Professional Documents

Culture Documents

Section9 5

Uploaded by

Ravi ShankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section9 5

Uploaded by

Ravi ShankarCopyright:

Available Formats

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

9.5 Compression Members

This section covers the following topics.

Introduction Analysis Development of Interaction Diagram Effect of Prestressing Force

9.5.1 Introduction

Prestressing is meaningful when the concrete in a member is in tension due to the external loads. Hence, for a member subjected to compression with minor bending, prestressing is not necessary. But, when a member is subjected to compression with substantial moment under high lateral loads, prestressing is applied to counteract the tensile stresses. Examples of such members are piles, towers and exterior columns of framed structures. As the seismic forces are reversible in nature, the prestressing of piles or columns is concentric with the cross-section. Some typical cross sections are shown below.

Partially prestressed column

Figure 9-5.1

Prestressed circular and hexagonal piles

Examples of prestressed members subjected to compression

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Figure 9-5.2

Stacked prestressed piles

(Reference: Industrial Concrete Products Berhad) Precast prestressed piles have the following advantages. 1) Large bending and axial tension capacities. 2) Better quality control than bored and CIP piles. 3) Section remains uncracked under service loads Increased durability. 4) Use of high strength concrete gives reduced section. The piles are prestressed by pre-tensioning. The procedure of pre-tensioning is explained under Pretensioning Systems and Devices. Since a prestressed member is under self equilibrium, there is no buckling of the member due to internal prestressing with bonded tendons. In a deflected shape, there is no internal moment due to prestressing.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The justification is explained in the next figure.

P P

C T

P

b) Under internal prestressing

a) Under external compression

Figure 9-5.3

Internal forces at deflected configuration

In the first free body sketch of the above figure, the external compression P causes an additional moment due to the deflection of the member. The value of the moment at mid-height is P. This is known as the member stability effect, which is one type of P- effect. If this deflection is not stable, then buckling of the member occurs. In the second free body sketch, there is no moment due to the deflection of the member and the prestressing force, since the compression in concrete (C) and the tension in the tendons (T) balance each other. When the additional moment due to deflection of the member is negligible, the member is termed as short member. The additional moment needs to be considered when the slenderness ratio (ratio of effective length and a lateral dimension) of the member is high. The member is termed as slender member. In the analysis of a slender member, the additional moment is calculated by an approximate expression or second order analysis. In this module only short members will be considered.

9.5.2 Analysis

Analysis at Transfer The stress in the section can be calculated as follows.

fc = P0 A

(9-5.1)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Here, A = Area of concrete P0 = prestress at transfer after short-term losses. In this equation, it is assumed that the prestressing force is concentric with the crosssection. For members under compression, a compressive stress is considered to be positive. The permissible prestress and the cross-section area are determined based on the stress to be within the allowable stress at transfer (fcc,all). Analysis at Service Loads The analysis is analogous to members under flexure. The stresses in the extreme fibres can be calculated as follows.

fc = Pe N Mc + A At It

(9-5.2)

In this equation, the external compression for a prestressed member is denoted as N and is concentric with the cross section. The eccentricity is considered in the external moment M. In the previous equation, A = area of concrete At = area of the transformed section c = distance of the extreme fibre from the centroid (CGC) It = moment of inertia of the transformed section Pe = effective prestress. The value of fc should be within the allowable stress under service conditions (fcc,all). Analysis at Ultimate When the average prestress in a member under axial compression and moment is less than 2.5 N/mm2, Clause 22.2, IS:1343 - 1980, recommends to analyse the member as a reinforced concrete member, neglecting the effect of prestress. For higher prestress, the analysis of strength is done by the interaction diagrams.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

At the ultimate limit state, an interaction diagram relates the axial force capacity (NuR) and the moment capacity (MuR). It represents a failure envelop. Any combination of factored external loads Nu and Mu that fall within the interaction diagram is safe. A typical interaction diagram is shown below. The area shaded inside gives combinations of Mu and Nu that are safe.

NuR

Compression failure

1 eN

Balanced failure Tension failure

MuR

Figure 9-5.4 A typical interaction diagram for compression and bending

The radial line in the previous sketch represents the load path. Usually the external loads increase proportionally. At any load stage, M and N are related as follows. M = N eN (9-5.3)

Here, eN represents the eccentricity of N which generates the same moment M. The slope of the radial line represents the inverse of the eccentricity (1/eN). At ultimate, the values of M and N (Mu and Nu, respectively) correspond to the values on the interaction diagram. For high values of N as compared to M, that is when eN is small, the concrete in the compression fibre will crush before the steel on the other side yields in tension. This is called the compression failure. For high values of M as compared to N, that is when eN is large, the concrete will crush after the steel yields in tension. This is called the tension failure. The transition of these two cases is referred to as the balanced failure, when the crushing of concrete and yielding of steel occur simultaneously. For a prestressed compression member, since the prestressing steel does not have a definite yield point, there is no explicit balanced failure.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

9.5.3 Development of Interaction Diagram

An interaction diagram can be developed from the first principles using the non-linear stress-strain curves of concrete under compression and steel under tension. Several sets of NuR and MuR for given values of eN or xu are calculated. The distance of neutral axis from the extreme compressive face is denoted as xu. Partial safety factors for concrete and prestressing steel can be introduced when the interaction diagram is used for design. Here, the procedure is illustrated for a rectangular section with prestressed tendons placed at two opposite faces symmetrically, and without non-prestressed reinforcement.

