Professional Documents

Culture Documents

Mechanical Engineering Syllabus

Uploaded by

Vikram BorkhediyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Engineering Syllabus

Uploaded by

Vikram BorkhediyaCopyright:

Available Formats

KING FAHD UNIVERSITY OF PETROLEUM & MINERALS

Department of Mechanical Engineering

ME 308 Machine Design II 2006-2007 (062)

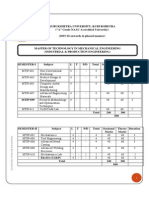

ME Mission The department is committed to providing highest quality education in mechanical engineering, conducting world-class basic and applied research, addressing the evolving needs of industry and society, and supporting the development of more competitive and new industry in the Kingdom of Saudi Arabia. Catalog Description Design of Elements: bearings (journal and anti-friction); spur, helical, bevel and worm gears; flexible drives (belts and chains); clutches and brakes; Springs; design optimization. Laboratory sessions to supplement and to apply the material covered in the lectures. Consideration of manufacturing aspects of the design (limits and fits); projects in stages leading to an assembly. Instructor Dr. Abdel-Salam M. Eleiche Bldg. 22-237 Phone: 860-3765 E-mail:eleichea@kfupm.edu.sa Office Hours SUMTW: 1-2 pm Text Mechanical Engineering Design by J.E. Shigley, C.R. Mischke and R. G. Budynas, 7th ed. References 1. Standard Handbook of Machine Design by J.E. Shigley and C.R. Mischke, McGraw Hill Book Company. 2. Marks Standard Handbook For Mechanical Engineers, by Avalone Baumeister, 10th Ed. McGraw Hill Book Company. 3. Machine Elements in Mechanical Design, by R. L. Mott, 2nd Ed. Prentice Hall 4. Fundamentals of Machine Components Design, by R. C. Juvinall and K. M. Marshek, 2nd Ed. John Wiley. 5. Fundamentals of Machine Elements, by B. J. Hamrock, Bo Jacobson and S. R. Schmid, 1 st Ed., McGraw Hill Book Company. 6. ME-308 Laboratory Manual, (General Design Procedures and Guidelines) Course Objectives 1. To analyze mechanical systems and select proper machine elements (bearings, gears, springs, belts and pulleys, chains and sprockets). 2. To design machine elements by specifying their type, geometry, material and heat treatment and how to integrate these elements to build a mechanical system. 3. To learn how to work in a design team and to understand group dynamics 4. To perform a complete project and present his work in an engineering design report. Prerequisites This is the second course of machine design. In the first course (ME 307), the student is expected to have learned: Stress and deflection analysis Buckling

Static and fatigue failure criteria Analysis and design of bolted and welded joints Shaft design and analysis The student is also expected to be able to use SOLIDWORKS (or AutoCAD) to perform drawings of machine elements and systems (ME 210). Course Outline 1. Rolling contact bearings 2. Spur gears 3. Helical worm and bevel gears 4. Strength of Spur and Helical gears 5. Lubrication and journal bearings 6. Clutches, brakes, couplings and flywheels 7. Belts and chain drives Reading Assignments: Chapter Chapter 11 Chapter 13 Chapter 13 Chapter 14 Chapter 12 Chapter 16 Chapter 17 (# lectures) (6-7) (5-6) (3-4) (5-6) (8-9) (8-9) (4-5)

Sections: 11.7; 13.8; 16.6; 17.6 and 17.7.

Omitted Material : Measurement of viscosity (p. 610); cross helical gears (689); sections 14.1, 14.2; 16.11 and 16.12. Evaluation: All Exams (including the Final) and Quizzes will be OPEN book 1. MAJOR and FINAL EXAMS: There will be two open book major exams containing open-ended problems. Major Exam 1: Saturday 24-3-07, 8-10 pm, Location: TBA. Major Exam 2: Sunday 29-4-07, 8-10 pm, Location: TBA. Final Exam: Monday 11-6-07, 7:30 am, Location: TBA. 2. ATTENDANCE: Attendance will be closely monitored, according to University regulations. HOMEWORKS: Homework will be assigned, collected and graded. Late submissions will NOT be accepted.

