Professional Documents

Culture Documents

New Product Development Process

Uploaded by

Poulami DeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Product Development Process

Uploaded by

Poulami DeCopyright:

Available Formats

New Product Development Process

Stage 1 Research/Planning/Concept Generation Create target and evaluate potential areas, which may benefit through new product development, in conjunction with the customer Evaluation of potential for new sales/upgrades and increased sales Suppliers/Customer origination of ideas through: Brainstorming Market Information Raw Material Supplier information Blue sky projects Range Strategy Brief Development Technologist to identify food market and customer trends by Comparative shopping Attending food shows and exhibitions Attending customers/Scottish Enterprise workshops Eating out and collecting menus Travelling Reading trend reports Presentation from ingredient suppliers Reading/collecting weekend newspaper articles on food/restaurants Before commencing kitchen development the following What is the reasoning behind developing this product? Why does or would the customers want this product? What will it achieve/objectives? Who is the consumer? What is the Eating Occasion? Agree date with customer for initial product presentation: Stage Gate 2 The list of product ideas. Stage 2 Kitchen Development Product samples to be generated in the kitchen with the main emphasis on flavour, texture and visual appearance. The aim is to create products, which meet the brief/brand values and present at the internal presentation Initial recipe to be generated with kitchen method. Each recipe to be given a recipe code, this code must change if an amendment is made to the recipe and the amendment documented. If using non-standard ingredients these must be sourced from appropriate supplier and initial cost/specification to be requested. Ensure ingredient/packaging readily available or highlight lead-times or potential issues with supply. Ingredient should have provenance as well as quality. Stage 3 Internal Presentation Kitchen developed products are to be presented to key representatives within the company. Representatives from commercial, production, buyers and technical should be present. Products to be presented in terms of:

Recipe formulation/visual and taste samples should be available. Proposed packaging Costing Cooking method Following comments at the internal review then product alterations to be made and the revised products are to be shown to the customer Guideline cooking instructions to be generated Begin preparation of the presentation documentation/sample submission form for the Gate 2 meeting.

Stage 4 Customer Presentation: Gate 2 The list of product ideas The commercial Manager, Development Manager and the Development Technologist to present the product to the customer. Taste and visual samples to be available. All products presented to be accompanied by a sample submission form. Development Technologist to work with Systems Co-ordinator to complete form. Costing information to be provided by the Commercial Manager. Products presented to be in the proposed packaging format. All samples submitted to be clearly labelled with product Name/Description, Pack Weight, Cooking Instructions, Production Date & Use By Date. Adjustments on products to be carried out in response to comments from the customer. All changes must be documented by the Development Technologist on the Recipe/Formulation sheet and on the project snag list. Final recipe and the approved kitchen product to be frozen and photographed for reference The Benchmark! Stage Gate 3 and 4 meeting and launch date gate 6 to be confirmed. Stage 5 Product Briefing/Trial Planning Development Technologist to show the product to representatives from production, technical, engineering and discuss the best way to manufacture the product in the factory. Approved product to be inserted on to critical Path and agreed trail dates to be documented and communicated to customer. Bill of materials to be sent to buyers Raw material suppliers to be sent a Raw Material Questionnaire and a supplier questionnaire for the new ingredients to be requested. Confirm costing, lead times, method of transport, delivery/production schedule, minimum order any potential issues supplier status are they M&S approved. New Product Information sheet to be placed at the front of the file and completed when an activity has been action. This is a checklist to ensure all activities are completed on time. Stage 6 Weekly NPD Meeting/Review All products in any stage of the development process to be reviewed and discussed at the weekly meeting at which representatives from development, technical, production, purchasing and planning attend. The Development Manager or Development Technologist to chair the meeting and record minutes.

Stage 7 Factory Trials The approved kitchen product is trialed in the factory to establish feasibility in terms of: Demonstrating that the initial samples can be matched in the factory, with actual ingredients and that they meet specification in terms of overall product safety and quality. Shelf life Process ability/time take/cost of manufacture/yields Potential issues/problems The number of trials required will depend on the complexity of the individual product Requirements: Product to be as close as possible to the final intended product using industrial sources of ingredients. All raw materials/suppliers to be approved by the Technical Department for use in the product. At each factory trial development, technical and production representatives must be present. Product made in the manufacturing environment is required for shelf life (organoleptic and microbiological), nutritional analysis, photography for artwork, and verification of cooking instructions. Factory trails may result in the alteration of method and/or formulation of the product. This is to be discussed and reviewed at the weekly NPD meeting.