D

CGC +

B Ap1

Figure 9-5.5 The notations used are as follows.

d1

d2

Ap2

A rectangular prestressed section

B = dimension of section transverse to bending D = dimension of section in the direction of bending Ap1 = area of prestressing tendons at the tension face Ap2 = area of prestressing tendons at the compression face d1, d2 = distances of centres of Ap1 and Ap2, respectively, from the centroid of the section (CGC). The strain compatibility equation is necessary to relate the strain in a prestressing tendon with that of the adjacent concrete. Due to a concentric prestress, the concrete at a section undergoes a uniform compressive strain. With time, the strain increases due to the effects of creep and shrinkage. At service, after the long term losses, let the strain be ce. Also, let the strain in the prestressing steel due to effective prestress be pe.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

ce pe

Figure 9-5.6

pe

Strain profile due to effective prestress only

The strain compatibility equation for the prestressed tendons is given below.

p = c + p where, p = pe - ce

(9-5.4)

The strain difference of the strain in a prestressing tendon with that of the adjacent concrete is denoted as p. The design stress-strain curve for concrete under compression is used. This curve is described in Section 1.6, Concrete (Part II). The design stress-strain curve for the prestressed tendon under tension is expressed as fp = F(p). The calculation of NuR and MuR for typical cases of eN or xu are illustrated. The typical cases are as follows. 1) Pure compression (eN = 0, xu = ) 2) Full section under varying compression (0.05D < eN eN xu = D , xu D) 3) Part of section under tension (eN xu = D < eN , xu < D) 4) Pure bending (eN = , xu = xu,min) The above cases are illustrated in the following sketches.

e=0

e

Elevation

xu

Case 1 Case 2

Strain diagram

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

e

Elevation

xu

Case 3

Figure 9-5.7

Strain diagram

xu

Case 4

Typical cases of eccentricity and depth of neutral axis

In addition to the above cases, the case of pure axial tension is also calculated. The straight line between the points of pure bending and pure axial tension provides the interaction between the tensile force capacity and the moment capacity.

MuR

NuR

Figure 9-5.8

A typical interaction diagram for tension and bending

1. Pure compression (eN = 0, xu = ). The following sketches represent the strain and stress profiles across the section and the force diagram.

0.002 p1 p2 Strain profile

fp1

0.447 fck

fp2

Stress profile

Tu1

Figure 9-5.9

Cu

Tu2

Force diagram

Sketches for analysis at pure compression

The forces are as follows.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Cu Tu1

= 0.447fck (Ag Ap) = Tu2 = Ap1 fp1 = Ap1 Ep ( 0.002 + p)

(9-5.5) (9-5.6)

The steel is in the elastic range. The total area of prestressing steel is Ap = Ap1 + Ap2. The area of the gross-section Ag = BD. The moment and axial force capacities are as follows. MuR = 0 NuR = Cu Tu1 Tu2 = 0.447fck (Ag Ap) Ap Ep (pe 0.002 ce)

(9-5.8) (9-5.7)

In design, for simplification the interaction diagram is not used for eccentricities eN 0.05D. To approximate the effect of the corresponding moment, the axial force capacity is reduced by 10%.

NuR = 0.4fck (Ag Ap) 0.9Ap Ep (pe 0.002 + ce) (9-5.9)

2. Full section under varying compression (0.05D < eN eN xu = D , xu D) The following sketches represent the strain and stress profiles across the section and the force diagram.

xu = kD

0.002 p1 p2 3 / 7 D Strain profile

f p1 g Asector Tu1

Figure 9-5.10

fp2

0.447 fck Stress profile Force diagram

Cu Tu2

Sketches for analysis for section under varying compression

The limiting case for full section under compression corresponds to xu = D, when the neutral axis lies at the left edge of the section. The strain diagram pivots about a value of 0.002 at 3/7D from the extreme compression face. To calculate Cu, first the

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

reduction of the stress at the edge with lower compression (g) is evaluated. Based on the second order parabolic curve for concrete under compression, the expression of g is as follows.

4 D 7 g = 0.447fck 3 kD - 7 D 4 = 0.447fck 7k - 3

2

(9-5.10)

The area of the complementary sector of the stress block is given as follows.

1 4 Asector = g D 3 7 4 = gD 21

(9-5.11)

Asector x/ g

+ 4/7D

Figure 9-5.11

Complementary area of the stress block

Distance of centroid from apex (x /) = (3/4)(4/7)D = 3/7 D The forces are as follows.

