Professional Documents

Culture Documents

ttt4 PDF

Uploaded by

tipo3331Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ttt4 PDF

Uploaded by

tipo3331Copyright:

Available Formats

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121 1234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

TomcoTechtips

TM

ISSUE 4

Ford's Microprocessor Control Unit (MCU)

In Issue 3, we covered "pulling codes" from Ford's EEC-III system. We will cover the EEC-IV in a later issue. The microprocessor control unit (MCU) computer system was first introduced by Ford in 1980 on California cars equipped with the 2.3L engine. Later, it was used with various 4, 6 and 8 cylinder engines. After 1985, MCU was only available on 5.8L cars with the optional police package, or on Canadian production. This system can be identified by the processor's location in the engine compartment. Further identification is its long, narrow connector located in the center of the case. The MCU controls engine air/fuel ratios, air injection, and, on some models, canister purge, spark retard, and also idle speed. The MCU system is similar in many respects to the EEC systems. The major difference is that the MCA system does not completely control ignition timing. DIAGNOSIS The microprocessor control unit can diagnose a malfunction currently present. It does not have a memory. Diagnosis output is through a self-test connector, similar in appearance to the EEC-IV, except that it does not have the separate single connector lead. CHECKING FOR CODES 1) Check vacuum hoses for leaks, cracks or improper routing. Check electrical connections. Ensure that all connections are clean and tight. 2) Warm engine to normal operating temperature. If air cleaner must be removed, leave all vacuum hoses attached. 3) Turn Ignition off. Locate self-test connector and insert a jumper wire between ground and trigger sockets (see illustration). Connect the positive lead of a pointer-type voltmeter to vehicle battery positive terminal, and the negative lead to self-test output socket. Set voltmeter on 0-20 volt scale.

GRD CONNECTOR

MCU MODULE

MICROPROCESSOR CONTROL UNIT

SELF-TEST OUTPUT

TRIGGER

Tomco, Inc.

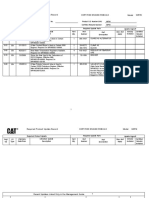

FORD MCU SYSTEM SERVICE CODES

4) On 4 cylinder engines, disable canister purge system by disconnecting and plugging hose from engine side of canister purge valve. On V-8 engines, remove PCV valve from valve cover. Key On, Engine Off Test Turn all accessories off, turn key on, but do not start engine. Watch voltmeter for code pulses which should appear within 30 seconds. Ignore any initial surge of voltage. Record code(s). CODE 11 12 25 41 42 44 45 46 51 52 53 4 CYL. System OK 6 CYL. System OK 8 CYL. System OK Idle Speed Knock System Fuel Lean Fuel Rich Thermactor Thermactor Diverter Thermactor By-Pass High/Low Vac Switch Open

Fuel Lean Fuel Rich Thermactor Thermactor Diverter Thermactor By-Pass Low Temp Switch Idle Tracking Switch WOT Vacuum Switch Open

Note:

Service codes are shown by voltage pulses. The first digit is indicated by a series of pulses, then the needle drops to zero for two seconds, then the second digit of the code is displayed. After all service codes are displayed, a four second pause will, occur, and then the codes will be repeated.

55 56

61 62 63 65 66 Idle Tracking Switch Closed WOT Vacuum Switch Closed *Altitude Switch

Fuel Lean Fuel Rich Thermactor Thermactor Diverter Thermactor By-Pass Low Temp Vac Switch WOT Vacuum Switch Open Crowd Vacuum Dual Temp Switch Open Switch Open Mid-Vac Switch Open Closed Throttle Vac Switch Open High/Low Vac Switch Closed WOT Vacuum *Altitude Switch Closed Switch Crowd Vacuum switch Closed

Note:

If voltmeter does not pulse but shows steady high or low readings, refer to a service manual for more detailed test procedures.

Closed Throttle Vac Switch Closed

*Not on all Models

ENGINE RUNNING AND NON-CODE TESTS

Engine running and noncode tests may be made after the vehicle has passed all other diagnosed tests. Refer to one of the service manuals for tests. When one of the diagnosed codes indicates a problem, check out the circuit - wiring, connectors, and the device itself - following procedure in the Ford Manual, or in one of the independent publications. One of the sources for this information is the Mitchell Ford Motor Co. MCU/EEC Driveabilty Procedures and Adjustments manual. Contact your local Mitchell representative or call Mitchell toll-free 1-800-8547030. (In California 1-800-4210159

NEW! Engine Performance Controls

DISK TYPE PORT FUEL INJECTORS

Port fuel injection is one of the major technical advancements responsible for today's fine performing and economical vehicles. But this advancement has had its drawbacks in that original equipment "pintle" type injectors tend to plug up with fuel deposits, particularly in short run operation. The Tomco injector uses a rotary selfcleaning disk instead of a pintle. Fuel spray is shot from high inside the injector, well away from excessive heat. The Tomco multi-point port fuel injector design overcomes the plugging problem by locating the disk and its seat up in the injector body away from combustion chamber heat. The disk has a rotating, self-cleaning feature similar to the disk type fuel inlet valve found in Tomco Carburetor kits. The small lightweight disk also minimizes injector noise and permits the injector to more closely follow the fuel requirments of the engine.