3.

4.

LAB ASSIGNMENTS: Laboratory sessions will be conducted in parallel with lectures and will include long projects. Your achievement and progress during class time will be graded by the end of each Lab. A final report for every project is also required and will be graded as well. When a new project is assigned the former one will be collected for grading. Late submissions will NOT be accepted.

5.

RELATIVE WEIGHTS AND GRADING: * * * * * * Homework & attendance Quizzes (4-6) Lab Projects Lab. participation Major Exams (2) Final Exam 7% 8% 15% 10% 30% (15% each) 30%

Student Learning Outcomes Objective 1 1. The student is expected to analyze mechanical systems and select the proper machine elements (bearings, gears, pulleys, belts, ) from commercial catalogs for a required application. Objective 2 2. The student is expected to be able to analyze proposed design solutions and suggest modifications and improvements. 3. The student should be able to execute original designs of machine elements. 4. The student should be able to produce design sketches and integrate the designed or selected elements into a working mechanical system. Objective 3 5. The student will be able to hold and lead efficient design team meetings 6. He is expected to write minutes Objective 4 7. The student will be able to implement design procedures to perform complete design projects individually or in a team. 8. The student is expected to communicate the implemented design ideas by performing production CAD drawings, writing technical reports and making oral presentations.

You might also like

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- MENG 3506 Syllabus Spring2018Document2 pagesMENG 3506 Syllabus Spring2018Hussein SeoudiNo ratings yet

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLANo ratings yet

- Md2 Syl PDFDocument3 pagesMd2 Syl PDFHimanshu JangidNo ratings yet

- MECH344 Course Ouline Winter 2012-13Document3 pagesMECH344 Course Ouline Winter 2012-13bookdigitNo ratings yet

- Chapters 1 To 4Document108 pagesChapters 1 To 4Andreu1287100% (1)

- Machine Elements Design SyllabusDocument2 pagesMachine Elements Design SyllabusJoão Luis BarrosNo ratings yet

- Criteria 3 - 21.11.2018 2.30pm PDFDocument54 pagesCriteria 3 - 21.11.2018 2.30pm PDFshivakeesNo ratings yet

- 6th Sem - 7 - Mechanical Engineering PDFDocument37 pages6th Sem - 7 - Mechanical Engineering PDFप्रबुद्ध खिलाड़ीNo ratings yet

- MENG 2013 Machine Design II OutlineDocument6 pagesMENG 2013 Machine Design II OutlineHazAuditoreNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- 6th Sem - 7 - Mechanical Engineering - 2 PDFDocument39 pages6th Sem - 7 - Mechanical Engineering - 2 PDFfotickNo ratings yet

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaNo ratings yet

- Product Design Engineering - II SyllabusDocument3 pagesProduct Design Engineering - II SyllabusSudeep UpadhyeNo ratings yet

- Mee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFDocument2 pagesMee3001 Design-Of-Machine-Elements TH 1.3 47 Mee3001 17 PDFAK PRODUCTIONSNo ratings yet

- 2173408Document3 pages2173408Dipen RavalNo ratings yet

- DKOM Lab ManualDocument24 pagesDKOM Lab Manualaakash chakrabortyNo ratings yet

- 4.32 & 4.33 TE & BE - Mech EnggDocument13 pages4.32 & 4.33 TE & BE - Mech EnggganeshNo ratings yet

- Bmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lDocument3 pagesBmee301l Design-Of-Machine-Elements TH 1.0 67 Bmee301lKrijayNo ratings yet

- Kom CoursefileDocument53 pagesKom CoursefileManda Ramesh BabuNo ratings yet

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- ME 805 D-Machine Tool DesignDocument3 pagesME 805 D-Machine Tool Designworkineh gebeyehuNo ratings yet

