Professional Documents

Culture Documents

BFV STD - Specdamper

Uploaded by

kselvan_1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BFV STD - Specdamper

Uploaded by

kselvan_1Copyright:

Available Formats

T2.

00 materials and of

INTENT OF SPECIFICATION This sub-chapter is intended to cover design, procurement,manufacture/fabrication,shop supply of various types of valves the testing C.W.system

2 nos 210 MW units. Scope of Work: Design, painting, site, comprehensive Testing as with of The contractor's scope of work shall Manufacture, at works, at site, Shop include

engineering, Packing, Unloading, insurance, commissioning

testing, to

loading

Transportation Storage, Erection, of

Handling

Preservation, of the

required number

valves

listed below along with a pair of counter flanges necessary nuts, bolts, washers and gaskets for each the valves. Scope of Supply

covered valves

i)

The

scope

of supply of

the

contractor

under this specifications shall include the as specified in the following paragraphs; and

maintenance T2.01 tested other and specified T2.01.02 T2.01.01

ii)

Mandatory

spare

parts

and

special

tools and tackles. Equipment Specifications The as valves shall be designed, manufactured and per relevant Indian Standards or as per

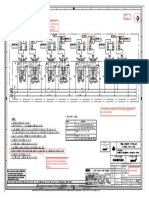

International standards acceptable to the Purchaser will below. Motor operated Butterfly i) No.of valves Valves 6 Nos. be suitable for the duty conditions

ii) valve 5155/AWWA electric iv)

Nominal diameter

1600 mm. Flanged as C per - 504 Butterfly BS with

iii) Type of valve

actuator. Location Indoor in pump house.

T2.01.03

Motor operated butterfly i) No.of valves Location -

valve 2 Nos. Makeup forebay. water pipe

to

ii)

iii) Nominal diameter valve 5155/AWWA electric up v) T2.01.04 A. for nos. pipeline iii) Nominal diameter Gear i) ii) Location operated butterfly No.of valves Location iv) Type of valve

600 mm. Flanged as C-504 actuator water. Butterfly

Per BS with for make-

Outdoor valves

8 Nos. 4 nos. on tappings

heat exchangers & 4 on makeup water as shown in the drawing. 600 mm

Flanged Per B. water tower)

iv)

Type6 of valve

Gear

operated valve as

Butterfly

BS- 5155/AWWA. i) ii) No.of valves Location 4 Nos. Cooling Tower Hot

inlet (2 Nos. per iii) Nominal diameter iv) Type of valve 1600 mm Gear operated

Flanged BS T2.01.05 Manually operated butterfly i) ii) No.of valves Nominal diameter -

Butterfly valve as Per - 5155/AWWA. valves 2 Nos. 300 mm.

operated valve for T2.01.06 and

iii) Type of valve

Manually Flanged as Butterfly

Per BS- 5155/AWWA

blow-down water. Miscellaneous valves Gate/sluice valves shall conform to IS:780-1984

IS:2906-1984(R.A.1990)Class PN 1.0 as applicable. I. I. Globe valves shall conform to IS:778-1984, Class

Non-return valves shall conform to IS:5312-1986,Part Butterfly valves shall conform to AWWA C-504/BS 5155.

Flange drilling of all valves shall be as per table 11

of IS:6392-1971. rating 1987. be and T2.01.07 All the Butterfly valves shall be of 6 Kg/cm2

and conform to B.S -5155-1984 or The valves shall be double flanged supplied gaskets. with matching

ANSI/AWWA-C-504type and shall

flanges

,bolts,nuts

of is T2.01.08 gear switches

Drilling

of

flanges

shall

be

as

per

table-11

IS-6392- 1971. The analysis of liquid to be handled given in Annexures-D All electric actuator a) Complete drive, with & E. driven valves electric motor shall be : ,necessary ,torque

position limit switches

and terminal board. power b) Complete with Micro switch for disconnecting supply when the valve is operated manually. and c) All limit and torque switches shall be dust

water proof. and and simultasuit T2.01.09 d) The humid 100% climate prevailing at site is tropical 50 Deg.C

with maximum temparature of humidity but both not

occuring

neously.

The equipment shall be designed to

this condition. the Direction of flow shall be clearly indicated on

valve by embossing an arrow on the valve body.

T2.01.10 steel

All

the valves shall have a permanent stainless

valve rating T2.01.11

name

plate and stainless steel tag fixed on the

body indicating the tag number,diameter,pressure and manufacturing standard code of the valve.

shut

The valves shall be designed for 100% water tight off.

wheel/ clearly to

T2.01.12

All

the

valves shall be provided The

with

hand be arrow

lever. marked

face of the wheel/lever shall

with the words OPEN and CLOSE and an

indicate the direction for opening/closing. flanges 1992 T2.01.13 All the valves shall be supplied with companion made of Carbon Steel plates conforming to Gr.2A IS:2062-

and drilled to I.S.6392-1971 Table-11.

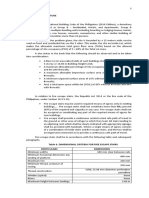

Materials of construction: 1. 2. 3. 4. 5. 6. T2.01.14 Body Disc Seat Shaft Seat retaining rings/and screws Shaft bearing : : : : : : C.I. IS-210 Grade FG260 C.I. IS-210 Grade FG260 Nitrite rubber/S.S (304) S.S. (304) S.S. (304) Self lubricated

TECHNICAL SPECIFICATION FOR MOTOR ACTUATORS FOR VALVES AC Motors

cooled,

Motor

shall

be

totally

enclosed,

fan

squirrel cage type. and Degree of protection for motors, bearings

terminal boxes shall be IP-55. either Shaft extension as per requirement. Bearing suitable for running of motors in

direction. Terminal box liberally Terminal box of all motors shall be

Aluminium enclosed

sized

to

accomodate PVC

termination as

of per

Conductor table.

armoured cables

the on

Terminal

box

shall be provided normally

on

right side when viewed from the driving end or the top. Cooling Motors shall be TEFC design Ventilation system shall be effective of direction of rotation. Quality of operation Rotor shall be dynamically balanced. Vibration and noise level shall be as

irrespective

per

IS-12O75- 1991 & IS-12O65-1987 respectively. Electrical Design Motors shall be suitable for DOL starting Shall be suitable for 415V + 6% , 50HZ + 3% Motors shall have class B to 65 insulation deg.C over

with an earthing 325-

temperature

rise

limited

ambient of 55 deg.C. All motors shall be provided with 2 nos. bolts. All motors shall be designed conforming to IS1978. Limit switches

robust repetitive

All

limit

switches

shall

be

of

construction, operations.