CLOSED

FUEL

ROTARY DISK

SEAT

FUEL

FUEL SPRAY LOCATION

THE INJECTOR USES A SELFCLEANING DISK INSTEAD OF A PINTLE.

DISK 2 NEW OXYGEN SENSORS

TOYOTA FLANGE TYPE SENSOR

Computer controlled Toyota vehicles have used oxygen (O2) sensors identical in their sensing and output characteristics to other foreign and domestic vehicles. Replacement sensors in the aftermarket have not been available because of the flange type mounting these sensors employ. Tomco's Toyota sensor #11013 uses flange type adapter assembled to universal sensor #11011 to solve this problem.

TOYOTA FLANGE TYPE O2 SENSOR

3 WIRE HEATED SENSOR

Certain late model foreign and domestic vehicles used a heated (3 wire) O2 sensor. These sensors employ a 12 volt heater to decrease the warm up time of the sensor. These sensors all have the same output characteristics. They differ only in the length of the leads and the type of connector. Tomco solved the problem availability of the correct lead length and connector type by using crimp type connectors and heat shrink tube insulations on the universal heated type sensor #11014.

3 WIRE HEATED SENSOR FOR LATE MODELS

NEW HEAVY DUTY ROTARY DISK EGR VALVE

BACK-PRESSURE TRANSDUCER

ROTARY DISK OPEN

SEAT (ORIFICE)

EGR valves are no longer just an engine accessory to meet emission standards. They play a vital part in eliminating detonation, ping or spark knock. Late model O.E. design valves have used a back pressure feature to

control the valves function. Clogging of the small back pressure passage in the diaphragm shaft by carbon deposits is a common problem with these type valves. Leakage at the valves seat has resulted in rough idle or stall-

ing complaints. Tomco's new heavy duty valves use a remotely located back pressure transducer and a self-cleaning rotating disk valve seat to solve these problems.

A.I.R. PUMP CHECK VALVES

A.I.R. PUMP CHECK VALVES

Air pump check valves are one-way valves in the air supply tubes to the exhaust system. They prevent exhaust gas back flow into the A.I.R.

Pump System which would damage the system. They can also be found in the Air Tube to three-way catalytic convertor and are then called converter check valves.

Underhood exhaust leak noise or exhaust bypassing the valve are failure symptoms.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PG PDFDocument72 pagesPG PDFtipo3331No ratings yet

- Rax PDFDocument8 pagesRax PDFtipo3331No ratings yet

- Ps PDFDocument30 pagesPs PDFtipo3331No ratings yet

- MTC PDFDocument162 pagesMTC PDFtipo3331No ratings yet

- Ma PDFDocument32 pagesMa PDFtipo3331No ratings yet

- Parking Brake System: SectionDocument8 pagesParking Brake System: Sectiontipo3331No ratings yet

- Lu PDFDocument16 pagesLu PDFtipo3331No ratings yet

- Tomcotechtips: Egr Valve Position SensorsDocument4 pagesTomcotechtips: Egr Valve Position Sensorstipo3331No ratings yet

- ttt12 PDFDocument4 pagesttt12 PDFtipo3331No ratings yet

- LT PDFDocument174 pagesLT PDFtipo3331No ratings yet

- Tomcotechtips: Idle Air ControlsDocument4 pagesTomcotechtips: Idle Air Controlstipo3331No ratings yet

- Tomcotechtips: Idle Speed Control MotorsDocument4 pagesTomcotechtips: Idle Speed Control Motorstipo3331No ratings yet

- AirBag 1 PDFDocument20 pagesAirBag 1 PDFYasid DisayNo ratings yet

- Sentra 2004 Inmo PDFDocument20 pagesSentra 2004 Inmo PDFtipo3331100% (2)

- Tomcotechtips: Titania 0xygen SensorsDocument4 pagesTomcotechtips: Titania 0xygen Sensorstipo3331No ratings yet

- Tomcotechtips: Cam and Crank Position SensorsDocument4 pagesTomcotechtips: Cam and Crank Position Sensorstipo3331No ratings yet

- Tomcotechtips: Cam and Crank Position SensorsDocument4 pagesTomcotechtips: Cam and Crank Position Sensorstipo3331No ratings yet

- ttt14 PDFDocument4 pagesttt14 PDFtipo3331No ratings yet

- Tomcotechtips: Air Charge Temperature SensorsDocument4 pagesTomcotechtips: Air Charge Temperature Sensorstipo3331No ratings yet

- ttt10 PDFDocument4 pagesttt10 PDFtipo3331No ratings yet

- ttt13 PDFDocument4 pagesttt13 PDFtipo3331No ratings yet

- Tomcotechtips: Engine Computer ControlsDocument4 pagesTomcotechtips: Engine Computer Controlstipo3331No ratings yet

- ttt11 PDFDocument4 pagesttt11 PDFtipo3331No ratings yet

- ttt1 PDFDocument4 pagesttt1 PDFtipo3331100% (1)

