Professional Documents

Culture Documents

JSA FORM SAFETY ANALYSIS

Uploaded by

PaulSwinbankOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA FORM SAFETY ANALYSIS

Uploaded by

PaulSwinbankCopyright:

Available Formats

[CLIENT] JOB SAFETY ANALYSIS FORM (JSA FORM)

Job Title: Department: Analysis By: Additional PPE Required: Tools Required: Identified Safety, Environmental and Procedure/ Hazards JSA No.: Revision No.: Reviewed By: Date of Issue: SCRIBE LEADER: Approved By: Project Supervisor in-charge: Recommended Safe Job Steps and Procedures Resp Person / Action by

Sequence of Basic Steps

1.

Mobilization of tools, equipment & fall arrest system materials

1.1

Accidental knocks onto process equipment

1.1.1 1.1.2.

Follow agreed access routes. Ensure that proper care and attention is paid to surrounding equipment when materials are being moved. Client will inform Contractor of any process related hazards in the area and identify any areas where access is restricted. Contractor to inform EM Control House directly or via EMR before start of every work day (to mitigate and keep the control house operator aware, and account for the people working in that area).

Contractor Supervisor Contractor Supervisor & Workers Client Supervisor, Contractor Supervisor Contractor Supervisor

1.2

Process related hazards

1.2.1.

1.2.2.

Page 1 of 13

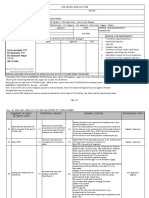

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

1.3 1.4.

Traffic Hazards Unauthorised access to work area.

1.3.1. 1.4.1.

1.5.

Bad housekeeping / Trip hazards Manual Handling related hazards.

1.5.1.

1.6.

1.6.1.

2.

Access to Flare Stack

2.1

Fall from height

2.1.1

All personnel to follow Jurong Refinery traffic rules and pedestrian rules. The work area will be barriered off using red and white barrier tape at agreed limits with signs stating that access is restricted to authorized personnel only. Good housekeeping will be maintained at all times. All tools and equipment to be placed properly to prevent trip hazards. All personnel will follow safe manual handling procedures. Personnel will assess each load before lifting and use team lifts where necessary. Where necessary the supervisor will arrange for alternative safe means of lifting. All personnel accessing the stack must wear either a full body safety harness or roped access harness complete with twin lanyards. Personnel must clip on to the ladders using the twin lanyards to maintain 100% tie off. After the initial access a temporary fall arrest system will be installed to the full height of the stack to allow ease of movement between levels. Once the fall arrest system has been installed and inspected by the supervisor personnel can clip to it using the rope grip devices.

Contractor Supervisor & Workers Contractor Supervisor

Contractor Supervisor & Workers Contractor Supervisor & Workers

Contractor Supervisor

Page 2 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

2.2.

Exhaustion, fatigue, heat stress and dehydration.

2.2.1. 2.2.2.

2.2.3.

2.2.4. 2.4. Inclement weather, lightning strike. 2.4.1.

2.4.2.

Workers to take breaks at intermediate platforms as necessary. Workers should not carry out any work at height if they are feeling unwell. If they begin to feel unwell whilst working at height they should inform their supervisor immediately and descend to next platform to rest. All workers should follow the ExxonMobil site heat stress management plan. Supervisors to ensure that all workers take adequate rest stops and drink enough water. All personnel carrying out works on the stack are to be physically fit and acclimatised. EM supervisor to provide Contractor with EM radio. Supervisor to check the CAT1 announcement from the control house via channel 1A and evacuate the workers immediately if there is CAT1 announcement. Contractor Supervisor to monitor weather conditions, instruct descent from stack and prevent ascent during periods of inclement weather or CAT1 situations.

