Professional Documents

Culture Documents

Bituminous Tack Coat

Uploaded by

Devrim GürselOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bituminous Tack Coat

Uploaded by

Devrim GürselCopyright:

Available Formats

9/30/2009

AC 150/5370-10E

ITEM P-603 BITUMINOUS TACK COAT

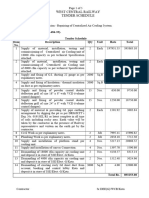

DESCRIPTION 603-1.1 This item shall consist of preparing and treating a bituminous or concrete surface with bituminous material in accordance with these specifications and in reasonably close conformity to the lines shown on the plans. MATERIALS 603-2.1 BITUMINOUS MATERIALS. The bituminous material shall be either cutback asphalt, emulsified asphalt, or tar and shall conform to the requirements of Table 1. The type, grade, controlling specification, and application temperature of bituminous material to be used shall be specified by the Engineer. TABLE 1. BITUMINOUS MATERIAL Type and Grade Emulsified Asphalt SS-1, SS-1h CSS-1, CSS-1h Cutback Asphalt RC-70 Tar RTCB 5, RTCB 6 Specification ASTM D 977 ASTM D 2397 ASTM D 2028 AASHTO M 52 Application Temperature Deg. F Deg. C 75-130 75-130 120-160 60-120 25-55 25-55 50-70 15-50

CONSTRUCTION METHODS 603-3.1 WEATHER LIMITATIONS. The tack coat shall be applied only when the existing surface is dry and the atmospheric temperature is above 60F (15C). The temperature requirements may be waived, but only when so directed by the Engineer. 603-3.2 EQUIPMENT. The Contractor shall provide equipment for heating and applying the bituminous material. The distributor shall be designed, equipped, maintained, and operated so that bituminous material at even heat may be applied uniformly on variable widths of surface at the specified rate. The allowable variation from the specified rate shall not exceed 10 percent. Distributor equipment shall include a tachometer, pressure gages, volume-measuring devices or a calibrated tank, and a thermometer for measuring temperatures of tank contents. The distributor shall be self-powered and shall be equipped with a power unit for the pump and full circulation spray bars adjustable laterally and vertically. If the distributor is not equipped with an operable quick shut off valve, the tack operations shall be started and stopped on building paper. The Contractor shall remove blotting sand prior to asphalt concrete lay down operations at no additional expense to the owner. A power broom and/or blower shall be provided for any required cleaning of the surface to be treated. 603-3.3 APPLICATION OF BITUMINOUS MATERIAL. Immediately before applying the tack coat, the full width of surface to be treated shall be swept with a power broom and/or airblast to remove all loose dirt and other objectionable material.

