Professional Documents

Culture Documents

4WD JM

Uploaded by

wreckedweaselOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4WD JM

Uploaded by

wreckedweaselCopyright:

Available Formats

4WD SYSTEM (ITM: Interactive Torque Management)

Electronically Controlled On-Demand 4WD System

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

CONTENTS

1. INTRODUCTION ----------------------------------------------------------------------

2. T/M & TRANSFER CASE ---------------------------------------------------

3. COUPLING & REAR AXLE ASSEMBLY

---------------------------------------

4. INPUTS AND OUTPUTS -------------------------------------------------------------

5. DIAGNOSIS ------------------------------------------------------------------------------

6. WIRING DIAGRAM ---------------------------------------------------------------------

7. 4WD COUPLING ASSEMBLY -------------------------------------------------------

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

1. INTRODUCTION

Controllability of the vehicle in all driving situations is becoming an important promotional factor for All-Wheel-Drive. An AWD vehicle has better road handling and is safer in all driving situations. Answering these requirements, the new Electronically Controlled On-Demand 4WD of JM offers fully controllable torque transfer characteristics and extremely rapid activation and deactivation automatically. SANTA FE equipped Diesel VGT (Variable Geometric Turbocharger) engine has been already using this system since November 2002. However most parts of the system such as T/M case, transfer case, front differential and rear differential cannot be interchangeable between JM and SANTA FE. The characteristics of this system is that it is in the 2WD state at constant vehicle speed but it changes the torque distribution to rear wheels in the 4WD state according to the driving state.

ENGINE

[Transfer Case]

[Coupling & Rear Axle Assembly]

[Layout of JM 4WD System]

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 1.1 APPLICATION

REGION LINE-UP DDC 2.0 DSL -2.0 CVVT -2.7 V6 M/T A/T M/T A/T A/T

KOREA O O -

GENERAL AREA O O O O O

MIDDLE EAST O O O O O

EC O O O O O

NORTH AMERICA O O O

AUS S O O

* O: Optional Item, S; Standard Item

1.2 ADVANTAGES Maximum performance and safety are achieved in all driving situations, as shown here:

Enhanced Vehicle Traction - Torque transfer up to 1,200 Nm - Full function in reverse - Instant activation on differential speed Enhanced Vehicle Dynamics - Improved dynamics during acceleration and deceleration - Rapid activation and deactivation - Fully controllable torque transfer characteristics Enhanced Vehicle System Compatibility - On-line communication with the CAN system Enhanced Vehicle Driving Comfort and Transparency - No wind-up during tight cornering and parking - Optimal traction during acceleration Enhanced Optimization of Weight and Fuel Consumption - The fully controllable torque transfer characteristic decreases the design requirements of the complete AWD drive line, resulting in reduced weight and reduced fuel consumption

4 Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

Variable Torque Control - At Parking: Low or zero torque transfer needed for easy and comfortable maneuverability - Acceleration: High torque transfer for maximum traction on all four wheels - High speed driving: Reduced torque transfer, to minimum, still adding dynamic stability - Driving on slippery/wet roads: Swift activation of the coupling for maximum traction and safety depending on the slip of the wheels. The coupling is in on-line communication with other safety systems in the vehicle - Braking/ABS: Immediate deactivation on ABS signal to ensure full function of ABS system - ESP/TCS Immediate deactivation on ESP/TCS signal to ensure full function of ESP/TCS system. Alternative is to communicate with the ESP/TCS system for adding the control possibility of the new ON-Demand 4WD System to the ESP/TCS System - Off-road: Rapid activation with high torque transfer for maximum traction

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

2. T/M & TRANSFER CASE

- 4WD Transfer Case: Santa Fe base modification - T/M Case: Modification of 4WD transfer matching part - T/M Differential for 4WD: Modification of transfer matching part

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

3. COUPLING & REAR AXLE ASSEMBLY

- Coupling: Same as Santa Fe - Rear Axle: Santa Fe base modification - Control Unit: Santa Fe base modification (Location: under the driver seat)

3.1 SPECIFICATION (ITM: Interactive Torque Management)

Feature Torque Weight Size ITM Housing Operating Voltage Operating Temperature 4WD Coupling Oil Primary Clutch Secondary Clutch

Self-contained, compact, light-weight, torque transfer device for on-demand 4WD 2000 Nm 8 kg 150mm Long, 140mm OD, 120mm ID Aluminum 12 volts -40 ~ 150 Mobil Fluid LT (0.15L) Disc (3 EA), Plate (3 EA) Disc (10 EA), Plate (10 EA)