- Engine PDFDocument254 pagesEngine PDFtipo333194% (18)

- ttt9 PDFDocument4 pagesttt9 PDFtipo3331No ratings yet

- ttt8 PDFDocument4 pagesttt8 PDFtipo3331No ratings yet

- ttt3 PDFDocument4 pagesttt3 PDFtipo3331No ratings yet

- Hydrogen ConverterDocument114 pagesHydrogen ConverterFloreia SileNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Generators: Model: PDG35 35 KVA Available in Single Phase and Three PhaseDocument2 pagesGenerators: Model: PDG35 35 KVA Available in Single Phase and Three Phaseefmartin21No ratings yet

- Product Update Record G3516 IND ENG-GEN SET ENG - WPW 00001-99999Document2 pagesProduct Update Record G3516 IND ENG-GEN SET ENG - WPW 00001-99999feryNo ratings yet

- Em PDFDocument94 pagesEm PDFdanieldario33No ratings yet

- Mercedes-Benz Mbe 4000 Valve Lash CheckingDocument7 pagesMercedes-Benz Mbe 4000 Valve Lash CheckingIslam ShoukryNo ratings yet

- MC 10163029 9999Document2 pagesMC 10163029 9999begueNo ratings yet

- PLP E-4-2003, Reciprocating Pumps-3rd Ed-RosenDocument47 pagesPLP E-4-2003, Reciprocating Pumps-3rd Ed-Rosenivanov5559No ratings yet

- Impulse Turbine and Reaction TurbineDocument5 pagesImpulse Turbine and Reaction Turbinerahul100% (1)

- Johnson Evinrude PDFDocument19 pagesJohnson Evinrude PDFcarlos saul pereira noguera0% (2)

- Daftar Alat Bahan Praktek Tehnik Kendaraan Ringan 2020Document2 pagesDaftar Alat Bahan Praktek Tehnik Kendaraan Ringan 2020Kpm BekasiNo ratings yet

- Cat 314Document905 pagesCat 314Anderson Freitas0% (1)

- Studi Kasus Kerusakan Silinder Liner Engine PC PDFDocument46 pagesStudi Kasus Kerusakan Silinder Liner Engine PC PDFApril KukuhNo ratings yet

- Performing A Multiple Cylinder Cutout TestDocument14 pagesPerforming A Multiple Cylinder Cutout TestHarzanyi MaldonadoNo ratings yet

- New Holland E385B Operational PricipleDocument22 pagesNew Holland E385B Operational PriciplePirates Ars100% (1)

- Type of ROPS / OPG (Top Guard)Document1 pageType of ROPS / OPG (Top Guard)RasoolKhadibiNo ratings yet

- Huafengdongli R Series SparepartcatalogDocument10 pagesHuafengdongli R Series Sparepartcatalogcolleen100% (54)

- ActivityDocument5 pagesActivityALDANA MARY GARCIANo ratings yet

- AC Checklist of Tools Equipment Supplies and Materials and FacilitiesDocument2 pagesAC Checklist of Tools Equipment Supplies and Materials and FacilitiesRINA VENIDANo ratings yet

- 00 Datasheet - Spec AllDocument2 pages00 Datasheet - Spec AllJusril HidayatNo ratings yet

- "The Green Engine": A Seminar OnDocument24 pages"The Green Engine": A Seminar Onkalpesh badhanNo ratings yet

- Mio Soul (14d)Document307 pagesMio Soul (14d)HidayatNo ratings yet

- Internal Combustion Engines - MidtermsDocument29 pagesInternal Combustion Engines - Midtermsfoj90532No ratings yet

- 2017 D 2.0 TCI-R D 2.0 TCI-R Schematic Diagrams Engine Electrical System Engine Control System Schematic DiagramsDocument1 page2017 D 2.0 TCI-R D 2.0 TCI-R Schematic Diagrams Engine Electrical System Engine Control System Schematic Diagramslyanna120168No ratings yet

- Continental Diesel Engine Reference Guide: Make Fits Application Engine DetailsDocument1 pageContinental Diesel Engine Reference Guide: Make Fits Application Engine DetailsalexanderNo ratings yet

- Design of Turbine BladeDocument15 pagesDesign of Turbine BladeKailash Chauhan100% (1)

- 4 V 158 TiDocument2 pages4 V 158 TiGeovanny BajañaNo ratings yet

- John Deere 9 Series TractorsDocument28 pagesJohn Deere 9 Series TractorsHadron ColliderNo ratings yet

- SCTRDocument4 pagesSCTRPesala Manoj KumarNo ratings yet

- Bendix RSA Installation TroubleshootingDocument3 pagesBendix RSA Installation TroubleshootingbyllebobNo ratings yet

- PLTMG Prabumulih 18V34SG Rev.3 PendahuluanDocument39 pagesPLTMG Prabumulih 18V34SG Rev.3 PendahuluanOctavianus HarahapNo ratings yet

- Engine PartsDocument94 pagesEngine PartsOZON ccNo ratings yet