Professional Documents

Culture Documents

Bolt Procedure

Uploaded by

Murugan RajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Procedure

Uploaded by

Murugan RajaCopyright:

Available Formats

Date: 28.07.

2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 1 of 19

FASTENERS TESTING PROCEDURE

Prepared By Justin. A

Reviewed BY Jessen P Abraham

Approved By Ramasamy.S

Page 1 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 2 of 19

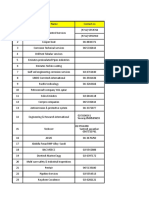

Sl.No

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Description of content

Scope Reference Documents Testing Machine Tension testing of machined test specimens Tension testing procedure Full size bolt test method Full size bolt procedure Hardness test for externally fastener Hardness test for internally fastener Proof load test Proof load procedure Acceptance criteria report Annexure 1

Page ref.

3 3 4 4 7 8 10 11 12 14 15 16 18 19

Page 2 of 19

Date: 28.07.2013 Rev 0

1. SCOPE

Fasteners Test Procedure

ARIES-MT-F-001 Page 3 of 19

The test procedures cover for conducting tests to determine the mechanical properties of externally and internally threaded fasteners, washers, and rivets. Property requirements and the applicable tests for their determination are speci ed in individual product standards. In those instances where the testing requirements are unique or at variance with these standard procedures, the product standard shall specify the controlling testing requirements. These test procedures describe mechanical tests for determining the following properties. a. b. c. d. Tension testing of machined test specimen Axial tension testing of full size Hardness test Proof load test

2. REFERENCE DOCUMENTS

a. Client / Engineer requirements b. Standard specification for carbon and alloy steel externally threaded metric fasteners as per ASTM F 568M c. Mechanical properties of fasteners made of carbon steel and alloy steelPart 1: Bolts, screws and studs with specified property classes Coarse thread and fine pitch thread as per ISO 898-1. d. Standard test methods for determining the mechanical properties of externally and internally threaded fasteners, Washers, and Rivets as per ASTM F 606 e. Standard test methods and definitions for mechanical testing of steel products as per ASTM A370. Mechanical properties of fasteners made of carbon steel and alloy steel part 2: Nuts with specified property classes Coarse thread and fine pitch thread as per ISO 898-2. f. Test methods for Rockwell hardness and Rockwell superficial hardness of metallic materials as per ASTM E18. g. Metallic materials Rockwell hardness test Part 1: Test method (scales A,B,C,D,E,F,G,H,K,N,T) as per ISO 6508-1 h. Metallic materials Tensile testing part 1: Method of test at room temperature.

Page 3 of 19

Date: 28.07.2013 Rev 0

3. TESTING MACHINE

Fasteners Test Procedure

ARIES-MT-F-001 Page 4 of 19

a. Fine manufacturing industries, India, Model No. TFUC-1000, Capacity 1000 kN is the Computerized universal testing machine used for the tensile test. Tensile test yield strength and Offset percentage of proof stress used for Electronic Extensometer. b. The Machine an accuracy of 1% guaranteed from 2% to 100% of capacity of the machine. c. Universal testing machine calibrated annually according to ASTM E4-09a and BS EN ISO 7500-1. d. Universal Calibration services can be undertaken in presence of National / International inspection agencies like UKAS.

4. Tension testing of machined test specimen a. When bolts and studs cannot be tested full size, conduct tests using test specimens machined from the bolt or stud (Test Methods ASTM E 8). b. Bolts and studs 9 16 in. in diameter and smaller may be machined concentric with the axis of the bolt or stud. The specimen shall have a turned section as large as feasible and shall have a gage length four times the diameter of the specimen. See Fig. 1 and Fig. 2.

Fig 1 : Tension test specimen for bolt with Turned Down shank

Page 4 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 5 of 19

Fig 2 : Examples of small-size specimens proportional to standard 2 in gauge length specimen c. Bolts and studs 5 8 in. in diameter through 1 1 4 in. in diameter may have their shanks machined concentric with the axis of the bolt or stud, leaving the bolt head and threadedsection intact as shown in Fig. 1. d. Alternatively, bolts and studs5 8 in. in diameter through 1 1 4 in. in diameter may have theirshanks machined to a test specimen with the axis of thespecimen located midway between the axis and outside surfaceof the bolt or stud as shown in Fig. 3. Bolts of a small crosssection that will not permit taking the 0.500-in. round, 2-in.gage length test specimen shall have a turned section as largeas feasible and concentric with the axis of the bolt or stud.