Cu = [0.447fck D - Asector ] B 4 = 0.447fck D - gD B 21 4 4 2 = 0.447fck BD 1- 21 7k - 3

(9-5.12)

Tu1 = Ap1fp1 = Ap1E p p1 = Ap1E p ( c1 + p ) D xu - + d1 2 + = Ap1E p -0.002 p 3D x u 7

(9-5.13)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Tu 2 = Ap 2fp 2 = Ap 2E p p 2 = Ap 2E p ( c 2 + p ) D -d x u 2 2 + = Ap 2E p -0.002 p 3D x u 7

(9-5.14)

The strains in the concrete at the level of the prestressing steels c1 and c2 are determined from the similarity of triangles of the following strain profile.

c1

xu (D/2 + d1) xu (3 / 7 D)

0.002

0.002

xu (3 / 7 D) xu ( D / 2 d 2 )

Figure 9-5.12

c2

Strain profile across section

The moment and axial force capacities are as follows. NuR = Cu Tu1 Tu2 MuR = Mc + Mp

(9-5.15) (9-5.16)

The expressions of Mc and Mp about the centroid are given below. Anticlockwise moments are considered positive. The lever arms of the tensile forces are shown in the following sketch.

3 D / Mc = 0.447fck DB 0 + Asector B x + D 7 2 10 = gD 2B 147

Mp = Tu1d1 Tu2d2

(9-5.17)

(9-5.18)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

d1 Tu1

Figure 9-5.13

d2

+

Cu Tu2

Force diagram across the section

3. Part of section under tension (eN xu = D < , eN , xu < D) The following sketches represent the strain and stress profiles across the section and the force diagram.

p 1

xu p2

0.0035 Strain profile

fp1

fp2

0.447fck Stress profile Force diagram

Tu1

Figure 9-5.14

Cu

Tu2

Sketches for analysis for part of section under tension

The forces are as follows. The compression is the resultant of the stress block whose expression can be derived similar to a reinforced concrete section. Cu = 0.36fck xu B Tu1 = Ap1 fp1 = Ap1 F (p1) = Ap1 F (c1+ p) Tu2 = Ap2 fp2 = Ap2 Ep p2 = Ap2 Ep (c2+ p) The strains c1 and c2 are calculated from the similarity of triangles of the following strain diagram.

D + d1 - xu 2

c 1

0.0035 xu

(9-5.19)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

c 2 0.0035 =D xu xu - - d2 2

(9-5.20)

c1

xu c2

0.0035

xu (D/2 d2) (D/2 + d1) xu

Figure 9-5.15

Strain profile across section

The moment and axial force capacities are as follows. NuR = Cu Tu1 Tu2 MuR = Mc + Mp The expressions of Mc and Mp about the centroid are as follows. Mc = 0.36fck xu B [ (D / 2) 0.42 xu ] Mp = Tu1d1 Tu2d2

(9-5.23) (9-5.24) (9-5.21) (9-5.22)

The lever arms of the forces are shown in the following sketch. The location of Cu is similar to that of a reinforced concrete section.

d1 Tu1

+

d2 Cu Tu2

(D / 2) 0.42 xu

Figure 9-5.16

Force diagram across the section

4. Pure bending (eN = , xu = xu,min) The value of xu is determined by trial and error from the condition that the sum of the forces is zero. Cu Tu1 Tu2 = 0 or, 0.36fck xu B Ap1 fp1 Ap2 fp2 = 0

(9-5.25)

or,

xu =

Ap1fp1 + Ap 2E p p 2 0.36fck B

(9-5.26)

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

The strains p1 and p2 are calculated from the strain compatibility equations. The strain p2 is within the elastic range, whereas p1 may be outside the elastic range. The stresses fp1 and fp2 are calculated accordingly from the stress versus strain relationship of prestressing steel. The steps for solving xu are as follows. 1) Assume xu = 0.15 D (say). 2) Determine p1 and p2 from strain compatibility. 3) Determine fp1 and fp2 from stress versus strain relationship. 4) Calculate xu from Eqn. (9-5.26). 5) Compare xu with the assumed value. Iterate till convergence. The moment and axial force capacities are as follows. NuR = 0 MuR = Mc + Mp The expressions of Mc and Mp are same as the previous case. 5. Axial tension The moment and axial force capacities are as follows. The cracked concrete is neglected in calculating the axial force capacity. NuR = 0.87fpk Ap MuR = 0 The above sets of NuR and MuR are joined to get the interaction diagram.

(9-5.29) (9-5.30) (9-5.27) (9-5.28)

Example 9-5.1

Calculate the design interaction diagram for the member given below. member is prestressed using 8 strands of 10 mm diameter. stress relieved with the following properties. Tensile strength (fpk) Total area of strands = 1715 N/mm2. = 8 51.6 The

The strands are

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

= 413.0 mm2 Effective prestress (fpe) Modulus (Ep) Strain under fpe (pe) Grade of concrete Strain under fpe (ce) = 1034 N/mm2 = 200 kN/mm2 = 0.0042.

= M40 = 0.0005.

