Professional Documents

Culture Documents

Solid Works Sheet Metal

Uploaded by

Sathish KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solid Works Sheet Metal

Uploaded by

Sathish KumarCopyright:

Available Formats

Presented By Jeff Parker for Yakima SolidWorks User Group

Part One Theory & Basics

Sheet Metal Theory

Definitions & Formulas Bending Theory

Part Two Adv. Topics

Bend Tables

Advanced Shapes Forming Tools

Using & Creating

Tools Overview

What tools are available? Special Tool Options

Sheet Metal Configurations Drawing Creation Using Imported Bodies Best Practices Compilation

How to Start Part

Start with SM Features Model Part then add SM

Features

Examples

Examples

Examples

Examples

Sheet Metal Theory

Definitions:

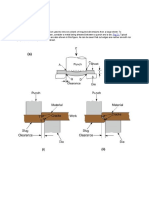

Bend Allowance Length of the arc through the bend area at the neutral axis. Bend Angle Angle of the arc formed by the bending operation. Bend Compensation Amount by which the material is stretched or compressed by bending.

Bend Lines The straight lines where the flange boundary meets the bend area.

Inside Bend Radius Radius of the arc on the inside surface of the bend area. K-factor Defines the location of the neutral axis. (distance from the inside of the material to the neutral axis divided by the material thickness). Mold Lines For bends of less than 180 degrees, the mold lines are the straight lines where the surfaces of the flange bounding the bend area intersect. Neutral Axis Looking at the cross section of the bend, the neutral axis is the theoretical location at which the material is neither compressed nor stretched. Set Back - For bends of less than 180 degrees, the set back is the distance from the bend lines to the mold line.

Sheet Metal Theory

Formulas:

Bend Allowance = Angle * (PI / 180) * (Radius + K-factor * Thickness) Bend Deduction = Bend Allowance (2 * Set Back) Inside Set Back = tan (Angle / 2) * Radius Outside Set Back = tan (Angle / 2) * (Radius + Thickness)

Calculating Bends forYour Equipment

Calculating the correct flat pattern layout is crucial. Lets start with a simple L bracket. The picture shows that the legs of the bracket are 2 and 3. The material thickness is 0.036, the inside radius is 0.125, and the angle of bend is 90 degrees. The flat length is the total of the flat portion of both flanges plus the length through the arc of the bend area. Do you calculate that on the inside of the material or the outside? Neither! This is where the K-factor comes into play. The K-factor is the percentage of the material thickness where there is no stretching or compressing of the material, for example, the neutral axis. For this simple L bracket, I will use a K-factor of 0.42. The formula is: Bend Allowance = Angle * (PI / 180) * (Radius + K-factor * Thickness). Plugging in our numbers, we get: Bend Allowance = 90 * (PI / 180) * (0.125 + 0.42 * 0.036) = 0.2200999813105009. So the flat pattern length is 2 + 3 + 0.2201 which is equal to 5.2201. So if you add up the flat length of all the flanges and add one Bend Allowance for each bend area you have the correct flat length of the part. Now we have to subtract two times the material thickness plus the bend radius (also known as the Setback) for each bend area.

Sample 1 Converting to Sheet Metal

Insert Bends vs. Convert to Sheet Metal Tools

Insert Bends Add Bends Select Edges for Bends Rip Edges X X X X X X X

New for 2009

Convert to Sheet Metal

Use Rip Sketches

Inside Radius Auto Relief Control Thickness & Direction

X

X X X

Bend Allowance

Sample 2 Ground Up Tools Review

Overview of Sheet Metal Tools while building a part.

With this we are going to go over the basic Sheet Metal tools

SolidWorks offers, while also introducing some Best Practices for creating sheet metal parts.

Base Flange/Tab Convert to Sheet Metal Insert Bends Lofted-Bend Miter Flange Edge Flange Rip Jog Hem Sketched Bend

Corner-Trim Break-Corner/Corner-Trim Welded Corner Closed Corner Cross-Break No Bends Fold Unfold Flatten Forming Tool

Sheet Metal Notable Tool Options

Bend & Gauge Tables

Sheet metal tables allow you to select from pre setup lists of material types, thicknesses, and inside radii. There are three types of tables, they are bend, gauge, and gauge/bend.