Fig 3. Location of standard round 2 in gage length tension test specimen when turned from large size bolt. Page 5 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 6 of 19

e. The gage length for measuring the elongation shall be four timesthe diameter of the specimen. Fig. 2 illustrates an example ofthese small-size specimens. For arbitration purposes, machinedtest specimens for bolts and studs 5 8 in. in diameter through1 1 4 in. in diameter shall be machined with the axis of thespecimen located midway between the center and outsidesurface. f. Bolts and studs 1 3 8 in. in diameter and larger mayhave their shanks machined to the dimensions of a 0.500-in.round, 2-in. gage length test specimen with the axis of thespecimen located midway between the center and outsidesurface of the bolt or stud as shown in Fig. 3. g. Machined test specimens shall exhibit tensilestrength, yield strength (or yield point), elongation, and reduction of area equal to or greater than the values of theseproperties speci ed for the product size in the applicableproduct speci cation when tested in accordance with thissection. h. Yield Strength Yield strength is the stress at which amaterial exhibits a speci ed limiting deviation from the proportionality of stress to strain. The deviation is expressed interms of strain, percent offset, total extension under load, etc Yield PointYield point is the rst stress in a material, less than the maximum obtainable stress, at which an increase in strain occurs without an increase in stress. Yield point is intended for application only for materials that may exhibit the unique characteristic of showing an increase in strain without an increase in stress. The stress-strain diagram is characterized by a sharp knee or discontinuity. Autographic Diagram MethodWhen a sharp kneed stress-strain diagram is obtained by an autographic recording device, take the stress corresponding to the stress at which the curve drops as the yield point (Fig. 4).

Fig 4 stress strain diagram showing yield point corresponding with top of knee Page 6 of 19

Date: 28.07.2013 Rev 0

i.Tensile Strength

Fasteners Test Procedure

ARIES-MT-F-001 Page 7 of 19

Calculate the tensile strength bydividing the maximum load the specimen sustains during atension test by the original cross-sectional area of the specimen. j. Elongation: Fit the ends of the fractured specimen togethercarefully and measure the distance between the gage marks tothe nearest 0.01 in. for gage lengths of 2 in. and under, and tothe nearest 0.5 % of the gage length for gage lengths over 2 in. A percentage scale reading to 0.5 % of the gage length may beused. The elongation is the increase in length of the gagelength, expressed as a percentage of the original gage length. Inreporting elongation values, give both the percentage increaseand the original gage length. If any part of the fracture takes place outside of themiddle half of the gage length or in a punched or scribed markwithin the reduced section, the elongation value obtained maynot be representative of the material. If the elongation someasured meets the minimum requirements speci ed, nofurther testing is indicated, but if the elongation is less than theminimum requirements, discard the test and retest. k. Reduction of Area Fit the ends of the fracturedspecimen together and measure the mean diameter or the widthand thickness at the smallest cross section to the same accuracyas the original dimensions. The difference between the areathus found and the area of the original cross section expressedas a percentage of the original area, is the reduction of area. 5. Tension testing procedure a. Completion of tensile test specimen preparation shall be ensured. Tensile Plate type test specimen width and corresponding thickness of the reduced section shall be measured. b. Tensile test reduced section minimum dimension of this test piece, maximum dimension of test piece shall not exceed. c. Cross sectional area shall be obtained by multiplying the width by the thickness. d. The original cross-sectional area shall be calculated from the measurements of the appropriate dimensions. The accuracy of the calculation depends on the nature and type of the test piece. e. The gage marks for measuring elongation after fracture shall be made on the flat or on the edge of Page 7 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 8 of 19