Stage 8 Factory Trail Procedure Date of Factory Trails to be agreed at NPD meeting and detailed on the Critical Path. Dates to be forwarded to M&S The following action points to be actioned by the Development Technologist the day prior to the trial: Confirm factory personnel and agreed timescales. Inform all relevant personnel. All non-standard ingredients to be ordered and delivered at least one day prior to trial commencing. All ingredients should be purchased to required quality standard and spec. Butchery Manager/Supervisor to be advised of meat requirements. Butchery request/order form to be completed. Quality of raw materials to be checked prior to trial commencing. Issue development recipe with correct batch sizes minimum 30 packs and a provisional method to relevant personnel. Note All development recipes to be clearly identified as such and should not be used by production. Development recipes to be coded so if there is any amendments to be made the product can be tracked back. Development technologist to produce kitchen sample of the product that will be replicated in the factory.

The following action points to be actioned by the Development Technologist on the day of the factory trail: Factory trail to be carried out with production manager/supervisor and technical representative present. Development Technologist to attend the 1st trail. The following information is to be obtained from the trail: Confirmation of factory processing method Timing of process steps e.g. cooking of onions and line speeds Yields of any processing steps Individual components and final pack weights Confirmation of travel test Critical processing temperatures Any modifications required to recipe/method Highlight any potential issues which may cause a delay to the launch date The Development Technologist must ensure that samples from the factory trail samples are collected for: Microbiological shelf life testing in conjunction with Technical Organoleptic testing Through life testing Freezer trails domestic and cold store Customer approval samples/travel test Photography standard Photography for artwork when requested Nutritional analysis once approved by customer Cooking Instruction trails From the factory trail the following needs to be actioned (customer approval required in some instances) A report detailing the comments and actions to be taken following the factory trail. This should be distributed to relevant personnel. New updated recipe with production methods, yields and timings to be drafted with new code and issued to the Technical Department and issued to the technical department together with the 3p document so that specification can be generated. Copy of amendments to be given to Cost Accountant to update costing. Al documentation to be placed in the product file. Confirmation on QUID and approval from Technical Department. Samples for nutritional analysis should be taken from the start, middle and end of the factory trial production run. 3 samples required for nutritional analysis. Analysis will take 10 working 10 to complete. Nutritional results to be approved by the Technical before being entered into the 3p document. Product from factory trail to be eaten against kitchen benchmark sample and any changes that need to be made or improvements required are to be documented. The development technologist to coordinate the panel. Shelf life tasting should be set up and documented by the Development Technologist. Products should be labelled with date of pack and then stored in a domestic fridge. Each date the product should be taken out of the fridge and cooked according to the

cooking instructions. Product should be assessed in the raw and cooked state. The product should be assessed in terms of odour, flavour, texture, and visual appearance. Details should be recorded on the taste panel/shelf life sheet. A copy of the results to be kept in the Product File. Contact the Customer Technologist/Selector and inform them when they will receive the factory trail samples. Approval to be received prior to sending the products out for nutritional analysis and proceeding to the next stage in the NPD process. Product from the factory trail should be used to establish the cooking instructions. All appropriate cooking methods should be evaluated e.g. gas, electric, fan assisted, grill, fry, microwave, barbecue. The results should be recorded on the cooking trial report; pack weight start temperature and final temperature in middle and edges should be recorded along with times. Each cooking method should be tested for a minimum of 3 times prior to completing the recommended cooking instructions for the packaging. Cooking from frozen should also be assessed. Freezer trails should be carried out. 5 samples to be placed in the domestic freezer to test the suitability for customer freezing. Product to be removed from freezer after 1 month and defrosted in a domestic fridge and assessed in terms of aroma, texture flavour and appearance. Results to be recorded and documented. Samples ex-freezer to be sent to customer on request. Technical with the assistance to Development Technologist to risk assess the product and document the HACCP. Product quality standards to be generated and criteria set. Photographic standards to be generated of acceptable and unacceptable product for use on the production lines.