300

300

50

200

50

Solution

Calculation of geometric properties and strain compatibility relationship. Ag Ap1 = Ap2 d1 = d2 p = 300 300 = 90,000 mm2 = 4 51.6 = 206 mm2 = 100 mm = 0.0042 + 0.0005 = 0.0047

p = c + 0.0047

1. Pure compression (eN = 0, xu = ) MuR Cu = 0 kNm = 0.447fck (Ag Ap) = 0.447 40 (90,000 413) = 1601.8 kN Tu1 = Tu2 = Ap1 Ep ( 0.002 + p) = 206.4 200 (0.0047 0.002) = 111.5 kN

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

NuR

= Cu Tu1 Tu2 = 1601.8 2 111.5 = 1378.8 kN

With 10% reduction, to bypass the use of interaction diagram for eccentricities eN 0.05D NuR = 1204.9 kN

2. Full section under compression (0.05D < eN eN xu = D , xu D)

400

Select xu

= 400 mm = (4 / 3) 300 mm

=4/3

2

4 g = 0.447 fck 7k - 3

4 = 0.447 40 7(4/3) - 3 = 7.13 N/mm2 4 4 2 Cu = 0.447fck BD 1- 21 7k - 3 2 4 4 2 = 0.447 40300 1- 21 7(4/3) - 3 = 1486.9 kN

271.4 (3/7) 300 = 128.6 0.002

150

c1

Tu1 = Ap1E p ( c1 + p ) 150 = 206.4 200 -0.002 + 0.0047 271.4 = 148.4 kN

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

271.4 0.002 350

c2

Tu 2 = Ap 2E p ( c 2 + p ) 350 = 206.4 200 -0.002 + 0.0047 271.4 = 87.5 kN NuR = Cu Tu1 Tu2 = 1486.9 148.4 87.5 = 1251.0 kN Limit NuR to 1240.9 kN to bypass the use of interaction diagram for eccentricities eN 0.05D. Mc = 10 gD 2B 147 10 = 7.133002 300 147 = 13.1 kNm

M p = T u1d1 - Tu 2d 2 = 148.4100 - 87.5100 = 6.1 kNm

MuR = Mc + Mp = 13.1 + 6.1 = 19.2 kNm Select xu = 300 mm k = 1 By similar calculations, g Cu Tu1 = 17.9 N/mm2 = 1304.1 kN = 169.9 kN NuR Mc Mp = 1060.6 kN = 32.9 kNm = 9.6 kNm

300

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Tu2

= 73.6 kN

MuR

= 42.5 kNm.

3. Part of section under tension (eN xu = D < eN , xu < D) Select xu Cu = 200 mm. = 0.36fck xu B = 0.36 40 200 300 = 864.0 kN

c 1 =

0.0035 50 200 = 0.0009

p1 = 0.0009 + 0.0047 = 0.0056

c1

50 200 0.0035

Strain corresponding to elastic limit py = 0.87 0.8fck / Ep = 0.87 1715 / 200 103 = 0.0059. p1 < py

fp1

= Ep p1 = 200 103 0.0055 = 1115 N/mm2

Tu1

= Ap1 fp1 = 206.4 1115 = 230.1 kN

c 2 = 0.0035 150 200 = - 0.0026

p 2 = - 0.0026 + 0.0047 = 0.0021

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

200

c2

150

0.0035

f p2

= Ep p2 = 200 103 0.0021 = 416 N/mm2

Tu2

= Ap2 fp2 = 206.4 416 = 85.9 kN

NuR

= Cu Tu1 Tu2 = 864 230.1 85.9 = 548.0 kN

Mc

= 0.36fck xu B [ (D / 2) 0.42xu ] = 864 (150 0.42 200) = 57.0 kNm

Mp

= Tu1d1 Tu2d2 = 230.1 100 85.9 100 = 14.4 kNm

MuR

= Mc + Mp = 57.0 + 14.4 = 71.4 kNm

4. Pure bending (eN = , xu = xu,min) NuR = 0.0 kN Try xu = 100 mm. Cu = 0.36fck xu B = 0.36 40 100 300 = 432.0 kN c 1 = 0.0035 150 100 = 0.0052

p1 = 0.0052 + 0.0047 = 0.0099

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

c1

100 150 0.0035

From stress-strain curve f p1 = 0.87fpk = 1492 N/mm2 Tu1 = Ap1 fp1 = 206.4 1492 = 308.0 kN

100

c2

50

0.0035

c 2 = -

0.0035 50 100 = - 0.0017

p 2 = - 0.0017 + 0.0047 = 0.0029 f p2 = Ep p2 = 200 103 0.0029 = 580 N/mm2 Tu2 = Ap2 fp2 = 206.4 580 = 120.0 kN Tu1 + Tu2 = 428.0 kN This is close enough to Cu = 432.0 kN. Hence, the trial value of xu is satisfactory.