the flat tension test specimen and within the parallel section; for the gage length specimen, one or more sets gage marks may be used, intermediate marks within the gage length being optional. Rectangular 2-in. gage length specimens, and round specimens, gauge marked with a double-pointed center punch or scribe marks. One or more sets of gage marks may be used; however, one set must be approximately centered in the reduced section. These same precautions shall be observed when the test specimen is full section. f. The test machine shall be set up and zeroed in such a manner that zero force indication signifies a state of force on the specimen, as indicated in the zeroing of the test machine. 6. Full size bolt test method It is preferred that bolts be tested full size, and it iscustomary, when so testing bolts to specify a minimumultimate load in pounds, rather than a minimum ultimatestrength in pounds per square inch. Three times the bolt nominal diameter has been established as the minimum bolt length subject to the tests described in the remainder of this section. Sections A proof load, section C proof load time of loading apply when testing boltsfull size. Section D Axial tension testing of full size bolts shall apply where the individualproduct speci cations permit the use of machined specimens. Section A. Proof Load Due to particular uses of certainclasses of bolts it is desirable to be able to stress them, whilein use, to a speci ed value without obtaining any permanentset. To be certain of obtaining this quality the proof load isspeci ed. The proof load test consists of stressing the bolt witha speci ed load which the bolt must withstand without permanent set. An alternate test which determines yield strength of afull size bolt is also allowed. Either of the following Methods,1 or 2, may be used but Method 1 shall be the arbitrationmethod in case of any dispute as to acceptance of thebolts. Section -B. Proof Load Testing Long BoltsWhen full sizetests are required, proof load Method 1 is to be limited inapplication to bolts whose length does not exceed 8 in. (203mm) or 8 times the nominal diameter, whichever is greater. Forbolts longer than 8 in. or 8 times the nominal diameter,whichever is greater, proof load Method 2 shall be used. (a) Method 1, Length MeasurementThe overall length ofa straight bolt shall be measured at its true center line with aninstrument capable of measuring changes in length of 0.0001in. (0.0025 mm) with an accuracy of 0.0001 in. in any 0.001-in.(0.025-mm) range. The preferred method of measuring thelength shall be between conical centers machined on the center line of the bolt, with mating centers on the measuring anvilsThe head or body of the bolt shall be marked so that it can beplaced in the same position for all measurements. The bolt shallbe assembled in the testing equipment as outlined in Page 8 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 9 of 19

Section - D. and the proof load speci ed in the product speci cation shallbe applied. Upon release of this load the length of the bolt shallbe again measured and shall show no permanent elongation. Atolerance of 60.0005 in. (0.0127 mm) shall be allowedbetween the measurement made before loading and that madeafter loading. Variables, such as straightness and thread alignment (plus measurement error), may result in apparent elongation of the fasteners when the proof load is initially applied. In such cases, the fastener may be retested using a 3 percent greater load, and may be considered satisfactory if the lengthafter this loading is the same as before this loading (within the0.0005-in. tolerance for measurement error). Section C. Proof Load-Time of LoadingThe proof load is tobe maintained for a period of 10 s before release of load, whenusing Method 1. (a) Method 2, Yield StrengthThe bolt shall be assembledin the testing equipment as outlined in section- D. As the load isapplied, the total elongation of the bolt or any part of the boltwhich includes the exposed six threads shall be measured andrecorded to produce a load-strain or a stress-strain diagram. The load or stress at an offset equal to 0.2 percent of the length of bolt occupied by 6 full threads shall be determined by themethod described in yield point off set methods. This loador stress shall not be less than that prescribed in the product speci cation. Section -D. Axial Tension Testing of Full Size BoltsBolts areto be tested in a holder with the load axially applied betweenthe head and a nut or suitable xture (Fig. 5), either ofwhich shall have sufficient thread engagement to develop thefull strength of the bolt. The nut or xture shall be assembledon the bolt leaving six complete bolt threads unengagedbetween the grips, except for heavy hexagon structural boltswhich shall have four complete threads unengaged between thegrips. To meet the requirements of this test there shall be a tensile failure in the body or threaded section with no failure at the junction of the body, and head. If it is necessary to record or report the tensile strength of bolts as psi values the stress area shall be calculated.

Page 9 of 19

Date: 28.07.2013 Rev 0

.

Fasteners Test Procedure

ARIES-MT-F-001 Page 10 of 19

Fig 5 . Tension testing full- size bolt. 7. Full bolt test procedure a. b. c. d. e. Ensure the specifications of the received bolt. Measuring the bolt diameter and length. Calculate the original cross section area of the bolt. Attaching the jigs of bolt to the jaw of machine. The test machine shall be set up to zero in such a manner that zero force indication signifies a state of force on the specimen, as indicated in the zeroing of the test machine. f. Fit the bolt to the jigs. g. Ensure the jigs & bolt assemblies h. Directly apply the tensile load to the bolt. i. Determination of yield strength: When yield strength is measured using software, the yield strength will be automatically given by the system. j. Determination of tensile strength: Calculate the tensile strength by dividing the maximum load carried by the test specimen by the original cross-sectional area of the test specimen. When software is being used in testing, the value is automatically given by the system Page 10 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 11 of 19