Contractor Worker Contractor Worker

Contractor Worker

Contractor Worker Contractor Supervisor

Contractor Supervisor

Page 3 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

2.4

Falling objects

2.4.1

2.5

Inadequate training

2.5.1

All hand tools are to be used correctly and without overreaching. When not in use the tool should be stored in a secure container, or attached to the operatives tool belt. Fixings and other materials which pose a fall risk should be stored in secure solid containers when not in use, and returned to stores at the end of each shift. At no time should personnel pass beneath those working at height. The area beneath personnel working at height should be considered an exclusion zone. All personnel involved in the works will have had the required training. All equipment will be checked by the senior operative in order to ensure that the technician has set it up correctly and is aware of its proper use. Third Party personnel who wish to climb using the temporary fall arrest system will be trained in its use by the supervisor and will sign onto a special toolbox talk to say that they understand its use and will follow the instructions of the supervisor.

Contractor Supervisor/ Contractor Worker

Contractor Supervisor/ Client Supervisor/ Client workers

Page 4 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

2.7.

Manual handling

2.7.1

2.8.

Worker becomes incapacitated

2.8.1.

Personnel will follow correct manual handling techniques at all times. Where personnel are operating from roped access heavy or unwieldy items will be lifted or lowered to them via hand line. Do not attempt to move/lift loads which may cause loss of balance or interfere with the access equipment. If necessary alternative mechanical means of lifting will be provided. Activate rescue plan Call EMR or SS to activate Fire & Security emergency personnel. Access ladders will be installed by trained and competent personnel. The ladder will be inspected by a senior steeplejack or supervisor and passed as safe before being released for general use. Access scaffolds will be installed by trained and qualified personnel using standard scaffold components. The scaffold will be inspected by a senior steeplejack or supervisor and passed as safe for use before being released for general use.

Contractor Supervisor/ Contractor Worker

3.

Installation and use of temporary access to Flare Tip

3.1.

Incorrect installation

3.1.1.

Contractor Supervisor Contractor Worker Contractor Supervisor Contractor Steeplejack Contractor Supervisor Contractor Steeplejack

3.1.2.

Page 5 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

3.2.

Unauthorised modification

3.2.1.

3.3.

Falling objects

3.3.1.

3.3.2.

3.3.3.

No personnel will carry out modifications to temporary access systems without authorisation and instruction from the supervisor. Any modifications must be inspected by the supervisor or senior steeplejack before the system is certified as safe for use. The area beneath the working party shall be barriered off. Access to the area will be forbidden whilst the works are ongoing. The area will be monitored by an operative stationed at ground level. Components will be lifted in a controlled manner using a hand line. Components will be secured at the installation level before being released from the hand line. Components will be securely stored away from edges at all times until secured in place. All personnel will be trained and competent in manual handling procedures at height. The supervisor will monitor the works to ensure that procedures are being followed. Where necessary an alternative means of lifting will be provided.

Contractor Supervisor

Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor

3.4.

Manual handling

3.4.1.

3.4.2.

Page 6 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

3.5.

Fall from height

3.5.1.

3.6.

Pinch points

3.6.1.

All personnel working at height will wear full body safety harnesses or full body roped access harnesses complete with twin lanyards. Personnel will maintain 100% tie off to a suitable hard point or fall arrest line at all times. Personnel will wear appropriate gloves when assembling access. Personnel to be familiar with the use of the hand tools. Hand tools will be used for the task for which they were intended, will not be modified and will be checked before use for defects. All personnel working at height will wear full body safety harnesses or full body roped access harnesses complete with twin lanyards. Personnel will maintain 100% tie off to a suitable hard point or fall arrest line at all times. The area beneath the working party shall be barriered off. Access to the area will be forbidden whilst the works are ongoing. The area will be monitored by an operative stationed at ground level.

Contractor Supervisor Contractor Workers

3.7.

Use of hand tools

3.7.1.

3.7.2.

4.

Replacement of corroded / missing items/ flare tip components etc.

4.1.

Fall from height

4.1.1.

Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers

4.2.

Falling objects

4.2.1.

Contractor Supervisor Contractor Workers

Page 7 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

4.2.2.

4.2.3.