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 3.2 LOCATION

[Location of ITM Coupling]

3.3 STRUCTURE

Coupling Case

Clutch Housing

Secondary Clutch From Front Wheel To Rear Wheel

Back Plate

EMC Coil

Primary Clutch

Armature

Apply Cam

Chonan Technical Service Training Center

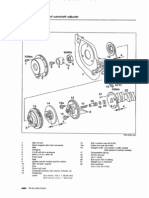

4WD SYSTEM (ITM: Interactive Torque Management) 3.4 COMPONENTS

Wave spring Snap ring Oil seal Snap ring Back plate Steel balls (6EA) Base cam Thrust washer Thrust race Snap ring

Primary clutch

Disc (3EA) Plate (3EA)

Secondary clutch

Plate Disc (10EA) (10EA)

Clutch housing

Electric magnetic clutch

Coupling case

Snap ring Oil seal

Armature

Flange Oil seal Spacer

Input shaft

Nut 214-218 (2140-2180, 158-161) TORQUE : Nm (kgcm, lbft)

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

[Housing]

Primary Clutch

[Primary Clutch]

[Armature]

Armature

Base Cam

[Base Cam]

4WD ECU

Apply Cam Balls

Back Plate To rear differential

EMC connector

10

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 3.5 OPERATION OF COUPLING - Constant speed drive: almost 2WD state - Torque distribution (4WD state) changes according to the driving state (ex: sudden start, turning, at low-mu surface) by the ECU logic - Basic information: Input torque (Throttle Position Sensor), Steering Angle Sensor, Wheel Speed Sensor, Brake Signal as well as ABS signal - EMC Coil energizes to operate the Primary Clutch - The amount of electromagnetic force in the Primary Clutch decides displacement of a Base Cam - Displacement of the Base Cam increases frictional force between Inner Plates and Outer Plates of the Secondary Clutch - While braking: performs a different control logic to get efficient braking

Judge the driving state

Throttle Position Sensor Wheel Speed Sensor Steering Angle Sensor ABS Signal

Decide an optimal torque distribution

4WD ECU

Torque distributed at the 4WD operation 4WD coupling

[Operating Chart]

11

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

Modulating Primary Clutch Secondary Wet Friction Clutch

Apply Force Multiplier

1) MODULATING PRIMARY CLUTCH

CLUTCH HOUSING PRIMARY CLUTCH EMC COIL

Compress Primary Clutch Magnetic Field

ARMATURE

Primary torque in base cam

Input torque from propeller shaft When an EMC Coil energizes, electromagnetic field is generated attracting an Armature as well as Primary Clutch and it increase the frictional force between inner metal plates and outer metal plates of Primary Clutch. Higher frictional force applies bigger torque to rotate the Base Cam because the outer plates splined to a clutch housing and the inner plates splined to a Base Cam..

12 Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 2) APPLY FORCE AMPLIFIER Apply Cam Primary torque in base cam

Apply Force Base Cam

Ball Primary torque in base cam

Ball cam at rest

When the primary torque in the Base Cam increases, the Base Cam begins to rotates over the Ball on the Apply Cam and it pushes the Apply Cam increasing the apply force to the Secondary Clutch. 3) SECONDARY WET FRICTION CLUTCH

Clutch Housing

Clutch Plates

Compress Secondary Clutch

Back Plate

Apply Cam Output torque to Rear Axle

The apply force from the Apply Cam compresses the Secondary Clutch and it increases the frictional force between inner plates which is splined with a Input Shaft and outer plates which is splined to a Clutch Housing. The more frictional force generates the higher output torque.

13

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 4. INPUTS AND OUTPUTS

INPUTS

OUTPUTS

BATTERY & IGNITION1 STEERING ANGLE SENSOR (ESP by CAN) WHEEL SPEED SENSOR (ABS/TCS, ESP by CAN)

EMC

4WD WARNING LAMP 4WD CONTROL

ABS ACTIVE (by CAN)

MODULE (ITMCM) 4WD LOCK LAMP

TPS (by CAN)

4WD LOCK SWITCH

DIAGNOSIS

* CAN (Controller Area Network)

14

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 1) STEERING ANGLE SENSOR (Refer to ESP section for detailed information) Steering angle signals of the vehicle with ESP (Electronic Stability Program) come to the ITMCM through the CAN BUS line. However without ESP, steering angle signals directly come to the ITMCM from the sensor side. With the steering angle information, the ITMCM detects the amount of steering and it controls the EMC coil current to prevent torque conflict between the front wheels and the rear wheels.