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Mc

= 0.36fck xu B [ (D / 2) 0.42xu ] = 0.36 40 100 300 (150 0.42 100) = 46.6 kNm

Mp

= Tu1d1 Tu2d2 = 308.0 100 120.0 100 = 18.8 kNm

MuR

= 46.6 + 18.8 = 65.4 kNm

5. Axial tension MuR NuR = 0.0 kNm = 0.87fpk Ap = 0.87 1715 413.0 = 616.2 kN The above sets of NuR and MuR are joined to get the following interaction diagram. The limit on axial force capacity to consider the effect of eccentricity less than 0.05D, is not shown.

1500 1000

N uR (kN)

500 0 0 -500 -1000 M uR (kNm) 20 40 60 80

9.5.4 Effect of Prestressing Force

Indian Institute of Technology Madras

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

Along with the interaction curve for the prestressed concrete (PC) section, the interaction curves for two reinforced concrete (RC) sections are plotted. The section denoted as RC 1 has the same moment capacity at zero axial force. The section denoted as RC 2 has the same axial force capacity at zero moment. The gross section of RC 1 is same as that of PC, but the section of RC 2 is smaller.

2500 2000 1500

NuR (kN)

1000 500 0 -500 0 -1000 M uR (kNm) 50 100 150

PC RC 1

RC 2

Figure 9-5.17

Interaction diagrams for reinforced and prestressed sections

0 0

NuR (kN)

20

40

60

80

-250 -500 -750 -1000

M uR (kNm)

PC Strength

PC Cracking

RC 1 Strength

RC 1 Cracking

Figure 9-5.18

Interaction of moment and tension for cracking and strength

Comparing the curves for PC and RC 2, it is observed that if the moment demand is small, then a smaller reinforced concrete section is adequate to carry the axial force. Of course with increasing moment, the flexural capacity of the prestressed concrete section is higher.

Indian Institute of Technology Madras

Comparing the curves for PC and RC 1, it is inferred that for two

Prestressed Concrete Structures

Dr. Amlan K Sengupta and Prof. Devdas Menon

sections with same flexural capacities, the axial load capacity of a prestressed concrete section is less. However if there is tension, the cracking load combination is higher for PC as compared to RC 1. Thus, prestressing is beneficial for strength when there is occurrence of: a) Large moment in addition to compression b) Moment along with tension. Such situations arise in piles or columns subjected to seismic forces. In presence of tension, prestressing is beneficial at service loads due to reduced cracking. prestressed reinforcement may be used for supplemental capacity. Non-

Indian Institute of Technology Madras

You might also like

- Compression MembersDocument22 pagesCompression Membersbemd_ali6990100% (2)

- P-M INTERACTIONDocument29 pagesP-M INTERACTIONGanesh MistercoolNo ratings yet

- Basic Concepts, Rectangular and T Beams PDFDocument49 pagesBasic Concepts, Rectangular and T Beams PDFAhmed Hussein KamelNo ratings yet

- Losses in Prestressed ConcreteDocument36 pagesLosses in Prestressed Concretedorel1900No ratings yet

- Analysis of continuous prestressed concrete beamsDocument14 pagesAnalysis of continuous prestressed concrete beamsChinnu JacobNo ratings yet

- Limit State DesignDocument85 pagesLimit State Designkeshav1980No ratings yet

- Analisis Anggota Beton Pracetak di bawah Lenturan (Bagian IDocument39 pagesAnalisis Anggota Beton Pracetak di bawah Lenturan (Bagian Izacoeb_a1669No ratings yet

- Analysis of Prestressed Concrete Members under Axial LoadDocument9 pagesAnalysis of Prestressed Concrete Members under Axial LoadNilesh KumarNo ratings yet

- One Way SlabsDocument16 pagesOne Way Slabsbemd_ali6990No ratings yet

- Explanation of One Way and Two Way Slab ActionDocument17 pagesExplanation of One Way and Two Way Slab Actionxckwzr100% (4)

- Basic Concepts Rectangular and T Beams PDFDocument49 pagesBasic Concepts Rectangular and T Beams PDFBookienowNo ratings yet

- Cve 201 Module 1Document5 pagesCve 201 Module 1Samuel Silas100% (1)

- Design of A Section.: NtroductionDocument12 pagesDesign of A Section.: NtroductionM Nur SalimNo ratings yet

- PSC Unit 3Document18 pagesPSC Unit 3Santosh ReddyNo ratings yet

- PCI Journal Prestressed Poles JL 88 January February 3Document23 pagesPCI Journal Prestressed Poles JL 88 January February 3nagenol100% (1)

- Stress Analysis in Elastic Bending Beams and Thick Hollow CylindersDocument6 pagesStress Analysis in Elastic Bending Beams and Thick Hollow Cylindersمحمد فطري فيك نظامNo ratings yet

- Structural Design III Losses in PrestressDocument81 pagesStructural Design III Losses in PrestressKiran BandeNo ratings yet

- Chapter 3 Flexural Analysis (Part 1) (Compatibility Mode)Document41 pagesChapter 3 Flexural Analysis (Part 1) (Compatibility Mode)Umair RazaNo ratings yet