Stage 9 Pre Production Trail This is the final trail before launch. Requirements Pre Production trail to be held ideally two weeks before the launch date Product to be manufactured on the intended shift on which the product will be made so personnel can be trained. Product to follow the complete manufacturing process up to despatch. All new machinery to be available for the actual intended production The batch sizes to be similar to those that the factory intends to produce when the product is launched Actual packaging to be used where possible sleeve/labels. Factory recipe/methods to be taken from product specification Samples to be submitted to the customer for final approval No amendments to be carried out to the product between preproduction and the launch unless additional trails are carried out. Specification to be written prior to pre-production trail and verified during the trail. Pre-Production Procedure

Follow same procedure as the factory trail where applicable. In addition all components of the completed product to be correct i.e. sources of ingredients, actual packaging, machinery to be used, production personnel.

10

Pre Launch Meeting Commercial Manager to advise on launch volumes and issue information to relevant personnel Technical to advise on product life as agreed with customer technologist All relevant documentation for product to have been generated and issued to the factory e.g. final spec including HACCP, raw material and packaging specifications, taste criteria, tick sheets etc Launch

11

Samples from launch to be sent to customer Development Technologist to be present to oversee the launch Final product to be tasted against approved benchmark sample and physical library samples to be kept.

Post Launch Review Development Technologist to review the product initially daily after launch for first week then weekly for 1-month period. Any issues to be highlighted at the NPD meeting.

12

You might also like

- Quality Control Procedures & Raw MaterialsDocument19 pagesQuality Control Procedures & Raw Materialsparisa100% (1)

- Ality Control and Quality AssuranceDocument22 pagesAlity Control and Quality AssuranceAlice MakeNo ratings yet

- Quality Assurance & QUALITY CONTROldocDocument15 pagesQuality Assurance & QUALITY CONTROldocapi-19786321No ratings yet

- GMP - SOP SampleDocument25 pagesGMP - SOP SampleRands Cruise100% (2)

- GMP Trainers Manual PDFDocument46 pagesGMP Trainers Manual PDFiabureid7460No ratings yet

- Product Qualification Requirements SummaryDocument3 pagesProduct Qualification Requirements SummaryAmit SinghNo ratings yet

- HACCP Plan PDFDocument30 pagesHACCP Plan PDFrasimc9475No ratings yet

- Mr.D.ramesh Babu CV 16.10.2018Document9 pagesMr.D.ramesh Babu CV 16.10.2018RamboNo ratings yet

- Production SOP - RIODocument8 pagesProduction SOP - RIOabu naym100% (1)

- PROCESS VALIDATION CONCEPT GUIDEDocument6 pagesPROCESS VALIDATION CONCEPT GUIDEYousifNo ratings yet

- GF0101 Generic Food Certification QuestionnaireDocument7 pagesGF0101 Generic Food Certification QuestionnaireRasadi MohamadNo ratings yet

- Cargotec Supplier Quality ManualDocument30 pagesCargotec Supplier Quality ManualVagabond HuynhNo ratings yet

- Project Scheduling Improvement Using Design Structure MatrixDocument17 pagesProject Scheduling Improvement Using Design Structure MatrixehtishamNo ratings yet

- Change Control Manufacturing MatrixDocument4 pagesChange Control Manufacturing MatrixPrem GoelNo ratings yet

- Change Management in Automated QMS SoftwareDocument31 pagesChange Management in Automated QMS SoftwareS SrikanthNo ratings yet

- F&B Production ManualDocument160 pagesF&B Production ManualF&B Deepak Sengupta50% (2)

- Supplier Quality Requirements Manual AMWAYDocument22 pagesSupplier Quality Requirements Manual AMWAYlizmillosbtaNo ratings yet

- GMP Quality Assurance ProceduresDocument22 pagesGMP Quality Assurance ProceduresLen Surban100% (1)

- USDA GAP GHP audit guidelinesDocument170 pagesUSDA GAP GHP audit guidelinesSofianisa RozdiandaNo ratings yet

- Corrective Action and Preventive Action Procedure: Revital Healthcare (Epz) Ltd. Standard Operating ProcedureDocument7 pagesCorrective Action and Preventive Action Procedure: Revital Healthcare (Epz) Ltd. Standard Operating ProcedureMusyoka UrbanusNo ratings yet