Components will be lifted in a controlled manner using a hand line. Components will be secured at the installation level before being released from the hand line. Components will be securely stored away from edges at all times until secured in place. All personnel will be trained and competent in manual handling procedures at height. The supervisor will monitor the works to ensure that procedures are being followed. Where necessary an alternative means of lifting will be provided. Personnel to be familiar with the use of the hand tools. Hand tools will be used for the task for which they were intended, will not be modified and will be checked before use for defects. Installation will be carried out by competent personnel. All installed items will be inspected by the supervisor to ensure that they have been installed correctly on completion.

Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers

4.3.

Manual handling

4.3.1.

4.3.2. 4.4. Use of hand tools 4.4.1.

4.4.2.

4.5.

Incorrect installation

4.5.1.

4.5.2.

Page 8 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

5.

Painting Works

5.1.

Chemical hazards

5.1.1.

5.2.

Falls from height

5.2.1.

5.3.

Falling objects

5.3.1.

The materials used will be subject to a COSHH assessment. Safe use procedures for the material will be specified in the assessment. The Supervisor will ensure that all personnel handling the material or likely to come into contact with it will be issued with the appropriate PPE and will follow the correct handling procedures as specified in the COSHH assessment. A toolbox talk will be carried out before the works start covering all safe work procedures to be followed. All personnel working at height will wear full body safety harnesses or full body roped access harnesses complete with twin lanyards. Personnel will maintain 100% tie off to a suitable hard point or fall arrest line at all times. The area beneath the working party shall be barriered off. Access to the area will be forbidden whilst the works are ongoing. The area will be monitored by an operative stationed at ground level.

Contractor Supervisor Contractor Worker

Contractor Supervisor Contractor Workers

Contractor Supervisor Contractor Worker

Page 9 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

5.3.2.

5.4.

Use of hand tools

5.4.1.

All tools will be secured to the operatives belt or in a suitable pouch secured to the bosuns chair or located on an adjacent platform when not in use. The paint containers will also be secured to the bosuns chair or stored on an adjacent platform. Personnel to be familiar with the use of the hand tools. Hand tools will be used for the task for which they were intended, will not be modified and will be checked before use for defects. Personnel to be familiar with the use of the hand tools. Power tools will be used for the task for which they were intended, will not be modified and will be checked before use for defects. All electrical tools and equipment will be inspected by an LEW before being used on site. Operatives will inspect their tools before use and report any defects to the supervisor.

Contractor Supervisor Contractor Worker

5.4.2.

5.5.

Use of power tools

5.5.1.

5.5.2.

5.6.

Electrocution

5.6.1.

5.6.2.

Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers

Page 10 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

5.6.3.

Power supplies will be fitted with a circuit breaker. All personnel working at height will wear full body safety harnesses or full body roped access harnesses complete with twin lanyards. Personnel will maintain 100% tie off to a suitable hard point or fall arrest line at all times. The area beneath the working party shall be barriered off. Access to the area will be forbidden whilst the works are ongoing. The area will be monitored by an operative stationed at ground level. All tools will be secured to the operatives belt or in a suitable pouch secured to the bosuns chair or located on an adjacent platform when not in use. The paint containers will also be secured to the bosuns chair or stored on an adjacent platform. Personnel to be familiar with the use of the hand tools. Hand tools will be used for the task for which they were intended, will not be modified and will be checked before use for defects.

6.

Cleaning of oxidised material at flare tip

6.1.

Falls from height

6.1.1.

Contractor Supervisor Contractor Workers Contractor Supervisor Contractor Workers

6.2.

Falling objects

6.2.1.

Contractor Supervisor Contractor Worker Contractor Supervisor Contractor Worker

6.2.2.

6.3.

Use of hand tools

6.3.1.

6.3.2.

Contractor Supervisor Contractor Worker Contractor Supervisor Contractor Worker

Page 11 of 13

Sequence of Basic Steps

Identified Safety, Environmental and Procedure/ Hazards

Recommended Safe Job Steps and Procedures

Resp Person / Action by

6.4.

Airborne dust

6.4.1. 6.4.2.

7.

Demobilisation and Housekeeping

7.1.

Accidental knocks onto process equipment

7.1.1 7.1.2.