capable of withstanding

depending

Shall

be lever

or rotating cam

type

upon requirement. contacts. and 65 Shall be provided with 10 A, 2 NO + 2 NC Shall weather be housed proof, in robust metalic, dust to IP-

enclosure

conforming

enclosure, suitable for outdoor installation. Earthing studs (2 nos) shall be provided

plates T2.02 T2.02.01 subbut

Shall be provided with suitable cable gland with knockout holes of required size

INSPECTION, TESTING & SHOP PAINTING Inspection & Testing The tests to be conducted at shop for various

assemblies/assemblies

of equipment shall include,

not limited to the following: Material test Testing during manufacture/fabrication Dimensional checking Hydrostatic testing of body and seat. Demonstration time. Any other test, as required to prove the of guaranteed opening &

closing

functional

requirement of various parts of equipment/system.

of for the out manufacitems, be

T2.02.02

The

final tests shall be conducted in the presence representative. shall be made Test certificates available to

the Purchaser's different Purchaser. items shall tests

Material test certificates for bought be obtained from original out shall

turer/reputed test

test house.

For all bought

certificates as relevant to the items

furnished by the contractor. T2.02.03 inspection authority. works all any T2.03 or GERMAN All the equipments shall be subject to stage by the contractor's Purchaser's own inspecting visit the

However, from the

Inspector may

time to time places

who should have free access to premises where

of the manufacturing

part/parts are under manufacture. Shop Painting a) Surface St-3 of preparation shall be as per St-2 and/ Swedish standard SIS 055900 or

STANDARD DIN 55928 Part 4

single alkyd per Thickness

After pack

surface air

preparation, two coats phenolic with Zn

of

drying primer

modified phosphate as

composition

IS:2074-1992 shall be applied. Dry Film of each coat should be 40 microns(minimum).

gloss

c)

Two

coats

of single pack air drying

high

paint, Final be T2.04 for General

phenolic suitably

alkyd modified synthetic pigmented shall be

enamel as

given

paint.Dry film 25 microns.

thickness of

each coat shall

Performance Guarantee and Warranty The valves supplied shall be as guaranteed per

satisfactory

performance

Conditions Of Contract. LIST OF MANDATORY SPARES FOR VALVES the The following mandatory spares shall be included in contract for Butterfly valves of each size. I) For DN 1600 motor operated butterfly valves. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. II) Valve disc. Shaft Shaft key Bearings Allen screw 'O' rings Gland packing Seal clamping units and bolts Position indicator Actuators (as applicable) Torque/limit switches Handle 1 1 1 1 1 1 2 1 1 1 1 1 Set set set set set set sets set set set set set

For DN 1600 gear operated butterfly valves. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Valve disc. Shaft Shaft key Bearings Allen screw 'O' rings Gland packing Seal clamping units and bolts Position indicator Actuators (as applicable) Torque/limit switches Handle 1 Set 1 set 1 set 1 set 1 set 1 set 2 sets 1 set 1 set NA NA 1 set

valves.

iii) For DN 600 motor / gear operated butterfly 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Iv) Valve disc. Shaft Shaft key Bearings Allen screw 'O' rings Gland packing Seal clamping units and bolts Position indicator Actuators (as applicable) Torque/limit switches Handle 2 2 2 2 2 2 4 2 2 2 2 2 Set set set set set set sets set set set set set

For DN 300 manually operated butterfly valves. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Valve disc. Shaft Shaft key Bearings Allen screw 'O' rings Gland packing Seal clamping units and bolts Position indicator Actuators (as applicable) Torque/limit switches Handle 1 Set 1 set 1 set 1 set 1 set 1 set 2 sets 1 set 1 set NA NA 1 set

Notes: 1. each One set shall be applicable for one valve of size.

DATA SHEET FOR VALVES I) MOTOR OPERATED BUTTERFLY VALVE AT PUMP DISCHARGE 1) 2) 3) Name of manufacturer Nominal diameter of valve in mm. Test Pressure a) b) Body Seat -Kg/Cm2 -Kg/Cm2 : : 9 6 : : Fouress 1600

4) 5) 6) 7) 8) 9)

Quantity - Nos. Manufacturing Standard

: :

6 BS 5155 As per BS 4504 PN-10 440 190

Drilling Standard for flanges : Length over flanges - mm Thickness of valve disc - mm Details of motor actuator. a) b) c) Make Model Type of motor K.W. motor speed Output RPM Class of Insulation/ degree of protection Voltage Frequency Duty : : : : : : : : : : : : :

Auma SA30E90 3 Phase AC motor, sq. 2.5 2800 90 CL B / IP68 415 V 50 Hz S2-15 75 + 5

cage d) e) f) g) h) i) j) 10)

Valve opening/ closing time in seconds

11)

Materials of construction a) b) c) d) e) f) Body Disc Drive Shaft Stub Shaft Seat Ring Clamping Ring : : : : : : IS 210 Gr. FG 260 IS 210 Gr. FG 260 AISI 431 AISI 431 Stainless Steel S.G.Iron

g) h) i) j) k) l) m) n) o) p) q) r) 12) II. 1) 2)

Bearing End Cover Plate Shaft Pin Seal Gears Hand Wheel Eye Bolt Integral Flanges Matching Flanges Bolts Nuts Gaskets

: : : : : : : : : : : : Kg. :

Teflon IS 210 Gr.FG 260 AISI 431 Nitrile rubber S.G.Iron Fabricated steel Steel IS 210 Gr. FG 260 Carbonsteel.IS2062,Gr-2A Iinternal SS304/External HTS/CS HTS/CS Nitrile Rubber 5650 (approx)

Weight of Valve Assembly

MOTOR OPERATED BUTTERFLY VALVE ON MAKE-UP WATER PIPELINE Name of manufacturer Nominal diameter of valve in mm. : : Fouress 600

3)

Test Pressure a) b) Body Seat -Kg/Cm2 -Kg/Cm2 : : : : 9 6 2 BS 5155 IS 6392-1971 Table-11 / 267 80

4) 5) 6) 7) 8) 9)

Quantity - Nos. Manufacturing Standard

Drilling Standard for flanges : Length over flanges - mm Thickness of valve disc - mm Details of motor actuator. : :

a) b) cage c) d) e) f) g) h) i) j) 10) 11)

