Professional Documents

Culture Documents

Development of A Laboratory Test Program To Examine Human-Structure Interaction

Uploaded by

anonymphantomOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development of A Laboratory Test Program To Examine Human-Structure Interaction

Uploaded by

anonymphantomCopyright:

Available Formats

Chapter 2

Development of a Laboratory Test Program to Examine Human-Structure Interaction

Nicholas C. Noss and Kelly A. Salyards

Abstract Vibration serviceability is a widely recognized design criterion for assembly-type structures likely subjected to rhythmic human-induced excitation. Current design guidance is based on the natural frequency of the structure. However, a phenomenon known as human-structure interaction suggests that there is a dynamic interaction between the structure and the occupants, altering the natural frequency of the system. It is unknown if this shift in natural frequency is signicant enough to warrant consideration in the design process. Therefore, there is a need to identify the circumstances under which humanstructure interaction should be considered because of its potential impact on serviceability assessment. Because the inuence of the structural properties on human-structure interaction cannot be separated from the inuence of the crowd characteristics, this study explores the interface of both factors through experimental testing. To do so, a laboratory test structure is designed, constructed, and operated based on particular design criteria selected with knowledge from previous human-structure interaction studies. This study provides a review of the design and construction of the test structure, methods used to validate a nite element computer model to the as-built structure, and the experimental testing procedure for testing with occupants. Keywords Human-structure interaction Experimental modal analysis Crowd dynamics

2.1

Introduction

Assembly-type structures are subjected to dynamic loading generated by the crowd occupying the structure. Motion of the crowd has the potential to induce vibrations that may be of concern to the occupants. Structural engineers refer to this as vibration serviceability. Vibration serviceability is of particular concern when the crowd is synchronized in its movement creating a signicant dynamic force on the structure. Because structural designs are utilizing higher-strength materials and advanced analysis methods, assembly-type structures are designed and constructed with longer and lighter spans which are more susceptible to excitation by such crowd motion. It is likely that these structures have a fundamental frequency in the range of 48 Hz [1] which corresponds to the frequency range over which humans are most sensitive to vibrations. Occupants of such structures can perceive and be disturbed by these vibrations and if vibrations are excessive [2], widespread panic can occur amongst the crowd, ultimately risking the safety of the occupants. For these reasons, it is important that research continues in the area of vibration serviceability to improve upon the design guidance currently available to structural engineers. In the United States, the design guidance available for the vibration serviceability design of assembly-type structures subjected to rhythmic excitation is limited. Design for rhythmic excitation is addressed in guidance published by the American Institute of Steel Construction (AISC) for oor structures [2]. This guidance species a minimum natural frequency of the structure to be achieved such that resonance with the expected rhythmic excitation is avoided. It assumes that only a single mode of vibration contributes to the dynamic response of the structure and also requires the identication of an appropriate acceleration limit for the purpose of the space. Whilst these assumptions may be reasonable for oor structures, the application of such assumptions to other types of structures, such as stadium grandstands, can be

N.C. Noss (*) K.A. Salyards Department of Civil and Environmental Engineering, Bucknell University, Lewisburg, PA 17837, USA e-mail: nick.noss@bucknell.edu; kas046@bucknell.edu J.M. Caicedo et al. (eds.), Topics on the Dynamics of Civil Structures, Volume 1, Conference Proceedings of the Society for Experimental Mechanics Series 26, DOI 10.1007/978-1-4614-2413-0_2, # The Society for Experimental Mechanics, Inc. 2012 7

N.C. Noss and K.A. Salyards

inappropriate. In addition, this guidance, along with others, utilizes the natural frequency of the empty structure for its assessment of serviceability. Although this may be representative of the extreme condition where all occupants are actively engaged in the rhythmic loading, it may not address all possible scenarios where some occupants are not engaged in the motion. In addition, it has been observed by several researchers that the natural frequency of a structural system is also affected by another phenomenon. This phenomenon is known as human-structure interaction and addresses how occupants act more as a spring-mass-damper system rather than mass alone, ultimately affecting the dynamic properties of the overall structural system. The majority of these observations indicate that the natural frequency of the system is decreased from that of the empty structure and the damping ratio is increased from that of the empty structure [3]. This is potentially problematic because the natural frequency could be lowered into a frequency range excitable by rhythmic loading. A short discussion of these observations, ensuing research, and the current guidance for incorporating such effects aims to provide the impetus for the research described in this paper.

