Professional Documents

Culture Documents

Chapter 8 Staircase

Uploaded by

Parth GondaliaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 8 Staircase

Uploaded by

Parth GondaliaCopyright:

Available Formats

8.

STAIRCASE

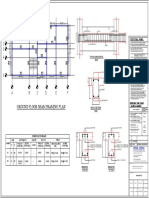

8.1 GENERAL Stair case is structural member used for vertical transportation in the building. In Meadows there are 3 lifts in each tower for vertical tower. So in case of power cut or any failur in lifts staircase can be used as emergency exit and for transportation of large funiture or material. Stair case consist of riser and tread. According to height of floor number of flight and risers are decided. In meadows two flights with one landing is provided.

In meadows, staircase is made up of RCC along with initial risers made up of block masonary. Different components of stair are as follows Riser Tread Nosing Going Hand Rail Landing Soffit etc TABLE 8.1 DETAIL OF STAIRCASE

SR NO. 1 2 3 4 5 6 7 8

DESCRIPTION

GENERAL DETAIL

Shape of stair case Number of flight Number of landing Number of riser Number of treads Type of staircase Formwork material used Reinforcement used

Dog legged 2 1 18 17 R.C.C Wooden HYSD

8.2 CONSTRUCTION PROCEDURE

FORMWORK ERECTION/ITS CHECK

STAIR CASE REINFORCEMENT

CHECKING OF REINFORCEMENT

CONCRETING

CURING

REMOVAL OF FORMWORK

FINISHING

FIG 8.1 CONSTRUCTION PROCEDURE

67

8.3 TOOLS AND EQUIPMENTS USED STAIR CASE CONSTRUCTION

1) Plumb bob 2) String (Dory) 3) Claw hammer 4) Spade 5) Rammer 6) Trowel 7) Iron Pan 8) Concrete Pump 9) Needle Vibrator 8.4 CONSTRUCTION PROCEDURE 8.4.1 FORMWORK ERECTION/ITS CHECK First of all, riser is marked from reference point. The level of bottom of landing slab is then determined from the drawing. Wooden sheets for the landing slab are laid on a support of props and wooden planks. From a landing slab, a thin plywood member is then fixed to the adjacent concrete wall with the help of nails. These wooden planks run along the length of flight. The shuttering of flight is then carried out. The bottom forms for the flight rests on horizontal member provided at regular spacing. These horizontal planks are supported on the runners. The runners in turn are support by props. Now, the level of tread and riser are marked on the adjacent wall by chalk. Riser forms are then placed according to the chalk marking. Their level and alignment is checked by spirit level. If the bubble in spirit level is in the centre then the alignment is correct. All the vertical wooden members are connected by a wooden plank in the centre and nailed. 68

Proper side support are then provided prior to concreting to resist the lateral pressure of concrete during the pour.

FIG 8.2 FORMWORK ERECTION 8.4.2 REINFORCEMENT ERECTION/ITS CHECK The reinforcement arrangement for the staircase start after the formwork is in place and confirms the desire level. First of all, the reinforcement laying for the landing slab is carried out as per drawing. Pull out bar from slab and are straightened. Bottom bars are laid according to the drawing. Approximately 60cm overlap is to be done.

69

After main bars are in position, the horizontal bars are fixed to them by means of binding wire. Concrete cover block are provided at bottom of main bar. Maximum bending moment is at bottom and so there is no top reinforcement in the middle portion of the flight.

FIG 8.3 REINFORCEMENT/ITS CHECK 8.4.3 CONCRETING After completion of reinforcement and formwork concreting started. Staircase concreting started from bottom riser. Then step by step upper riser has been concreted. Concreting done with boom placer or bucket crane. Concrete is laying properly with help of needle vibrator. M25 grade concrete is used. Capactiy of bucket is 0.3 cu m. Surface has finished with muster with help of levelling staff and dumpy level.

70

FIG 8.4 CONCRETING

71

8.4.4 CURING Formwork for staircase is removed generally after 7 days and curing is done for 10-14 days.

FIG 8.5 FINISHING/CURING

72

You might also like

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Proposed Apartment - : Sankalp Imperial House at MysuruDocument46 pagesProposed Apartment - : Sankalp Imperial House at MysuruMohammed AyanNo ratings yet

- BTEC HND in QUANTITY Surveying British College of Applied StudiesDocument8 pagesBTEC HND in QUANTITY Surveying British College of Applied StudiesDhanushka MadhurangaNo ratings yet

- Metode Erection LastDocument3 pagesMetode Erection Lastkrisna monicaNo ratings yet

- 15 StaircaseDocument128 pages15 Staircaseeunice1997031533% (3)