- Sample Food Safety Audit ChecklistDocument11 pagesSample Food Safety Audit Checklistgkiyer7No ratings yet

- Non Conforming Product Management: Quality Systems ManualDocument5 pagesNon Conforming Product Management: Quality Systems ManualSalman SheikhNo ratings yet

- Developing Raw Material Specifcation AIBDocument3 pagesDeveloping Raw Material Specifcation AIBakNo ratings yet

- Ch-6 (New Product Development)Document13 pagesCh-6 (New Product Development)api-19958143No ratings yet

- New Product Development ProcessDocument3 pagesNew Product Development ProcessDasari Chandra Kanth ReddyNo ratings yet

- ASEAN Guideline Process OnDocument7 pagesASEAN Guideline Process OnVipin GuptaNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Food Quality Control & Study of Critical Control Points Ensuring Food SafetyDocument135 pagesFood Quality Control & Study of Critical Control Points Ensuring Food Safetymnegm2890No ratings yet

- New Product Introduction ChecklistDocument3 pagesNew Product Introduction ChecklistJoan DelNo ratings yet

- Quality Assurance (QA) Management Procedures: SOP ListDocument9 pagesQuality Assurance (QA) Management Procedures: SOP ListPranav UppadhyayNo ratings yet

- Good Manufacturing Practices PPDocument33 pagesGood Manufacturing Practices PPchevypickupNo ratings yet

- Carbonated BeveragesDocument7 pagesCarbonated BeveragesKapithas EswaranNo ratings yet

- ValidationDocument5 pagesValidationjyothisahadevanNo ratings yet

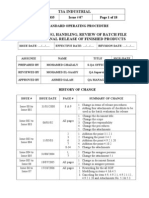

- Issuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07Document18 pagesIssuing, Handling, Revision of Batch File and Final Release of Finished Products For Sale and Distribution 07ibrahimgomaaNo ratings yet

- GMP ManualDocument29 pagesGMP ManualZeeshan Ramzan100% (2)

- New Product Development Process of FMCG ProductDocument9 pagesNew Product Development Process of FMCG ProductChanduChandranNo ratings yet

- Mars allergen management standard protects food-allergic consumersDocument21 pagesMars allergen management standard protects food-allergic consumersCristhianNo ratings yet

- Sweets and Confectionery HACCP ManualDocument26 pagesSweets and Confectionery HACCP Manual9960662744100% (1)

- QRM SOP Issue# 01 ApprovedDocument9 pagesQRM SOP Issue# 01 ApprovedibrahimgomaaNo ratings yet

- Quality Procedure for New Product DevelopmentDocument15 pagesQuality Procedure for New Product DevelopmentRahul Yadav88% (8)

- Pasteurization ManualDocument61 pagesPasteurization ManualAdilawi MuhammadNo ratings yet

- Quality Assurance Job DescriptionDocument1 pageQuality Assurance Job DescriptionSWPriestNo ratings yet

- How To Improve Food Quality ManagementDocument20 pagesHow To Improve Food Quality ManagementalaaNo ratings yet

- ACF SOP Medical Supplies201611Document29 pagesACF SOP Medical Supplies201611Mohammed Abdullah100% (1)

- Customer Complaint ProcedureDocument7 pagesCustomer Complaint Procedureadhavan_ma80% (5)

- CPGP Cert Insert PDFDocument20 pagesCPGP Cert Insert PDFmmmmmNo ratings yet

- Sops For SamplingDocument97 pagesSops For SamplingPrashant KumarNo ratings yet

- Engage in Quality ImprovementDocument21 pagesEngage in Quality ImprovementRegency Placer100% (1)

- Product Brief Snack Food IndustryDocument36 pagesProduct Brief Snack Food IndustryThục HiềnNo ratings yet

- Risk Assessment 2012-11-6 FDA GuidanceDocument95 pagesRisk Assessment 2012-11-6 FDA GuidancedahearnNo ratings yet

- Guide-Mqa-024-004 AprDocument9 pagesGuide-Mqa-024-004 Aprdrs_mdu48No ratings yet

- Food and Drink - Good Manufacturing Practice: A Guide to its Responsible Management (GMP7)From EverandFood and Drink - Good Manufacturing Practice: A Guide to its Responsible Management (GMP7)No ratings yet