New for 2009 Bend Thickness Radius Different Bend Allowance Values Bend Allowance Type X X X Gauge X X Gauge/Bend X X

X

X

Bend & Gauge Tables

Advanced Forming Shapes

Can you model this formed edge? How about as a mitered edge?

This is probably one of the most complex bend profiles that I

have seen. It is a prime example of a little knowledge of SolidWorks and some planning ahead before starting to model the part.

Forming Tools Using & Creating

Using forming tools

Forming Tools Using & Creating

Creating forming tools Items to consider:

Positioning sketch Material to cut Stopping faces Minimum Radius of Curvature 1. Start with base sized larger than the finished tool. 2. Sketch the layout sketch of tool. 3. Start modeling the tool body of the louver. 4. Add all features wanted for the tool. 5. Add fillet that has the same >= radius than the material. 6. Cut the base from the newly created tool. 7. Create a positioning sketch at the base of the tool.

8. Color all cutting faces red and stopping face RGB(202,209,238)

Sheet Metal Configurations

Configurations are the same with sheet metal parts as with

other parts with the exception that when you add a flatpattern view onto a drawing, SolidWorks automatically creates a derived configuration. By default the derived configuration is called Name of Configuration & SM-FLATPATTERN.

Tip: Use configurations to show the steps to form parts. You can use progressive configurations as a How To reference for forming.

Sheet Metal Drawings

Adding the flat pattern view

Legacy vs. View Palette

Using Model View must select Flat Pattern to import view onto sheet. View Palette allows the user to see preview and quickly add all needed views onto sheet. Also importing of annotations is built into the palette. Use of either technique will produce the same view. The flat pattern view has also been improved over the last couple releases as it now automatically adds the bend notes.

Using Imported Bodies

Importing Options

There are two main methods to convert imported geometry

to sheet metal.

Importing the model and then converting to sheet metal. Using FeatureWorks to automatically read the sheet metal features

into SolidWorks. Tip: To be able to define the radii of the part, first import as a normal part file not a sheet metal part. Then use FeatureWorks to identify the radii. Now remove the radii and then use the Convert to Sheet Metal tool, this will allow you to define your own radii and not be confined by the import model radii.

Best Practices Compilation

Sheet Metal Part Drawing Modeling Modeling a sheet edges metal part. Start Use with tangent set to a non-solid line type to help On existing parts define sheet metal early, this way you can take advantage of the visualize the bends Link to Thickness option. in ISO views. Features.. ALWAYS!!! Name Do not use tangent edges on orthographic or flat pattern Edit flange profiles to add features like holes and cutouts. When using the legacy views. method, take advantage of being able to create multiple flanges with one sketch. Let model the radii, not model it manually. SolidWorks Be aware of the Flip do View button on flat pattern views, this You can model your own reliefs to add further control over their profile and size. helps you orient the flat pattern to match the manufacturing Take manufacturing processes into consideration when modeling the part. practice for the given material. Minimize any reference to bend lines, this is a bad practice as they are volatile and change based on sheet metal options. able Youto can hide/show bend notes and lines. Also you can edit Use tables centralize forming information within the company. theBend/Gauge format of theto bend note in the file bendnoteformat.txt Forming tools do not show on flat patterns. (see Help). Understand the Normal Cut option. bothas XSmart & Y dimensions Showing Use PEM fasteners Components in the BOM for sheet metal parts (example if time allows, if not please contact me for example files).

SolidWorks Sheet Metal Links

http://www.theswgeek.com/category/tutorials/sheet-metal-tutorials/ http://www.sheetmetaldesign.com/ http://video.google.com/videosearch?hl=en&safe=off&num=20&q=solidworks+sheet+metal#

You might also like

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)From EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Rating: 4.5 out of 5 stars4.5/5 (5)

- Sheet Metal Design HandbookDocument9 pagesSheet Metal Design Handbooktrujillo4769No ratings yet

- Catia Aerospace Sheet Metal DesignDocument89 pagesCatia Aerospace Sheet Metal DesignemrreuysallNo ratings yet

- K Factors + Bending InfoDocument9 pagesK Factors + Bending InfoashkansoheylNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingFrom EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingNo ratings yet