- STAGES of ConstructionDocument34 pagesSTAGES of Constructionbhaskar_065No ratings yet

- (S) Week 9 To 10 Tutorial - StairsDocument4 pages(S) Week 9 To 10 Tutorial - StairsnnnnnnnNo ratings yet

- Tunnel Form ConstructionDocument11 pagesTunnel Form Constructionmohammed alzanganaNo ratings yet

- Plinth Beam Work ProcedureDocument3 pagesPlinth Beam Work ProcedureMohd Muksin100% (2)

- StaircaseDocument9 pagesStaircaseNNo ratings yet

- Detailing StairsDocument7 pagesDetailing Stairselmerbarreras100% (1)

- Building Structure Fettuccine Bridge ReportDocument23 pagesBuilding Structure Fettuccine Bridge ReportChloe'No ratings yet

- Omicron/Tekton Construction Joint VentureDocument3 pagesOmicron/Tekton Construction Joint VentureRalph GalvezNo ratings yet

- StairsDocument22 pagesStairsPtpgStucNo ratings yet

- Introduction of StaircaseDocument9 pagesIntroduction of StaircaseRuzengulalebih ZEta's-ListikNo ratings yet

- Methods of ConstructionDocument25 pagesMethods of ConstructionIra MejiaNo ratings yet

- Screenshot 2023-04-02 at 9.22.27 AMDocument44 pagesScreenshot 2023-04-02 at 9.22.27 AMGamal AbdelwahidNo ratings yet

- Objectives of On The Job Training ProgramDocument17 pagesObjectives of On The Job Training ProgramArjun Kumar YadavNo ratings yet

- Unit8 PDFDocument14 pagesUnit8 PDFVictor OmotoriogunNo ratings yet

- Surge Shaft Concreting by Slip Form MethodDocument4 pagesSurge Shaft Concreting by Slip Form MethodCharumitra Singh YadavNo ratings yet

- Inspection and Maintenance of Steel Girders-9Document10 pagesInspection and Maintenance of Steel Girders-9vpmohammedNo ratings yet

- Well SinkingDocument9 pagesWell SinkingMRITYUNJAY PANDEYNo ratings yet

- Lift ShaftDocument21 pagesLift Shaftvijking100% (2)

- Chapter 4 Columns, Frames and WallsDocument40 pagesChapter 4 Columns, Frames and WallssijuwolaolurantiNo ratings yet

- Design and Construction of High and Large Span Cast-In-Place Reinforced Concrete Cantilever Flowering Frame BeamDocument5 pagesDesign and Construction of High and Large Span Cast-In-Place Reinforced Concrete Cantilever Flowering Frame BeamPreetham PjNo ratings yet

- Form WorkDocument12 pagesForm Workdharul khairNo ratings yet

- K SpanDocument36 pagesK SpanMerve MerveNo ratings yet

- Assignment 03Document4 pagesAssignment 03Sohail ShaikhNo ratings yet

- Structural Design Detailing and Construc PDFDocument40 pagesStructural Design Detailing and Construc PDFIbnuyusoff77No ratings yet

- Construction and Design of MultistoreyDocument37 pagesConstruction and Design of MultistoreyFawadNo ratings yet

- Unit 5 - Structural Design and Drawing (RCC-I) - WWW - Rgpvnotes.inDocument8 pagesUnit 5 - Structural Design and Drawing (RCC-I) - WWW - Rgpvnotes.insaheba khanNo ratings yet

- Tower ErectionDocument4 pagesTower Erectionparry_handa220100% (1)

- Building and Construction Project ReportDocument25 pagesBuilding and Construction Project ReportrfadeNo ratings yet

- Oil Storage Tank Construction ProcedureDocument11 pagesOil Storage Tank Construction ProcedureANGEL TORRES100% (3)

- Precast Building Using Dovetail JointDocument17 pagesPrecast Building Using Dovetail JointcmuruganNo ratings yet

- Dubai Metro ProjectDocument67 pagesDubai Metro ProjectMustafa Uzyardoğan100% (4)

- Types of StairsDocument12 pagesTypes of Stairsfaris danial100% (1)

- Detailing of Steel in Stair CasesDocument9 pagesDetailing of Steel in Stair CasesSandesh Kumar100% (1)

- StaircaseDocument14 pagesStaircaserameshbabu_1979No ratings yet

- Methodology For Cast in Place Girder CastingDocument10 pagesMethodology For Cast in Place Girder CastingHasnain Bukhari100% (2)

- Construction and Design of Multi Storey Building by Abhimanyu ParidaDocument38 pagesConstruction and Design of Multi Storey Building by Abhimanyu Paridadriverx47100% (19)