Make Model Type of motor K.W. Motor speed Output RPM Class of Insulation/ degree of protection Voltage Frequency Duty

: : : : : : : : : : :

Auma SA12E63 3 Phase AC motor, sq. 1.1 2800 63 CL B / IP68 415 V 50 Hz S2-15 42 + 5

Valve opening/ closing time in seconds Materials of construction a) b) c) d) Body Disc Drive Shaft Stub Shaft

: : : :

IS 210 Gr. FG 260 IS 210 Gr. FG 260 AISI 431 AISI 431

e) f) g) h) i) j) k) l)

Seat Ring Clamping Ring Bearing End Cover Plate Shaft Pin Seal Gears Hand Wheel

: : : : : : : :

Stainless Steel S.G.Iron Teflon IS 210 Gr.FG 260 AISI 431 Nitrile rubber S.G.Iron Fabricated steel

m) n) 2A o)

Eye Bolt Integral Flanges Matching Flanges Bolts

: : : :

Steel IS 210 Gr. FG 260 Carbonsteel.IS2062,GrIinternal HTS/CS

p) SS304/External q) r) 12)

Nuts Gaskets

: : :

HTS/CS Nitrile Rubber 600 (approx)

Weight of Valve Assembly Kg.

III) GEAR OPERATED BUTTERFLY VALVE 1) 2) 3) Name of manufacturer Nominal diameter of valve in mm. Test Pressure a) b) 4) 5) 6) Body Seat -Kg/Cm2 -Kg/Cm2 -Nos. Standard : : : : 9 6 8 BS5155 IS 6392-1971 Table-11/ BS4504 PN10 4 : : Fouress 600 1600

Quantity

Manufacturing

Drilling Standard

for flanges:

7) 8) 9)

Length over flanges -mm Details of gears Materials of construction a) b) c) d) e) Body Disc Drive Shaft Stub Shaft Seat Ring

: :

267

440

: : : : :

IS 210 Gr. FG 260 IS 210 Gr. FG 260 AISI 431 AISI 431 Stainless Steel

f) g) h) i) j) k) l) m) n) 2A o)

Clamping Ring Bearing End Cover Plate Shaft Pin Seal Gears Hand Wheel Eye Bolt Integral Flanges Matching Flanges Bolts

: : : : : : : : : : :

S.G.Iron Teflon IS 210 Gr. FG260 AISI 431 Nitrile rubber SG iron Fabricated steel Steel IS 210 Gr. FG 260 Carbonsteel.IS2062,GrIinternal HTS/CS

p) SS304/External q) r) 10) (appx)

Nuts Gaskets

: : :

HTS/CS Nitrile Rubber 530 kg 5650 Kg

Weight of Valve Assembly

IV) 1) 2) 3)

MANUALLY OPERATED BUTTERFLY VALVES Name of manufacturer Nominal diameter of valve in mm. Test Pressure a) b) Body Seat -Kg/Cm2 -Kg/Cm2 -Nos : : : : 9 6 2 IS 5155 IS 6392-1971 Table-11 114 : : Fouress 300

4) 5) 6) 7)

Quantity

Manufacturing Standard Drilling Standard

for flanges: :

Length over flanges - mm

8)

Materials of construction a) b) c) d) e) f) g) h) i) j) k) l) m) n) Body Disc Drive Shaft Stub Shaft Seat Ring Clamping Ring Bearing End Cover Plate Shaft Pin Seal Hand Wheel Eye Bolt Integral Flanges Matching Flanges

: : : : : : : : : : : : : : : IS 210 Gr. FG 260 IS 210 Gr. FG 260 AISI 431 AISI 431 Stainless Steel SG Iron Teflon IS210 Gr.FG 260 AISI 431 Nitrile rubber Fabricated steel Steel IS 210 Gr. FG 260 Carbonsteel.IS2062,Gr-

2A

o) SS304/External p) q) 9) 10)

Bolts

Iinternal HTS/CS

Nuts Gaskets

: : :

HTS/CS Nitrile Rubber 120 kg(approx)

Weight of Valve Any other information

GUARNTEED DATA FOR B.F.VALVES

for performance

The

contractor

guarantees

that meet

each the

Butterfly valve following

cooling water system shall requirement : 1.00.00 2.00.00 2.01.00 2.02.00 3.00.00

Design working pressure of Butterfly Valve (Kg/cm2(g)) When valve fully closed Rate of leakage Maximum shut-off pressure, (Kg/cm2(g)) Valve operating time in secs. from open to close and viceversa (only for electrically operated valves)

: : : : : : : :

6 6 Nil 6 For 1600mm dia 75 +15 sec. For 600mm dia 42 +5 sec. Not Applicable

4.00.00

Guarantee Characteristic curves: for regulating valves submitted

Note

: This Guaranteed Performance Data is applicable for each size of the valve.

contractor ............

SIGNATURE OF THE

NAME ................................... DESIGNATION ............................ NAME AND ADDRESS OF COMPANY ...................................... .. DATE ................................... COMPANY SEAL: T3.00 design, INTENT OF SPECIFICATION This sub-chapter is intended to cover

materials manufacture/fabrication,

procurement,

fabricated joints, items of

testing and supply of various types of and boughtout screens pipes,fittings,expansion and other miscellanious system

gates,

connected

with the circulating water

2 x 210 MW units. C.W.PIPING Scope of Work design, accessories, insurance, at pipes, painting, testing system. like / and required The contractor's scope of work shall supply of steel include

engineering, loading,

plates,

unloading at site, of

comprehensive piping of

fabrication site,

required circulating water

outside surface coating and wrapping

inside painting for pipes above 1600mm dia., handling of fabricated pipes at site, erection, and The commissioning of circulating water piping scope of work also includes Civil works

excavation, and back filling, construction of anchor thrust blocks chamber of man holes / air valves

other miscellaneous civil works that would be for installation of piping. Scope of Services

drawings final inlet heat piping and

All

piping

systems

as

shown

in

enclosed

No.MEC/S/P123/A04/S4/01 and 02 complete with all joint welding at Battery limits viz., piping from and outlet of condensers, cooling water pipe for

exchangers (inlet and outlet), connection of C.W at cooling tower inlet, make up water pipes

blowdown pipes.