- 18ME62Document263 pages18ME62Action Cut EntertainmentNo ratings yet

- Nirma University Institute of Technology School of EngineeringDocument30 pagesNirma University Institute of Technology School of EngineeringKarthikeyanNo ratings yet

- Renewable Energy TechnologiesDocument8 pagesRenewable Energy Technologiesd.sarukNo ratings yet

- Honours CurriculumDocument13 pagesHonours CurriculumJOIJODENo ratings yet

- Course Outline: International Islamic University MalaysiaDocument6 pagesCourse Outline: International Islamic University Malaysiade_stanszaNo ratings yet

- A Level GeometricalDocument10 pagesA Level GeometricalBion SigosNo ratings yet

- MTech Machine Design PDFDocument41 pagesMTech Machine Design PDFswapnilNo ratings yet

- Uceou - Edu Mechanical M.E. Approved Syllabus 2010-2011 ME PRODUCTION 2010Document30 pagesUceou - Edu Mechanical M.E. Approved Syllabus 2010-2011 ME PRODUCTION 2010J KishanNo ratings yet

- Course Outline: International Islamic University MalaysiaDocument5 pagesCourse Outline: International Islamic University MalaysiafazdrulakiffNo ratings yet

- Design of Machine Elements (MCT 3214)Document20 pagesDesign of Machine Elements (MCT 3214)Abdin YousifNo ratings yet

- Study Material 10ME52 DME1Document242 pagesStudy Material 10ME52 DME1Sagar GowdaNo ratings yet

- MEC531 Intro & Course Outline 2015 - HalimDocument7 pagesMEC531 Intro & Course Outline 2015 - Halimarina azharyNo ratings yet

- Mec531 IntroductionDocument14 pagesMec531 IntroductionMuhammad ZulhilmiNo ratings yet

- 4th Sem Milling MachineDocument32 pages4th Sem Milling MachineKaran KantiNo ratings yet

- 6th Sem. Syllabus.Document13 pages6th Sem. Syllabus.ashutosh.vssplNo ratings yet

- CAE Lab 065 RecordDocument38 pagesCAE Lab 065 RecordRudra Sai SandeepNo ratings yet

- VTU - V & VIIIsem Syllabus 23-7-8Document11 pagesVTU - V & VIIIsem Syllabus 23-7-8manjunatha tNo ratings yet

- Course Syllubus Design 2Document5 pagesCourse Syllubus Design 2melihNo ratings yet

- Instruction Plans: InstructionsDocument20 pagesInstruction Plans: InstructionsDivy GuptaNo ratings yet

- Machine Design II (ME-3217)Document12 pagesMachine Design II (ME-3217)Somnath SomadderNo ratings yet

- BE Mechanical-Mumbai UniversityDocument82 pagesBE Mechanical-Mumbai UniversityJayesh NavareNo ratings yet

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDocument16 pagesMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarNo ratings yet

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDocument23 pagesBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNo ratings yet

- MACHINEDESIGNDocument35 pagesMACHINEDESIGNBrandon AllenNo ratings yet

- ECE 7995-Embedded Systems For Vehicles-Syllabus S17 - v2Document6 pagesECE 7995-Embedded Systems For Vehicles-Syllabus S17 - v2AsraButoolNo ratings yet

- AU 7th SEM - AU 21-22140921010753Document7 pagesAU 7th SEM - AU 21-22140921010753Sumit VermaNo ratings yet

- Application of PBL in The Course Fluid and Electrical Drive Systems, Case Study: Manufacturing An Automated Punch MachineDocument11 pagesApplication of PBL in The Course Fluid and Electrical Drive Systems, Case Study: Manufacturing An Automated Punch MachineAndrian PutraNo ratings yet

- Portable Car Lift (ME 303-308 Lab)Document3 pagesPortable Car Lift (ME 303-308 Lab)Abdullah MashatNo ratings yet

- Fem PDFDocument65 pagesFem PDFManda Ramesh BabuNo ratings yet

- Foundry and Forging Laboratory ManualDocument110 pagesFoundry and Forging Laboratory Manualvampiredraak2712No ratings yet