2.2

Evidence of Human-Structure Interaction

The human-structure interaction phenomenon was rst acknowledged in 1966 in a oor vibration study by Lenzen at the University of Kansas [4]. It was not further examined until 1991 when in-situ monitoring of a stadium grandstand structure provided further evidence of this interaction with a lower natural frequency when the structure is occupied along with an additional mode of vibration [5]. The natural frequency of another assembly structure was found to be reduced from 16 Hz to around 5 Hz when occupied by a crowd [5]. Littler [6] provided further evidence of human-structure interaction, including its dependence on posture, through the in-situ testing of several retractable grandstands. These results from in-situ testing prompted further investigation and laboratory testing. Experimental testing was performed in the laboratory by several researchers on simple structures. Ellis [7] examined the effects of human-structure interaction on a simply supported concrete beam (fn 18.68 Hz) with a single individual. Similarly, Brownjohn [8] explored the effects of a single individual on a precast plank (fn 3.16 Hz) varying posture. Falati [9] advanced the previous studies by examining the effects of two people on a concrete structure. Yao et al. [10, 11] expanded the range of structural frequencies examined through the use of a testing rig with a single individual. These laboratory experiments provide additional evidence of the phenomenon but are limited in their direct application because they utilize only one or two people. The experimental evidence indicates that the crowd behaves as a dynamic spring-mass-damper system attached to the supporting structure. Several analytical studies have been undertaken to provide guidance for modeling this type of combined system and to identify the appropriate dynamic properties of the system representing the crowd. Several numerical models have been developed to model the human body for civil engineering applications [9, 12, 13]. Dougill et al. [14] provides a detailed modeling theory that accounts for human-structure interaction for structures with a single dominant natural frequency. Yet, no guidance for incorporating the human-structure interaction into the design process had been presented prior to 2008. In 2000, a Joint Working Group was formed with members from the Institution of Structural Engineers (IStructE), the Department for Transport, Local Government (DTLG), and the Regions and Department for Culture, Media and Sport (DCMS) in the United Kingdom. This Joint Working Group published comprehensive design guidance aimed specically toward grandstands entitled Dynamic Performance Requirements for Permanent Grandstands Subject to Crowd Action [15]. Currently, this publication is the only to address the human-structure interaction phenomenon, recognizing that previous recommendations for grandstands with dense crowd loading and natural frequencies below 7 Hz gave insufcient consideration to the nature of the loading or to the effects of the mechanical interaction between individuals and the structure [15]. The recommendations for modeling are based on Dougills analytical results [14] which have been corroborated with experimental measurements from bobbing on a exible test rig structure at the University of Manchester. Additional experimental results are desirable to further validate the modeling recommendations.

2.3

Overview of Experimental Study

The test structure described herein is critical to the planned experimental investigation of the effects of human-structure interaction. The test structure is specically design to represent a range of dynamic properties representative of cantilevered grandstands. The planned study addresses how crowd characteristics, such as posture and location, combine with structural characteristics, such as frequency and mass, to inuence the dynamic properties of the combined system. Several of the

2 Development of a Laboratory Test Program to Examine Human-Structure Interaction

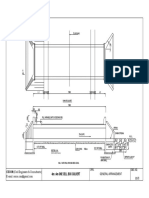

limitations of previous experimental studies, as referenced above, are addressed in this study. One such limitation is the experimental consideration of a structure occupied by more than a single individual. In addition, this study is designed to investigate a wider range of natural frequencies of the structure as opposed to previous studies or experimental measurements which were limited to a single frequency of the constructed structure. The objectives of the experimental work are: 1. To experimentally identify the circumstances for which the effects of human-structure interaction should be considered because of its potential impact on serviceability assessment. 2. Provide experimental evidence of the inuence of structure and crowd characteristics on the recommended dynamic parameters for an appropriate crowd model. To accomplish these objectives, a cantilevered steel test structure was designed as shown in Fig. 2.1. The natural frequency of the empty structure can be varied between 4.35 and 6.25 Hz or higher through the relocation and addition of supports which fasten to the wide-ange shape support beams. The test structure accommodates a maximum of nine passive occupants in various postures and locations on a concrete plank decking surface. The constructed structure is shown in Fig. 2.2. Experimental testing is planned to determine the dynamic properties of the human-structure system and how it is inuenced by the structural and crowd characteristics when the test structure is occupied.

14 9 Tube Steel Superstructure 6

2 9 Tube Steel Shaker Frame Moveable Support (Uplift) Moveable Support Wide Flange Support Beam Concrete Planking 6

Fig. 2.1 Conceptual model of the cantilevered test structure

Fig. 2.2 As-built cantilevered test structure

10

N.C. Noss and K.A. Salyards

This paper will describe how the conditions for the study are achieved through the design and construction of the test structure. A summary of the design and construction of a cantilevered test structure with a tunable fundamental natural frequency is presented rst. The process of how experimental modal analysis, using shaker excitation and acceleration response, is employed to determine the dynamic properties and validate the nite element model of the structure is described.

2.4

Test Structure Design and Construction

This section describes how the required conditions for the experimental study are translated into design criteria implemented in the design and construction of the cantilevered test structure. The conditions to be met for the study include: 1. The test structure must safely accommodate small groups of individuals that have a combined mass which is in a desired proportional range to the mass of the empty structure. 2. The test structure must have dynamic properties that are representative of typical cantilevered grandstands. 3. The natural frequency of the test structure must be adjustable through the relocation and/or addition of supports. 4. Data collection techniques must yield reliable experimental data. A detailed description of the geometry and layout of the test structure is given before addressing the specic design criteria.

2.4.1

Geometry and Layout

A cantilevered test structure is chosen for this study because cantilevers are widely used in assembly type structures, like stadiums, for the benet of improved sightlines. However, they are often subject to vibration serviceability issues. The typical fundamental frequency range for cantilevered stadium sections is between 4 and 8 Hz [1], which can be achieved in a small scale experimental test structure. During the design phase a nite element model of the test structure was created in SAP2000 [16]. Initial design consisted of experimenting with various structural congurations, cantilever lengths, support conditions and material types. Controlling factors leading to the nal design were the target frequency range, material stresses, and the deection of the cantilever. The nal design resulted in a test structure with a fundamental frequency ranging from 4.35 to 6.25 Hz with only two supports and higher with the addition of a third support. The base dimensions of the structure measures 14.750 long by 60 wide. The structural conguration that results in a lower bound natural frequency of 4.35 Hz was achieved with a 60 backspan and a 60 concrete decking surface. The decking surface is constructed of reinforced concrete planks (1200 W 7200 L 5.2500 D) spanning between the cantilevered sections. The last 2.750 of the test structures cantilever provides a mounting location for the electrodynamic shaker. Increasing the natural frequency of the test structure from a range of 4.356.25 Hz is accomplished through shortening the length of the decking surface from 60 to 40 by moving a knife edge support in 400 increments. The natural frequency of the test structure can be further increased though the addition of a support on the backspan of the structure as depicted in Fig. 2.3. The constructed connections are depicted in Fig. 2.4. A steel bushing connection in Fig. 2.4a was fabricated to represent an idealized pinned condition to restrain vertical, horizontal, and lateral movement. The pin was oiled to reduce friction and wear. The connection in Fig. 2.4b was designed and constructed to restrain vertical movement along the backspan of the test structure. A pin and eyebar connected to a knife edge support reduces deection on the backspan of the test structure, increasing the natural frequency. The connection depicted in Fig. 2.4c is a knife edge support located at