- The Cosmos Companion: Analyzing Sheet Metal Parts & Assys in CosmosworksDocument31 pagesThe Cosmos Companion: Analyzing Sheet Metal Parts & Assys in CosmosworksraddyrajNo ratings yet

- Sheet MetalDocument186 pagesSheet Metalwalid_mohammady1616100% (1)

- Tolerance Analysis of Deformable AssemblyDocument287 pagesTolerance Analysis of Deformable Assemblymamunruet100% (2)

- Metal Stamping DiesDocument7 pagesMetal Stamping DiesedpsousaNo ratings yet

- Progressive Die Design Using NX-10-Video TutorialsTraining-Level1Document3 pagesProgressive Die Design Using NX-10-Video TutorialsTraining-Level1Smartlearning TechnologyNo ratings yet

- Sheet Metal Design ConsiderationsDocument2 pagesSheet Metal Design ConsiderationsKrishna Teja MutyalaNo ratings yet

- Sheet Metal DesignDocument39 pagesSheet Metal DesignGokul ganeshNo ratings yet

- AutoForm Software Solutions enDocument3 pagesAutoForm Software Solutions enNina GregorioNo ratings yet

- NX Progressive Die DesignDocument3 pagesNX Progressive Die Designbadboys123No ratings yet

- Solidworks 2018 Reference Guide: A Comprehensive Reference Guide With Over 250 Standalone TutorialsDocument70 pagesSolidworks 2018 Reference Guide: A Comprehensive Reference Guide With Over 250 Standalone TutorialsInnabilaNo ratings yet

- Metal Forming TechniquesDocument49 pagesMetal Forming TechniquesSachinBhagiNo ratings yet

- SolidWorks For Sheet MetalDocument15 pagesSolidWorks For Sheet MetalCodreanu Petru100% (2)

- Deep DrawDocument4 pagesDeep DrawBalvinder PrajapatiNo ratings yet

- Sheet Metal Design in SolidworksDocument27 pagesSheet Metal Design in SolidworkstnchsgNo ratings yet

- Sheetmetal Design GuidelinesDocument20 pagesSheetmetal Design Guidelinesbrpnaidu2157No ratings yet

- DFM - Sheet Metal Design PDFDocument14 pagesDFM - Sheet Metal Design PDFSivaiah AdikiNo ratings yet

- LO 03 - BendingDocument61 pagesLO 03 - Bendingladyinred90No ratings yet

- Deep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnDocument4 pagesDeep Drawing: Deep Drawing Is A Sheet Metal Forming Process in Which A Sheet Metal Blank Is Radially DrawnbrahimNo ratings yet

- Sheet Metal DesignDocument33 pagesSheet Metal DesignNanda Sagar100% (3)

- Solidworks-Sheetmetal - Tips and TricksDocument22 pagesSolidworks-Sheetmetal - Tips and TrickscvetaNo ratings yet

- CATIA ICEM Shape Design Brochure PDFDocument4 pagesCATIA ICEM Shape Design Brochure PDFCalin PopaNo ratings yet

- NX 12 - 5-Surface ModelingDocument34 pagesNX 12 - 5-Surface Modelingdavidjone90100% (1)

- Chapter 16 Sheet Metal Design Solidworks 2003Document80 pagesChapter 16 Sheet Metal Design Solidworks 2003Oscar LeonardoNo ratings yet

- Lecture 8 Sheet Metal Working PDFDocument6 pagesLecture 8 Sheet Metal Working PDFluisimtzNo ratings yet

- Core & Cavity Design: CATIA TrainingDocument47 pagesCore & Cavity Design: CATIA TrainingMehdin MujanovicNo ratings yet

- Catia V5: Compiled by Er. Bijendra PrajapatiDocument70 pagesCatia V5: Compiled by Er. Bijendra PrajapatiAnonymous uTC8baNo ratings yet

- Using Sheet Metal Bodies in SOLIDWORKS Simulation: Model CreationDocument6 pagesUsing Sheet Metal Bodies in SOLIDWORKS Simulation: Model CreationBlashko GjorgjievNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- The Basics of Applying Bend FunctionsDocument18 pagesThe Basics of Applying Bend Functionssssf-dobojNo ratings yet

- Manufacturing EssentialsDocument675 pagesManufacturing EssentialsManuelHerediaHeredia100% (1)