- Calculation and limits of crack width in prestressed concreteDocument7 pagesCalculation and limits of crack width in prestressed concreteJeet DesaiNo ratings yet

- Principles of Limit State Design and UltimateDocument85 pagesPrinciples of Limit State Design and UltimateUmar Saba50% (2)

- Design For Torsion (Part I)Document7 pagesDesign For Torsion (Part I)bemd_ali6990No ratings yet

- 3.6 Analysis of Members Under Flexure (Part V)Document10 pages3.6 Analysis of Members Under Flexure (Part V)Nilesh KumarNo ratings yet

- Torsion in Engineering StructuresDocument16 pagesTorsion in Engineering Structuresabouelrich188No ratings yet

- MOR and Modes of Failure of BeamsDocument9 pagesMOR and Modes of Failure of Beamsward dhapakhelNo ratings yet

- Circular PrestressingDocument18 pagesCircular Prestressingbemd_ali69900% (1)

- Losses in Prestress-Friction, Anchorage SlipDocument16 pagesLosses in Prestress-Friction, Anchorage SlipSravanthi MeharNo ratings yet

- Advanced Design of Steel and Concrete Composite StructuresDocument30 pagesAdvanced Design of Steel and Concrete Composite StructuresCristian BlanaruNo ratings yet

- CVX7640 28Document18 pagesCVX7640 28malingauomNo ratings yet

- Introduction To Prestressed Concrete - 1Document15 pagesIntroduction To Prestressed Concrete - 1Deepu SivakumarNo ratings yet

- 1 Viga ColunaDocument27 pages1 Viga ColunaFrank JohnNo ratings yet

- Chapter 2 - Stresses in Machine Elements-1Document8 pagesChapter 2 - Stresses in Machine Elements-1felixnziokiNo ratings yet

- Generalized Flexural Design Equations For Prestressed ConcreteDocument11 pagesGeneralized Flexural Design Equations For Prestressed Concreteunix0123No ratings yet

- Prestressed Concrete Structures - Design PDFDocument20 pagesPrestressed Concrete Structures - Design PDFyanickdouce1206No ratings yet

- Tension StiffeningDocument13 pagesTension StiffeningRahul BhatiaNo ratings yet

- Cie 525Document12 pagesCie 525Richard PadillaNo ratings yet

- SOM Part-2 FinalDocument67 pagesSOM Part-2 FinalSumithra Nataraj80% (5)

- Nottingham Concrete Beam TestingDocument8 pagesNottingham Concrete Beam TestingYaasiin OozeerNo ratings yet

- Section4 3 PDFDocument13 pagesSection4 3 PDFRavi ShankarNo ratings yet

- Mechanics of Materials Course OutlineDocument45 pagesMechanics of Materials Course OutlineKelly GbandehNo ratings yet

- Simple Analysis of Cracked Concrete Section Under FlexureDocument19 pagesSimple Analysis of Cracked Concrete Section Under FlexureabooosyNo ratings yet

- Stresses in BeamsDocument9 pagesStresses in BeamsAyad SlabyNo ratings yet

- Ch-3 Introduction To Prestressed ConcreteDocument29 pagesCh-3 Introduction To Prestressed ConcreteGolisa RobaNo ratings yet

- Curved Beam Stress AnalysisDocument17 pagesCurved Beam Stress Analysisfsirfan0% (1)

- 5 Axially CompressedDocument8 pages5 Axially CompressedNilesh Balkrishna Sunita ApteNo ratings yet

- 1 1 PDFDocument50 pages1 1 PDFBalaji ArumugamNo ratings yet

- Module-3: G Madegowda Institute of Technology (Gmit), Bharathinagara Page 1Document10 pagesModule-3: G Madegowda Institute of Technology (Gmit), Bharathinagara Page 12BA19CV059 Rakshita SarangmathNo ratings yet

- Magnel's graphical method for prestressed concrete designDocument12 pagesMagnel's graphical method for prestressed concrete designRavi ShankarNo ratings yet

- CIE 525 HW 3 - Mkumar2Document13 pagesCIE 525 HW 3 - Mkumar2xxazninvasionxx2697No ratings yet

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- TOT OneDocument4 pagesTOT OneRavi ShankarNo ratings yet

- Elite Bargains and Political Deals Project: Bosnia and Herzegovina Case StudyDocument36 pagesElite Bargains and Political Deals Project: Bosnia and Herzegovina Case StudyRavi ShankarNo ratings yet

- Elite Bargains and Political Deals Project: Colombia Case StudyDocument32 pagesElite Bargains and Political Deals Project: Colombia Case StudyRavi ShankarNo ratings yet

- A National Study On Leveraging Public Infrastructure Funds Project Performance and Financing Source Analysis For Public-Private Partnerships (PPP) in The U.S. Transportation SectorDocument177 pagesA National Study On Leveraging Public Infrastructure Funds Project Performance and Financing Source Analysis For Public-Private Partnerships (PPP) in The U.S. Transportation SectorRavi ShankarNo ratings yet