CONCRETE PLANKING TUBE STEEL SUPERSTRUCTURE SHAKER FRAME

MOVEABLE SUPPORTS

WIDE FLANGE SUPPORT BEAM

Fig. 2.3 Elevation view of the test structure

2 Development of a Laboratory Test Program to Examine Human-Structure Interaction Fig. 2.4 (a) Pin support, (b) moveable backspan support, (c) moveable knife edge support

11

the transition between the backspan and the cantilever. This support will always remain in compression. Steel plates are attached to the knife support to reduce lateral movement of the tube steel superstructure. The movable supports are bolted to wide-ange beams (W8 48) that have holes drilled along their top ange every 400 . The support beams were used for two main reasons. The support beams distribute the concentrated compressive and uplift forces from the supports along the length of the beam through the laboratory slab-on-grade. The support beams also provide a safe, consistent, and fast method for movement of the supports when adjusting the natural frequency of the test structure. The movable supports can be relocated and/or added by lifting the structure with a hydraulic bottle jack located under the tube steel frame at the end of the cantilevered decking surface, effectively removing the load from the supports temporarily.

2.4.2

Design and Materials

The test structure was designed using Load and Resistance Factor Design (LRFD) for static loading. ASCE 710: Minimum Design Loads for Buildings and Other Structures [17] recommends 100 psf live loading for stadium seating. This loading was compared to situations where nine individuals at 95th percentile weight (255 lb) were represented in the nite element model occupying the structure in loading scenarios that would be considered extreme for this type of experimental testing. An example of an extreme situation would be where all nine occupants are located within 3 ft of the end of the cantilevered decking surface; another would be unbalanced loading where all of the occupants would be located to one side of the structure. The ASCE 710 recommended static live loading of 100 psf on 36 ft2 of the decking surface produced higher bending stresses and reaction forces than that of the extreme loading conditions described above. The superstructure of the test structure was constructed of 500 400 3/1600 tube steel sections with a minimum yield stress of 46 ksi. These steel tubes provided the exibility for a low fundamental frequency of the structure, yet still remained in the elastic bending range for the factored dead and live loads applied. However the deection of the cantilever is quite noticeable when loaded to capacity. The deection of the cantilever under design load condition is approximately 0.82 in., which is in the range of L/90 where L is the length of the cantilever. This is slightly more than the recommended cantilever deection of L/140 [18]. The recommended deection limit is not applicable as the structure is not attached to other systems which would be impacted and the deection is not likely to be visually objectionable to the occupants as it is a test structure and not a regularly occupied structure. The 500 400 3/1600 tube steel sections are also considered compact eliminating the potential for local buckling; this is not the case for wide ange beams with a similar stiffness. The natural frequencies of vibration modes in the horizontal direction are increased with a higher moment of inertia in the lateral bending direction provided by the tube steel and the addition of the tube steel shaker frame attached to the end of the cantilevered decking surface. Reinforced concrete planks (1200 W 7200 L 5.2500 D) are designed to span from one tube steel cantilever to another, using a maximum of six planks to provide 36 ft2 of decking surface for the occupants. The connection between the concrete

12

N.C. Noss and K.A. Salyards

planks and the steel structure is a simple gravity connection. The decking surface was designed as reinforced concrete planking for the following reasons: 1. Additional mass was needed to achieve the lower bound of frequency at 4.35 Hz and the desired mass ratio range of 0.060.58. 2. Narrow planks without a mechanical connection to the steel structure limit the level of potential composite action of the cantilever. 3. Reinforced concrete planks are sufciently rigid to resist excitation of local vibrations modes of the decking surface caused by occupants. 4. Planks can be added or removed to change the length of the cantilevered decking surface.

2.4.3

Occupancy and Mass Ratio

The test structure was designed to accommodate small groups of individuals in either standing postures or seated positions. It was determined that a test structure with an occupant capacity of nine people would provide additional insight into the human-structure interaction phenomenon when compared to previous experimental testing that used only one or two occupants on a structure. Previous research, along with the recommended modeling guidance, suggest that the relative size of the crowd compared with the size of the structure can be a factor in the level of interaction between the occupants and the structure [3, 15], this can be interpreted as a function of the crowd and structure mass. Mass ratio is dened to be the ratio of the combined mass of the occupants to the mass of the empty structure [5]. A mass ratio of 0.250.75 is suggested for typical stadiums at full capacity [19]. Previous laboratory studies involving test structures used to investigate human-structure interaction had estimated mass ratios ranging from 0.067 to 0.431 [8, 20]. Further investigation of several in-service stadiums has shown that mass ratios vary between 0.27 and 0.63 at full occupancy based on ASCE 710 recommended live loading for stadium structures. For this study, the upper mass ratio was chosen to be roughly 0.60 when the test structure is at full capacity with nine occupants. Knowing the desired mass ratio and number of occupants at full capacity, the weight of the empty structure is estimated by assuming an average weight of each occupant. Studies have indicated that the average weight of an adult is 180 lb [15]. Therefore, the weight of the empty test structure is designed to be 2,800 lb in order to achieve the desired mass ratio range. The platform size for the occupants is determined based on the space needed for an occupant to be in either a seated or standing position. An area of four square feet per occupant was deemed adequate.

2.5

Finite Element Model

The original nite element model used for the design of the test structure was created in SAP2000. The model was constructed of nodes and frame elements that represent the 500 400 3/1600 tube steel members and 1200 7200 5.2500 concrete planks as shown in Fig. 2.5. Nodes of the model are at locations of support conditions and accelerometer locations.

Fig. 2.5 SAP2000 nite element frame model

2 Development of a Laboratory Test Program to Examine Human-Structure Interaction Fig. 2.6 Frequency response function (FRF) created from SAP2000 modal results and compared with the corresponding experimentally measured FRF

13

The wide ange support beams were not modeled in SAP2000 because they are a rigid base for the supports. During the modeling process, several assumptions were made when creating the original nite element model: 1. Pin connections of the as-built test structure are frictionless and allow free rotation. 2. The gravity connection between the concrete planks and the tube steel cantilever beams are best modeled as a pin connection. 3. Material properties from the AISC database in SAP2000 are representative of the materials used during actual construction. 4. The geometry of the as-built structure is identical to the geometry of the nite element model (no fabrication or installation errors). The test structure was designed and constructed based on the nite element model and the above assumptions. Strength design of the structure is of the utmost concern for safety; however the dynamic properties such as natural frequency and modes shapes are also of particular interest in this study. SAP2000 is used to perform modal analysis to determine vibration modes of the modeled structure using Eigenvector analysis for undamped free-vibration modes and frequencies. The modal displacements at the accelerometer locations and natural frequencies of the modeled test structure are used to generate a series of analytical frequency response functions, illustrated in Fig. 2.6, to aid in the validation of the nite element model by comparison with experimentally measured frequency response functions from the as-built test structure.

2.6 2.6.1

Validation of Design Experimental Testing

In order to better understand the behavior of the as-built test structure and validate the original nite element model created in SAP2000, dynamic properties of the empty test structure are determined using experimental modal analysis (EMA). EMA is based on the evaluation of the dynamic response of a structure due to a known excitation force. A swept-sine dynamic force is applied to the structure through the use of an electrodynamic shaker located on the end frame of the cantilever. The acceleration response of the structure is measured by accelerometers that are attached to the steel superstructure at various locations. The input force and the acceleration response are analytically combined to form a frequency response function in the eZ-Analyst data acquisition software [21]. From these response functions, modal properties such as natural frequencies, damping ratios, and mode shapes were estimated using curve-tting techniques utilizing Vibrant Technologys MEscopeVES 5.0 [22].

14 Fig. 2.7 Accelerometer attachment to the armature of the shaker

N.C. Noss and K.A. Salyards

Ten PCB model 393A03 uniaxial seismic accelerometers are fastened using threaded steel studs at locations along the backspan and cantilever of the steel superstructure. The excitation source for cantilevered test structure is an APS Dynamics, Model 400 electrodynamic shaker. The sinusoidal input force from the shaker is calculated using the acceleration response and mass of the shaker armature. A PCB model 393A03 uniaxial accelerometer was attached to the armature to measure acceleration as shown in Fig. 2.7. The data acquisition system for this study, an IOTech Wavebook 516E with WBK18 signal conditioning module, is connected to a computer and used in conjunction with eZ-Analyst software to output and collect real-time voltage signals. Amplied output voltages operate the shaker over a frequency range of 150 Hz in an 8 s time frame. The sampling rate for data collection is 128 samples/s corresponding to a frequency step of 0.125 Hz over a bandwidth of 50 Hz. The experimental data collection plan consists of collecting a minimum of three individual data sets for each experimental conguration of the empty test structure. Each of the data sets is a linear average of a minimum of three complete cycles of the electrodynamic shaker (24 s of data). The test structure was also loaded with steel weights to simulate an equivalent mass test from 500 to 2,000 lb in 500 lb increments. EMA was used to determine the modal properties associated with each conguration of the test structure and static deections were measured along the backspan and cantilever.

2.7

Results

The modal parameters of the as-built test structure varied slightly from the analytical modal results of the original nite element model, despite the highest attention to detail and acceptable tolerances during the construction of the structure. The natural frequencies of the test structure determined from EMA were slightly higher than the natural frequencies predicted by the model. Two contributing factors to the inconsistency are the inappropriate modeling of the connections, and the slight imprecision in the cross-sectional properties of the structural steel sections. The reinforced concrete planks were originally modeled as pin-connected to the tube steel since they bear directly on top of the cantilevered tube steel beams. However, an increase in frequency of the torsional mode of the structure indicates that the planks add stiffness to the second mode of vibration which is a torsional mode of the cantilevered section. The connection was adjusted in the FE model to a xed connection as most modeling guidance suggests for vibration serviceability. However, the frequency of the torsional mode increased beyond that of the as-built structure. As a result, the plank connection to the cantilevered tube steel beam is modeled as a rotational spring to simulate the torsional behavior of the as-built test structure. The nite element model was further modied by updating the cross sectional properties of the 500 400 3/1600 tube steel to represent the actual dimensions of the tube steel that was used in the construction the test structure. The changes were

2 Development of a Laboratory Test Program to Examine Human-Structure Interaction Table 2.1 Comparison of analytically predicted and experimentally measured natural frequencies 40 deck, 50 cantilever 60 deck, 60 cantilever Mode 1 2 3 FE model (Hz) 4.36 15.8 28.0 Experimental (Hz) 4.35 15.8 30.5 FE model (Hz) 5.05 16.7 33.0 Experimental (Hz) 5.00 15.4 32.0