k. Determination of elongation: Fit the fractured ends together carefully and measure the distance between the gage marks to get the increased (final) gage length. Calculate the elongation by dividing the difference in gage lengths (original and final) by the original gage length. When the software is used enter the final gage length to the system to give the percentage automatically. Note: Bolt dia should be maximum 20mm and length should be minimum 75mm according to our facilities. 8. Hardness Tests for Externally Fasteners Tests shall be conducted after the removal of any surface oxide, decarburization, plating or other coating. All readings shall be within the hardness values listed in the product speci cation. The average of all readings on the same part shall be considered as the product hardness. Test results shall conform to the product speci cation for the lot represented by the test specimens to be considered conforming. Test specimen preparation and hardness test shall be conducted in accordance for Rockwell hardness test. The method used is at the option of the manufacturer, with regards to the size and grade of the products. Routine Test Locationsfor testing the hardness of the nished product, the following test locations can be used: a. For hex and square head bolts; test shall be conducted on the wrench ats, top of head, unthreaded shank, end of bolt or at the arbitration location. b. For studs, products without parallel wrench ats and for head styles other than hex and square; tests shall be conducted on the unthreaded shank, end of the bolt or stud or at the arbitration location. c. Stress relieved products are measured anywhere on the surface or through the cross section. Refer to the product speci cation for particular test location or use the arbitration location. d. The Rockwell Hardness Scale may be used for all product diameters. Laboratory InspectionAfter observing product hardness and routine Test Locations, a minimum of three readings shall be taken on each sample of nished product. Arbitration Test LocationHardness tests shall be conducted at the mid-radius (r/2) of a transverse section through the threads taken at a distance of approximately one diameter from the point end of the bolt or one end of the stud. Four readings shall be taken from the point end of the bolt or one end of the stud. Four readings shall betaken approximately 90 to one another on the same plane, if product

Page 11 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 12 of 19

size permits. Smaller diameter products may also usethe opposite parallel surface area of the bolt head end assectioned above. (See Fig. 6).

Fig 6. Hardness Arbitration test location 9. Hardness Tests for internally Fasteners

a. Product HardnessFor routine inspection of both heat treated and non heat-treated nuts, hardness shall be determined on the bearing face or wrench ats after removal of any oxide, decarburization, plating, or other coating material. Rockwell or Brinell hardness shall be used at the option of the manufacturer, taking into account the size and grade of the product. b. The preparation of test specimens and the performance of hardness tests for Rockwell testing shall be in conformance with the requirements of test Methods. c. Readings when taken on the bearing face shall be halfway between the major diameter of the thread and one corner. The reported hardness shall be the average of two hardness readings located 180 apart. The readings when taken on the wrench ats shall be one third of the distance from a corner to the center of the wrench face. The reported harness shall be the average of two readings located from opposite corners. d. Sample nuts shall be sectioned laterally at approximately one half ( 1 2 ) of the nut height. Such samples need not be threaded, but shall be part of the manufacturing lot that was formed (in the case of heat-treated nuts, formed and heattreated) with the product to be shipped. All readings shall be conducted on a Rockwell Hardness testing machine. e. Non heat-Treated Nuts (See Fig. 7)Two readingsshall be taken 180 apart at the core (halfway between themajor diameter if threaded, or blank hole if not threaded) anda corner of the nut. The Page 12 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 13 of 19

reported hardness shall be the averageof the two readings, and in addition both readings shall bewithin the hardness values listed in the product speci cation.

Fig 7. Non heat - Treated nut f. Heat-Treated Nuts (See Fig. 8)Two sets of threereadings 180 apart shall be taken. The three readings shall betaken across the section of the nut at the following positions: Position 1As close to the major diameter, as possible, if threaded, orhole side wall if the nut is blank, but no closer than 2 1 2 mes the indentdiameter. Position 2At the core (halfway between the major diameter, ifthreaded, or hole side wall, if blank) and a corner of the nut. Position 3As close to the corner of the nut as possible, but no closerthan 2 1 2 mes the indent diameter.

Fig 8 . Heat - Treated nut Page 13 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 14 of 19