P-603-1

AC 150/5370-10E

9/30/2009

Emulsified asphalt shall be diluted by the addition of water when directed by the Engineer and shall be applied a sufficient time in advance of the paver to ensure that all water has evaporated before any of the overlying mixture is placed on the tacked surface. The bituminous material including vehicle or solvent shall be uniformly applied with a bituminous distributor at the rate of 0.05 to 0.15 gallons per square yard (0.24 to 0.72 liters per square meter) depending on the condition of the existing surface. The type of bituminous material and application rate shall be approved by the Engineer prior to application. Following the application, the surface shall be allowed to cure without being disturbed for such period of time as may be necessary to permit drying out and setting of the tack coat. This period shall be determined by the Engineer. The surface shall then be maintained by the Contractor until the next course has been placed. Suitable precautions shall be taken by the Contractor to protect the surface against damage during this interval. 603-3.4 BITUMINOUS MATERIAL CONTRACTOR'S RESPONSIBILITY. Samples of the bituminous material that the Contractor proposes to use, together with a statement as to its source and character, must be submitted and approved before use of such material begins. The Contractor shall require the manufacturer or producer of the bituminous material to furnish material subject to this and all other pertinent requirements of the contract. Only satisfactory materials so demonstrated by service tests, shall be acceptable. The Contractor shall furnish the vendor's certified test reports for each carload, or equivalent, of bituminous material shipped to the project. The tests reports shall contain all the data required by the applicable specification. If the Contractor applies the material prior to receipt of the tests reports, payment for the material shall be withheld until they are received. If the material does not pass the specifications it shall be replaced at the contractor's expense. The report shall be delivered to the Engineer before permission is granted for use of the material. The furnishing of the vendor's certified test report for the bituminous material shall not be interpreted as a basis for final acceptance. All such test reports shall be subject to verification by testing samples of material received for use on the project. 603-3.5 FREIGHT AND WEIGH BILLS. Before the final estimate is allowed, the Contractor shall file with the Engineer receipted bills when railroad shipments are made, and certified weigh bills when materials are received in any other manner, of the bituminous materials actually used in the construction covered by the contract. The Contractor shall not remove bituminous material from the tank car or storage tank until the initial outage and temperature measurements have been taken by the Engineer, nor shall the car or tank be released until the final outage has been taken by the Engineer. Copies of freight bills and weigh bills shall be furnished to the Engineer during the progress of the work. METHOD OF MEASUREMENT 603.4.1 The bituminous material for tack coat shall be measured by the [gallon (liter)] [ton (kg)]. Volume shall be corrected to the volume at 60F (15C) in accordance with ASTM D 1250 for cutback asphalt, ASTM D 633 for tar, and Table 603.4.2 IV-3 of The Asphalt Institute's Manual MS-6 for emulsified asphalt. Water added to emulsified asphalt will not be measured for payment. BASIS OF PAYMENT 603.5-1 Payment shall be made at the contract unit price per [gallon (liter)] [ton (kg)] of bituminous material. This price shall be full compensation for furnishing all materials, for all preparation, delivery, and application of these materials, and for all labor, equipment, tools, and incidentals necessary to complete the item. Payment will be made under: Item P-603-5.1 Bituminous Tack Coatper [gallon (liter)][ton (kg)]

P-603-2

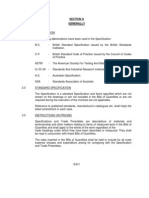

9/30/2009 MATERIAL REQUIREMENTS ASTM D 633 ASTM D 977 ASTM D 1250 ASTM D 2028 ASTM D 2397 Asphalt Institute Manual MS-6 Table IV-3 Volume Correction Table for Road Tar Emulsified Asphalt Petroleum Measurement Tables Cutback Asphalt (Rapid-Curing Type) Cationic Emulsified Asphalt

AC 150/5370-10E

Asphalt Pocketbook of Useful Information (Temperature-Volume Corrections for Emulsified Asphalts)

END ITEM P-603

P-603-3

AC 150/5370-10E

9/30/2009

Intentionally Left Blank

P-603-4

You might also like

- Method Statement Concrete PouringDocument4 pagesMethod Statement Concrete PouringSmart ShivaNo ratings yet

- Post Installation Evaluation and Repair of Installed Reinforced Concrete PipeDocument37 pagesPost Installation Evaluation and Repair of Installed Reinforced Concrete PipeMunarwand Ahmad100% (1)

- Steel Tank & FoundationDocument10 pagesSteel Tank & Foundationhamsarajshetty50% (2)

- Aegis LPG TenderDocument147 pagesAegis LPG TenderKazeem100% (1)

- Technical InstrumentationDocument209 pagesTechnical Instrumentationrenjithv_40% (1)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- AustStab Model Specification For Insitu Stabilisation For Main RoadsDocument20 pagesAustStab Model Specification For Insitu Stabilisation For Main RoadsprmraoNo ratings yet

- Item P-610 Structural Portland Cement Concrete 105Document11 pagesItem P-610 Structural Portland Cement Concrete 105Anthony McguireNo ratings yet

- Guidelines For PrimeCoat and Tack CoatDocument111 pagesGuidelines For PrimeCoat and Tack CoatBalasubramanian Mahadevan100% (1)

- Bituminous Prime CoatDocument4 pagesBituminous Prime CoatDevrim Gürsel100% (2)

- Design Reinforced Concrete PipeDocument24 pagesDesign Reinforced Concrete PipecruceruutgjiuroNo ratings yet

- Reclamation SpecifiactionDocument24 pagesReclamation SpecifiactiongedekhresnaNo ratings yet

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocument48 pages4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNo ratings yet

- Guidelines-for-the-Design-Construction-and-Operation-of-Compressed-Natural-Gas-CNG (Done) PDFDocument13 pagesGuidelines-for-the-Design-Construction-and-Operation-of-Compressed-Natural-Gas-CNG (Done) PDFBraviiNo ratings yet