15

40 deck, 40 cantilever FE model (Hz) 6.33 22.6 40.8 Experimental (Hz) 6.25 19.1 36.4

slight; resulting in deviations of a few thousandths of an inch from the AISC specied properties. This simple updating of cross sectional properties affected the natural frequency by approximately 0.1 Hz bringing it in line with the experimental results. The updated nite element model is able to satisfactorily represent the dynamic behavior of the structure for a range of support conditions for the empty structure and for each phase of the equivalent mass testing previously described. The FE model is also able to replicate the static deection associated with the equivalent mass testing. The natural frequencies identied in the FE model for the rst three modes are compared to the experimentally determined natural frequencies in Table 2.1 for three congurations of the adjustable test structure. The comparison is reasonable for the rst mode of vibration for all three congurations. The second and third modes are less critical for this study as the effect of human-structure interaction is likely to be more dominant in the rst mode of vibration. In addition to the numerical comparison of natural frequencies, the frequency response functions analytically synthesized from the updated nite element model are compared to the experimentally measured frequency response functions. One such comparison is shown in Fig. 2.6. The initial comparison between the synthesized FRF and the experimental FRF is visual. Key features that should align are the location, magnitude, and slope leading to the peaks of the FRF. Further evaluation will be made by comparing the mode shapes of the nite element model to the experimental test data using the modal assurance criterion (MAC). Additional model updating is currently being pursued to further enhance the agreement of higher modes of vibration.

2.8

Summary

The design and construction of a cantilevered test structure has been described as it applied to the experimental investigation of the effects of human-structure interaction and its potential impact on serviceability assessment. The test structure is representative of a cantilevered grandstand with respect to its natural frequency and cantilever construction. This test structure has been specically designed to allow for the relocation and/or addition of support conditions providing the ability to adjust the natural frequency. The design considerations pertaining to the planned experimental study and the associated design criteria have been presented. A FE model of the test structure has been created and updated. The dynamic properties of the test structure in its empty condition were determined using experimental modal analysis; this data was used in the preliminary validation of this nite element model. The test structure described herein is to be utilized in the experimental program currently underway investigating human-structure interaction.

References

1. Comer A, Blakeborough A, Williams MS (2010) Grandstand simulator for dynamic human-structure interaction experiments. Exp Mech 50 (6):825834 2. Murray TM, Allen DE, Ungar EE (1997) Floor vibrations due to human activity, Steel design guide series, no. 11. American Institute of Steel Construction (AISC), Chicago 3. Sachse R, Pavic A, Reynolds P (2003) Human-structure dynamic interaction in civil engineering dynamics: a literature review. Shock Vib Digest 35:318 4. Lenzen KH (1966) Vibration of steel joist-concrete slab oors. AISC Eng J (6th Ser) 3:133 5. Ellis BR, Ji T (1997) Human-structure interaction in vertical vibrations. Proc Inst Civil Eng Struct B 122(1):19 6. Littler JD (1998) Full-scale testing of large cantilever grandstands to determine their dynamic response. In: Thompson PD, Tolloczko JJA, Clarke JN (eds) Stadia, arenas and grandstands. E and FN Spon, London, pp 123134 7. Ellis BR, Ji T (1994) Floor vibration induced by dance-type loads: verication. Struct Eng 72(3):4550 8. Brownjohn JMW (1999) Energy dissipation in one-way slabs with human participation. In: Proceedings of Asia-Pacic vibration conference, vol 1. Nanyang Technological University, Singapore 9. Falati S (1999) The contribution of non-structural components to the overall dynamic behavior of concrete oor slabs. Thesis, University of Oxford, Oxford

16

N.C. Noss and K.A. Salyards

10. Yao S, Wright J, Pavic A, Reynolds P (2004) Experimental study of human-induced dynamic forces due to bouncing on a perceptibly moving structure. Can J Civil Eng 31(6):11091118 11. Yao S, Wright JR, Pavic A, Reynolds P (2006) Experimental study of human-induced dynamic forces due to jumping on a perceptibly moving structure. J Sound Vib 296:150165 12. Sim JH (2006) Human-structure interaction in cantilever grandstands. Thesis, University of Oxford, Oxford 13. Ji T, Ellis BR (1995) Human actions on structures. Soc Earthquake Eng Civil Eng Dyn (SECED) Newsl (ICE) Autumn, 45 14. Dougill JW, Wright JR, Parkhouse JG, Harrison RE (2006) Human structure interaction during rhythmic bobbing. Struct Eng 84(22):3239 15. Institution of Structural Engineers (2008) Dynamic performance requirements for permanent grandstands subject to crowd action, IStructE/DTLR/DCMS working group on dynamic performance and design of stadia structures and seating decks. Institution of Structural Engineers, London 16. SAP2000 (2011) Overview, Computers and Structures, Inc. http://www.csiberkeley.com/sap2000. Accessed 16 Sep 2011 17. American Society of Civil Engineers (2010) Minimum design loads for buildings and other structures. ASCE/SEI 710, Reston 18. American Institute of Steel Construction (2007) Steel construction manual, 13th edn. American Institute of Steel Construction, Chicago 19. Dougill JW (2005) Recommendations for design of grandstands subject to dynamic crowd excitation. In: Proceedings of the 6th European conference on structural dynamics (EURODYN 2005). European Association for Structural Dynamics (EASD), Munich, pp 491496 20. Firman RJ III (2010) Investigating the effects of various crowd characteristics on the dynamic properties of an occupied structure. Thesis, Bucknell University, Lewisburg 21. IOtech eZ-Series (2011) Analysis software for IOtech devices National instruments. http://sine.ni.com/nips/cds/view/p/lang/en/nid/208342. Accessed 13 Sep 2011 22. Vibrant Technology, Inc. (2011) Modal analysis, ODS, acoustic, and nite element analysis software (MEscope). http://www.vibetech.com/ go.cfm/enus/content/index. Accessed 13 Sep 2011

http://www.springer.com/978-1-4614-2412-3

You might also like

- DLRB Design ReportDocument61 pagesDLRB Design ReportRaviTeja100% (2)