All personnel carrying out the works or working in the area will wear N95 type respiratory protection. Personnel may also be issued with goggles for eye protection from dust. Follow agreed access routes. Ensure that proper care and attention is paid to surrounding equipment when materials are being moved. Client will inform Contractor of any process related hazards in the area and identify any areas where access is restricted Contractor to inform EM Control House directly or via EMR before start of every work day (to mitigate and keep the control house operator aware, and account for the people working in that area). All personnel to follow Jurong Refinery traffic rules and pedestrian rules. The work area will be cleared and housekeeping carried out to return it to its original condition and remove any waste material. Barriers will only be removed once housekeeping is completed.

Contractor Supervisor Contractor Supervisor Contractor Supervisor Contractor Supervisor & Workers Client Supervisor, Contractor Supervisor Contractor Supervisor

7.2.

Process related hazards

7.2.1.

7.2.2.

7.3. 7.4.

Traffic Hazards Bad housekeeping / Trip hazards

7.3.1. 7.4.1.

Contractor Supervisor & Workers Contractor Supervisor & Workers Contractor Supervisor & Workers

7.4.2.

Page 12 of 13

This JSA was reviewed the following team members:

Name Signature Dept /Company Tel / VHF

Page 13 of 13

You might also like

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- JSA HandToolsDocument2 pagesJSA HandToolsCristina Rican100% (3)

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Crane JSADocument5 pagesCrane JSAKritsada Tiwutanon100% (1)

- Lifting Bridge JSADocument8 pagesLifting Bridge JSAeslamNo ratings yet

- Evacuation Drill Details 7-2018Document5 pagesEvacuation Drill Details 7-2018Mustafa Adel100% (3)

- Jsa Grinding Welding Gas CuttingDocument4 pagesJsa Grinding Welding Gas CuttingMark Roger Huberit IINo ratings yet

- Safety Induction - EdittedDocument41 pagesSafety Induction - EdittedsyooloveNo ratings yet

- All ChecklistsDocument0 pagesAll Checklistsmalika_00No ratings yet

- Job HAzard Analysis Welding Operations MiftahDocument3 pagesJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- JHA General Maintenance Activity PDFDocument5 pagesJHA General Maintenance Activity PDFdede SinbadNo ratings yet

- Job Safety Analysis Worksheet For Petroleum Site InspectionsDocument2 pagesJob Safety Analysis Worksheet For Petroleum Site InspectionsIsaac Entebi100% (2)

- Air Compressor Operation SafetyDocument10 pagesAir Compressor Operation SafetyKelvin TanNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Confined Spaces Toolbox TalkDocument3 pagesConfined Spaces Toolbox TalkWaSim AKramNo ratings yet

- Concrete Surface Coating JSA-027Document5 pagesConcrete Surface Coating JSA-027shivgovind pal100% (1)

- Health & Safety Induction ChecklistDocument2 pagesHealth & Safety Induction ChecklistSharani KamaludinNo ratings yet

- The Basics of Confined SpaceDocument17 pagesThe Basics of Confined SpaceRobVajko50% (2)

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- JSA DOWNLOADING RELAY CONFIGURATIONDocument4 pagesJSA DOWNLOADING RELAY CONFIGURATIONfrancis_e_tan100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- JOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRDocument12 pagesJOB SAFETY ANALYSIS FOR HEAT TRACING REPAIRChung Trịnh100% (2)

- Construction Job Safety Analysis - Safety Science Y2010Document10 pagesConstruction Job Safety Analysis - Safety Science Y2010Yongsak Yungyuen100% (2)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiNo ratings yet

- PPE Standard Training GuideDocument56 pagesPPE Standard Training Guidehadeed shaikh100% (2)

- Civil JSA Form Application of Protective Coating On Sump PitsDocument1 pageCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Lockout/tagoutDocument13 pagesLockout/tagoutLaxman BadiniNo ratings yet

- JSA For New EmployeesDocument20 pagesJSA For New EmployeesNilayNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Hazards of Structural Steel WorkDocument3 pagesHazards of Structural Steel WorkRobbie Grose100% (3)