- Overview of The ModuleDocument11 pagesOverview of The ModuleyoyogiftuNo ratings yet

- Nba mp-1Document5 pagesNba mp-1krunal07786No ratings yet

- CN4122: Process Synthesis and SimulationDocument2 pagesCN4122: Process Synthesis and SimulationEsmond TanNo ratings yet

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessFrom EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessNo ratings yet

- Schaum's Outline of Strength of Materials, Seventh EditionFrom EverandSchaum's Outline of Strength of Materials, Seventh EditionRating: 4.5 out of 5 stars4.5/5 (9)

- 218 ECAB4 D 01Document114 pages218 ECAB4 D 01Vikram BorkhediyaNo ratings yet

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdNo ratings yet

- Storage Tank DesignDocument42 pagesStorage Tank Designronavanessa70% (10)

- Desub Mandual TbeltDocument141 pagesDesub Mandual TbeltVikram BorkhediyaNo ratings yet

- Common Engineering TermsDocument23 pagesCommon Engineering TermsAitazaz Ahsan0% (1)

- Mechanical Engineering Job Interview Preparation GuideDocument25 pagesMechanical Engineering Job Interview Preparation Guidenage_scribdNo ratings yet

- QpmeDocument16 pagesQpmeSandeep PandeyNo ratings yet

- Maintenance Manual - Hero ScooterDocument3 pagesMaintenance Manual - Hero ScooterVikram BorkhediyaNo ratings yet

- Sai Machine Tool LTD CapabilitiesDocument10 pagesSai Machine Tool LTD CapabilitiesVikram BorkhediyaNo ratings yet

- Owners Manual Activa 5G EnglishDocument83 pagesOwners Manual Activa 5G EnglishVikram Borkhediya50% (2)

- Patwari 2017 CutoffDocument66 pagesPatwari 2017 CutoffVikram BorkhediyaNo ratings yet

- Hero PleasureDocument4 pagesHero PleasureVikram BorkhediyaNo ratings yet

- Guide To Buying A HouseDocument57 pagesGuide To Buying A HouseVikram BorkhediyaNo ratings yet

- Book Arab Spring West AsiaDocument172 pagesBook Arab Spring West AsiaVikram BorkhediyaNo ratings yet

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaNo ratings yet

- Sheetmetal Design GuidelinesDocument5 pagesSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- Casting Details and CavitiesDocument14 pagesCasting Details and CavitiesVikram BorkhediyaNo ratings yet

- Ojas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringDocument2 pagesOjas Dekor - Plywood, Veener, Laminates, Alluminium, Wood, MDF, Wooden FlooringVikram BorkhediyaNo ratings yet

- Kitchen WorkstationDocument15 pagesKitchen WorkstationVikram BorkhediyaNo ratings yet

- Fundamentals of CastingDocument18 pagesFundamentals of CastingKasinathan JeevaNo ratings yet

- Gadget Notification of MP Education DepartmentDocument9 pagesGadget Notification of MP Education DepartmentVikram BorkhediyaNo ratings yet

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- 2 - Design BasicsDocument26 pages2 - Design BasicsVikas TiwariNo ratings yet

- Automobile BrakesDocument36 pagesAutomobile BrakesVikram BorkhediyaNo ratings yet

- Shafts and Axles Chapter 29Document28 pagesShafts and Axles Chapter 29Vikram BorkhediyaNo ratings yet

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyNo ratings yet

- Indore Illigal ColoneyDocument7 pagesIndore Illigal ColoneyVikram BorkhediyaNo ratings yet

- Dr. A. Aziz Bazoune: Mechanical Engineering DepartmentDocument36 pagesDr. A. Aziz Bazoune: Mechanical Engineering DepartmentVikram BorkhediyaNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaNo ratings yet

- AWS Solution Architect SampleDocument3 pagesAWS Solution Architect SamplepandiecNo ratings yet

- RTP Cap III GR I June 2022Document92 pagesRTP Cap III GR I June 2022मदन कुमार बिस्टNo ratings yet