g. The reported hardness shall be the average of all sixreadings. In addition all readings shall be within hardnessvalues listed in the product speci cation. h. For nuts on which hardness and proof load tests areperformed, acceptance based on proof load requirements shalltake precedence in the event of controversy with hardness tests. 10. Proof load test A sample nut shall be assembled on a hardened threaded mandrel or on a bolt conforming to the particular speci cation. A load axial with the mandrel or bolt and equal to the speci ed proof load of the nut shall be applied. The nut shall resist this load without stripping or rupture. If the threads of the mandrel are damaged during the test the individual test shall be discarded. Assemble the nut to be tested on a hardened threaded mandrel or a test bolt as illustrated in Fig. 9 a) Tension Method or Fig. 9(b) Compression Method. The hardened test mandrel and the tension method shown in Fig. 9(a) shall be mandatory as a referee if arbitration is necessary. Apply the speci ed proof load for the nut against the nut. The nut shall resist this load without stripping or rupture, and shall be removable from the test bolt or mandrel by the ngers after the load is released. Occasionally it may be necessary to use a manual wrench or other means to start the nut in motion. Use of such means is permissible, provided the nut is removable by the ngers following the initial loosening of not more than one-half turn of the nut. If the threads of the mandrel or test bolt are damaged during the test, discard the test. The test bolt shall have threads appropriate to the standard speci ed for the nut being tested and shall have a yield strength in excess of the speci ed proof load of the nut being tested.Mandrels shall have a hardness of 45 HRC minimum and shall have threads conforming to Class 3A except that the maximum major diameter shall be the minimum major diameter plus 0.002 in. or 0.25 times the major diameter tolerance (whichever is greater) of Class 3A threads. The proof load shall be determined at a free running cross head speed not exceeding 1.0 in/minute and shall be held at load for 10s minimum.

Page 14 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 15 of 19

Fig 9. a. Tension method

Fig 9. B Compression Method 11. Proof load procedure a.We are using the compression method for proof load test to the nut. Page 15 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 16 of 19

b. Choose the bolt specification either same as nut or higher specification. c. Keep the appropriate support block on the machine bed. d. Zeroing of the test machine: The testing machine shall be set up in such a manner that zero force indication signifies a state of zero force on the specimen. e. The magnitude of the application of compression load to the nut should be greater than the load mentioned as per standard to the nut. f. While loading ensure the non-displacement of the nut. Hold the proof load for 10s 12. Acceptance criteria Fasteners acceptance criteria as per ASTM F568M

Page 16 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 17 of 19

Page 17 of 19

Date: 28.07.2013 Rev 0

13. Report

Fasteners Test Procedure

ARIES-MT-F-001 Page 18 of 19

Test information to be reported shall include the following when applicable: a. Material Grade and sample identification b. Applicable test code c. Test specimen dimensions d. Original gage length e. Yield load and yield strength f. Tensile load and tensile strength g. Gauge length after testing h. Elongation I. Reduction of area j. Hardness Value k. Proof load l. Percentage of Chemical composition

Page 18 of 19

Date: 28.07.2013 Rev 0

Fasteners Test Procedure

ARIES-MT-F-001 Page 19 of 19

Annexure 1

Page 19 of 19

You might also like

- DNV 271 Annex1Document6 pagesDNV 271 Annex1Andy TaylorNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Flange Design: Welding UnitsDocument0 pagesFlange Design: Welding Unitsabhi1648665No ratings yet

- EnCal 3000 Gas Chromatograph Software ManualDocument83 pagesEnCal 3000 Gas Chromatograph Software ManualMostafa NabilNo ratings yet

- ISA Control Valve Data Sheet GuideDocument1 pageISA Control Valve Data Sheet GuidechandruhbkkNo ratings yet

- List Files in A FolderDocument12 pagesList Files in A Foldervincent02hk_57881301No ratings yet

- Determining The Remaining Strength of Corroded Pipelines ASME B31G-1991Document30 pagesDetermining The Remaining Strength of Corroded Pipelines ASME B31G-1991ravi00098No ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- AKG C414 B Xls XlII ServiceDocument3 pagesAKG C414 B Xls XlII Servicepassme369No ratings yet

- Norma ASTM E837 08Document18 pagesNorma ASTM E837 08linceokNo ratings yet

- Design and Analysis On Ajm NozzleDocument34 pagesDesign and Analysis On Ajm NozzleRahul KolukuluriNo ratings yet

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticepaulortsNo ratings yet

- Dashboard: MT/PT Status Joints Status Welded Joints StatusDocument1 pageDashboard: MT/PT Status Joints Status Welded Joints StatusZaidiNo ratings yet

- Hydratight Morgrip Swivel Ring Flyer PDFDocument2 pagesHydratight Morgrip Swivel Ring Flyer PDFSenthil KumarNo ratings yet

- ASME Piping Standards and Material Selection GuideDocument36 pagesASME Piping Standards and Material Selection Guideتدریس زبان ESLNo ratings yet

- FEA Validation Release 2010Document7 pagesFEA Validation Release 2010DHAVAL PANCHALNo ratings yet

- 08 Hydrostatic Test Procedure Section I OKDocument9 pages08 Hydrostatic Test Procedure Section I OKEduardo GarciaNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- ES-30.99.37.0017 - External Pipeline Coatings - Part 1Document63 pagesES-30.99.37.0017 - External Pipeline Coatings - Part 1maheshNo ratings yet