- 28 Job Safety AnalysisDocument7 pages28 Job Safety Analysisashish_kamat100% (3)

- 14 - Job Safety Analysis-loading and Offloading Materials装卸料Document5 pages14 - Job Safety Analysis-loading and Offloading Materials装卸料Jayvee Baradas Valdez100% (1)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Hand and Power ToolsDocument25 pagesHand and Power ToolsVishwash Goyal100% (1)

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDocument5 pagesUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaNo ratings yet

- Normal Operating Procedures for Parks Machinery and TasksDocument7 pagesNormal Operating Procedures for Parks Machinery and TasksHafiezul HassanNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- Daily Hse Report Job Safety Analysis MakcoDocument14 pagesDaily Hse Report Job Safety Analysis MakcoSafety Mohini100% (2)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Excavation and TrenchingDocument2 pagesExcavation and TrenchingvikasNo ratings yet

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- HSE InductionDocument22 pagesHSE InductionDaniel Reyes100% (3)

- List of Toolbox Talk Topics: TopicDocument1 pageList of Toolbox Talk Topics: TopicCaptain100% (1)

- EARTHWORKS SAFETYDocument4 pagesEARTHWORKS SAFETYsatti100% (2)

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocument4 pagesDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNo ratings yet

- Risk Assessment For Partition MarkingDocument5 pagesRisk Assessment For Partition Markingkhalid14No ratings yet

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- Risk Assesment-Rebar Loading & UnloadingDocument1 pageRisk Assesment-Rebar Loading & Unloadingmainraj rajNo ratings yet

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77No ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Jha Lifting Permit - Tower CraneDocument3 pagesJha Lifting Permit - Tower CraneJohn Ralph Vega100% (1)

- Trinity Jurong Map PDFDocument1 pageTrinity Jurong Map PDFPaulSwinbankNo ratings yet

- Resist 78 Technical Data SheetDocument4 pagesResist 78 Technical Data SheetPaulSwinbankNo ratings yet

- GlideLoc Fall Protection - Basic User InstructionsDocument3 pagesGlideLoc Fall Protection - Basic User InstructionsPaulSwinbankNo ratings yet

- Syntex OrganogramDocument1 pageSyntex OrganogramPaulSwinbankNo ratings yet

- A CatDocument1 pageA CatPaulSwinbankNo ratings yet

- Syntex Engineering Services LTD BrochureDocument38 pagesSyntex Engineering Services LTD BrochurePaulSwinbankNo ratings yet

- Weekly Time Sheets for COMPANY NAME SITE NAMEDocument1 pageWeekly Time Sheets for COMPANY NAME SITE NAMEPaulSwinbankNo ratings yet

- Quality Plan Inspection Test Syntex EngineeringDocument1 pageQuality Plan Inspection Test Syntex EngineeringPaulSwinbankNo ratings yet

- Interlocking Brickwork Arrangement SketchDocument1 pageInterlocking Brickwork Arrangement SketchPaulSwinbankNo ratings yet

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankNo ratings yet

- Steeplejack Competency RequirementsDocument3 pagesSteeplejack Competency RequirementsPaulSwinbankNo ratings yet

- Control of Cracking in Concrete E-C107Document56 pagesControl of Cracking in Concrete E-C107Ye Kyaw KhaungNo ratings yet

- COSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsDocument2 pagesCOSHH Assessment: Product Name Supplier Date Ref No. Chemical Identification PPE RequirementsPaulSwinbankNo ratings yet

- Buildings Department Approved Materisla List CDBSFDocument47 pagesBuildings Department Approved Materisla List CDBSFPaulSwinbankNo ratings yet

- Syntex Engineering Services LTD BrochureDocument38 pagesSyntex Engineering Services LTD BrochurePaulSwinbankNo ratings yet

- Example Inspection Test PlanDocument2 pagesExample Inspection Test PlanPaulSwinbank100% (1)

- CODE of PRACTICE For Site SupervisionDocument120 pagesCODE of PRACTICE For Site SupervisionRaymond Kam100% (4)

