwind OperationsDocument3 pagesTailwind Operationsiceman737No ratings yet

- Center of Gravity Limitations - BoeingDocument63 pagesCenter of Gravity Limitations - Boeingiceman737No ratings yet

- Overweight Landing What To ConsiderDocument8 pagesOverweight Landing What To Considericeman737No ratings yet

- Driftdown and Oxygen Procedures Over High TerrainDocument22 pagesDriftdown and Oxygen Procedures Over High Terrainiceman737No ratings yet

- Procedural Instrument Approaches ExplainedDocument17 pagesProcedural Instrument Approaches Explainediceman737100% (1)

- Men's Fitness Workout Manual 2015Document149 pagesMen's Fitness Workout Manual 2015Mustafa SharkawyNo ratings yet

- Article Wise - A320 Sharklet PDFDocument3 pagesArticle Wise - A320 Sharklet PDFiceman737No ratings yet

- Characteristic Speeds PDFDocument29 pagesCharacteristic Speeds PDFiceman737100% (4)

- Cabin Smoke Awareness PDFDocument11 pagesCabin Smoke Awareness PDFiceman737No ratings yet

- Standard Go Around PDFDocument35 pagesStandard Go Around PDFiceman737100% (1)

- Airbus Flight Control Laws: Normal LawDocument4 pagesAirbus Flight Control Laws: Normal LawEmonAzzameenNo ratings yet

- Low Visibility OperationsDocument4 pagesLow Visibility Operationsiceman737100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Metode Erection Pierhead - Tandem CraneDocument27 pagesMetode Erection Pierhead - Tandem CraneDheny IrliansandyNo ratings yet

- Slam ShutDocument5 pagesSlam ShutchemtrolsNo ratings yet

- Thermodynamic Analysis For Industrial Refrigeration SystemsDocument113 pagesThermodynamic Analysis For Industrial Refrigeration SystemsAllan VillanuevaNo ratings yet

- 3D Stress and Strain Tutorial SheetDocument2 pages3D Stress and Strain Tutorial SheetTasmin Chandran0% (1)

- A Technique To Determine Lift and Drag Polars in FlightDocument7 pagesA Technique To Determine Lift and Drag Polars in Flightmykingboody2156No ratings yet

- 11C043F0300-5330 - 2 Calculation Carbon FilterDocument120 pages11C043F0300-5330 - 2 Calculation Carbon FilterLorenzoNo ratings yet

- Lecture 3 Kinematics and DynamicsDocument53 pagesLecture 3 Kinematics and Dynamicsyurong FengNo ratings yet

- SF 2700Document2 pagesSF 2700CristianMahechaNo ratings yet

- IRC 22 2015 Road Bridges Composite - Limit StateDocument91 pagesIRC 22 2015 Road Bridges Composite - Limit StateAnil Suryawanshi0% (1)

- Manual de Partes Catar Pillar Cargador Frontal 950 LDocument1,009 pagesManual de Partes Catar Pillar Cargador Frontal 950 Ljuan100% (4)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNo ratings yet

- How To Replace Front Suspension Shock Absorbers On Peugeot 407Document13 pagesHow To Replace Front Suspension Shock Absorbers On Peugeot 407Zoran AngelovskiNo ratings yet

- FFXMQ-P-Ducted-Engineering-Data4 FXMQ P Ducted Engineering DataDocument42 pagesFFXMQ-P-Ducted-Engineering-Data4 FXMQ P Ducted Engineering Datalongtt100% (1)

- Wheel Specifications: Line Comp 40 Boost Rear TLR Disc 27.5Document4 pagesWheel Specifications: Line Comp 40 Boost Rear TLR Disc 27.5diegoNo ratings yet

- DubaiDocument716 pagesDubaiAnkur100% (1)

- Parts FS3-30001 PDFDocument4 pagesParts FS3-30001 PDFJosé RezendeNo ratings yet

- Kobelco Crawler Crane Ck850 2f Operator Maintenance Manual S2gg24001ze09Document20 pagesKobelco Crawler Crane Ck850 2f Operator Maintenance Manual S2gg24001ze09hazel100% (44)

- Boiler Reference Manual: Section 2 Feedwater TreatmentDocument53 pagesBoiler Reference Manual: Section 2 Feedwater TreatmentSaad Javed100% (2)

- PDS Na GTSPP100 3L PDFDocument2 pagesPDS Na GTSPP100 3L PDFhamza2085No ratings yet

- Gpu400 120Document2 pagesGpu400 120dedonezaNo ratings yet

- SECTION 15075: Not For ConstructionDocument4 pagesSECTION 15075: Not For ConstructionahmadNo ratings yet

- FSB-5406B July 2011Document18 pagesFSB-5406B July 2011Anonymous J1sELDp7No ratings yet

- ERIKS - Techniki UszczelnienDocument28 pagesERIKS - Techniki UszczelnienAdrian BożykNo ratings yet

- A320 - 70 Powerplant (CFM56) - GFC-1Document33 pagesA320 - 70 Powerplant (CFM56) - GFC-1belinda koyaiyeNo ratings yet

- Vol 5 Issue 10 M 13Document4 pagesVol 5 Issue 10 M 13G venkateshNo ratings yet

- 3118F 3318F 3618F-SeriesDocument6 pages3118F 3318F 3618F-SeriesDavid CandoNo ratings yet

- Electromagnetic Induction 1. ACJC - 08H2P1 - Q31Document22 pagesElectromagnetic Induction 1. ACJC - 08H2P1 - Q31Jorge Vega RodríguezNo ratings yet

- AMME2200 2014 Semester 2 StudentDocument3 pagesAMME2200 2014 Semester 2 StudentdivaaaaaaaaaNo ratings yet

- SKF Lubrication Products and SystemsDocument60 pagesSKF Lubrication Products and SystemsNguyễn ĐạiNo ratings yet

- White Outdoor Parts Manual 13CO616G190 LT 1650 Year 2002Document17 pagesWhite Outdoor Parts Manual 13CO616G190 LT 1650 Year 2002Anonymous cPSmlINA30% (1)