- Scope of WorkDocument24 pagesScope of WorkGijo GeorgeNo ratings yet

- IRS T39 PSC SleepersDocument28 pagesIRS T39 PSC Sleepersradhakrishnang100% (2)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Specifications For Concrete SleepersDocument28 pagesSpecifications For Concrete Sleepersgerfreecalls50% (2)

- DCP To CBR 01Document5 pagesDCP To CBR 01ersalf50% (2)

- DCP To CBR 01Document5 pagesDCP To CBR 01ersalf50% (2)

- DCP To CBR 01Document5 pagesDCP To CBR 01ersalf50% (2)

- DCP To CBR 01Document5 pagesDCP To CBR 01ersalf50% (2)

- DCP To CBR 01Document5 pagesDCP To CBR 01ersalf50% (2)

- Method Statement For Asphalt Concrete WorkDocument7 pagesMethod Statement For Asphalt Concrete WorkBasem Donia100% (1)

- Road Marking SpecsDocument6 pagesRoad Marking SpecsAbdullah AboodiNo ratings yet

- Method Statement For AsphaltDocument10 pagesMethod Statement For AsphaltJer Fortz100% (3)

- 150 5370 10d Part3aDocument224 pages150 5370 10d Part3aDave BillonaNo ratings yet

- EB - 44 - Coal Tar RejuvenationDocument5 pagesEB - 44 - Coal Tar RejuvenationManInTheBushNo ratings yet

- Bituminous Prime Coat PDFDocument3 pagesBituminous Prime Coat PDFMuhammad ArifNo ratings yet

- Section 02610 - Prime CoatDocument26 pagesSection 02610 - Prime Coatmail3shenNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- SpecDocument29 pagesSpecAnonymous iinjEi4E2No ratings yet

- Technical Specification For Road WorksDocument13 pagesTechnical Specification For Road WorkssandeepuaeNo ratings yet

- 304.12 M SubbaseDocument16 pages304.12 M SubbasegullipalliNo ratings yet

- Sor Wef 01-02-2013Document104 pagesSor Wef 01-02-2013Anonymous g1LSaANo ratings yet

- 2021-03-12 - Special ConditionDocument11 pages2021-03-12 - Special ConditionMAULIK RAVALNo ratings yet

- Construction Specification 36-Roller Compacted Concrete: 1. ScopeDocument20 pagesConstruction Specification 36-Roller Compacted Concrete: 1. ScopeLen KahnNo ratings yet

- GSKMotorways - Expressway System - Sect 3 - Sub-Base and Base CourseDocument19 pagesGSKMotorways - Expressway System - Sect 3 - Sub-Base and Base Coursemohamed samirNo ratings yet

- Bituminous Tack CoatDocument2 pagesBituminous Tack CoatshawonscribdNo ratings yet

- ITEM 300 Latest 2004Document75 pagesITEM 300 Latest 2004Avelino De Leon JrNo ratings yet

- TTender Schedule EL-50-67-2020-21Document5 pagesTTender Schedule EL-50-67-2020-21kaygupta301102No ratings yet

- Bituminous Prime Coat: DescriptionDocument4 pagesBituminous Prime Coat: DescriptionHurriyat AliNo ratings yet

- Item 702Document18 pagesItem 702Art AV B LimNo ratings yet

- Std. Terms & ConditionsDocument8 pagesStd. Terms & ConditionsJKKNo ratings yet

- Audible & Vibratory Pavement MarkingDocument4 pagesAudible & Vibratory Pavement MarkingRoslan 'Abok' KamarudinNo ratings yet

- Section 5-Part 8-Transportation and Placing of ConcreteDocument6 pagesSection 5-Part 8-Transportation and Placing of ConcreteAdamNo ratings yet

- GL Spec1 PDFDocument71 pagesGL Spec1 PDFnght7942No ratings yet

- Bituminous PavementsDocument13 pagesBituminous PavementsMahesh SuranaNo ratings yet

- 7 Technical Specification CivilDocument97 pages7 Technical Specification CivilRaj BakhtaniNo ratings yet

- 2016 Supplemental Specifications 2018-06-15Document37 pages2016 Supplemental Specifications 2018-06-15fantahun angawNo ratings yet