- Project Hse Plan Rev2 - ScribdDocument35 pagesProject Hse Plan Rev2 - ScribdPaulSwinbank94% (36)

- Methode of Statement Lightning Protection & Earthing System Review 4Document27 pagesMethode of Statement Lightning Protection & Earthing System Review 4firman zakirNo ratings yet

- 2011 Equipment Packing InstructionsDocument3 pages2011 Equipment Packing InstructionsNidhi MurthyNo ratings yet

- Pass4sure 200-120 PDF DownloadDocument8 pagesPass4sure 200-120 PDF DownloadEleanor19No ratings yet

- Nonwoven Material StandardsDocument5 pagesNonwoven Material StandardsRajesh Dwivedi0% (1)

- R07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)Document32 pagesR07-HC3C20-AAP-MTS-CI-0005 (02) Method Statement of Site Mobilization at Island (Revised)like saddamNo ratings yet

- Rocket Icluster V8.1Document16 pagesRocket Icluster V8.1Felipe Cervantes EspinosaNo ratings yet

- ABS Thickness Measurement Requirement For Ship in Operation PDFDocument2 pagesABS Thickness Measurement Requirement For Ship in Operation PDFMohd Fouzi AbdullahNo ratings yet

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDocument7 pagesMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94No ratings yet

- Main Engine Cylinder Liner Crack: Return To TOCDocument2 pagesMain Engine Cylinder Liner Crack: Return To TOCRani NoumanNo ratings yet

- Ijso 2012Document5 pagesIjso 2012bhaskarNo ratings yet

- Thermal Arc 161 STL 201 Ts Inverter Welder SM PDFDocument96 pagesThermal Arc 161 STL 201 Ts Inverter Welder SM PDFduyNo ratings yet

- Optimal Transformer Tap Changing SettingDocument7 pagesOptimal Transformer Tap Changing Settingtrust4joshNo ratings yet

- Q7 Running GearDocument54 pagesQ7 Running GearJoseph MorantNo ratings yet

- Operating Manual Parts List: 1000Vmc (Siemens)Document226 pagesOperating Manual Parts List: 1000Vmc (Siemens)apodshNo ratings yet

- Davao October 2014 Criminologist Board Exam Room AssignmentsDocument113 pagesDavao October 2014 Criminologist Board Exam Room AssignmentsPRC Board0% (1)

- Silo Fluidizer: Keep Dry Bulk Materials MovingDocument2 pagesSilo Fluidizer: Keep Dry Bulk Materials MovingHùng Thanh NguyễnNo ratings yet

- ASTMDocument4 pagesASTMSupriyo PNo ratings yet

- HP Fortify Higher Order Tech PrevDocument2 pagesHP Fortify Higher Order Tech PrevanbuselvangNo ratings yet

- Notice No.8: Rules and Regulations For TheDocument40 pagesNotice No.8: Rules and Regulations For TherickNo ratings yet

- How To Build A Backyard PergolaDocument15 pagesHow To Build A Backyard PergolaMichael Wilkins100% (1)

- Basic Silicone Chemistry P 1Document21 pagesBasic Silicone Chemistry P 1Rahul Yadav100% (1)

- L Uk SulphDocument24 pagesL Uk SulphypyeeNo ratings yet

- Cable Memebres ProfiledirectoryDocument5 pagesCable Memebres ProfiledirectoryMigration Solution100% (1)

- Slip and Crystallographic TexturesDocument34 pagesSlip and Crystallographic TexturesSunkulp GoelNo ratings yet

- Physics Exit 3q1718 .Document16 pagesPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- Payables Open Interface Import in Oracle Apps R12Document11 pagesPayables Open Interface Import in Oracle Apps R12sudharshan79No ratings yet

- Improved M16A2 - A3 - A4 Zero TargetDocument6 pagesImproved M16A2 - A3 - A4 Zero Targetbeetho1990No ratings yet

- ECOSYS M6526cdn Fax SetupDocument204 pagesECOSYS M6526cdn Fax SetupAnonymous gn8qxxNo ratings yet

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259No ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet