Professional Documents

Culture Documents

45519955

Uploaded by

Mayank GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

45519955

Uploaded by

Mayank GuptaCopyright:

Available Formats

Journal of Advanced Manufacturing Systems Vol. 8, No.

2 (2009) 137152 c World Scientic Publishing Company

A FLEXIBLE MICRO MANUFACTURING SYSTEM FOR MICRO PARTS ASSEMBLY VIA MICRO VISUAL SENSING AND EAP BASED GRASPING

DUGAN UM Mechanical Engineering, Texas A&M University Corpus Christi Corpus Christi, Texas, 78412, USA dugan.um@tamucc.edu BAHRAM ASIABANPOUR and JESUS JIMENEZ Manufacturing Engineering, Texas State University San Marcos, Texas, 78666, USA ba13@txstate.edu jj30@txstate.edu

In this paper, we developed a exible micro workcell for micro part assembly and bio materials handling. The primary focus of the research is on the exible manufacturing system that can handle parts in the size of 100 to 500 m for various applications. Flexibility in micro assembly, though important, has not been examined in depth due to the complexity of micro operations of small parts. Micro gears, micro glass bers or fragile bio materials require exibility in gripping and haptic feedback control for further operation. To that end, we design grippers made out of electro active polymer, controlled by high precision micro manipulator for a novel micro assembly process, namely exible micro assembly system (FMAS). The areas of research include micro/nano electro-mechanical system (MEMS) material and structure, micro sensor/actuator system, visual feedback control system, micro-robotic arm motion control and exible micro-gripper system. In order to verify the functional aspect of the FMAS, we made micro mechanical gears fabricated via bulk micromachining technology for 3D micro vision capability and handling precision of micro robotic manipulator. Keywords : Micro assembly; micro workcell; MEMS; exible manufacturing; micro vision.

1. Introduction Demands for micro/nano products and assembly systems have been signicantly raised to meet the ever complex technical needs for modern society. The market for such microsystems has been climbing at a rate of 20% to 30% per year since 1990; the worldwide market for microsystems has been estimated to approach 30 billion dollars in 2009.13 Full-blown application of microsystems, however, is hindered by manufacturing constraints together with a high assembly cost. For example, a comprehensive study showed the assembly cost is more than half of the microdevice cost.5 Although many institutes have been involved in the micro/nano manufacturing studies in recent decades, a full blown solution with exible manufacturing

137

138

D. Um, B. Asiabanpour & J. Jimenez

capability still falls short of industrial implementation in terms of mass production. Successful development of a micro-manufacturing system will open up wide-ranging application opportunities in homeland security, transportation, aerospace, biomedical, advanced manufacturing, and many other commercial applications. Existing micro-manufacturing systems have been developed primarily to assemble a matrix of arranged micro components for various micro-structures. Novel processes like LIGA (lithography, electroplating, and molding), microcasting, and micro electrical discharge machining (microEDM) have been developed to fabricate microcomponents for miniature machines. When considering the manufacturing aspects of such miniaturized components, however, neither an ecient nor an automated assembly system has been reported for a full-edged solution. This research aims to develop a novel microassembly system that can see and feel when handling micro objects by 3D vision and haptic feedback respectively. Development of microdevices, micro sensors, and microactuators has been escalating due to increasing trends for product miniaturization and advances in science and technology. Greater exibility and capability in microassembly systems will be facilitated by the development of improved microgrippers. Ideal microgrippers would be able to handle a variety of micro/nano components for biological, medical, aerospace, manufacturing, chemical, or security applications. Most commercially available micro assembly devices are open loop systems, i.e. a trained operator is required to operate the system via high magnication. Without sensitive feedback, handling of fragile biological cells and advanced materials such as carbon nano tubes or optical bers proves dicult since an operator has to constantly watch for minute shape change of the sample or risk damaging it. Although microassembly of prototypes and low volume microsystems could be done with skillful operators, having human operators assembling high volume microsystems would not be economically justiable due to high labor and training cost, fatigue, low yield, and inconsistent product quality. The risk is even higher when having a human operator working on hazardous chemicals, radioactive components, or contaminated biological microtissues. While some preexisting micro-manufacturing systems, such as the one from Zyvex, Inc., provide excellent accuracy, they lack the exibility to span the assembly system to the next level of technical domains, including military, homeland security, transportation, aerospace, and other commercial applications due to material constraints and lack of exibility. The micro gripper system developed by Sandia National Laboratory demonstrates excellent object identication and manipulation capability (James). Their micro-manufacturing cell, composed of several compartments, can cope with up to 100 m parts with its multi-camera micro-vision system. However, since the image processing system works only o-line, the application area is signicantly limited. Furthermore, next generation micro-manufacturing systems are required to be exible enough to handle various materials in arbitrary shapes. Cecil et al. mentioned that micron sized devices that need incompatible processes, dierent materials or complex geometries in micro size have to be assembled

A Flexible Micro Manufacturing System

139

either by manual or autonomous assembly operations. Due to the tedious and time consuming assembly works by manual operator, innovative autonomous assembly platforms are in essential demand. The general domain of micro devices assembly (MDA) now thus emerges into the eld involving the study of computer-based methods to accomplish the assembly of micron-sized parts described as automated micro devices assembly (AMDA). To that end, delicate and dexterous micro assembly grippers are the core technology and have been under in-depth scrutiny so far. In Bohringers study, thorough reviews have been made as to the role of the interactive forces at the micro level including sticking eects, adhesion, electrostatic forces, etc. In the course of the wide ranged study of the micro forces, force measuring devices for micro level have been proposed and tested. One example of the micro-grippers design is introduced in Carrozzas study, where a LIGA-based micro-gripper is manufactured with semiconductor strain gauges. The micro-gripper system is composed of a micro-gripper, 3 DOF micropositioners, a PC, and Phantom 1.0 haptic device. In the decision of strain-gauge location, they utilized FEM to nd the maximum stress point. Another important aspect of micro assembly for AMDA development is on the machine vision and virtual reality technology for micro-parts localization. The primary usage of machine vision in micro assembly is to facilitate object identication and to measure the gripping forces during the grasping operation. Virtual reality in conjunction with the machine vision enables users to propose and estimate assembly operation beforehand. Some optimization can be made on robotic motion and path planning via VR technology as well. As is addressed in the literature survey, micro assembly system, as an integrated manufacturing cell, requires various technical components, such as intelligent

Fig. 1.

Micro robotic assembly system.

140

D. Um, B. Asiabanpour & J. Jimenez

micro-grippers, machine vision, and robotic manipulators. To meet these needs, researches are being conducted to develop a novel micro-manufacturing system that is autonomous, intelligent, and exible in structure as shown in Fig. 1. The proposed micro-manufacturing systems can assemble or disassemble arbitrary components based on assembly sequence maps to deal with mission critical parts such as micro sensors, micro actuators or biologically/chemically hazardous embodiments, etc.

2. Research and Results The complete embodiment of the novel microassembly system is composed of a micro-robot, micro-grippers, and a microscopic visual feedback system. In order to make a micro-work cell functional, a 3 degree-of-freedom (DOF) mini robotic hand is utilized. To form optimally shaped ngers for this robot hand, the ngers are fabricated from piezoelectric materials, namely polyvinylidene uoride (PVdF) ionic polymer. A prefabricated prototype of the piezoelectric materials used for the robotic hand and ngers is shown in Fig. 10. Such electroactive polymers (EAPs), which can be molded into an intricate shape, can move micro to millimeter distance when a small voltage is applied to the grippers. Use of EAP for robotic actuators was also recommended due to the material characteristics (i.e. high power density, low cost, easy to form into special shapes), and ability to combine sensing and actuation into a single device.10 Both the vision system and micro-grippers are integrated into an autonomous assembly system to recognize, grasp, and then manipulate a micro object. The image processor converts the captured infrared image to 3D geometry, followed by template matching for object localization. During the template matching process, the current geometry obtained from an infrared image is compared against the reference template in a database from which incremental changes will be calculated, thereby determining the exact position and orientation of the to-be-manipulated object. 2.1. Micro gear fabrication In order to provide mechanical components of micro size for assembly testing, silicon-based micro gears are fabricated. Bulk micro machining, one of the MEMS technologies, has been utilized for fabrication of the gears in a class-10,000 certied cleanroom.15 Figure 3 illustrates the overall process of bulk micro machining of MEMS gears from oxidation to KOH etch. The critical dimension that is sought after is 1 micro meter. The wafers used to create the aforementioned micro parts are from doped P -type silicon with a Miller Indices crystal orientation of <100>. The oxide layer used to create the parts is grown using a wet oxidation furnace. Once the oxide layer has reached the desired thickness, the image of the parts is imprinted onto the wafer using a standard photolithography and develop processes.

A Flexible Micro Manufacturing System

141

Fig. 2.

Photomask of micro gears, latch, piston and assembly bed masks.

Unwanted SiO2 is then removed during the buered oxide etch process. In the nal step of the process, the parts are released from the wafer using an etch solution of potassium hydroxide. In order to fabricate micro gears, the thickness of the SiO2 layer needs to be at least 20,000 Angstroms thick.17 This was accomplished by baking the wafers at 1,000C for 15 hours while introducing 2 liters per minute or 58 millimeters on the ow meter scale of wet oxygen gas. In the photolithography process, an image of the desired parts is optically transferred onto the SiO2 layer using ultra violet (UV) light. The photomask for this research project was created using a CAD model and a photo reduction camera and appears in Fig. 2. Details of the bulk micro machining process has been excerpted from the previous work described in the paper by Dugan & Scott as below. The optical transfer of the image on the photomask to the silicon substrate is accomplished by adding an even layer of photoresist to the wafer through the use of a vacuum hold and a high RPM programmable spinner. Once the wafer is baked, it is placed in the photolithography machine. Proper alignment of the wafer with the photomask is essential in this stage. The wafer is then exposed to UV light for 2.5 min. Best results are achieved using 2.5 ml of AZ5124E photoresist and applying it to the wafer at 2,000 RPM spin rate. In the develop process the unwanted photoresist is removed leaving only the desired parts protected by the photosensitive polymer. Satisfactory results were achieved by using a 1:1 ratio of developer and de-ionized water and gently agitating the wafer for 10 seconds. In order to remove unwanted SiO2 on the wafer, Buered Oxide Etch (B.O.E.) solution is used. Finally, micro parts such as gears, latch, piston, etc. . . are removed from the wafer using a potassium hydroxide (KOH) solution. The growth of the oxide layer has been estimated and observed with limetry testbed as shown in Fig. 4. The initial estimation was useful for oxidation time calculation. As shown in the result, the calculated estimation by diusion model complies well with the actual result of the oxide layer thickness measure.

142

D. Um, B. Asiabanpour & J. Jimenez

Fig. 3.

Micro gear fabrication process.

The bulk micro machining technology utilizes discriminate etching between materials; pure silicon etches at a rate of 100 micron per hour while the SiO2 etches at the much slower rate of 800 nm per hour at 90C. A method experiment was then conducted to attempt the optimization of the part removal technique. The initial method experiment run had the parts wafer in the vessel face up with the KOH layer just touching the bottom of the silicon substrate. The idea behind this experiment was that only the silicon would be etched while minimizing the exposure of the SiO2 parts. Once the parts are released from the wafer and fallen

A Flexible Micro Manufacturing System

Growth over Time

25000.0 19698.3 20000.0 AVG SiO2 Growth 15218.3 15000.0 8369.4 10000.0 8507 5000.0 16703 12991.7 11839 14450

Results Calculations

143

17740.0 18897

0.0 3:21 6:11 9:00 Time 11:51 15:00

(a)

(b) Fig. 4. (a) Silicon-Oxide (SiO2 ) layer thickness growth, (b) KOH Etching rate at 45% solution.

into the bottom of the tray, they can be removed from the solution by lifting the vessel out of the KOH. The preliminary results using this method, however, were less than successful. The gears were over etched and formed square angles on all surfaces. In order to resolve this issue, a gravity driven stop etch process used to create cantilever beams for atomic force microscopes was adopted as a possible solution.11 It was determined that an etch stop needs to meet the following three criteria. (1) The chemical used as an etch stop should not exhibit an obvious density change when subjected to external heating.

144

D. Um, B. Asiabanpour & J. Jimenez

Fig. 5.

Etch stop bed.

(2) The temperature of the etchant should be easily controlled with the heating energy transmitted through the etching stop solution. (3) The etch stop solution must be chemically inert to both silicon and KOH. In order to meet the criteria for etch stop, a etch stopper has been designed and fabricated by a Rapid Prototype machine (Fig. 5). As an etch stop solution, Diiodomethane (CH2 I2 ) was chosen due to the fact that the CH2 I2 is a very dense liquid and naturally separates itself from the KOH into two distinct layers. The basic idea behind this process is that as the parts release from the silicon wafer they fall through the KOH layer into the CH2 I2 and the etch process immediately stops preventing the parts from being over etched, thereby preserving the integrity of the parts. This allowed us to fabricate a gear of micro size as shown in Figs. 6 and 7. The square feature appearing in Fig. 7 has been formed by the crystallographic arrangement of the silicon wafer and reaction with the KOH. Based on the various

Fig. 6.

SiO2 layer gear denition.

A Flexible Micro Manufacturing System

145

Fig. 7.

Released gear with unwanted square features.

conducted experiments, squaring of the features is unavoidable. The three main orientations of crystal silicon are <100>, <110>, <111>; of these only the <100> orientation was tested.11 The subsequent orientations will need to be tested in order to determine whether they can be used to improve the nal parts. Wafers with dierent crystal orientation, or even amorphous orientation, can also be tested. The anisotropic nature of KOH etch may be used as an advantage in creating precise parts. If the nature of the etch rate and selectivity can be predetermined the parts can be designed to begin as an amorphous non-descript shape but become perfectly dened as the etch process evolves. 2.2. Micro 3D infrared vision In order to realize a microscopic 3D visual feedback system, a monovision based 3D visualization system is studied and developed using an infrared proximity array (IPA) to capture image and geometric data of a 3D object. As a 3D visual device, the IPA system includes light sources utilizing infrared light-emitting diodes, an infrared light ltering lens, and a charge coupled device array. The principle of 3D visual sensing via monovision IPA is; Ep (dp )2 , (1)

where Ep is the reected infrared light energy and dp is the distance to an object from the pixel, p.14 This relationship allows the scanning of the infrared energy of all the pixels to obtain not only an accurate geometry of the object but also to capture the position and orientation of the object relative to the sensor.16 As a result, one IPA system is equivalent to 307,200 infrared sensors in a 2.5 2.5 mm2 (0.1 0.1 in2 ) sensor array. A light intensity matrix of 307,200 sensors immediately generates a gray scale matrix, and further constructs a 3D computer model.

146

D. Um, B. Asiabanpour & J. Jimenez

The goal of the 3D infrared vision technology is to determine x, y, z coordinates of the micro gears fabricated by MEMS technology. The vision system determines the location of the gears on the x-y plane so that the robot will be able to locate the gear and grip the gear. The micro vision system uses infrared sensor technology to accurately measure distance with a 2D array image and, thus, synthesizes 3D geometry of sensed objects in real time. In order to generate a micro parts image, the vision system is assembled together with a microscope for miniature parts recognition (Fig. 8). To make the gear recognition simple, a prole averaging technique is used to nd the centroid of a gear as detailed below. Scan the 3D image prole produced by the infrared camera. If the prole is higher than the threshold, then add the values of x and y location into x-sum and y -sum. Divide x-sum and y -sum by the number of data points to get the centroid of the part.

Fig. 8.

Micro vision system assembly with micro robot.

A Flexible Micro Manufacturing System

147

(a) No voltage applied. Fig. 9.

(b) Voltage applied.

States of the IPMC-based Electro-Active Polymer before and after voltage is applied.

2.3. EAP gripper Electro-Active Polymer (EAP) is a material that contracts when voltage is applied as illustrated in Fig. 9. The response of this material is similar to the contraction of a human muscle, and therefore is commonly referred to as an articial muscle. Several types of articial muscles are commercially available. The type of articial muscle used in this research is based on an ionic polymeric gel treated with platinum, material also known as ionic polymer metal composite (IPMC). To manufacture an IPMC, a thin strip of polymer undergoes the oxidation process to composite a metal coating on either side of the polymer surface. To create movement, voltage is run through the material by applying opposite charges to either side of the strip. Voltage produces an electric eld that causes redistribution of charges in the IPMC, which then causes the muscle-like movement of the polymer. In general, IPMCs have shown to be eective for micro-gripping because of their large motion sensing and actuation and low cost. See Ref. 12 for a detailed description of IPMC. 2.4. Load carrying capacity vs voltage A specic amount of voltage is required to produce a force sucient enough to lift the mass of the gears. The trends found by previous researchers show that both displacement and force of the IPMC increases proportionally to increases in voltage. For instance, Deole and Lumin found that applying a voltage of ve volts or less can produce large displacements in micro-object manipulation. The method of experimentation used by Lumin and Deole characterizes load carrying capacity as a function of voltage by using a trial and error approach (i.e. lifting several loads of varying weights and noting the applied voltage). Higher load carrying capacity enables heavier load lift without failure. Material with repeated use for 23 -factorial experiment was conducted to nd the combination of factors that produce maximum force (load carrying capacity). The factors tested in the experiment include: length of micro-gripper (Factor A),

148

D. Um, B. Asiabanpour & J. Jimenez

width of micro-gripper (Factor B ), and applied voltage (Factor C ). As for the length of micro-grippers, two dierent lengths (i.e. 5 mm and 15 mm) were chosen to be proportional to the size of the gears. The two levels of width, 1 mm and 2 mm, were chosen in the same manner as length. The two limits of applied voltage were chosen to be 3 volts, as a minimum necessary to cause a signicant force displacement, and 6 volts, to avoid damaging the material from overvoltage. The experimental results were analyzed using the analysis of variance (ANOVA) (see Fig. 10). The signicant factors can be observed graphically in Fig. 11 on a normal probability plot. Any signicant factor lies a considerable distance from the theoretical normal line. Results show that width, length, voltage, and width/voltage interaction were signicant at = 0.05. The increase in width and the decrease in length resulted in better performance. Initially, the increase in voltage caused an increase in force but became unpredictable throughout the experiment. This experimentation suggests that a 5 mm 2 mm EAP-based micro-gripper should be used. Similarly, 3V should be applied in order to lift the objects used in this research. 2.5. Micro robotic system Fuzzy logic is a methodology used to make computers assimilate our way of thinking to solve problems.1 Thus, fuzzy logic is useful to provide reasoning for systems that may be too complex or for which a dynamic model is not available. The purpose of using fuzzy logic in this research is to provide a system capable of fast and accurate manipulation of MEMS products with a cost eective and simple methodology. Attaching the gripper to the robotic system was facilitated by developing a stage attachment for the gripper assembly. The robotic system is positioned outside of the cameras eld of view with the EAP micro-grippers extended into the work

Fig. 10.

ANOVA.

A Flexible Micro Manufacturing System

149

Fig. 11.

Normal probability plot.

Fig. 12.

MM-3M-F robotic arm with holder and EAP micro-grippers.

area to be seen by the camera. The integrated system will provide for complete and autonomous manipulation of any object within the cameras eld of view (Fig. 12). The code for the robot control is to receive the location information of a target object from the real-time vision system and identify the X, Y and Z coordinates. Once the program reads the coordinates it then incorporates them into the fuzzy logic controller to help decelerate the approach speed of the robot as it nears its target to avoid overshoot or collision. The fuzzy logic will control the transition speed with respect to distance of the next known location. Fuzzy logic suits the goal of translational movement control, because it allows the development of the

150

D. Um, B. Asiabanpour & J. Jimenez

robot specic case scenarios. To successfully complete this task, one must rst determine the input and output variables that aect motor speed. For the needs of this experiment, encoder counts are read to control the speed and position respectively. The development of the fuzzy logic speed control is to be broken down into three parts: Fuzzication, Rule Declaration, and Defuzzication.8 Fuzzication will be between our input (encoder counts) and output (speed). From this point a group of sets will be established to create the necessary membership value needed for our defuzzication as represented by Fig. 13. Rule declaration is the stage when one will develop a series of IF-Then statements to go along with our membership values created in the fuzzication (Fig. 14). These rules are produced in a way that, when the input falls within a particular set, the defuzzication will produce the appropriate output actions. Defuzzication will then convert the rst two steps into a viable output being used to tell the motor how fast to move. This is done by determining how much the input falls within a certain set or sets. Output speed can be found for the formulated fuzzy logic by determining the centroid of the membership sets (2). Xi represents centroid of the ith fuzzy set and Yi being weighted membership in ith set. X will be the output speed which will then be supplied to the motors. X= Xi Yi . Yi (2)

Fig. 13.

Fuzzy logic rule.

Fig. 14.

Fuzzication.

A Flexible Micro Manufacturing System

151

The robot is set to move a predetermined distance and then notify if the position has been reached. If the robot has not reached the desired location the program will loop to determine the actual position, and apply the fuzzy logic. The program will continue looping as the robot moves slower and gets closer to the desired location. 3. Conclusion In this paper, we proposed a novel design of micro manufacturing work cell composed of micro-grippers, micro vision, and micro robotic manipulator for exible assembly of micro parts. In order to overcome the current system limits of nonexible micro assembly operation, micro visual feedback system has been proposed as well as EAP-based exible micro-grippers. Micro robotic system in conjunction with the micro-grippers and micro visual feedback system demonstrated the capability of assembly of micro parts. For assembly tests, micro scale gears are fabricated via bulk micromachining technology. Potassium hydroxide is used to carve the silicon substrate controlled precisely by photo lithography. Fabricated gears are used to verify the micro manufacturing cells performance, especially for micro visual feedback system and microgripper system. As for the micro-grippers, the experimental results reveal that further research should be done pertaining to the lifespan of the IPMC. As discussed before, an equation to account for longevity would be ideal. Since it is known that deterioration is caused by the loss of water molecules, humidity monitoring would help predict the lifespan of the EAP grippers in a precision assembly process. Micro infrared proximity array (IPA) technology has been utilized to capture images of micro parts. Further image processing technique such as object recognition has been adopted for micro gear localization. Thus, the micro robot react to the gear location. Fuzzy logic-based distance and speed control loop has been implemented on a micro-robotic platform for assembly operation. Overall, a novel system design for exible micromanufacturing is demonstrated. Further development of each compartment and precision turning, however, will help produce a commercially functioning workcell for the micromanufacturing industry. References

1. R. N. Bateson, Fuzzy Logic Controllers: Introduction to Control Systems Technology, 7th edn. (Prentice Hall, 2001). 2. K. Bohringer, K. Fearing and D. Goldberg, A Chapter on Micro Assembly, the Handbook of Industrial Robotics, 2nd ed. (1998) <http://www.ee.wasington,edu/research/ mems/publications/1999/chapters/industrialrobotics-bohringer- 99.pdf>. 3. M. C. Carrozza, A. Eishinberg, A. Menciassi, D. Campolo, S. Micera and P. Dario, Towards a force-controlled micro gripper for assembling biomedical microdevices, J. Micromech. Microeng. 10(2) (2000) 271276. 4. J. Cecil, D. Powerll and D. Vasquez, Assembly and manipulation of micro devices A state of the art survey, Robotics and Computer-Integrated Manufacturing, Elsevier Ltd. 23 (Elsevier Ltd., 2007) 580588.

152

D. Um, B. Asiabanpour & J. Jimenez

5. S. K. Chollet, F. Bourgeois and J. Jacot, Economical justication of exible microassembly cells, in Proc. on IEEE Symposium on Assembly and Task Planning (2003), pp. 4853. 6. U. Deole and R. Lumia, Measuring the load-carrying capability of IPMC microgripper ngers, in Proc. on IEEE Industrial Electronics (France, 2006), pp. 29332938. 7. R. J. James, Precision Micro Assembly Laboratory, Sandia National Lab., http:// www.sandia.gov/isrc/precmicroassy.html. 8. Ch. S. Kim, W. H. Seol, S. H. Han and O. Khatib, Fuzzy logic control of a robot manipulator based on visual servoing, IEEE International Symposium on Industrial Electronics, Pusan, KOREA (July 2001). 9. W. Kim and N. Bhat, Precision force and position control of an ionic polymer metal composite, Systems and Control Engineering 218 (2004) 421432. 10. R. Kornbluh, R. Pelrine, Q. Pei and S. Shastri, Application of dielectric elastomer EAP actuators: Electroactive polymer (EAP) actuators as articial muscles, SPIE Press (2001), pp. 457495. 11. W. C. Lin and L. J. Yang, A liquid-based gravity-driven etching-stop technique and its application to wafer level cantilever thickness control of AFM probes, Journal of Micromechanics and Microengineering 15(5) (May 2005). 12. R. Lumia and M. Shahinpoor, Microgripper design using electro-active polymers, SPIE 3669 (1999) 322329. 13. A. McWilliams, Tech Report ID: IAS027A (July, 2008), http://www.bccresearch. com/report/treport.php?rcode=IAS027A&type=high. 14. P. M. Novotny and N. J. Ferrier, Using infrared sensors and the Phong illumination model to measure distance, IEEE Int. Conf. on Robotics and Automation (1999), pp. 16441649. 15. D. Um, Microelectronics Lab Manual, Texas State University San Marcos, Photomask Preparation (2006). 16. D. Um and W. N. P. Hung, A novel infrared proximity array sensor for microworkcell: Modeling and applications, IEEE Int. Conf. on Robotics, Automation and Mechatronics (2006). 17. D. Um and S. Lloyd, MEMS research and curriculum development by bulk micromachining technology, Journal of Education and Human Development 1(1) (2007). 18. K. Yun and W. Kim, System identication and microposition control of ionic polymer metal composite for three-nger gripper manipulation, Systems and Control Engineering 220 (2006) 539551.

Copyright of Journal of Advanced Manufacturing Systems is the property of World Scientific Publishing Company and its content may not be copied or emailed to multiple sites or posted to a listserv without the copyright holder's express written permission. However, users may print, download, or email articles for individual use.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Balanced Scorecard at Philips ElectronicsDocument5 pagesThe Balanced Scorecard at Philips ElectronicsAudrius MiknevičiusNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Does India Need More Fair Or: Free Trade?Document4 pagesDoes India Need More Fair Or: Free Trade?Mayank GuptaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Av Er Ick W TR Ick S Ne W TR Ick SDocument7 pagesAv Er Ick W TR Ick S Ne W TR Ick SMayank GuptaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lessons of The Japanese Mavericks: The View From AsiaDocument4 pagesLessons of The Japanese Mavericks: The View From AsiaMayank GuptaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- T Cop Y T Cop Y: Bharti Airtel (B)Document12 pagesT Cop Y T Cop Y: Bharti Airtel (B)Mayank GuptaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Project ReportDocument24 pagesProject ReportMayank GuptaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- LogitechDocument20 pagesLogitechMayank GuptaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Computer-Integrated ManufacturingDocument12 pagesComputer-Integrated ManufacturingGagandeep Singh SidhuNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Power PDFDocument6 pagesPower PDFelrajilNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- SyllabusDocument2 pagesSyllabusprajari ghoshNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Instruction Manual: RA 0025 F, RA 0040 F, RA 0063 F, RA 0100 FDocument24 pagesInstruction Manual: RA 0025 F, RA 0040 F, RA 0063 F, RA 0100 FAlexandru SavuNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pt. Emira Energi: PWHT ProcedureDocument13 pagesPt. Emira Energi: PWHT ProcedureAull Krizz NaGrtNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Theory of Shear Transfer Strength of Reinforced ConcreteDocument12 pagesTheory of Shear Transfer Strength of Reinforced ConcretePremasiri Karunarathna100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Arbed Report On Composite Columns in Fire 1992 REFAO IIDocument238 pagesArbed Report On Composite Columns in Fire 1992 REFAO IIwhadddupNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- MultistoreybuildingDocument43 pagesMultistoreybuildingmohan890100% (1)

- Structural Analysis of Crane HookDocument5 pagesStructural Analysis of Crane HookAkesh KakarlaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CD6 Prototype Control PlanDocument3 pagesCD6 Prototype Control Planmpedraza-1No ratings yet

- Distillation Column Case StudyDocument26 pagesDistillation Column Case Studysachin2010No ratings yet

- ATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedDocument430 pagesATLAS OF ISOTHERMAL TRANSFORMATION AND COOLING TRANSFORMATION DIAGRAMS - CompressedYENIFER PLATA LOPEZNo ratings yet

- Acid and Base EnglishDocument38 pagesAcid and Base EnglishdivyaNo ratings yet

- Cbse Class 10 Science Chapter 1 McqsDocument5 pagesCbse Class 10 Science Chapter 1 Mcqsleena_louisNo ratings yet

- 1 The Diagram Shows A Kettle of Boiling Water.: SublimationDocument13 pages1 The Diagram Shows A Kettle of Boiling Water.: SublimationNethuni KumarasingheNo ratings yet

- Program Book ICPAM 2014Document48 pagesProgram Book ICPAM 2014AstoriaDtefanNo ratings yet

- Cafflano Ç Klassic User TipsDocument14 pagesCafflano Ç Klassic User TipsismuNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Дизельные электростанции EMSADocument52 pagesДизельные электростанции EMSABrizmotorsNo ratings yet

- Electricity QuestionsDocument22 pagesElectricity Questionssanat kr pratiharNo ratings yet

- (PDF) Systematic Review of Powder Metallurgy CurDocument1 page(PDF) Systematic Review of Powder Metallurgy Curhtx5jfkzhkNo ratings yet

- REDLINE IdőkapcsolóDocument2 pagesREDLINE IdőkapcsolórimitomiNo ratings yet

- Green Cosmos AKS Lining PDFDocument8 pagesGreen Cosmos AKS Lining PDFMeng WaiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- CE2021 ME2010 2016 Tute 05 PDFDocument3 pagesCE2021 ME2010 2016 Tute 05 PDFAAKIL AHAMEDNo ratings yet

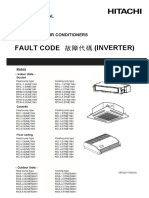

- Fault Code InverterDocument11 pagesFault Code InverterHuawei HuaweiNo ratings yet

- AWS D1 Visual InspectionDocument2 pagesAWS D1 Visual InspectionBHUSHAN KALENo ratings yet

- Swaged and Lightweight Welding NozzlesDocument5 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Patent Pervious ConcreteDocument28 pagesPatent Pervious ConcreteChong Ting ShengNo ratings yet

- COA LonganDocument1 pageCOA LonganBoonyi UnaiNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Designing of Chain Drive MechanismDocument1 pageDesigning of Chain Drive MechanismrasgeetsinghNo ratings yet