ends the

All bends , reducers, tees distance pieces, dished etc. of all sizes and shape required for complete

system. instruments stubs All piping and fittings for vents, drains, tapping points with stubs and root valves and

for the thermowell connections etc. necessary gaskets All counter flanges, blank flanges, caps etc. for the piping. All necessary bolts, nuts, and

required for installation of the system.

tees valves the nos. (Double be be gate

All with

flanges, manhole and manhole covers, flanged blank on flanges, above automatic piping are air-vent included in

required

contractor's scope of supply.A minimum number of 6 automatic air vent) air release cum vacuum break valves for each unit (total 12 nos.) shall

provided of

on CW piping.The air release valves shall isolation

200 mm dia with separate 200mm dia

valves. the for Manhole Butterfly shall be provided on either side of

valves for maintenance purpose

(except

300mm dia.). also and other with The pipework covered under this section shall include internal pipework for the pumphouse

piping between pump house and main plant and units as indicated in the drawings enclosed

various work air is -

the

specification

and

described

in pipe

paragraphs

of the specification. G.I.

for drinking water, service air and instrument piping etc., pipe work for service water air

also included in the scope of the contractor. generally tees, unions, pieces, T3.01 specified The The term 'pipework' referred (such herein as bends,

covers

pipes,

fittings

reducers,

plugs,

nipples,

sockets,

flanges, crosses, etc) valves, throttling stubs for primary sensing instruments etc. pipes shall be manufactured/supplied as

below: pipes ISPart-I With ii) 200 mm to 350 mm size i) Upto 150 mm nominal size M.S ERW Black conforming 1239-1984 (Medium Duty) to

Plain ends. Pipes ISthickspecified Nominal Dia DN DN DN DN 200 250 300 350 mm mm mm mm : : : : M.S. ERW to

conforming

3589-1973 but ness as

below : O.D X Thickness in mm 219.1 273.0 323.9 355.6 x x x x 6.35 7.14 7.14 7.14

M.S. Pipes( Steel commercial

iii) 400 mm to 600 mm size Manufactured

Spirally Welded

at

Rourkela

Plant) of quality. Nominal Dia DN DN DN DN iv) 400 450 500 600 mm mm mm mm : : : : O.D X Thickness in mm 406.4 457.0 508.0 610 x x x x 7.14 7.14 7.90 9.50 Fabricated from plates as in para T3.02 a) For Service Air : IS:1239 - 1984 (Part-I) Heavy duty/IS:1978 St.25 seamless b) For Instrument Air : IS:1239 - 1984 (Part-I) Heavy duty/IS:1978 St.25 seamless (Hot dip galvanised) c) d) Drinking water Service water : : IS:1239 - 1984 (Part-I) Heavy G.I. IS:1239 - 1984 (Part-I) Heavy / IS:3589.

1600 mm and above

M.S. specified

1984

1984

T3.02 be T3.02.01

Fabricated Steel Pipe lines All fabricated pipelines specified below shall

conforming welding thickness

fabricated to

from tested quality M.S. plates Grade -A by submerged arc

IS-2O62-1992

process as per IS-10234

or equivalent having

indicated against the pipe dia: ------------------------------------------------------Nominal dia Outside dia Plate of pipe mm of pipe mm

thickness mm

------------------------------------------------------16OO mm 24OO mm 1632 2432 16 16

-------------------------------------------------------

T3.02.02 cold plates so plate.The plate

All

fabricated using

pipes shall be a plate bending

manufactured machine. The

by

bending shall that

be gradually bent to true cylindrical no undue stress develops in the

shape

tolerances on dimensions of pipe fabricated from shall be as follows: i) On outer diameter as calculated from circumference Out of roundness

: :

+ 1/4 of plate + 3 mm & -1.5 mm

thickness. ii)

iii) Out of straightness : T3.02.03 a any T3.02.04 erection field be site T3.02.05 drawings fabrication The

1 mm per metre length (Max.)

pipe circumferential weld shall be done in such

way that the longitudinal welds become staggered in two consecutive sections. Pipe sections in straight lengths delivered at site joints done at shall be of suitable length to minimise shall

as far as possible. the fabrication

End preparation yard to

facilitate

welding.Straps shall be provided at field joints. The of contractor shall submit detailed working pipelines and fittings including

These complete fabrication proposed T3.03 II from

drawings for approval by Purchaser/ Consultants. drawings bill shall indicate design parameters, other

of materials, welding and all

details.

Details of hydrostatic and ND tests

to be done shall also be specified. Pipe fittings Fittings shall be supplied as per IS:1239-1992 Part for pipes upto 150 mm dia and shall be fabricated

pipes for dia 200 mm and above. air, etc., All root joint welding from headers for service

instrument air, service water and drinking water shall be carried out by the contractor.

flanges, etc required the

Gate valves, Drain valves, Root valves, Blind pipe shall flanges, Gaskets, Bolts, nuts and washers

be supplied in quantities and sizes as

during detailed engineering with price included in lumpsum quoted.

T3.04 tools, and gas welding for welding per T3.04.01

Fabrication of pipelines and welding of pipe joints The contractor welding shall arrange at his cost transformers, all

plant,

instruments and oxygen

consumables

including any acytelene

cylinders, welding electrodes for electric arc and filler rods, fluxes etc. for gas welding

carrying out the welding at site. Submerged orc as per IS 10234-1982 shall be carried out as

relevant International code.

The contractor shall indicate the procedure he is going of T3.04.02 all T3.04.03 requirements to follow for fabrication/erection/hydraulic testing M.S.Pipes. The contractor shall arrange at his own cost for

tests outlined in this section. Requirement of welded joints The contractor shall ensure the following while welding the plates/ pipejoints etc. i) ii) Strength-equality with parent metal Absence of defects

iii) Corrosion resistance of the weld shall not be less agressive T3.04.04 contractor, make than that of the parent metal in

environment. Method of Quality Control in Welded Joints Following besides steps shall be taken quality in by the to

controlling

general,

effective control in carrying out welded joints. a) Welding procedures shall be prepared in line IS:7307(Part-I)-1974, reaffirmed in 1991 and shall be carried out to quality procedures. of procedures will depend on variables

with tests Number like a adherence b) IS:7310 passing

positions of welding, thickness range etc. Once welding procedure is qualified, strict

to it shall be made during actual welding. Welders employed shall be qualified as per (Part-I)-1974, necessary tests. reaffirmed in 1987 after

c) type. to 1991. approved Besides, be d)