- Sheet Metal DFMDocument3 pagesSheet Metal DFMNageswar ReddyNo ratings yet

- Faz CT (.NT (-5) .: Accelerators '"Document2 pagesFaz CT (.NT (-5) .: Accelerators '"AkhilMohananNo ratings yet

- NX Total Machining PDFDocument5 pagesNX Total Machining PDFHussein ZeinNo ratings yet

- Tool Design - Chapter 4 (Part 3)Document59 pagesTool Design - Chapter 4 (Part 3)Fiq IFTNo ratings yet

- Progressive Die Design Using NX-10-Video TutorialsTraining-Advanced Level-2Document4 pagesProgressive Die Design Using NX-10-Video TutorialsTraining-Advanced Level-2Smartlearning TechnologyNo ratings yet

- Siemens NX Shop DocsDocument5 pagesSiemens NX Shop DocsfluxferreNo ratings yet

- Rapid Sheet Metal Design GuideDocument20 pagesRapid Sheet Metal Design Guidemawais150% (1)

- Design and Calculations of Piercing & Blanking DieDocument89 pagesDesign and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- CATIADocument979 pagesCATIARajeuv GovindanNo ratings yet

- General CAD (Drafting) Standards: Product EngineeringDocument21 pagesGeneral CAD (Drafting) Standards: Product EngineeringpuneethudupiNo ratings yet

- Advance Trick & Tips NX - Teamcenter (New)Document34 pagesAdvance Trick & Tips NX - Teamcenter (New)Kishor kumar Bhatia100% (14)

- Mat mt11050 SDocument204 pagesMat mt11050 SSachin GajjarNo ratings yet

- NX Sheet Metal Design PDFDocument2 pagesNX Sheet Metal Design PDFHussein Zein0% (1)

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationFrom EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationRating: 5 out of 5 stars5/5 (4)

- ch11Document17 pagesch11Sathish KumarNo ratings yet

- Prtoblem J BDocument24 pagesPrtoblem J BjhpandiNo ratings yet

- Back Wrapper Twad Res MatlDocument1 pageBack Wrapper Twad Res MatlSathish KumarNo ratings yet

- Tutorial Gearbox 2012 enDocument33 pagesTutorial Gearbox 2012 enSathish KumarNo ratings yet

- MR - Ramaiyan, A Resident of Golden Colony, Plot No.1387, Ward 89 of ZoneDocument1 pageMR - Ramaiyan, A Resident of Golden Colony, Plot No.1387, Ward 89 of ZoneSathish KumarNo ratings yet

- Format - PRIVILEGED CUSTOMER PROFILE - A4.pdffDocument1 pageFormat - PRIVILEGED CUSTOMER PROFILE - A4.pdffSathish KumarNo ratings yet

- Maruti Suzuki India LTD (Msil) Head Office Maruti Suzuki, India Limited Nelson Mandela Road, Vasant Kunj, New Delhi-110070. Phone: +91-8588978870 Send Your Details TO: EmailDocument3 pagesMaruti Suzuki India LTD (Msil) Head Office Maruti Suzuki, India Limited Nelson Mandela Road, Vasant Kunj, New Delhi-110070. Phone: +91-8588978870 Send Your Details TO: EmailSathish KumarNo ratings yet

- Packing List: P C Pumps & SystemsDocument1 pagePacking List: P C Pumps & SystemsSathish KumarNo ratings yet

- TANZANIA INVOICE Latest PDFDocument1 pageTANZANIA INVOICE Latest PDFSathish Kumar100% (1)

- Good Hope Hospital: Send Your Details To This EmailDocument2 pagesGood Hope Hospital: Send Your Details To This EmailSathish KumarNo ratings yet

- What Factors Led You To Choose To Above Institutions?Document2 pagesWhat Factors Led You To Choose To Above Institutions?Sathish KumarNo ratings yet

- Dear Valued CustomerDocument1 pageDear Valued CustomerSathish KumarNo ratings yet

- TR 20040521 1 PDFDocument44 pagesTR 20040521 1 PDFSathish KumarNo ratings yet

- Prima Dr. Addition / Deletion Format Emp No. Name HQ Add / Del SR - No DR - ID DR Name City Speciality ClassDocument6 pagesPrima Dr. Addition / Deletion Format Emp No. Name HQ Add / Del SR - No DR - ID DR Name City Speciality ClassSathish KumarNo ratings yet