- S No Name of The Company Regional OfficeDocument39 pagesS No Name of The Company Regional OfficeNo nameNo ratings yet

- Due Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxDocument3 pagesDue Friday, February 21, 2014 by 5:00 P.M. To The AE312 MailboxankstamanNo ratings yet

- File 1379580604 PDFDocument9 pagesFile 1379580604 PDFMuhammad Salik TaimuriNo ratings yet

- Code of Ethics Multiple Choice QuestionsDocument4 pagesCode of Ethics Multiple Choice QuestionsGideon P. Casas88% (24)

- However, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To PrescriptionDocument7 pagesHowever, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To Prescriptionkemsue1224No ratings yet

- Abstract 2 TonesDocument8 pagesAbstract 2 TonesFilip FilipovicNo ratings yet

- D Fwxfs Fzô Fee F Fs Wû Àfiy°Ff WX' Af° F Ff°Fe W F FF 21 D F°Ff Izy QZVF FWX A FZ Afz FF FF 23Document24 pagesD Fwxfs Fzô Fee F Fs Wû Àfiy°Ff WX' Af° F Ff°Fe W F FF 21 D F°Ff Izy QZVF FWX A FZ Afz FF FF 23Govind Chandra DwivediNo ratings yet

- Prime Time FeaturesDocument15 pagesPrime Time FeaturesPruthwish PatelNo ratings yet

- 13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkDocument20 pages13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkAbidullahNo ratings yet

- Snubbing PDFDocument134 pagesSnubbing PDFNavin SinghNo ratings yet

- Safety Manual For DumperDocument9 pagesSafety Manual For DumperHimanshu Bhushan100% (1)

- Indiabulls PILDocument64 pagesIndiabulls PILPGurus100% (1)

- JSSG-2010-7 - Crash Systems Handbook PDFDocument155 pagesJSSG-2010-7 - Crash Systems Handbook PDFdaymonNo ratings yet

- Learning Dynamics and Vibrations by MSC AdamsDocument80 pagesLearning Dynamics and Vibrations by MSC AdamsFrancuzzo DaniliNo ratings yet

- 75 December Month Current Affairs Questions 35Document34 pages75 December Month Current Affairs Questions 35Sailo AimolNo ratings yet

- Train Details of New DelhiDocument94 pagesTrain Details of New DelhiSiddharth MohanNo ratings yet

- Snmpwalk Westermo DSL ModemDocument24 pagesSnmpwalk Westermo DSL ModemAexNo ratings yet

- SEMIKRON DataSheet SK 30 GD 066 ET 24914960Document5 pagesSEMIKRON DataSheet SK 30 GD 066 ET 24914960prajwalNo ratings yet

- Ujar10 10434839Document11 pagesUjar10 10434839Fitryane LihawaNo ratings yet

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocument10 pagesSpecification For Wrought Austenitic Stainless Steel Piping FittingsAnilNo ratings yet

- 8 - Surface Mining - Wire - RopeDocument11 pages8 - Surface Mining - Wire - RopeSuelen Barbosa Sdrill do BrasilNo ratings yet

- AAU Karate Handbook: "Sports For All, Forever"Document58 pagesAAU Karate Handbook: "Sports For All, Forever"jeffrey_trzaskusNo ratings yet

- ECEN 160 Final Project Logisim Instrs and DecoderDocument2 pagesECEN 160 Final Project Logisim Instrs and DecoderEvandro Fernandes LedemaNo ratings yet

- Sky 1Document14 pagesSky 1Vũ Quang HưngNo ratings yet

- P443 OrderForm - v43 - 122020Document14 pagesP443 OrderForm - v43 - 122020Tuan Dang AnhNo ratings yet

- Cbjessco 13Document3 pagesCbjessco 13Fawaz ZaheerNo ratings yet

- CASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Document7 pagesCASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Laiza MayNo ratings yet

- Icd-10 CM Step by Step Guide SheetDocument12 pagesIcd-10 CM Step by Step Guide SheetEdel DurdallerNo ratings yet