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsFrom EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 4: Baking and Cooling of BiscuitsNo ratings yet

- FSMA and Food Safety Systems: Understanding and Implementing the RulesFrom EverandFSMA and Food Safety Systems: Understanding and Implementing the RulesNo ratings yet

- Biscuit, Cookie and Cracker Manufacturing Manuals: Manual 6: Biscuit Packaging and StorageFrom EverandBiscuit, Cookie and Cracker Manufacturing Manuals: Manual 6: Biscuit Packaging and StorageRating: 5 out of 5 stars5/5 (2)

- Good documentation practice The Ultimate Step-By-Step GuideFrom EverandGood documentation practice The Ultimate Step-By-Step GuideRating: 5 out of 5 stars5/5 (1)

- HimshitolDocument91 pagesHimshitolPoulami DeNo ratings yet

- Alor PhulkiDocument96 pagesAlor PhulkiPoulami DeNo ratings yet

- After Cancer TreatmentDocument282 pagesAfter Cancer TreatmentPoulami De100% (1)

- Nonte Fonte Vol 10Document31 pagesNonte Fonte Vol 10Poulami DeNo ratings yet

- Nonte Fonte Vol 6Document31 pagesNonte Fonte Vol 6Poulami DeNo ratings yet

- Repertoar Flori de BachDocument74 pagesRepertoar Flori de BachLidia Dicu100% (1)

- Puzzles To Puzzle YouDocument136 pagesPuzzles To Puzzle Youshahisk100% (1)

- Nonte Fonte Vol 8Document30 pagesNonte Fonte Vol 8Poulami DeNo ratings yet

- Story of My LifeDocument366 pagesStory of My LifePoulami De100% (1)

- Readers Digest Best JokesDocument16 pagesReaders Digest Best JokesEskay95% (58)

- Spoken English ExpressionsDocument52 pagesSpoken English Expressionsapi-3806123100% (3)

- Nonte Fonte Vol 9Document30 pagesNonte Fonte Vol 9Poulami DeNo ratings yet

- Cambridge Self-Scoring IQ TestDocument60 pagesCambridge Self-Scoring IQ TestPoulami DeNo ratings yet

- Nonte Fonte Vol 4Document31 pagesNonte Fonte Vol 4Poulami DeNo ratings yet

- Nonte Fonte Vol 7Document27 pagesNonte Fonte Vol 7Poulami DeNo ratings yet

- Appendix-Global Allergen Lists - V 2.0 Dec 12 2005Document4 pagesAppendix-Global Allergen Lists - V 2.0 Dec 12 2005Poulami DeNo ratings yet

- Nonte Fonte Vol 5Document31 pagesNonte Fonte Vol 5Poulami DeNo ratings yet

- Nonte Fonte Vol 3Document29 pagesNonte Fonte Vol 3Poulami DeNo ratings yet

- Food DefenseDocument34 pagesFood DefensePoulami De100% (1)

- Learn Spoken English QuicklyDocument20 pagesLearn Spoken English QuicklyPoulami DeNo ratings yet

- Challenging Logic and Reasoning Problems PDFDocument161 pagesChallenging Logic and Reasoning Problems PDFMalvado Aun Mas MalvadoNo ratings yet

- Hada Vodar Kando KarkhanaDocument60 pagesHada Vodar Kando KarkhanaPoulami DeNo ratings yet

- Netaji's unfinished autobiographyDocument150 pagesNetaji's unfinished autobiographysoceeNo ratings yet

- Readers Digest Apr 06Document222 pagesReaders Digest Apr 06Poulami DeNo ratings yet

- Emergency Handbook For Food ManagersDocument79 pagesEmergency Handbook For Food ManagersPoulami DeNo ratings yet

- Factory Safety PDFDocument48 pagesFactory Safety PDFPoulami DeNo ratings yet

- h07 - Freescale Crisis Management PlanDocument10 pagesh07 - Freescale Crisis Management PlanPoulami DeNo ratings yet

- Delivery SOPDocument1 pageDelivery SOPPoulami DeNo ratings yet

- Food Safety Security ResourcesDocument4 pagesFood Safety Security ResourcesPoulami DeNo ratings yet