- Do Welfare Programs Work in Weak States Why Evidence From A Maternity Support Program in India PDFDocument18 pagesDo Welfare Programs Work in Weak States Why Evidence From A Maternity Support Program in India PDFRavi ShankarNo ratings yet

- Analyzing and Improving Transportation Infrastructure Privatization in A Competitive EnvironmentDocument165 pagesAnalyzing and Improving Transportation Infrastructure Privatization in A Competitive EnvironmentRavi ShankarNo ratings yet

- Political Economy of Infrastructure, Development and Poverty in A Democratic Setting PDFDocument178 pagesPolitical Economy of Infrastructure, Development and Poverty in A Democratic Setting PDFRavi ShankarNo ratings yet

- Elite Bargains and Political Deals Project: Democratic Republic of Congo (M23) Case StudyDocument24 pagesElite Bargains and Political Deals Project: Democratic Republic of Congo (M23) Case StudyRavi ShankarNo ratings yet

- Are Infrastructure Assets Experiencing A Case of Overvaluation, and Can The Asset Class As A Whole Continue To Deliver Adequate Risk-Adjusted ReturnsDocument74 pagesAre Infrastructure Assets Experiencing A Case of Overvaluation, and Can The Asset Class As A Whole Continue To Deliver Adequate Risk-Adjusted ReturnsRavi ShankarNo ratings yet

- A Hazy Future Local-Scale Air Pollution, Public Opinion, and Government Legitimacy in Contemporary ChinaDocument202 pagesA Hazy Future Local-Scale Air Pollution, Public Opinion, and Government Legitimacy in Contemporary ChinaRavi ShankarNo ratings yet

- Building Connections Political Corruption and Road Construction in India PDFDocument17 pagesBuilding Connections Political Corruption and Road Construction in India PDFRavi ShankarNo ratings yet

- WestCoast SOILrptDocument67 pagesWestCoast SOILrptRavi ShankarNo ratings yet

- A Marxist History of Detroit (1913-2018)Document292 pagesA Marxist History of Detroit (1913-2018)Ravi ShankarNo ratings yet

- Political Economy of Land Acquisition For Urban Infrastructure Projects in India PDFDocument202 pagesPolitical Economy of Land Acquisition For Urban Infrastructure Projects in India PDFRavi ShankarNo ratings yet

- Political Economy of Infrastructure, Development and Poverty in A Democratic Setting PDFDocument178 pagesPolitical Economy of Infrastructure, Development and Poverty in A Democratic Setting PDFRavi ShankarNo ratings yet

- 3 FoundationsDocument42 pages3 FoundationsWHfamilyNo ratings yet

- Tendernotice 1Document3 pagesTendernotice 1Ravi ShankarNo ratings yet

- BUILDABLE SOLUTIONS FOR LANDED RESIDENTIAL DEVELOPMENT IN SINGAPORE Lowres PDFDocument157 pagesBUILDABLE SOLUTIONS FOR LANDED RESIDENTIAL DEVELOPMENT IN SINGAPORE Lowres PDFAbdulrahman AlnagarNo ratings yet

- T2288MSLLnontechinalschedule PDFDocument38 pagesT2288MSLLnontechinalschedule PDFRavi ShankarNo ratings yet

- Feasibility Studies For Renewable EnergyDocument85 pagesFeasibility Studies For Renewable EnergyRavi ShankarNo ratings yet

- Paper Flare Gas 3 PDFDocument11 pagesPaper Flare Gas 3 PDFFaza InsanNo ratings yet

- LinkforXLSFileSubconcessionFeeCalculation PDFDocument1 pageLinkforXLSFileSubconcessionFeeCalculation PDFRavi ShankarNo ratings yet

- PHD Thesis Mohammad Arif RohmanDocument369 pagesPHD Thesis Mohammad Arif RohmanRavi ShankarNo ratings yet

- T2288 Subconcession Fee CalculationDocument1 pageT2288 Subconcession Fee CalculationRavi ShankarNo ratings yet

- Module1researchmethods2010 tcm77-189669Document73 pagesModule1researchmethods2010 tcm77-189669M Umair ManiNo ratings yet

- Research MDocument1 pageResearch MRavi ShankarNo ratings yet

- KPMG Toll Benchmarking Study 2015 v2 PDFDocument28 pagesKPMG Toll Benchmarking Study 2015 v2 PDFRavi ShankarNo ratings yet

- Pages From DCA TOT 3Document4 pagesPages From DCA TOT 3Ravi ShankarNo ratings yet

- How Does Port Efficiency Affect Maritime Transport Costs and Trade?Document24 pagesHow Does Port Efficiency Affect Maritime Transport Costs and Trade?Ravi ShankarNo ratings yet

- SSRN Id2978681Document43 pagesSSRN Id2978681Ravi ShankarNo ratings yet

- THE RISE OF HIGH-RISE BUILDINGSDocument1 pageTHE RISE OF HIGH-RISE BUILDINGSMistyNo ratings yet