Welding Such

consumables consumables

shall be of are, however,

approved subject

qualifying initial check tests as per IS:814The contractor shall strictly follow

welding procedures during actual welding. the following stages of inspection shall also

carried out : proper slag etc., ii) i) Weld edge preparation before welding, fit up, position of welding, cleaning of between the passes, proper weld profile shall be checked visually, amongst others. welded approved T3.04.05 the per in Non-destructive joints tests of weld of

shall be carried out as per

procedures/ drawings. Preparation of joints The contractor shall prepare the edge correctly to shape, ANSI size and dimensions of the vee-grooves B-16.25 unless otherwise as

specified

drawings/documents. free may loose other to avoid The welding surfaces shall be smooth, uniform and from fins, teers, notches or any other defect which adversely afect welding and shall be free from

scale, slag, rust, grease, paint, moisture or any foreign about material. 10 mm The clean surface shall the welding faces extend to

beyond

material T3.04.06 and about contractor at using of quality

contamination

of the weld metal with foreign

and to avoid unsound weld deposit. Assembly, Alignment & Welding The sequence of welding shall be so planned

followed that there shall be a balance of welding the shall neutral axis of the fabrication. The working

employ sufficient number of welders

the same time in diagonal quadrants of the shell back-step each method of welding. The rate of shall be more or less equal progress and

welder

uniform. the shell to The general direction of welding shall be towards

free end of the joint, but in a long joint as in fabrication, back-step technique shall be used

reduce distortion.

welding, and horizontal the complete their

To minimise internal locked up stresses due to the vertical joints for the shell shall be welded

completed to a circular course and then the circumferential welding of seam welded. seam However, started, before the

horizontal

circular course shall be aligned and adjusted for correct axes.

each prein

Alternatively, course in

the

contractor

shall

complete then and the placed

all respects on ground and course shall be lifted

assembled

same axis each penstock bigger

position. principle

In

such a sequence and planning,

the

of balancing of weld about the neutral

shall be followed and the method of fabrication of course pipes shall be similar to fabrication of of

or transmission/industrial pipelines

diameter. by If fused T3.04.07 Pipe and attachment and shall be aligned properly welding. either

accurate tack

permanent methods prior to are used, the tack shall be

welds

into the first layer of weld or else chipped out. Tests on welded joints (a) and all close less other magnifying and mm from following The Visual examination contractor shall conduct visual examination

measurement of external dimensions of the weld for joints. Before examining the welded joints, areas to than it on both sides of the weld for a width 20 mm shall be cleared of slag not and

impurities. glass

Examination shall be done by a

which has a magnification power of ten (10)

measuring instrument which has an accuracy of + 0.1 or by weld gauges. Welded joints shall be examined both sides. The contractor shall examine the during the visual examination :-

the

i)

Check

the

correctness of shape and size

of

welded joints ii) Incomplete penetration of weld metal

iii) Influx iv) v) Burns Under cuts

vi)

Unwelded crates

vii) Cracks in welded spots and heat affected zones viii)Porosity in welds and spot welds ix) of contact x) The as about by test Compression electrode welding Displacement of welded element. contractor shall carryout any or all tests in welded while joints as a out result

impact

carrying

specified

hereinafter to satisfy the

Purchaser

the acceptability of the welded joints, as directed the Purchaser. However minimum 10% DPT or MP

shall be carried out in the fabricated pipes. (b) Liquid Dye-penetrant Test dye-penetrant tests shall be carried out 1991

Liquid in for

accordance

with IS:3658-1981, reaffirmed in

surface/sub-surface defects. (c) The Test by Blowing surface of the weld shall be of covered of with water

soap and be to and of Portable if

solution

consisting

one (1) litre

hundred (100) grammes of soap. Compressed air shall blown 5 from the opposite side at pressure of 4

kg/cm. sq. The distance between the tip of base

the weld shall not be more than 50 mm. Any formation soap buble will indicate shall welding defects. the contractor,

compressor

be arranged by

necessary, for this purpose. Tolerance be Deviations for assembly of welded joints may

permitted to the following extent : Tolerance ------------------------Automatic a) Source butt-joints i) Gap between the ends of plates + 2.00 mm - 1.00 mm + 1.00 mm Manual arc

Tolerance ------------------------Automatic ii) Stepping of one plate over the other Manual arc

1.00 mm

2.00 mm

b)

Single Vee-groove Joints i) ii) Bevol angle Gap between two + 5 deg. + 2.00 mm - 1.00 mm 2.00 mm + 5 deg. + 1.00 mm

iii) Stepping of one plate over other c) Lap Joint i) ii) d) Overlap Gap between the surface

2.00 mm

5.00 mm 2.00 mm

5.00 mm 1.00 mm

Tee-filler joints i) Gap between the 2.00 mm 2.00 mm

edge of the web and the surface of the flange T3.05 T3.05.01 the and data joint is Rubber Expansion Joints Design and Construction Design of the expansion joint shall take care of

axial, angular or rotational movement of the bellow / or the equipment vibration, as stipulated in the specification shall sheets enclosed. The expansion

be designed such that no periodic adjustment

required.

T3.05.02 construction natural with of holding T3.05.03 used the shall to

Body Expansion bellow shall be of heavy duty

manufactured from high grade abrasion resistant or synthetic rubber, as specified in data sheets, Split retaining rings

integral flanges at both ends. adequate

design shall be supplied for securely

the expansion joint with connecting pipe flanges. Carcass Fabrics of high strength synthetic fibres shall be in suitable number of plies to hold the shape of

bellow at the working condition. be

All fabric plies components

impregnated with rubber or synthetic

permit flexibility between them. Copper coated steel wire or solid endless rings

embedded the

in

the carcass shall be used for reinforcement

of

expansion bellow.

T3.05.04 shall carcass

Cover The exterior and interior surfaces of the bellow

be coated with suitable material to protect the from outside damage and fluid corrosion.

the T3.05.05 rod contraction of washers, assembly

Protective exterior.

hypalon

coatings

may

be

applied

at

Control Rod Assembly Each expansion joint shall be supplied with control assembly to prevent excessive elongation or of long the bellow. bolt, nuts Control rod assembly will & lock nuts, spherical consist

connecting plates (gusset plate) for fixing the with mating flanges.

and of

Control

rod

assembly

shall

allow

transverse

rotational movements under limiting axial conditions the expansion joints.

of on the

Design

of the control rod assembly shall take

care

the maximum axial thrust across the bellow calculated the basis of maximum fluid internal pressure and

internal diameter of the arch.