- NCERT Solutions For Class 11th: CH 1 Indian Economy On The Eve of IndependenceDocument53 pagesNCERT Solutions For Class 11th: CH 1 Indian Economy On The Eve of IndependenceSai KrishnaNo ratings yet

- Sabeco - Information Disclosure PDFDocument53 pagesSabeco - Information Disclosure PDFNgoanNguyễnNo ratings yet

- Nectar PresentationDocument11 pagesNectar PresentationYogendra Gupta0% (1)

- MANNA Biscuits Sales StrategyDocument13 pagesMANNA Biscuits Sales StrategyVinu DNo ratings yet

- Module One Lesson One ActivityDocument3 pagesModule One Lesson One ActivityKhadija TahirkheliNo ratings yet

- Smith - Ilustrated Encyclopedia of Gold and Silver Coins of The World (1886)Document511 pagesSmith - Ilustrated Encyclopedia of Gold and Silver Coins of The World (1886)Goran Miljkovic100% (1)

- Green Screen ScriptDocument4 pagesGreen Screen Scriptapi-539419913No ratings yet

- Business Plan V.3.1: Chiken & Beef BBQ RestaurantDocument32 pagesBusiness Plan V.3.1: Chiken & Beef BBQ RestaurantMohd FirdausNo ratings yet

- Paradise JazzDocument469 pagesParadise JazzMiguel M. Neves100% (2)

- 42 47 ListDocument6 pages42 47 ListMartha DewaNo ratings yet

- Customer Preferences For Restaurant Technology InnovationsDocument22 pagesCustomer Preferences For Restaurant Technology InnovationsDeepankar SinghNo ratings yet

- SOP - Customer CHDocument3 pagesSOP - Customer CHkitekNo ratings yet

- Karnataka Cooperative Milk ProducersDocument9 pagesKarnataka Cooperative Milk ProducersPoirei Zildjian0% (1)

- CpkelcoDocument16 pagesCpkelcoPramod PokhrelNo ratings yet

- Clorox Company Goes Green Case StudyDocument28 pagesClorox Company Goes Green Case StudyStefano VitaleNo ratings yet

- Government Guidelines for Classifying Apartment HotelsDocument20 pagesGovernment Guidelines for Classifying Apartment HotelsAdarsh Patil100% (1)

- Report of Amul IndiaDocument11 pagesReport of Amul IndianehaNo ratings yet

- Comparative Analysis Between Pizza Hut and Dommino'sDocument30 pagesComparative Analysis Between Pizza Hut and Dommino'sDhananjay Kumar86% (21)

- Ice Cream Business Plan.Document41 pagesIce Cream Business Plan.Daniel Sanchez76% (25)

- Crisil ReportDocument40 pagesCrisil ReporthimadhavNo ratings yet

- French Fries The Ultimate RecipeDocument118 pagesFrench Fries The Ultimate RecipekwonshinNo ratings yet

- Ratio and Proportion: STRAND A: Computation Unit 5Document16 pagesRatio and Proportion: STRAND A: Computation Unit 5Fayeed Ali RassulNo ratings yet

- Jamie Oliver's Food Tube YouTube StrategyDocument3 pagesJamie Oliver's Food Tube YouTube StrategyT PNo ratings yet

- Swot Analysis: S W O TDocument38 pagesSwot Analysis: S W O TSHI TING NGNo ratings yet

- Front Office Reservation PowerpointDocument50 pagesFront Office Reservation PowerpointJervy Aurestila Item75% (4)

- Focus Strategy of VinamilkDocument14 pagesFocus Strategy of VinamilkMTCB BlogNo ratings yet

- Global Business StrategyDocument27 pagesGlobal Business StrategyshizabidiNo ratings yet

- Arid Agriculture University, Rawalpindi: Mid Exam / Spring 2020 (Paper Duration 48 Hours) To Be Filled by TeacherDocument2 pagesArid Agriculture University, Rawalpindi: Mid Exam / Spring 2020 (Paper Duration 48 Hours) To Be Filled by TeacherHisham TariqNo ratings yet

- Entrep Business Plan HOUSE OF SPAMDocument12 pagesEntrep Business Plan HOUSE OF SPAMAnne DSNo ratings yet

- MM For HavmorDocument13 pagesMM For HavmorvyapiNo ratings yet