- Department of Public Works and Highways: Regional Office Iv-B Palawan 3Rd District Engineering OfficeDocument24 pagesDepartment of Public Works and Highways: Regional Office Iv-B Palawan 3Rd District Engineering Officejayson mariNo ratings yet

- Column Splice Plate DesignDocument4 pagesColumn Splice Plate Designinnovativekarthi100% (1)

- Group 8 Lesson 11 PresentationDocument30 pagesGroup 8 Lesson 11 PresentationAaron PinedaNo ratings yet

- Detailed Unit Price Analysis (Dupa)Document10 pagesDetailed Unit Price Analysis (Dupa)RaymundNo ratings yet

- NOTESDocument6 pagesNOTESJella DulatreNo ratings yet

- Earthquake Analysis Using Seismic Coefficient MethodDocument4 pagesEarthquake Analysis Using Seismic Coefficient MethodV.m. RajanNo ratings yet

- 2258-6003 210514 192200Document220 pages2258-6003 210514 192200Patrick Julian RezendeNo ratings yet

- DR Fixit General Repair Remedial Waterproofing Guide PDFDocument40 pagesDR Fixit General Repair Remedial Waterproofing Guide PDFandrealeger755774No ratings yet

- A Practical Course in Advanced Structural DesignDocument25 pagesA Practical Course in Advanced Structural DesignAndrés Juárez Sánchez100% (1)

- ProgrammeDocument2 pagesProgrammeAdrienNo ratings yet

- Lemn Pin FinlandezDocument16 pagesLemn Pin FinlandezRoxana HuțanuNo ratings yet

- 5.0 Design of Top Ring BeamDocument3 pages5.0 Design of Top Ring BeamJayNo ratings yet

- Revised Mix VarrocPolymers 111223Document1 pageRevised Mix VarrocPolymers 111223kkkdjNo ratings yet

- Construction Quality and MaintenanceDocument40 pagesConstruction Quality and MaintenanceRamesh AnanthanarayananNo ratings yet

- 350.2R-04 - Concrete Structures For Containment Hazardous Materials PDFDocument17 pages350.2R-04 - Concrete Structures For Containment Hazardous Materials PDFEduardo Quezada LarenasNo ratings yet

- M04 Rebar WorksDocument66 pagesM04 Rebar WorksReynaldo LugtuNo ratings yet

- 4 Equivalent Frame MethodDocument16 pages4 Equivalent Frame MethodwieirraNo ratings yet

- 7.7.1.4 Trusses SpecificationsDocument3 pages7.7.1.4 Trusses Specificationsishaan choudharyNo ratings yet

- Daftar Pustaka Pengaruh Inhibitor Anodik NaNO3 Dan Na2CrO4 Terhadap Korosi Dan Fatik Korosi Pada Aluminium Paduan AA 7050 Di Lingkungan 3.5% NaClDocument4 pagesDaftar Pustaka Pengaruh Inhibitor Anodik NaNO3 Dan Na2CrO4 Terhadap Korosi Dan Fatik Korosi Pada Aluminium Paduan AA 7050 Di Lingkungan 3.5% NaClPramesti Ayu Dwi WulandariNo ratings yet

- STR DWG ChecklistDocument2 pagesSTR DWG Checklistomar42170No ratings yet

- A2 Historia de Freyssinet ACI CI Octubre 2013 PDFDocument117 pagesA2 Historia de Freyssinet ACI CI Octubre 2013 PDFJancarlo Mendoza MartínezNo ratings yet

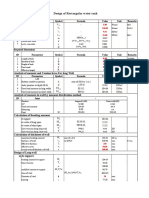

- Design of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit RemarksDocument5 pagesDesign of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit Remarkskiran_karki_8No ratings yet

- Solve Problem 883 Using Moment Distribution MethodDocument2 pagesSolve Problem 883 Using Moment Distribution Methodanil basnetNo ratings yet

- Limit States Method (Cec402 Assignment of Group3a)Document50 pagesLimit States Method (Cec402 Assignment of Group3a)Kingshuk MukherjeeNo ratings yet

- INDUSTRY GUIDE T38 Reinforced Concrete Design in Accordance With AS3600 PDFDocument225 pagesINDUSTRY GUIDE T38 Reinforced Concrete Design in Accordance With AS3600 PDFEden De Guzman100% (1)

- Behavior of Concrete and Ecc Structures Under Simulated Earthquake MotionDocument49 pagesBehavior of Concrete and Ecc Structures Under Simulated Earthquake Motionsreejithp104No ratings yet

- NOTES SeviceabilityDocument81 pagesNOTES Seviceabilitydileep 443No ratings yet

- Fatigue Life Assessment of An Excavator Arm BoxDocument6 pagesFatigue Life Assessment of An Excavator Arm BoxThanh Duc NguyenNo ratings yet

- Brochure - INSDAG Civil Competition 2021Document7 pagesBrochure - INSDAG Civil Competition 2021Mani MohanNo ratings yet