T3.05.06 fabric on the

End Flanges The expansion joint shall have integral The bolt hole

reinforced

full face rubber flanges.

the flange shall have no eccentricity in relation to

face. the be during T3.05.07

corresponding bolt hole of the flange on the other The end rubber flange shall be drilled to suit

companion pipe flanges. suitably match

The companion flanges shall identification

marked for easy

erection by others. Counter Flanges Counter flanges shall be as per AWWA C-207. washers 7.05.08 Required numbers of carbon steel nuts, bolts,

and rubber gaskets shall be furnished. Hydrostatic Pressure Test and Vacuum Test a) internal half the All Pressure Test expansion bellows shall be subjected to

hydrostatic (1.5) times

pressure test at a value of one and a the maximum working pressure under

following conditions for thirty (30) minutes: i) ii) lateral Free position of the bellow With permitted (design) elongation and

deflections iii) With design contraction and lateral deflection Inspection for leakage from the bellow shall be out during pressure test.

carried

over, check

Before the hydro test and after the hydro test is the bellow shall be dimensionally inspected to

deformation, if any. suitably During the test, the control assembly shall be adjusted to obtain the test conditions of the bellow. b) test in Vacuum Test

All expansion joint shall be subjected to a vacuum at 700 mm of Hg vacuum. The test shall be conducted

thirty positions

three different positions for a minimum period of (30) minutes duration in each position. are as described above for pressure test. These

c) additional assurance. extra T3.05.09

Additional Tests shall have the right to demand

Purchaser

tests as may be found necessary for quality All the above tests shall be carried out without cost to Purchaser.

the

The

Rubber

Expanson

Joints

shall

conform

to

following standards/codes: USA i) Expansion standards ii) axial, or Fluid sealing Association, USA joints manufacturers' Association,

Design of Expansion joint shall take care of the angular or rotational movements of the bellow and/

the equipment vibration. abrasion The body of expansion joint shall be made from resistant rubber. at The expansion joints shall have integral flanges

both ends complete with split retaining rings. expansion a The joint external shall and internal surfaces of the with

be of Neoprene of 3 mm thickness

shore hardness of 65 + 5 deg. for Steel wire/synthetic fabric shall be used

reinforcement of the expansion bellows. Tie rods shall be provided in the expansion joints.

T3.05.10

Design Requirement i) ii) Qty. Nominal diameter 5 Nos. 1600 mm. Single arch type. 6 Kg/cm2 Circulating water (for analysis see Annexure-D & E). 44/30

iii) Type iv) v) Design pressure

Liquid to be handled-

vi)

Working temperature (oC) (Max./Min.) -

vii) Maximum flow (M3/hr) viii)Location ix) x) xi) Test pressure (kg/cm2g) Vacuum design Vacuum test

16500 Indoor 7.5 750mm of Hg vacuum 700mm of Hg vacuum Manufacturers std. AWWA-C 207, 1-50 lb slip on type

xii) Freelength (mm) xiii)Counter flange class

xiv) Axial elongation(mm)xv) Axial contraction (mm) -

15 15 15 0.5 0.5 497

xvi) Lateral deflection (mm) xvii)Angular deflection (deg.)

xviii) Torsional movement (deg.) xix) Pump speed (rpm) -

T3.05.11

Materials of Construction Bellow Carcass Stiffening ring External cover Internal cover Control assembly Retaining ring Synthetic Rubber Synthetic fibre Manufacturers standard Hypalon or approved equivalent Manufacturer's standard Manufacturer's standard Galvanised Steel

Flanges/Counter flanges Gasket Nuts, bolts and washers

Carbon Steel IS:2062 3 mm thick reinforced rubber Carbon Steel - ASTM A Grade A

307

Pipe thickness

16 mm

DATA SHEET FOR RUBBER EXPANSION JOINT 1.00.00 1.01.00 1.02.00 1.03.00 1.04.00 1.05.00 1.06.00 GENERAL Service Nominal size (NB)/Qty. Duty Type Overall dimensions (mm) Gross weight of the complete assembly (kg) : : : : : : C.W.System 1600mm - 5 Nos. Continuous Spool type 750 1750 kgs (appx)

1.07.00 2.00.00 2.01.00 2.02.00 2.03.00 2.04.00 2.05.00 2.06.00 2.07.00t 2.08.00

Model No. PERFORMANCE CAPABILITY

During Detail engg.

Axial elongation / contraction (mm) : Lateral deflection (mm) Angular movement Torsional movement (degrees) Axial spring rate (N/mm) Torsional spring rate (kg/mm/deg) Frequency of vibration (Hz) : : : : : :

15/15 15 0.5o 0.5 1925 (Appx) 180 During detail Engg.

Maximum pressure drop through the expansion joint at design flow rate, Kg/cm2g : DESIGN AND CONSTRUCTION Design standard Design pressure (kg/cm2g) : :

< 0.01

3.00.00 3.01.00 3.02.00 3.03.00 3.04.00

As per spec. 6 750 60

Design vacuum in mm of mercury: Design Temperature (oC) :

3.05.00 3.06.00 3.07.00 3.08.00 4.00.00 4.01.00 4.02.00 4.03.00

No. of arch / corrugation Flange pressure rating and drilling standard No. of limit / control rods Bursting pressure of bellow (kg/cm2g) MATERIAL OF CONSTRUCTION Bellow Carcass Bellow exterior : : :

: : : :

Single BS 4504 PN-10 6Nos./Per Joint Twice the design pressure

Synthetic Rubber Synthetic fibre Neoprene Rubber

4.04.00 4.05.00 Ring 4.06.00 4.07.00 4.08.00 4.09.00 4.10.00

Bellow interior

Neoprene Rubber IS 2062 Gr. A Sq. Annular IS1367 Gr.63.8/6.0, stretcher plate IS-2062 Gr.A.