- CTS 49 CTS 59 Operation ManualDocument83 pagesCTS 49 CTS 59 Operation ManualKrista Maldonado100% (3)

- Piping Theory As Per ASME B31.3 PROCESS PIPINGDocument107 pagesPiping Theory As Per ASME B31.3 PROCESS PIPINGDeen first sdiNo ratings yet

- 18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFDocument19 pages18 Inch 9 5 MM Combo (MFL+CLP+IMU) (Ver Data Sheet Pàg. 8) PDFOscar Miguel Fuquen SanabriaNo ratings yet

- Steel Line Blanks & Spacer Dimension TableDocument5 pagesSteel Line Blanks & Spacer Dimension TableSeungmin PaekNo ratings yet

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Document19 pagesTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNo ratings yet

- Seamless Stainless Tubes For Hydraulic and Instrumentation SystemsDocument10 pagesSeamless Stainless Tubes For Hydraulic and Instrumentation Systemsfezzeh kabiri kenariNo ratings yet

- Spherical TankDocument30 pagesSpherical TankNuzuliana EnuzNo ratings yet

- ASME Section I Code Preheat and PWHT GuidanceDocument4 pagesASME Section I Code Preheat and PWHT GuidanceArul Edwin Vijay VincentNo ratings yet

- Calculation PP Piping SystemDocument24 pagesCalculation PP Piping SystemDavid FonsecaNo ratings yet

- Lite Cad User HelpDocument46 pagesLite Cad User HelpManuel Nuñez ManriquezNo ratings yet

- Sultanate's ultrasonic flowmeter standardsDocument3 pagesSultanate's ultrasonic flowmeter standardsaltipatlarNo ratings yet

- Shell Noise Guide 1991Document82 pagesShell Noise Guide 1991rosshvac100% (3)

- Doha North Sewerage Treatment & Associated WorksDocument67 pagesDoha North Sewerage Treatment & Associated WorksLito MendozaNo ratings yet

- EPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationDocument4 pagesEPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationHernán DazaNo ratings yet

- Fig I 10 Api 650Document1 pageFig I 10 Api 650muhd.qasimNo ratings yet

- CRS SheetDocument1 pageCRS SheetОсама А.ШоукиNo ratings yet

- Pga1000998050010 01Document1 pagePga1000998050010 01Amit SaxenaNo ratings yet

- NCTL Project: Proposal Welding Procedure SpecificationDocument4 pagesNCTL Project: Proposal Welding Procedure SpecificationRotimi Shitta-BeyNo ratings yet

- EQT Welding Procedure Qualification RequirementsDocument101 pagesEQT Welding Procedure Qualification RequirementsCeki CeriaNo ratings yet

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 pagesAB 520 Finite Element Analysis FEA Requirements PDFbello imamNo ratings yet

- Anchor FlangeDocument1 pageAnchor FlangeHector MejiaNo ratings yet

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocument24 pagesFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhNo ratings yet

- PSV Guidance NotesDocument3 pagesPSV Guidance Notescarr007No ratings yet

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDocument8 pagesBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamNo ratings yet

- Flange Leakage 6Document2 pagesFlange Leakage 6hamid sobirinNo ratings yet

- Bolted JointDocument9 pagesBolted JointkhanhtruongNo ratings yet

- Bolt Tensioning: What is it and how does it workDocument2 pagesBolt Tensioning: What is it and how does it work4jawwy markme026No ratings yet

- Calculation Pipe Clamp 10 BarDocument13 pagesCalculation Pipe Clamp 10 BarDica Rasyid MaulidhaniNo ratings yet

- Manufacturing Data ReportDocument14 pagesManufacturing Data Reportfuransu777No ratings yet

- CAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingDocument61 pagesCAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingRokan PipelineNo ratings yet

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 pagesCalculation Sheet For 700mm SQ Metal FloatersAdagharaNo ratings yet

- Visual Inspection Checklist PipingDocument2 pagesVisual Inspection Checklist PipingshifaNo ratings yet

- WHP02-SMO1 Pressure Test & Test Pack - For ReviewDocument21 pagesWHP02-SMO1 Pressure Test & Test Pack - For ReviewkristianNo ratings yet

- IDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and InspectionDocument32 pagesIDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and Inspectionjoey garciaNo ratings yet

- Api 5L1 - 2002Document15 pagesApi 5L1 - 2002GentelmanOnlyNo ratings yet

- Pipe Wall Thickness CalculationDocument1 pagePipe Wall Thickness Calculationfarhad soopithodiNo ratings yet