- Modeling and Analysis of Soil-Pile InteractionDocument21 pagesModeling and Analysis of Soil-Pile InteractionLhester NavascaNo ratings yet

- Rigid Frame Structure ThesisDocument109 pagesRigid Frame Structure ThesisAdil Khan Hasan KhailNo ratings yet

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberDocument27 pagesThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberIrfan SyafriNo ratings yet

- Step by Step Deflection Analysis Using CSI SAFEDocument18 pagesStep by Step Deflection Analysis Using CSI SAFEhahaer100% (1)

- Shell Analysis PDFDocument27 pagesShell Analysis PDFafzalNo ratings yet

- Recent Advances in Pile Foundation - BCM SeminarDocument15 pagesRecent Advances in Pile Foundation - BCM Seminarapi-19915731No ratings yet

- IEC/EN 60204-1: Appliance of Reference Designations On Machinery in Accordance With ISO/IEC/EN 81346Document24 pagesIEC/EN 60204-1: Appliance of Reference Designations On Machinery in Accordance With ISO/IEC/EN 81346soleil_ro100% (1)

- High-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441Document13 pagesHigh-Strength Concrete Columns: State of The Art: Repor Ted by Joint ACI-ASCE Committee 441DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Damping of StructuresDocument231 pagesDamping of StructuresMarcel Toruño MendezNo ratings yet

- Batching Plant Installation Schedule With Comment Rev 24september2017Document1 pageBatching Plant Installation Schedule With Comment Rev 24september2017crys suryo prayogo100% (1)

- Sample EstimateDocument12 pagesSample EstimateAngelli Juelar Naigan100% (1)

- Retaining Wall PDFDocument34 pagesRetaining Wall PDFMatni La100% (1)

- Progressive Collapse Analysis of Structures: Numerical Codes and ApplicationsFrom EverandProgressive Collapse Analysis of Structures: Numerical Codes and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Dynamic analysis of composite floor systems under human walking loadsDocument10 pagesDynamic analysis of composite floor systems under human walking loadsOmar CaballeroNo ratings yet

- DaSilva&Vellasco&Andrade-An Evaluation of The Dynamical Performance of Composite SlabsDocument9 pagesDaSilva&Vellasco&Andrade-An Evaluation of The Dynamical Performance of Composite SlabsOmar CaballeroNo ratings yet

- Perception of Motion Criteria For Tall Buildings Subjected To WindDocument2 pagesPerception of Motion Criteria For Tall Buildings Subjected To WindLatanya JenkinsNo ratings yet

- Structures: K. Van Nimmen, A. Pavic, P. Van Den BroeckDocument16 pagesStructures: K. Van Nimmen, A. Pavic, P. Van Den BroeckCamilo GalindoNo ratings yet

- Resm2023 25me0915rsDocument13 pagesResm2023 25me0915rsGaddam KalpanaNo ratings yet

- Human-Structure Dynamic Interaction in Civil EnginDocument54 pagesHuman-Structure Dynamic Interaction in Civil EnginJAIME ANDRES GUEVARA RIVERANo ratings yet

- Scale Effects On Structural Dynamic Properties andDocument13 pagesScale Effects On Structural Dynamic Properties andSuresh HubballiNo ratings yet

- Literature Review 2Document4 pagesLiterature Review 2K.ANISHNo ratings yet

- Soil - Structure Interaction Analysis of Pile Foundations Subjected To Dynamic LoadsDocument17 pagesSoil - Structure Interaction Analysis of Pile Foundations Subjected To Dynamic LoadsAkash ChordiyaNo ratings yet

- Engineering Structures: Sigong Zhang, Lei Xu, Jingwei QinDocument14 pagesEngineering Structures: Sigong Zhang, Lei Xu, Jingwei QinAngel CristhianNo ratings yet

- Gao, Weihang Et Al - 2021 - Time Reversal Damage Localization in Concrete Based On Two-DimensionalDocument14 pagesGao, Weihang Et Al - 2021 - Time Reversal Damage Localization in Concrete Based On Two-Dimensionalxiaohui sunNo ratings yet

- Direct displacement-based seismic design of flexible-base structures for pulse-like ground motionsDocument23 pagesDirect displacement-based seismic design of flexible-base structures for pulse-like ground motionsMunyaNo ratings yet

- Bahareh, Dilshan 2020 Hybrid Simulation of A Structure To A Tsunami LoadingDocument19 pagesBahareh, Dilshan 2020 Hybrid Simulation of A Structure To A Tsunami LoadingYashintha PandukaNo ratings yet

- Pem Saikat ManoharDocument13 pagesPem Saikat ManoharhamadaniNo ratings yet

- Structures: P.M. Stylianidis, D.A. Nethercot, B.A. Izzuddin, A.Y. ElghazouliDocument16 pagesStructures: P.M. Stylianidis, D.A. Nethercot, B.A. Izzuddin, A.Y. ElghazouliRatul RanjanNo ratings yet

- Sensing and Monitoring For Stadium Structures: A Review of Recent Advances and A Forward LookDocument18 pagesSensing and Monitoring For Stadium Structures: A Review of Recent Advances and A Forward LookAnonymous X5tjPm268No ratings yet

- Elastic Plastic Response Spectra For Exponential Blast LoadingDocument21 pagesElastic Plastic Response Spectra For Exponential Blast LoadingNanny LeeNo ratings yet

- Engineering Structures: Kapil Khandelwal, Sherif El-TawilDocument9 pagesEngineering Structures: Kapil Khandelwal, Sherif El-TawiltirursachinNo ratings yet

- Earthq Engng Struct Dyn - 2016 - Mirzaie - Probabilistic Analysis of Soil Structure Interaction Effects On The SeismicDocument20 pagesEarthq Engng Struct Dyn - 2016 - Mirzaie - Probabilistic Analysis of Soil Structure Interaction Effects On The SeismicAkhilesh WableNo ratings yet