- Application No.:: For Office Use Only For D.D. EndorsementDocument3 pagesApplication No.:: For Office Use Only For D.D. EndorsementSathish KumarNo ratings yet

- Manufacturing: Home AboutDocument4 pagesManufacturing: Home AboutSathish KumarNo ratings yet

- TUe MotDocument3 pagesTUe MotSathish KumarNo ratings yet

- Numerical Modelling and Design of Electrical DevicesDocument69 pagesNumerical Modelling and Design of Electrical Devicesfabrice mellantNo ratings yet

- The Wayland News October 2014Document16 pagesThe Wayland News October 2014Julian HornNo ratings yet

- Derebe TekesteDocument75 pagesDerebe TekesteAbinet AdemaNo ratings yet

- Bad Memories Walkthrough 0.52Document10 pagesBad Memories Walkthrough 0.52Micael AkumaNo ratings yet

- Question Answers of Chapter 13 Class 5Document6 pagesQuestion Answers of Chapter 13 Class 5SuvashreePradhanNo ratings yet

- LspciDocument4 pagesLspciregistroosNo ratings yet

- Civ Beyond Earth HotkeysDocument1 pageCiv Beyond Earth HotkeysExirtisNo ratings yet

- Acc116 Dec 2022 - Q - Test 1Document6 pagesAcc116 Dec 2022 - Q - Test 12022825274100% (1)

- Pioneer vsx-1020-k 1025-k SM PDFDocument132 pagesPioneer vsx-1020-k 1025-k SM PDFluisclaudio31No ratings yet

- Project Management TY BSC ITDocument57 pagesProject Management TY BSC ITdarshan130275% (12)

- M. Ircham Mansyur 07224005 Microprocessor-2 (H13)Document7 pagesM. Ircham Mansyur 07224005 Microprocessor-2 (H13)emiierNo ratings yet

- Types of Water Pump and Applications in Power Plant.Document6 pagesTypes of Water Pump and Applications in Power Plant.abbas bilalNo ratings yet

- Chemistry Investigatory Project (R)Document23 pagesChemistry Investigatory Project (R)BhagyashreeNo ratings yet

- Individual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per QuestionDocument2 pagesIndividual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per Questionapi-526813290No ratings yet

- A Hybrid Genetic-Neural Architecture For Stock Indexes ForecastingDocument31 pagesA Hybrid Genetic-Neural Architecture For Stock Indexes ForecastingMaurizio IdiniNo ratings yet

- BIAN How To Guide Developing Content V7.0 Final V1.0 PDFDocument72 pagesBIAN How To Guide Developing Content V7.0 Final V1.0 PDFميلاد نوروزي رهبرNo ratings yet

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- Draft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Document13 pagesDraft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Patrick PenachosNo ratings yet

- Knee JointDocument28 pagesKnee JointRaj Shekhar Singh100% (1)

- Native VLAN and Default VLANDocument6 pagesNative VLAN and Default VLANAaliyah WinkyNo ratings yet

- Aliping PDFDocument54 pagesAliping PDFDirect LukeNo ratings yet

- I I Formularies Laundry Commercial Liquid Detergents 110-12-020 USDocument6 pagesI I Formularies Laundry Commercial Liquid Detergents 110-12-020 USfaissalNo ratings yet

- Syllabus PDFDocument3 pagesSyllabus PDFBibin Raj B SNo ratings yet

- ALE Manual For LaserScope Arc Lamp Power SupplyDocument34 pagesALE Manual For LaserScope Arc Lamp Power SupplyKen DizzeruNo ratings yet

- Surgery - 2020 With CorrectionDocument70 pagesSurgery - 2020 With CorrectionBaraa KassisNo ratings yet

- Prospekt Puk U5 en Mail 1185Document8 pagesProspekt Puk U5 en Mail 1185sakthivelNo ratings yet

- Chapter 4 - Basic ProbabilityDocument37 pagesChapter 4 - Basic Probabilitynadya shafirahNo ratings yet

- Open Source NetworkingDocument226 pagesOpen Source NetworkingyemenlinuxNo ratings yet

- BARUDocument53 pagesBARUhueuaNo ratings yet

- ThorpeDocument267 pagesThorpezaeem73No ratings yet