- STP SPecifiucationsDocument186 pagesSTP SPecifiucationsAnonymous d6tUk8QZNo ratings yet

- Vol-III of IV - Laying - HPCLDocument527 pagesVol-III of IV - Laying - HPCLbolinagNo ratings yet

- 1001Document6 pages1001enterlogNo ratings yet

- 5sec.500 (Base & Surface Courses)Document92 pages5sec.500 (Base & Surface Courses)pankaj_mbmNo ratings yet

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickNo ratings yet

- 4fii Maricopa Spec PDFDocument25 pages4fii Maricopa Spec PDFSusana Chuy TaiNo ratings yet

- Cement Kiln Dust (CKD) Treated SubgradeDocument4 pagesCement Kiln Dust (CKD) Treated SubgradeDevrim GürselNo ratings yet

- Compression Joint Seals For Concrete PavementsDocument10 pagesCompression Joint Seals For Concrete PavementsDevrim GürselNo ratings yet

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselNo ratings yet

- Book-IV Gen. Spec For MaterialsDocument77 pagesBook-IV Gen. Spec For Materialsgourav kumar choudharyNo ratings yet

- Section 403-A: Warm Mix Asphalt - Open Graded Friction Course (NON-QLA) Page 149Document3 pagesSection 403-A: Warm Mix Asphalt - Open Graded Friction Course (NON-QLA) Page 149Opata OpataNo ratings yet

- Section 5008764275514Document99 pagesSection 5008764275514Loganathan PeriyasamiNo ratings yet

- Tech SpecsDocument8 pagesTech SpecsJomz OlañoNo ratings yet

- 16 23Document4 pages16 23Munarwand AhmadNo ratings yet

- SD-027 Road Section and Detail GIS 150kV TJS Substation PDFDocument1 pageSD-027 Road Section and Detail GIS 150kV TJS Substation PDFMunarwand AhmadNo ratings yet

- Self-Compacting Concrete - Procedure For Mix DesignDocument10 pagesSelf-Compacting Concrete - Procedure For Mix DesignM HAFEEZ RAJA100% (1)

- Self-Compacting Concrete - Procedure For Mix DesignDocument10 pagesSelf-Compacting Concrete - Procedure For Mix DesignM HAFEEZ RAJA100% (1)

- 2013-10-03 150720 496 PDFDocument7 pages2013-10-03 150720 496 PDFMunarwand AhmadNo ratings yet

- KakuDocument10 pagesKakuMunarwand AhmadNo ratings yet

- Agustus No Kegiatan 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 1 Survey Tofografi 2 BB 3 LHR 4 DCP / Test PitDocument2 pagesAgustus No Kegiatan 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 1 Survey Tofografi 2 BB 3 LHR 4 DCP / Test PitMunarwand AhmadNo ratings yet

- Self-Compacting Concrete - Procedure For Mix DesignDocument10 pagesSelf-Compacting Concrete - Procedure For Mix DesignM HAFEEZ RAJA100% (1)

- VHVHVHDocument2 pagesVHVHVHMunarwand AhmadNo ratings yet

- RudiDocument1 pageRudiMunarwand AhmadNo ratings yet

- Self-Compacting Concrete - Procedure For Mix DesignDocument10 pagesSelf-Compacting Concrete - Procedure For Mix DesignM HAFEEZ RAJA100% (1)

- VHVHVHDocument2 pagesVHVHVHMunarwand AhmadNo ratings yet

- DDocument1 pageDMunarwand AhmadNo ratings yet

- Article 15Document5 pagesArticle 15Munarwand AhmadNo ratings yet

- 16 23Document4 pages16 23Munarwand AhmadNo ratings yet

- Bearing CapacityDocument9 pagesBearing Capacitygm11hrNo ratings yet

- Article 15Document5 pagesArticle 15Munarwand AhmadNo ratings yet

- Article 15Document5 pagesArticle 15Munarwand AhmadNo ratings yet

- Bearing CapacityDocument9 pagesBearing Capacitygm11hrNo ratings yet

- 16 23Document4 pages16 23Munarwand AhmadNo ratings yet

- 16 23Document4 pages16 23Munarwand AhmadNo ratings yet

- Retaining WallDocument32 pagesRetaining WallCortney JohnsonNo ratings yet