- Mid Semester ReportDocument26 pagesMid Semester ReportBewitchedHombreNo ratings yet

- J Ijnonlinmec 2017 09 005Document23 pagesJ Ijnonlinmec 2017 09 005Nabin KalauniNo ratings yet

- Escholarship UC Item 9t09660mDocument13 pagesEscholarship UC Item 9t09660mpradeepjoshi007No ratings yet

- Finite Element Modelling of Soil-Structure Interaction: Jurnal Teknologi May 2015Document6 pagesFinite Element Modelling of Soil-Structure Interaction: Jurnal Teknologi May 2015IMJ JNo ratings yet

- Advanced Topics in Offshore Wind Turbines Design: Franco - Bontempi@uniroma1.itDocument11 pagesAdvanced Topics in Offshore Wind Turbines Design: Franco - Bontempi@uniroma1.itkhalijimhNo ratings yet

- 2016 Chen Li Racic Eng StuDocument10 pages2016 Chen Li Racic Eng StuOmar CaballeroNo ratings yet

- Med16 2Document7 pagesMed16 2Haile SimachewNo ratings yet

- Offshore Wind Turbines Structural Design AnalysisDocument25 pagesOffshore Wind Turbines Structural Design Analysispasanac77No ratings yet

- Structural Reliability YaoDocument5 pagesStructural Reliability YaoAbdul Hamid HamatNo ratings yet

- G01 Zhou2017 Article DamageAssessmentByStiffnessIdeDocument20 pagesG01 Zhou2017 Article DamageAssessmentByStiffnessIdeIZPNo ratings yet

- Incremental Dynamic Analysis For Estimating Seismic Performance Sensitivity and UncertaintyDocument23 pagesIncremental Dynamic Analysis For Estimating Seismic Performance Sensitivity and UncertaintyJefferson Piedrahita GonzalezNo ratings yet

- Experimental Studies On Progressive Collapse Behavior of RC Frame Structures: Advances and Future NeedsDocument23 pagesExperimental Studies On Progressive Collapse Behavior of RC Frame Structures: Advances and Future NeedsDr. M.V.Krishna RaoNo ratings yet

- Yuan XiaoliDocument248 pagesYuan XiaoliBlack SkyNo ratings yet

- Torsional Parameters Importance in The Structural Response of Multiscale Asymmetric-Plan BuildingsDocument20 pagesTorsional Parameters Importance in The Structural Response of Multiscale Asymmetric-Plan BuildingsDuc Linh DangNo ratings yet

- Engineering Structures: M. Latour, V. Piluso, G. RizzanoDocument10 pagesEngineering Structures: M. Latour, V. Piluso, G. RizzanoAnonymous kBl0u3nNo ratings yet

- A Critical Review On Idealization and Modeling For Interaction Among Soil-Foundation-Structure SystemDocument16 pagesA Critical Review On Idealization and Modeling For Interaction Among Soil-Foundation-Structure SystemtavialimNo ratings yet

- The Role of Advanced Constitutive Relations in Practical Applications Le Role Des Lois Constitutes Avancees Dans Les Applications PratiquesDocument1 pageThe Role of Advanced Constitutive Relations in Practical Applications Le Role Des Lois Constitutes Avancees Dans Les Applications PratiquesLeing CKNo ratings yet

- A Continuum Based Structural Modeling Approac - 2018 - Journal of The MechanicsDocument25 pagesA Continuum Based Structural Modeling Approac - 2018 - Journal of The MechanicsingdanymartinezpNo ratings yet

- Numerical and Experimental Investigations OnDocument22 pagesNumerical and Experimental Investigations OnAnkita PalNo ratings yet

- Recent Research on Blast Performance of Tunnel StructuresDocument7 pagesRecent Research on Blast Performance of Tunnel StructuresakshayNo ratings yet

- On The Limitations of Predictions of The Dynamic Response of Machines With Clearance ConnectionsDocument25 pagesOn The Limitations of Predictions of The Dynamic Response of Machines With Clearance Connectionsstefanovicana1No ratings yet

- 1 s2.0 S0022460X1500901Document14 pages1 s2.0 S0022460X1500901iza boneNo ratings yet

- A Probability-Based Prediction of Footbridge VibrationDocument3 pagesA Probability-Based Prediction of Footbridge Vibrationkoce_todorovNo ratings yet

- Li Jun 2013Document233 pagesLi Jun 2013hahaerNo ratings yet

- 2018 - Zhang Et AlDocument19 pages2018 - Zhang Et AlDeviprasad B SNo ratings yet

- SEISMIC DESIGN GUIDELINES FOR TALL BUILDINGSDocument93 pagesSEISMIC DESIGN GUIDELINES FOR TALL BUILDINGSprasadsmishaNo ratings yet

- Design of General Lattice Structures For LightweigDocument15 pagesDesign of General Lattice Structures For LightweigJaime Valente Morales BazalduaNo ratings yet

- Structures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDocument11 pagesStructures: Muhammad Zain, Muhammad Usman, Syed Hassan FarooqDilum VRNo ratings yet

- Wang Et Al Stress TestDocument11 pagesWang Et Al Stress TestShamsher SadiqNo ratings yet

- SonalDocument348 pagesSonalPallavi PandeyNo ratings yet

- 1999 - Seismic Soil Structure Interaction in Buildings - II Empirical Findings PDFDocument12 pages1999 - Seismic Soil Structure Interaction in Buildings - II Empirical Findings PDFCesar PugsioNo ratings yet