2) WHEEL SPEED SENSOR (Refer to ESP section for detailed information) Wheel speed sensor signals of the vehicle with ABS/TCS, ESP come to the ITMCM through the CAN BUS line. However vehicle with a conventional brake system, wheel speed signals directly come to the ITMCM from the sensor side. 4WD system always comes with ABS/TCS, ESP or conventional brake system not with ABS only. ITMCM varies the EMC current by the Information of the speed difference between the front wheels and the rear wheels. For example, if the speed difference is high, more EMC current is applied by the ITMCM to reduce the speed gap. Front wheel speed = (FL Wheel Speed + FR Wheel Speed) / 2 Rear wheel speed = (RL Wheel Speed + RR Wheel Speed) / 2

3) ABS ACTIVE SIGNAL Vehicle is in ABS control, ITMCM does not control the EMC current. Vehicle condition is in 2WD state.

IGN ITMCM ABSCM 17 10

- Type : ABSCM side --- OPEN COLLECTOR TYPE - ITMCM side --- 12V PULL UP (NO ABS CONTROL 9.0V, ABS IN CONTROL 0.5V)

- PULL UP resistance = 10

4) TPS

15 Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) TPS information comes from the ECM through the CAN BUS line. TPS is an input torque data. TPS angle suddenly increases, then the applied current to an EMC goes up. Therefore the torque distribution to rear wheels goes up.

5) 4WD LOCK SWITCH This switch is selected 4WD LOCK lamp comes on. The ITMCM applies maximum current to the EMC resulting in 50 to 50 torque distribution.

[4WD LOCK Switch]

[4WD LOCK Lamp]

6) EMC (Electro Magnetic Clutch) The ITMCM varies the applied current to the EMC to make a torque distribution to the rear wheels. The EMC current increases then the magnetic force increases. Stronger magnetic force results in higher pressing force to secondary clutch.

[In Engine Idling]

[When 4WD LOCK is selected]

16

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

7) 4WD WARNING LAMP 4WD warning lamp blinks (2Hz) when a system failure is detected.

5. DIAGNOSIS

17 Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

While the ITMCM is actived it periodically monitors its inputs and outputs. If a fault is detected the Diagnostic Bulb is illuminated and flash at a rate of 0.25 seconds ON, and 0.25 seconds OFF. A fault code will also be stored in the ECU memory. The first time a fault is detected a DTC is stored in the ECUs Non-Volatile memory. This DTC will remain in memory until the ITMCM is instructed to erase DTC's by the diagnostic tester. DTC's will not be erased by disconnecting power to the ITMCM. [ITM Control Module]

DTCs P1717 P1718 P1719 P1726 P1728 P1729 P1750 P1751 P1752 P1753 P1764 P1765 Steer 1 Steer 2 Steer C

ITMES

DESCRIPTION Loss of signal out of range Loss of signal out of range Loss of signal out of range Loss of signal out of range Short/Open to battery Short to ground Malfunction of front & left speed sensor Malfunction of front & right speed sensor Malfunction of rear & left speed sensor Malfunction of rear & right speed sensor Malfunction of ECM-ITMCM CAN line Malfunction of TCSCM-ITMCM CAN line

TPS input-loss of signal EMC-open/short to battery EMC-short to ground FLSS loss of signal FRSS loss of signal RLSS loss of signal RRSS loss of signal ECM-ITM CAN line, or ECM side malfunction TCS-ITM CAN line, or ECM side malfunction

Input

Error Description

Diagnostic

Diagnostic Lamp

Clearing Strategy

18

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) Loss of signal Out of range

TPS Error Strategy ECU Action

P1726

Blinking

Active P-code cleared error is removed after 1 second

A fault code from the CAN Bus, Signal lost for 1 sec. Fault code stored in memory

TPS=0, The ITMCM will not send current to the clutch coil. Loss of signal Out of range Loss of signal Out of range Loss of signal Out of range Blinking Active P-code cleared if error is removed after 1 second Active P-code cleared if error is removed after 1 second Active P-code cleared if error is removed after 1 second

Steer_1

P1717

Blinking P1718

Steer_2

Steer-C Error Strategy ECU Action FLSS

P1719

Blinking

Out of Range Signal : Voltage >= 4.5 vdc for greater than 1 second

Steering Wheel Sensor input=0. The ITMCM will not send current to the clutch coil. P1750 (C1201) P1751 Loss of signal (C1201) P1752 (C1201) P1753 (C1201) Measure individual wheel, if speed difference is 30kph for 30 seconds fault code will be set. Ignition cycle reset Speed sensor error will turn ITM off. ITM will not have output Blinking Fault cleared at ignition cycle reset. P-code stored, and erased by K-Line tool

FRSS

RLSS

RRSS Error Strategy ECU Action

Input

Error Description

DTC

Diagnostic Lamp

Clearing Strategy

19

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) ECM-ITMCM Communication Line, or ECM side malfunction

C.A.N

P1764

Blinking

Active P-code cleared if error is removed

Error Strategy ECU Action

Loss of the following signals TPS, Transmission type.

The ITMCM will not send current to the clutch coil. TCSCM-ITMCM CAN Line, or ECM side malfunction

C.A.N

P1765

Blinking

Active P-code cleared if error is removed

Error Strategy ECU Action

Loss of the following signals Wheel Speed No signal for greater than 1 second, and a fault will be set. Speed sensor error will turn ITM off. ITM will not have output

Short/Open to EMC Battery

P1728

Blinking Same as Speed sensor fault

Short to Grid

P1729

Blinking

Error Strategy ECU action

25 occurrences in a row mature

EMC Error will turn ITM off. The ITMCM will not send current to the clutch coil

6. WIRING DIAGRAM (for CBS)

20

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

[Connector-Male]

21

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) PIN DESCRIPTION

Pin No.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 4WD WARNING LAMP RR SPEED SENSOR RL SPEED SENSOR FR SPEED SENSOR FL SPEED SENSOR 4WD LOCK LAMP IGNITION INPUT K LINE 4WD LOCK LAMP IGNITION INPUT K LINE 4WD LOCK LAMP IGNITION INPUT K LINE 4WD WARNING LAMP 4WD WARNING LAMP BATTERY INPUT EMC OUTPUT STEERING REF 5V STEERING 2 INPUT STEERING 1 INPUT BATTERY INPUT EMC OUTPUT STEERING REF 5V STEERING 2 INPUT STEERING 1 INPUT BATTERY INPUT EMC OUTPUT

44-50-000-093-a (95447-39980, CBS)

EMC GND STEERING REF GND STEERING REF C 4WD LOCK SWITCH INPUT RRSS GND RTN RLSS GND RTN FRSS GND RTN FLSS GND RTN CAN H CAN L ITMCM GROUND

44-50-000-094-a (95447-39982, ABS/TCS)

EMC GND STEERING REF GND STEERING REF C 4WD LOCK SWITCH INPUT

44-50-000-095-a (99447-39984, ESP)

EMC GND

4WD LOCK SWITCH INPUT

CAN H CAN L ITMCM GROUND

CAN H CAN L ITMCM GROUND

* CBS: Conventional Brake System (without ABS)

7. 4WD COUPLING ASSEMBLY

22 Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management)

7.1 SPECAL TOOLS TOOLS (PART NUMBER & NAME) ILLUSTRATION USE

09432-33200 Bearing removing plate

Removal of 4WD coupling flange oil seal

09478-26000 Flange oil seal installer

Installation of 4WD coupling flange oil seal

09478-26100 Back plate remover

Removal of 4WD coupling back plate

7.2 TORQUE ITEMS Coupling flange lock nut EMC (Electric Magnetic Clutch) mounting nuts (3EA) Rear propellar shaft to 4WD coupling mounting bolts (3EA) 4WD coupling to rear differential carrier bolts Nm 214-218 8-11 100-120 60-65 kgcm 2140-2180 80-110 1000-1200 600-650 lbft 158-161 6-8 74-88 44-48

23

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 7.3 REMOVAL AND INSTALLATION 1. Remove the 4WD coupling bolts (3EA) mounted to the rear propellar shaft.

Connecting bolts (3EA)

Coupling assembly

2. Using a flat tool, separate the propellar shaft from 4WD coupling.

Flat tool

Rear propellar shaft

Coupling assembly

24

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 3. Remove the rear axle (Differential carrier) bolts mounted to the 4WD coupling.

Socket

Coupling assembly Rear differential carrier 4. Remove the electric magnetic clutch connector. Magnetic clutch connector

5. Using a flat tool, separate the 4WD coupling assembly from the rear differential carrier. Rear differential carrier

Flat tool 6. Remove the 4WD coupling assembly.

7. Installation is the reverse of the removal. Coupling assembly

25

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 7.4 DISASSEMBLY

1. Remove the coupling flange mounting nut. Nut

Flange

2. Remove the flange spacer.

Spacer

3. Remove the coupling flange oil seal.

Oil seal

26

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 4. Using a general tool, 3-way puller, remove the flange assembly. 3-way puller

Flange

5. Remove the flange oil seal using special tool (09432-33200).

Press

Suitable tool 09432-33200

Oil seal

6. Remove the coupling case assembly.

Coupling case

Clutch housing

1) Remove the coupling case oil seal.

Oil seal

NOTE Insert the (-) driver between the oil seal and the clutch housing, then remove the oil seal.

27

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 2) Remove the snap ring.

Snap ring

3) Remove the Electric Magnetic clutch mounting nuts (3EA).

Magnetic clutch 7. Remove the wave spring for fixing the back plate and the secondary clutch assembly.

Wave spring Back plate

8. Remove the snap ring. Snap ring

28

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 9. After removing the oil seal, remove the snap ring.

10. Remove the back plate and the secondary clutch assembly simultaneously using special tool (09478-26100). 09478-26100

Back plate & secondary clutch

1) Separate the back plate from the input shaft. Back plate

2) Remove the plates (10EA) and the discs (10EA). Plate Disc

29

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 3) Remove the armature. Armature

4) Remove the input shaft. Input shaft

11. Remove the steel balls (6EA) on the base cam. Steel ball

12. Remove the base cam. Base cam

30

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 13. Remove the thrust washer.

Thrust washer

14. Remove the thrust race.

Thrust race

15. Remove the clutch of the primary clutch. Snap ring

16. Remove the plate of the primary clutch. Plate

NOTE Additionally remove each 2EA discs and plates alternately.

31

Chonan Technical Service Training Center

4WD SYSTEM (ITM: Interactive Torque Management) 7.5 REASSEMBLY

1. When reassembling the back plate oil seal, reassemble it using a suitable tool. Suitable tool Oil seal

2. In case of the coupling case oil seal, too, reassemble it using a suitable tool. Suitable tool Coupling case oil seal

3. When reassembling the 4WD coupling assembly and the flange, too, reassemble them using a suitable tool. Suitable tool Flange

4. Install the flange oil seal using special tool. 09478-2600 Flange Oil seal

32

Chonan Technical Service Training Center

You might also like

- 2007 Toyota Camry TSBs (Technical Service Bulletins) - ToyotaProblemsDocument30 pages2007 Toyota Camry TSBs (Technical Service Bulletins) - ToyotaProblemskkhambadkone67% (3)

- Caterpillar C9 Engine SpecsDocument3 pagesCaterpillar C9 Engine Specsjinxy577991% (11)

- EE - Engine Electrical SystemDocument80 pagesEE - Engine Electrical Systemwreckedweasel100% (15)

- 1994 Chevrolet Blazer S10 Owner's ManualDocument340 pages1994 Chevrolet Blazer S10 Owner's ManualRoberto Stefani67% (3)

- BMW Automatic Trans ServiceDocument31 pagesBMW Automatic Trans ServiceJone Khang83% (6)

- Common Rail Direct Injection (CRDi) Diesel Engine in Hyundai TucsonDocument49 pagesCommon Rail Direct Injection (CRDi) Diesel Engine in Hyundai Tucsonwreckedweasel82% (22)

- 1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Document86 pages1 - A - Manual de Taller Motor D4B Del Hyundai H1 (Inglés) (001-086)Lala Céspedes100% (1)

- Apex'i Super ITC English ManualDocument37 pagesApex'i Super ITC English ManualAkemi SeagalNo ratings yet

- Nissan Patrol Y61 Series 1 Brake SystemDocument10 pagesNissan Patrol Y61 Series 1 Brake SystemKofetoNo ratings yet

- ETM - HL - Harness LayoutDocument18 pagesETM - HL - Harness Layoutwreckedweasel100% (4)

- ETM - HL - Harness LayoutDocument18 pagesETM - HL - Harness Layoutwreckedweasel100% (4)

- Hyundai H1 Shop Manual: FLBDocument30 pagesHyundai H1 Shop Manual: FLBddddddsa100% (5)

- Hyundai: No Engine Car Name/Year/Model Full Set Head Set Cylinder HeadDocument8 pagesHyundai: No Engine Car Name/Year/Model Full Set Head Set Cylinder HeadNopNo ratings yet

- File TreeDocument25 pagesFile TreeDima DimaNo ratings yet

- Hyundai H1 Shop Manual:RTDocument41 pagesHyundai H1 Shop Manual:RTddddddsa100% (2)

- Technical data on the Hyundai H1 2.5 TCI vehicleDocument22 pagesTechnical data on the Hyundai H1 2.5 TCI vehicleJesús AraizaNo ratings yet

- Camshaft Adjuster Mercedes w202 M111Document5 pagesCamshaft Adjuster Mercedes w202 M111Everton Farias100% (1)

- Hyundai Getz SuspensionDocument29 pagesHyundai Getz SuspensionStuGnu100% (3)

- Kia Hyundai DTCDocument63 pagesKia Hyundai DTCDante Allegro100% (2)

- Welcome To Today's Presentation Sponsored byDocument47 pagesWelcome To Today's Presentation Sponsored byfadrique54No ratings yet

- E61 Technical Manual 2005Document72 pagesE61 Technical Manual 2005mmitev80% (5)

- Hyundai H1 Shop Manual: BDDocument70 pagesHyundai H1 Shop Manual: BDddddddsaNo ratings yet

- JM Engine 20040209Document43 pagesJM Engine 20040209wreckedweasel100% (2)

- JM Engine 20040209Document43 pagesJM Engine 20040209wreckedweasel100% (2)

- 4 WD SystemDocument126 pages4 WD SystemSantiago Morales100% (1)

- Hyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10Document10 pagesHyundai D4EB EM (D4EB - Diesel 2.2) Engine Workshop Manual-1-10hoàng gia bùiNo ratings yet

- Hyundai H1 Shop Manual: EEDocument44 pagesHyundai H1 Shop Manual: EEddddddsa100% (8)

- Engine Control Mitsubishi v6 3.0Document5 pagesEngine Control Mitsubishi v6 3.0Juanck Todelar100% (1)

- 66-86 Ford BroncoDocument64 pages66-86 Ford Broncotruckshop100% (4)

- Santa Fe D4eaDocument90 pagesSanta Fe D4eaDona Tas100% (12)

- FaultCodeReaderINSTDocument78 pagesFaultCodeReaderINSTBogdan Stefan100% (1)

- ST - Steering SystemDocument44 pagesST - Steering Systemwreckedweasel100% (3)

- Hyundai Tucson Quick Reference GuideDocument17 pagesHyundai Tucson Quick Reference Guidewreckedweasel50% (2)

- 01 TQ EngineDocument39 pages01 TQ EngineHarlinton descalzi100% (2)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- DS - Driveshaft and AxleDocument76 pagesDS - Driveshaft and Axlewreckedweasel100% (1)

- Diagrams Sistema Eléctrico / Wiring Diagram Electrical System Hino 300 XZU600 / XZU700 /WU600 / WU700Document17 pagesDiagrams Sistema Eléctrico / Wiring Diagram Electrical System Hino 300 XZU600 / XZU700 /WU600 / WU700JC Ramos100% (1)

- GI - General InformationDocument25 pagesGI - General Informationwreckedweasel100% (2)

- Terracan BodyDocument137 pagesTerracan BodyIvan Alexandru50% (2)

- Eaton - 9 SpeedDocument16 pagesEaton - 9 SpeedHenry GramajoNo ratings yet

- TF PDFDocument69 pagesTF PDFIsaac Galvez Escudero100% (1)

- HEATED OXYGEN SENSOR (HO2S) DIAGNOSIS AND REPAIRDocument98 pagesHEATED OXYGEN SENSOR (HO2S) DIAGNOSIS AND REPAIRwessamalex100% (1)

- JM Introduction 20040205Document27 pagesJM Introduction 20040205wreckedweasel100% (5)

- VSA DTC Troubleshooting: 83-11Document2 pagesVSA DTC Troubleshooting: 83-11Ali100% (1)

- JM Etacs - 20040203Document26 pagesJM Etacs - 20040203wreckedweasel100% (2)

- Hyundai H1 Shop Manual: EmaDocument86 pagesHyundai H1 Shop Manual: Emaddddddsa100% (9)

- Drive Control (FR) FunctionDocument3 pagesDrive Control (FR) Functionمحمد يونس100% (3)

- ETM - CL - Component LocationsDocument23 pagesETM - CL - Component Locationswreckedweasel100% (1)

- Hyundai H1 Shop Manual: ECDocument16 pagesHyundai H1 Shop Manual: ECddddddsa100% (5)

- Cam Belt (M40)Document11 pagesCam Belt (M40)Metin OmerNo ratings yet

- Engine Mechanical System ManualDocument5 pagesEngine Mechanical System ManualJC Ramos25% (4)

- Esp JMDocument40 pagesEsp JMwreckedweasel100% (2)

- Esp JMDocument40 pagesEsp JMwreckedweasel100% (2)

- Suzuki DieselDocument746 pagesSuzuki DieselDante Allegro100% (1)

- As-T-T014 SQR372 Engine MechanicalDocument37 pagesAs-T-T014 SQR372 Engine MechanicalJunior Edder Aguilar ApolayaNo ratings yet

- Hyundai US Tucson 2009Document30 pagesHyundai US Tucson 2009wreckedweaselNo ratings yet

- ActyonSports (LHD)Document12 pagesActyonSports (LHD)childofheavenNo ratings yet

- En Tech E4wdDocument1 pageEn Tech E4wdwirelesssoulNo ratings yet

- TEREX Equipment Limited Maintenance ManualDocument536 pagesTEREX Equipment Limited Maintenance ManualYeison RamirezNo ratings yet

- Ps 1144BL-4WD 1Document53 pagesPs 1144BL-4WD 1Gheorghe HolteaNo ratings yet

- JM at - 20040129Document11 pagesJM at - 20040129wreckedweaselNo ratings yet

- MY99 Legacy TwinTurbo ECU PinoutDocument2 pagesMY99 Legacy TwinTurbo ECU PinoutJosé Fabio LouNo ratings yet

- P0100 Mass Air Flow CircuitDocument7 pagesP0100 Mass Air Flow CircuitDaniel rodriguez alayoNo ratings yet

- Hyundai Tucson. Руководство по эксплуатации.Document301 pagesHyundai Tucson. Руководство по эксплуатации.wreckedweasel100% (1)

- F-CON Is ManualDocument32 pagesF-CON Is ManualAndrei Russky Sidorov75% (4)

- C1340Document8 pagesC1340Carlos VelásquezNo ratings yet

- Thermal Oil-Level Sensor: Technical InformationDocument2 pagesThermal Oil-Level Sensor: Technical InformationРадослав БошковNo ratings yet

- Great Wall Motors Company LimitedDocument10 pagesGreat Wall Motors Company Limitedsagar pajankarNo ratings yet

- Sony Cdx-Gt670u Cdx-Gt670us enDocument65 pagesSony Cdx-Gt670u Cdx-Gt670us enRodrigo Pereira Landeros100% (1)

- Sistema de Lubricación VW Passat 1.8LDocument6 pagesSistema de Lubricación VW Passat 1.8LOsvaldoMarianoNo ratings yet

- BYD S6-Owner's Manual20110615-ENDocument114 pagesBYD S6-Owner's Manual20110615-ENMouyaser KodabNo ratings yet

- 2 325688851819397353Document126 pages2 325688851819397353امین پارساNo ratings yet

- DTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Document2 pagesDTC P0340/12 Engine Speed Sensor Circuit 1 (TDC or G1 Circuit)Andi KaNo ratings yet

- SDLG E6350hDocument1 pageSDLG E6350hrizqin ilmanNo ratings yet

- BNM 3 Cyl DieselDocument128 pagesBNM 3 Cyl DieselAnonymous uxZ5FYLP3jNo ratings yet

- Aero Town (Bare Chassis)Document5 pagesAero Town (Bare Chassis)Philippine Bus Enthusiasts SocietyNo ratings yet

- Diagrama ABS Toyota HiluxDocument2 pagesDiagrama ABS Toyota HiluxMário Oliveira100% (1)

- 4 Toyota Fortuner (Cont. Next Page) : Power SourceDocument4 pages4 Toyota Fortuner (Cont. Next Page) : Power Sourcealexander pinto100% (1)

- Electronically Controlled On-Demand 4WDDocument32 pagesElectronically Controlled On-Demand 4WDjulio797No ratings yet

- Dodge Challenger NAG1 5-Speed Automatic Transmission RefresherDocument4 pagesDodge Challenger NAG1 5-Speed Automatic Transmission RefresherEdBunge100% (1)

- Hyundai Tucson. Руководство по эксплуатации.Document301 pagesHyundai Tucson. Руководство по эксплуатации.wreckedweasel100% (1)

- ETM - SD - Schematic DiagramsDocument160 pagesETM - SD - Schematic Diagramswreckedweasel100% (10)

- JM Fatc GuideDocument32 pagesJM Fatc Guidewreckedweasel100% (3)

- Hyundai Tucson EbrochureDocument12 pagesHyundai Tucson EbrochureautoocarmanualdotcomNo ratings yet

- TR - Transaxle/TransmissionDocument244 pagesTR - Transaxle/Transmissionwreckedweasel100% (1)

- Suspension PDFDocument52 pagesSuspension PDFCarlos Eduardo LocatelliNo ratings yet

- ETM - CC - Connector ConfigurationDocument9 pagesETM - CC - Connector Configurationwreckedweasel100% (2)

- RT - RestraintsDocument112 pagesRT - Restraintswreckedweasel100% (1)

- HA - Heating, Ventilation & Air ConditioningDocument112 pagesHA - Heating, Ventilation & Air Conditioningwreckedweasel100% (2)

- FL - Fuel System (D4EA)Document439 pagesFL - Fuel System (D4EA)wreckedweasel100% (42)

- EMA - Engine (G4GC)Document106 pagesEMA - Engine (G4GC)wreckedweasel80% (5)

- FLB - Fuel System (G6BA)Document502 pagesFLB - Fuel System (G6BA)wreckedweasel100% (3)

- EMB - Engine (D4EA)Document102 pagesEMB - Engine (D4EA)wreckedweasel94% (79)

- FLA - Fuel System (G4GC)Document398 pagesFLA - Fuel System (G4GC)wreckedweasel100% (2)

- EC - Emission Control SystemDocument21 pagesEC - Emission Control Systemwreckedweasel100% (1)

- Massey Ferguson 8700 Series SpecsheetDocument4 pagesMassey Ferguson 8700 Series SpecsheetParaschiv FlorinNo ratings yet

- 312 Application ChartDocument5 pages312 Application Chartdon chethiya de silvaNo ratings yet

- 2015 Lexus RC Brochure 2 PDFDocument69 pages2015 Lexus RC Brochure 2 PDFUsmanRajaNo ratings yet

- Chery A1 PartesDocument54 pagesChery A1 PartesAlexferminNo ratings yet

- 1953 1967 Corvette Specification GuideDocument129 pages1953 1967 Corvette Specification GuideLaurent ChapronNo ratings yet

- COCU 02 AsDocument2 pagesCOCU 02 AsThiruselvan AyyadoraiNo ratings yet

- Supplemental Restraint System (SRS) schematic diagramDocument1 pageSupplemental Restraint System (SRS) schematic diagramHuy Trần QuốcNo ratings yet

- Bentley Brochure PDFDocument8 pagesBentley Brochure PDFChoong Li KhaiNo ratings yet

- Mitsubishi Asx-Euro Limited Edition Brochure Lo ResDocument6 pagesMitsubishi Asx-Euro Limited Edition Brochure Lo ResPaul TanNo ratings yet

- Golf 4Document3 pagesGolf 4pepos3094No ratings yet

- AvioServiceBG spare partsDocument2 pagesAvioServiceBG spare partsKestutisNo ratings yet

- 12 LS 600h L / LS 600h (Before Nov. 2009 Production) (Cont. Next Page)Document2 pages12 LS 600h L / LS 600h (Before Nov. 2009 Production) (Cont. Next Page)Waleed AlshgaaaNo ratings yet

- Parts Catalogue YTO-500,554Document101 pagesParts Catalogue YTO-500,554Mathews Matos100% (1)

- Crash Test Results: Honda CR-ZDocument2 pagesCrash Test Results: Honda CR-ZcarbasemyNo ratings yet

- Engine Controls - Engine Code BGP (Powertrain Management) - ALLDATA RepairDocument5 pagesEngine Controls - Engine Code BGP (Powertrain Management) - ALLDATA RepairEnrique Arevalo Leyva100% (1)

- GKN Project 2Document25 pagesGKN Project 2Sameer KapoorNo ratings yet

- 5 Series - P Cab 2022Document56 pages5 Series - P Cab 2022usedpomona3No ratings yet

- K100S K100M: © Ponsse Oyj 1 18.10.2005Document7 pagesK100S K100M: © Ponsse Oyj 1 18.10.2005vitrinetecnicaNo ratings yet

- Clark 125Document136 pagesClark 125reman partsNo ratings yet

- TextDocument7 pagesTexttomNo ratings yet

- Fuji ToyotaDocument27 pagesFuji ToyotaNeftali RosalesNo ratings yet