Metal reinforcement : Control rod assembly:

Retaining ring segments: IS:2062 Gr.A Galvanised Flanges/counter flanges: IS:2062 Gr.A Fasteners Gaskets : : IS:2062 Gr.4.6/4.0 Not recommended as Internal Rubber flange shall act as self gasket

5.00.00 5.01.00 5.02.00 5.03.00 5.04.00

INSPECTION AND TESTING INCLUDED Materials Test Certificates Certificates for bought out items Dimensional tolerance as per specification Hydrotest as per specification : Yes : Yes : Yes : Yes

6.00.00 6.01.00 6.02.00 7.00.00 7.01.00 7.02.00 7.03.00 7.04.00

ACCESSORIES INCLUDED Control rod assembly with gusset plate, nuts spherical washers etc. : Yes Counter flanges with nuts, bolts etc. : Yes

LIST OF TECHNICAL DOCUMENTS ENCLOSED WITH THE CONTRACT Dimensional General Arrangement drawing as specified A cross-sectional drawing of the expansion bellow Manufacturers standard catalogues and Literature A write-up on the manufacturing inspection and testing facilities available at the manufacturer's works Any other information : Yes : Yes : No

: :

7.05.00

LIST OF MANDATORY SPARES FOR R.E. JOINTS 1. 2. 3. 4. Note: Rubber Expansion Joint Complete assembly of 1600 mm dia. Slip-on type matching flange with bolts, nuts and gaskets Reinforced Rubber Gasket for above R.E. Joints Control rod assembly complete with nuts etc. One set corresponds to the quantity of part used in one R.E. Joint. : 1 set : 1 set : N.A. : 2 sets

particular

GUARANTEED DATA FOR R.E.JOINTS. The joint performance for data. 1.00.00 2.00.00 3.00.00 4.00.00 5.00.00 6.00.00 7.00.00 Design working pressure of bellow (kg/cm2 g) : 6 Kg/cm2 12 kg/Cm2 15/15 15 0.5 0.5 BS 4504 PN-10 contractor guarantees that each rubber expansion minimum

CW system shall meet the following

Minimum bursting pressure of bellow (kg/cm2 g) : Axial elongation/contraction (mm) : Lateral deflection (mm) Angular movement (degrees) : :

Torsional movement (degrees) : Flange standard :

SIGNATURE .........................

NAME .............................. DESIGNATION ....................... NAME AND ADDRESS OF COMPANY .. DATE .............................. .................................

You might also like

- Is 14845-2000Document18 pagesIs 14845-2000Sarbendu Paul100% (1)

- Perkins - General Ti BulletinDocument65 pagesPerkins - General Ti BulletinUTEL CARTERNo ratings yet

- Hal Ahu BoqDocument16 pagesHal Ahu Boqmdalt9180100% (1)

- CraneDocument32 pagesCranesabes26100% (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Lifting Lug Calculation RefDocument2 pagesLifting Lug Calculation Refmarc_albertoNo ratings yet

- 2.2 Functional Specification For Deluge ValveDocument7 pages2.2 Functional Specification For Deluge Valveramachandran_chem100% (1)

- Mechanical Interview Jgc-KjoDocument6 pagesMechanical Interview Jgc-Kjonaveed7861100% (1)

- Safety Relief ValvesDocument52 pagesSafety Relief ValvesHamza NoumanNo ratings yet

- Detail Study of Working in Blast Furnace Area (Vizag Steel Plant)Document42 pagesDetail Study of Working in Blast Furnace Area (Vizag Steel Plant)kselvan_1No ratings yet

- Hydraulic HoseDocument86 pagesHydraulic Hosekselvan_1No ratings yet

- Standard Spec For ROVDocument10 pagesStandard Spec For ROVHitendra PanchalNo ratings yet

- FS SSIV ActuatorDocument11 pagesFS SSIV Actuatorscribd_thakurNo ratings yet

- Gravitational Fields 1Document18 pagesGravitational Fields 1Smart linkNo ratings yet

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1No ratings yet

- B.4.4 - STD Spec For Steel StacksDocument6 pagesB.4.4 - STD Spec For Steel StacksEkta SanguleNo ratings yet

- Centrifugal Pump BrochuresDocument16 pagesCentrifugal Pump BrochuresAbsar Mamun100% (3)

- KochDocument181 pagesKochRichard FelipNo ratings yet

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- Specification For Butterfly ValvesDocument10 pagesSpecification For Butterfly Valvesdeepdaman18891No ratings yet

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- Technical SpecificationDocument42 pagesTechnical SpecificationHadisupriadiNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagNo ratings yet

- Deluge ValveDocument10 pagesDeluge ValvevpnrrajaNo ratings yet

- (Fanuc Lad 0I-Mc) Ladder Diagram 1Document160 pages(Fanuc Lad 0I-Mc) Ladder Diagram 1Ujang NachrawiNo ratings yet

- Allweiler SN SeriesDocument12 pagesAllweiler SN SeriesAlexis Ernesto Cardenas BeltranNo ratings yet

- Double Flap Gate ValvesDocument16 pagesDouble Flap Gate Valveskselvan_1No ratings yet

- Brochure Exterior LightingDocument49 pagesBrochure Exterior Lightingmurali_227No ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Electrical Tech SpecificationDocument62 pagesElectrical Tech SpecificationNipun KohliNo ratings yet

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- Eops & Hopd SpecDocument6 pagesEops & Hopd SpecNaveen NagisettiNo ratings yet

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- Is - 14845Document17 pagesIs - 14845mechftpNo ratings yet

- STANDARD TECHNICAL SPECIFICATION Ball Valves PDFDocument2 pagesSTANDARD TECHNICAL SPECIFICATION Ball Valves PDFSen vanNo ratings yet

- Format - Zip GBDocument26 pagesFormat - Zip GBIonela MaraNo ratings yet

- Specification For Control ValveDocument5 pagesSpecification For Control ValveamilasriNo ratings yet

- Model BFV-N Butterfly Valve Grooved End Technical Data General DescriptionDocument4 pagesModel BFV-N Butterfly Valve Grooved End Technical Data General DescriptionPatricio SabettaNo ratings yet

- Topworx Position SwitchDocument60 pagesTopworx Position SwitchsarkaftNo ratings yet

- Topworx Valvetop D-Series With GO Switches ManualDocument20 pagesTopworx Valvetop D-Series With GO Switches ManualJuan LuisNo ratings yet

- Apv Delta Sv1Document20 pagesApv Delta Sv1VLASTARNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Globe Valve Type Flow Switch: DescriptionDocument4 pagesGlobe Valve Type Flow Switch: DescriptiongoparsucoNo ratings yet

- Model BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionDocument8 pagesModel BFV-300/BFV-300C Butterfly Valve Grooved End General DescriptionMERCURE GARINDOLPGNo ratings yet

- Is 13095 1991Document15 pagesIs 13095 1991Surendra MalasaneNo ratings yet

- Des Cote Actuated Globe ValvesDocument4 pagesDes Cote Actuated Globe ValvesOrueta ClaudioNo ratings yet

- Service Manual - Sandpiper s15Document24 pagesService Manual - Sandpiper s15tineohNo ratings yet

- ValvesDocument6 pagesValvesstevegazeleyNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- Specs Fci St51 0807Document7 pagesSpecs Fci St51 0807cwiejkowskaNo ratings yet

- MSS SP 70.98-Cast Iron Gate Valves - (1998)Document13 pagesMSS SP 70.98-Cast Iron Gate Valves - (1998)thiagorep17No ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Annexture N1 427Document14 pagesAnnexture N1 427DEBASISH SARKARNo ratings yet

- Section 05110 - Butterfly ValvesDocument6 pagesSection 05110 - Butterfly Valvesse781No ratings yet

- 220523-General-Duty Valves For Plumbing PipingDocument9 pages220523-General-Duty Valves For Plumbing PipingAttef BedaweNo ratings yet

- Section 2 Water Chilling Unit (Screw) GeneralDocument5 pagesSection 2 Water Chilling Unit (Screw) GeneralmatzoyekNo ratings yet

- Specification For Fire MonitorDocument4 pagesSpecification For Fire Monitorromdhan88No ratings yet

- TFP1511 09 2015Document8 pagesTFP1511 09 2015Enrique MurgiaNo ratings yet

- Viking SPK StandardDocument6 pagesViking SPK StandardCostel BalasoiuNo ratings yet

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryNo ratings yet

- TFP910 03 2021Document20 pagesTFP910 03 2021muralyyNo ratings yet

- V9271 Fivalco 2902eDocument6 pagesV9271 Fivalco 2902eharenas7No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Development of Beneficiation Process For High Alumina Iron Ores of Bellary - Hospet RegionDocument2 pagesDevelopment of Beneficiation Process For High Alumina Iron Ores of Bellary - Hospet Regionkselvan_1No ratings yet

- Sturt Air ClassifierDocument6 pagesSturt Air ClassifierHenry Vladimir VianchaNo ratings yet

- CokemakingTechnologies ComparisonDocument9 pagesCokemakingTechnologies Comparisonkselvan_1100% (1)

- U.S. Bellows 101: Expansion Joint BasicsDocument35 pagesU.S. Bellows 101: Expansion Joint Basicskselvan_1No ratings yet

- StAccMill Stack DesignDocument3 pagesStAccMill Stack Designkselvan_1No ratings yet

- Short Circular Steel StacksDocument12 pagesShort Circular Steel Stackskselvan_1No ratings yet

- Dimensions Shall Be Clearly Marked For All Such Marking: Upgradation of Bf. No. 1 Unitdescr AreadescrDocument1 pageDimensions Shall Be Clearly Marked For All Such Marking: Upgradation of Bf. No. 1 Unitdescr Areadescrkselvan_1No ratings yet

- Comments As Marked in This Drawing Is Applicable For All Such SchematicDocument1 pageComments As Marked in This Drawing Is Applicable For All Such Schematickselvan_1No ratings yet

- PSC 53613 C 6 PDFDocument1 pagePSC 53613 C 6 PDFkselvan_1No ratings yet

- EP RefineriesDocument16 pagesEP Refinerieskselvan_1No ratings yet

- Design & HypothesisDocument37 pagesDesign & Hypothesiskselvan_1No ratings yet

- Module-2: SolidificationDocument16 pagesModule-2: SolidificationSachin AgnihotriNo ratings yet

- Definition, Scope and Nature of EconomicsDocument29 pagesDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarNo ratings yet

- Week 14 Report2Document27 pagesWeek 14 Report2Melaku DesalegneNo ratings yet

- Description: Super Thoroseal Is A Blend of PortlandDocument2 pagesDescription: Super Thoroseal Is A Blend of Portlandqwerty_conan100% (1)

- Assignment ProblemsDocument22 pagesAssignment ProblemsPooja Yadav100% (1)

- ECON 304 Course ContentDocument2 pagesECON 304 Course ContentAanand JhaNo ratings yet

- Cloudworx Pdms UsDocument2 pagesCloudworx Pdms Usguru4lifegmailcomNo ratings yet

- Integrated Curriculum For Secondary Schools: Mathematics Form 2Document139 pagesIntegrated Curriculum For Secondary Schools: Mathematics Form 2Izawaty IsmailNo ratings yet

- Seventh Pay Commission ArrearsDocument11 pagesSeventh Pay Commission Arrearssantosh bharathyNo ratings yet

- The Roosh ProgramDocument2 pagesThe Roosh ProgramVal KerryNo ratings yet

- p-100 Vol2 1935 Part5Document132 pagesp-100 Vol2 1935 Part5Matias MancillaNo ratings yet

- Long PassagesDocument12 pagesLong PassagesAml AmlNo ratings yet

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghNo ratings yet

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocument28 pagesA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoNo ratings yet

- Translated Copy of Jurnal B.inggris 41117110162 Aditya NurfajriDocument16 pagesTranslated Copy of Jurnal B.inggris 41117110162 Aditya Nurfajriaditya estimatorNo ratings yet

- Conventional and Box-Shaped Piled RaftsDocument6 pagesConventional and Box-Shaped Piled RaftsAdrian VechiuNo ratings yet

- Dyn ST 70 Ser 2Document12 pagesDyn ST 70 Ser 2alexgirard11735100% (1)

- Semantic SearchMonkeyDocument39 pagesSemantic SearchMonkeyPaul TarjanNo ratings yet

- Investigation: Present By:Shivam Ranabhat Project Title: Esport Players Recruit SystemDocument18 pagesInvestigation: Present By:Shivam Ranabhat Project Title: Esport Players Recruit Systemjames chhetriNo ratings yet

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDocument4 pagesComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanNo ratings yet

- Renaissance QuestionsDocument3 pagesRenaissance QuestionsHezel Escora NavalesNo ratings yet

- Project Scheduling: Marinella A. LosaDocument12 pagesProject Scheduling: Marinella A. LosaMarinella LosaNo ratings yet

- AutoCAD 2006 Installing Network License Manager0Document12 pagesAutoCAD 2006 Installing Network License Manager0gurugovindanNo ratings yet

- TrapsDocument11 pagesTrapsAmandeep AroraNo ratings yet