- Lift Slab 2Document8 pagesLift Slab 2mr_sunnydeiNo ratings yet

- Method Statement For Civil WorksDocument11 pagesMethod Statement For Civil Workssivanand90% (20)

- Bucket Elevator ManualDocument12 pagesBucket Elevator ManualKoevoet1No ratings yet

- StairsDocument21 pagesStairstomnubiNo ratings yet

- Reinforced Concrete SlabDocument9 pagesReinforced Concrete SlabUzil GabiolaNo ratings yet

- Arba Minch Institution of Technology: Internshipreport ON Eprdf Traning CenterDocument23 pagesArba Minch Institution of Technology: Internshipreport ON Eprdf Traning Centersamuel lireNo ratings yet

- 1.0 Objectives: Steel Portal Frame - Dqs 252Document14 pages1.0 Objectives: Steel Portal Frame - Dqs 252illya amyraNo ratings yet

- Method Statement For Construction of Box Culvert - Anil KumarDocument3 pagesMethod Statement For Construction of Box Culvert - Anil KumarAsad AshfaqNo ratings yet

- Method Installation of Steel Portal FrameDocument7 pagesMethod Installation of Steel Portal Frameillya amyra100% (1)

- Roofing ChannelDocument16 pagesRoofing ChannelarchayuNo ratings yet

- Method Installation of Steel Portal FrameDocument8 pagesMethod Installation of Steel Portal FrameMuhammad haziq Danial Bin HisharudinNo ratings yet

- Practical Stair Building and Handrailing: By the square section and falling line systemFrom EverandPractical Stair Building and Handrailing: By the square section and falling line systemNo ratings yet

- Stair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareFrom EverandStair-Building and the Steel Square: A Manual of Practical Instruction in the Art of Stair-Building and Hand-Railing, and the Manifold Uses of the Steel SquareNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Nit 1Document4 pagesNit 1Parth GondaliaNo ratings yet

- CC Road WorkDocument117 pagesCC Road WorkParth GondaliaNo ratings yet

- Bbs Format - Feet SystemDocument4 pagesBbs Format - Feet SystemParth GondaliaNo ratings yet

- Arts GK Questions and Answers in Gujarati Part1Document1 pageArts GK Questions and Answers in Gujarati Part1Parth GondaliaNo ratings yet

- Chapter 12 Concluding RemarkDocument1 pageChapter 12 Concluding RemarkParth GondaliaNo ratings yet

- Chapter 1 IntroductionDocument9 pagesChapter 1 IntroductionParth GondaliaNo ratings yet

- Academic Calender - M Tech Semester - Iii and V (Split) - Odd Term 2013-14 PDFDocument2 pagesAcademic Calender - M Tech Semester - Iii and V (Split) - Odd Term 2013-14 PDFParth GondaliaNo ratings yet

- Nirma University Practical Training ProgramDocument1 pageNirma University Practical Training ProgramParth GondaliaNo ratings yet

- Rheomac 760Document2 pagesRheomac 760Parth GondaliaNo ratings yet

- Analysis and Design of Guyed Transmission Towers-Case Study in Kuwait PDFDocument19 pagesAnalysis and Design of Guyed Transmission Towers-Case Study in Kuwait PDFParth Gondalia100% (2)

- Space FrameDocument3 pagesSpace FrameParth GondaliaNo ratings yet

- Chapter 12 Concluding RemarkDocument1 pageChapter 12 Concluding RemarkParth GondaliaNo ratings yet

- Theisis TopicDocument1 pageTheisis TopicParth GondaliaNo ratings yet

- 771 - 2 (Kitchen and Laboratary Sinks)Document16 pages771 - 2 (Kitchen and Laboratary Sinks)Parth GondaliaNo ratings yet

- Acceptance Criteria of Cement, Concrete and Steel and Its Physical TestDocument24 pagesAcceptance Criteria of Cement, Concrete and Steel and Its Physical TestParth GondaliaNo ratings yet

- Technical Specification ConcareDocument6 pagesTechnical Specification ConcareParth GondaliaNo ratings yet

- Rheomac 760Document2 pagesRheomac 760Parth GondaliaNo ratings yet

- 1.1 GeneralDocument10 pages1.1 GeneralParth GondaliaNo ratings yet

- MASTERSEAL - 501-502 - v5Document2 pagesMASTERSEAL - 501-502 - v5Parth GondaliaNo ratings yet

- Principles of Concrete Mix DesignDocument67 pagesPrinciples of Concrete Mix DesignAbu Mariam80% (5)

- IS 883 Design of Structural Timber in Building-Code of Pract PDFDocument18 pagesIS 883 Design of Structural Timber in Building-Code of Pract PDFHusseinali Hussein100% (2)

- Lessons From The Damage Behaviour of BuildingsDocument7 pagesLessons From The Damage Behaviour of BuildingsParth GondaliaNo ratings yet

- Quality Management in ConstructionDocument18 pagesQuality Management in ConstructionParth GondaliaNo ratings yet

- Concrete Mix Design Comparison Between BIS and ACIDocument7 pagesConcrete Mix Design Comparison Between BIS and ACIPraveen JainNo ratings yet

- On-Job-Training Activities and Outputs: Week 1Document42 pagesOn-Job-Training Activities and Outputs: Week 1Jem Fulgencio Dela CruzNo ratings yet

- Speedy ConstructionDocument53 pagesSpeedy ConstructionZash Ansari100% (3)

- BoQ 33 - 11 KV SUBSTATION - 01Document13 pagesBoQ 33 - 11 KV SUBSTATION - 01Ricky ChangNo ratings yet

- SMARTDEK Brochure PDFDocument12 pagesSMARTDEK Brochure PDFGhofur Yudhistira HartonoNo ratings yet

- Catalog Atlas FormDocument196 pagesCatalog Atlas FormrobertofortNo ratings yet

- Industry Guide For Formwork: Construction Industry South Australia JUNE 2012Document37 pagesIndustry Guide For Formwork: Construction Industry South Australia JUNE 2012tino3528100% (6)

- SikaGrout-220 2011-11 - 1 PDFDocument4 pagesSikaGrout-220 2011-11 - 1 PDFGabriel LimNo ratings yet

- Under The Guidance of Dr. A. Mallika: Neeta Rautela 15071D2005Document22 pagesUnder The Guidance of Dr. A. Mallika: Neeta Rautela 15071D2005Neeta RautelaNo ratings yet

- U-BOOTS (1) Technical SeminarDocument18 pagesU-BOOTS (1) Technical SeminarBasavaraj M PatilNo ratings yet

- Work Breakdown Structure (WBS)Document6 pagesWork Breakdown Structure (WBS)Zamri MohamedNo ratings yet

- 2020 RAB PANTI ASUHAN (Englis G)Document3 pages2020 RAB PANTI ASUHAN (Englis G)LJ LJ rahmatNo ratings yet

- 1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2Document11 pages1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2mijanur rahmanNo ratings yet

- TEC-033000 - MET-DoR-PIV-P635 (Method Statement For Casting Sloped RCC Elements)Document13 pagesTEC-033000 - MET-DoR-PIV-P635 (Method Statement For Casting Sloped RCC Elements)Tomi Wiryandi SaputraNo ratings yet

- Civil BidDocument120 pagesCivil BidVirendra ChavdaNo ratings yet

- Site VisitDocument17 pagesSite VisitShantanuShahNo ratings yet

- Anchor System DW 15,20,26Document28 pagesAnchor System DW 15,20,26idesawy1982No ratings yet

- Pt. Cemindo Gemilang Mechanical Daily Work Report: Total 0.00 0.000% 0.000% 0.000%Document2 pagesPt. Cemindo Gemilang Mechanical Daily Work Report: Total 0.00 0.000% 0.000% 0.000%fauzan tarmiziNo ratings yet

- Architectural Formwork in High Rise ConstructionDocument59 pagesArchitectural Formwork in High Rise ConstructionShivaraju HNo ratings yet

- Ground Floor Beam Framing PlanDocument1 pageGround Floor Beam Framing Planabhishek negiNo ratings yet

- Project ReportDocument19 pagesProject ReportSomeshwar BàndNo ratings yet

- Syllabus For Construction (MES)Document90 pagesSyllabus For Construction (MES)anislinek15No ratings yet

- Contractor'S Statement of Work Accomplished: Environmental Management Bureau 10Document3 pagesContractor'S Statement of Work Accomplished: Environmental Management Bureau 10Razul DaranginaNo ratings yet

- Cross Drainage Works BOQ RATESDocument4 pagesCross Drainage Works BOQ RATESvmpandey100% (2)

- Sample EstimatesDocument159 pagesSample Estimatesadhinarayan1998No ratings yet

- Morth 1500 FormworkDocument9 pagesMorth 1500 FormworkRamesh50% (2)

- Manual 9T Edge Lifter 2015Document8 pagesManual 9T Edge Lifter 2015darren dmuscat1hotmail.comNo ratings yet

- Yale Nandoms Technical ReportDocument48 pagesYale Nandoms Technical ReportJy GrilloNo ratings yet

- Technical SpecificationsDocument8 pagesTechnical SpecificationsSaud PathiranaNo ratings yet

- Centering and ShutteringDocument7 pagesCentering and ShutteringpreethiNo ratings yet