- Nozzle neck thickness calculation UG-45Document2 pagesNozzle neck thickness calculation UG-45Lcm TnlNo ratings yet

- Piping Design InfoDocument273 pagesPiping Design InfoFerry SiswantoNo ratings yet

- Equivalent GradesDocument37 pagesEquivalent GradesUmesh SakhareliyaNo ratings yet

- BB 1 - 1 Estapa - Pump WorksDocument2 pagesBB 1 - 1 Estapa - Pump WorksMarco Pompa ReyesNo ratings yet

- B 565 - 94 R00 - Qju2ns05nfiwmaDocument3 pagesB 565 - 94 R00 - Qju2ns05nfiwmamalika_00No ratings yet

- Eticket RMTN6JA54Z362Document1 pageEticket RMTN6JA54Z362Murugan RajaNo ratings yet

- Ticket From HWH To DhanbadDocument3 pagesTicket From HWH To Dhanbadpradeep kumarNo ratings yet

- Eticket RMTN6JA54Z362Document1 pageEticket RMTN6JA54Z362Murugan RajaNo ratings yet

- Details of UKAS Recalibration Due of Mechanical Test EquipmentsDocument1 pageDetails of UKAS Recalibration Due of Mechanical Test EquipmentsMurugan RajaNo ratings yet

- New English Book PDFDocument239 pagesNew English Book PDFMurugan Raja0% (1)

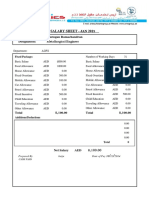

- Salary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerDocument1 pageSalary Sheet - Jan 201: Employee Name: Murugan Ramachandran Designation: Metallurgical EngineerMurugan RajaNo ratings yet

- Jobs AppliedDocument5 pagesJobs AppliedMurugan RajaNo ratings yet

- Surface AreaDocument5 pagesSurface AreaMurugan RajaNo ratings yet

- EIL Employee Requests Home Construction AdvanceDocument1 pageEIL Employee Requests Home Construction AdvanceMurugan RajaNo ratings yet

- E1351 - 01Document6 pagesE1351 - 01Murugan RajaNo ratings yet

- Surface AreaDocument5 pagesSurface AreaMurugan RajaNo ratings yet

- wp136 enDocument26 pageswp136 enMurugan RajaNo ratings yet

- Failure Investigation TemplateDocument11 pagesFailure Investigation TemplateMurugan Raja100% (1)

- Information To Be Gathered From ClientDocument1 pageInformation To Be Gathered From ClientMurugan Raja0% (1)

- Confirmation - Your Booking Confirmation and Reference - FlydubaiDocument2 pagesConfirmation - Your Booking Confirmation and Reference - FlydubaiMurugan Raja67% (9)

- ARIES Marine Sample Testing of Different QualitiesDocument1 pageARIES Marine Sample Testing of Different QualitiesMurugan RajaNo ratings yet

- By Laws - 26 Février 2013Document17 pagesBy Laws - 26 Février 2013Murugan RajaNo ratings yet

- Waslab PrintDocument1 pageWaslab PrintMurugan RajaNo ratings yet

- Ref No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentDocument2 pagesRef No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentMurugan RajaNo ratings yet

- Cathodic Protection: The BasicsDocument8 pagesCathodic Protection: The BasicsbookbumNo ratings yet

- IMSP NO.28-Chemical Handling Control ProcecdureDocument6 pagesIMSP NO.28-Chemical Handling Control ProcecdureMurugan RajaNo ratings yet

- Jebel Ali Client ListDocument5 pagesJebel Ali Client ListMurugan RajaNo ratings yet

- Ref No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentDocument2 pagesRef No. Project No: Revision No. 0 Date: 04.06.13: Risk AssessmentMurugan RajaNo ratings yet

- Sgs Ogc RDK Brochure A4 Web LRDocument4 pagesSgs Ogc RDK Brochure A4 Web LRMurugan RajaNo ratings yet

- ARIES Marine Sample Testing of Different QualitiesDocument1 pageARIES Marine Sample Testing of Different QualitiesMurugan RajaNo ratings yet

- Cathodic Protection: The BasicsDocument8 pagesCathodic Protection: The BasicsbookbumNo ratings yet

- RA - Angle GrinderDocument4 pagesRA - Angle GrinderMurugan RajaNo ratings yet

- JafzaDocument6 pagesJafzaMurugan RajaNo ratings yet

- Lathe Work InstructionsDocument3 pagesLathe Work InstructionsMurugan RajaNo ratings yet