- Development of Small Scale Models For K 12 and Undergraduate Students To Demonstrate Earthquake Effects On Building Structures and Aseismic Design ProceduresDocument23 pagesDevelopment of Small Scale Models For K 12 and Undergraduate Students To Demonstrate Earthquake Effects On Building Structures and Aseismic Design Proceduresutsav_koshtiNo ratings yet

- Bamboo Deployable Structural Systems: An Exploration Study in Responding To Rapid Alteration ChallengesDocument10 pagesBamboo Deployable Structural Systems: An Exploration Study in Responding To Rapid Alteration ChallengesArnold C. LasitNo ratings yet

- Implementation and Verification of Interface Constitutive Model in FLAC3DDocument13 pagesImplementation and Verification of Interface Constitutive Model in FLAC3Dbereket gNo ratings yet

- Study of Substitute Frame Method of Analysis For Lateral Loading ConditionsDocument39 pagesStudy of Substitute Frame Method of Analysis For Lateral Loading ConditionschauhannishargNo ratings yet

- VipsDocument1 pageVipsjohnNo ratings yet

- 08 Catalog SIP E7a Transformer Differential ProtectionDocument48 pages08 Catalog SIP E7a Transformer Differential ProtectionanonymphantomNo ratings yet

- bb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)Document6 pagesbb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)anonymphantomNo ratings yet

- PDMS command documentDocument17 pagesPDMS command documentanonymphantomNo ratings yet

- 7UM62 Catalog SIP E7 PDFDocument36 pages7UM62 Catalog SIP E7 PDFu_ulloaNo ratings yet

- Efacec Switchgear SolutionsDocument32 pagesEfacec Switchgear SolutionsanonymphantomNo ratings yet

- CF 10448Document62 pagesCF 10448anonymphantomNo ratings yet

- PDMS command documentDocument17 pagesPDMS command documentanonymphantomNo ratings yet

- AV02-2041EN Reg-Guide - IPD 15sep2011,0Document91 pagesAV02-2041EN Reg-Guide - IPD 15sep2011,0anonymphantomNo ratings yet

- ABB QT10 - Photo Voltaic PlantsDocument107 pagesABB QT10 - Photo Voltaic PlantsDieuHoNo ratings yet

- Glossary of Dam and Fish TermsDocument7 pagesGlossary of Dam and Fish TermsanonymphantomNo ratings yet

- MENNEKES 2010 - TomadasDocument20 pagesMENNEKES 2010 - TomadasanonymphantomNo ratings yet

- ZFDatagrid 0.8 - ManualDocument79 pagesZFDatagrid 0.8 - ManualshambalicNo ratings yet

- Other Sample Googleanalytics ReportDocument6 pagesOther Sample Googleanalytics ReportanonymphantomNo ratings yet

- 3RW4434 6BC34 Datasheet enDocument6 pages3RW4434 6BC34 Datasheet enanonymphantomNo ratings yet

- Am GF Gi-Gg Gi-Gg AmDocument4 pagesAm GF Gi-Gg Gi-Gg AmanonymphantomNo ratings yet

- ISMEP Seismic GuidelineDocument155 pagesISMEP Seismic GuidelinearpNo ratings yet

- RAM Connection Verification ManualDocument47 pagesRAM Connection Verification ManualBenedict OgbaghaNo ratings yet

- Steel Cap Plate Connections DesignDocument18 pagesSteel Cap Plate Connections DesignVinoth KumarNo ratings yet

- Neutral Axis Depth Profile of Reinforced Concrete BeamsDocument9 pagesNeutral Axis Depth Profile of Reinforced Concrete Beamsrahmat sahilNo ratings yet

- MRDC Operations Corporation Highway Maintenance & Rehabilitation PracticesDocument28 pagesMRDC Operations Corporation Highway Maintenance & Rehabilitation PracticesEbsa KelifaNo ratings yet

- Slab Work 15cm Thick Slab Concrete:, C-25 Mechanical Mix 1:2:3 For SlabDocument1 pageSlab Work 15cm Thick Slab Concrete:, C-25 Mechanical Mix 1:2:3 For SlabsonteNo ratings yet

- Lenton CouplersDocument20 pagesLenton CouplersSherief MagdyNo ratings yet

- Reinforcing Bar Couplers LRDocument16 pagesReinforcing Bar Couplers LRNessa NesschtNo ratings yet

- QS - BasicsDocument20 pagesQS - BasicsPanyam Babu ShivanandNo ratings yet

- Dam Concrete Problems Detection DeteriorationDocument2 pagesDam Concrete Problems Detection DeteriorationManish WaniNo ratings yet

- Quick Installation Benefits of Inverted T BeamsDocument2 pagesQuick Installation Benefits of Inverted T BeamsUhGuanHongNo ratings yet

- Precision Drafting LLCDocument22 pagesPrecision Drafting LLCLester Louis EleseoNo ratings yet

- Bolt Design Based On BS Code:: Input DataDocument14 pagesBolt Design Based On BS Code:: Input DataSURIYANo ratings yet

- 4m x 4m One Cell Box Culvert Plan and SectionsDocument6 pages4m x 4m One Cell Box Culvert Plan and SectionsKush DekaNo ratings yet

- Timber Diaphragm - in Plane StiffnessDocument19 pagesTimber Diaphragm - in Plane StiffnessPatrick TebbleNo ratings yet

- Truss Structure - Building ConstructionDocument1 pageTruss Structure - Building ConstructionJiya RobertNo ratings yet

- Purlin section design beam displacement analysisDocument7 pagesPurlin section design beam displacement analysisIjaz AhmedNo ratings yet

- Site Class B Response Spectrum GraphDocument8 pagesSite Class B Response Spectrum Graphsudhir12345100% (1)

- Brick Masonry Material Properties GuideDocument10 pagesBrick Masonry Material Properties GuideRoy H Mayo JrNo ratings yet