- UAE Power Plant ListDocument2 pagesUAE Power Plant ListMurugan Raja0% (1)

- 8 - Chitapon - TR Winding Buckling - Paper PDFDocument5 pages8 - Chitapon - TR Winding Buckling - Paper PDFbcqbaoNo ratings yet

- Confined SpacesDocument27 pagesConfined SpacesDivya RastogiNo ratings yet

- (Altium Tutorial) PCB Symbol Naming ConventionDocument7 pages(Altium Tutorial) PCB Symbol Naming ConventionDefne AktemizNo ratings yet

- FFA Furfural Fire and Health HazardsDocument2 pagesFFA Furfural Fire and Health HazardsYuga Pria PungkasanNo ratings yet

- Zebralette User GuideDocument24 pagesZebralette User GuideGiacomo TimbrelloNo ratings yet

- Powerfactory 2020: Technical ReferenceDocument13 pagesPowerfactory 2020: Technical ReferenceDaniel ManjarresNo ratings yet

- Chapter 1. Griffiths-Vector Analysis - 1.1 1.2Document24 pagesChapter 1. Griffiths-Vector Analysis - 1.1 1.2Hazem TawfikNo ratings yet

- Blockchain Unconfirmed Transaction Hack Script Docx PDF FreeDocument2 pagesBlockchain Unconfirmed Transaction Hack Script Docx PDF FreeHealing Relaxing Sleep Music100% (1)

- CS610 Final Term Past Papers Mega FileDocument35 pagesCS610 Final Term Past Papers Mega Filehowtoplaygames38No ratings yet

- DIN-Rail AC Current Transducer 0.25% AccuracyDocument3 pagesDIN-Rail AC Current Transducer 0.25% AccuracyjoseluisbeitoNo ratings yet

- Dome Enclosure: MoellerDocument3 pagesDome Enclosure: MoellerLjubomir VasicNo ratings yet

- 0580 w13 QP 41Document20 pages0580 w13 QP 41Haider AliNo ratings yet

- Jetty Modification - Upd 250417Document86 pagesJetty Modification - Upd 250417Deni Yudha PermanaNo ratings yet

- Service Manual: NSX-SZ100Document27 pagesService Manual: NSX-SZ100Goran ChaparNo ratings yet

- Carbohydrates Explained: Monosaccharides, Disaccharides and PolysaccharidesDocument21 pagesCarbohydrates Explained: Monosaccharides, Disaccharides and PolysaccharidesJhayce Christian S. CapanayanNo ratings yet

- 925E II 24 PG A4 Broch - 12 - 2020 - DCECDocument13 pages925E II 24 PG A4 Broch - 12 - 2020 - DCECekkyagungNo ratings yet

- AminesDocument12 pagesAminesEmelda BanumathyNo ratings yet

- GGGDocument3 pagesGGGAnkitNo ratings yet

- Vodafone Bid HBS Case - ExhibitsDocument13 pagesVodafone Bid HBS Case - ExhibitsNaman PorwalNo ratings yet

- Swat Luu: User ManualDocument13 pagesSwat Luu: User ManualgjferreiraNo ratings yet

- Stator Generator EolianDocument40 pagesStator Generator EolianCatalin BordeiNo ratings yet

- Star and Its PropertiesDocument4 pagesStar and Its PropertiesRemond BalabaNo ratings yet

- ATR 72 - Flight ManualDocument490 pagesATR 72 - Flight Manualmuya78100% (1)

- Lecture 1-5 Atomic and Molecular Physics by Nek M ShaikhDocument25 pagesLecture 1-5 Atomic and Molecular Physics by Nek M Shaikh125-The Legend StarNo ratings yet

- Rudolf Steiner - Warmth Course GA 321Document119 pagesRudolf Steiner - Warmth Course GA 321Raul PopescuNo ratings yet

- GD-1884 Manual PDFDocument10 pagesGD-1884 Manual PDFAnonymous srwHCpANo ratings yet

- Adiabatic Logic: An Alternative Approach To Low Power Application CircuitsDocument6 pagesAdiabatic Logic: An Alternative Approach To Low Power Application CircuitsBibartan DasNo ratings yet

- Holiday Assignment XDocument2 pagesHoliday Assignment XMonis ShaikhNo ratings yet

- Quiz 3Document4 pagesQuiz 3dEEP THE hELPERNo ratings yet

- BasrahDocument19 pagesBasrahDurban Chamber of Commerce and IndustryNo ratings yet