Professional Documents

Culture Documents

Engineering Scales

Uploaded by

AmshgautamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Scales

Uploaded by

AmshgautamCopyright:

Available Formats

PROJECT PROFILE ENGINEERING SCALE

A. INTRODUCTION & USES: An engineer's scale is a tool for measuring distances and transferring measurements at a fixed ratio of length. It is commonly made of plastic and is just over 12 inches (305 mm) long, but with only 12 inches of markings, leaving the ends unmarked so that so that the first and last measuring ticks do not wear off. It is used in making engineering drawings, commonly called blueprints, in scale. For example, "one-tenth size" would appear on a drawing to indicate a part larger than the paper itself. It is not to be used to measure machined parts to see if they meet specifications. In scientific and engineering terminology, a device to measure linear distance and create proportional linear measurements is called a scale. A device for drawing straight lines is a ruler. In common usage both are referred to as a ruler. B. MARKET POTENTIAL Engineer scale is having an increased demand with development of more engineering industries for the purpose of measuring items. The scales are used in schools, science colleges, architects, drawing office &* engineering workshops and hence there is growing demand for this item. C. Production Target: It is proposed to manufacture 4,00,000 Nos of Engineering Scale per annum. D. BASIS AND PRESUMPTION: (i) The unit is expected to work at 75% efficiency on 8 hrs. Single shift basis for full capacity utilizations. (ii) The full capacity utilisation will be achieved in three years. 70% in the first year followed by 85% in the next year and the 100% in subsequent years. (iii) Labour and wages mentioned as per prescribed minimum wages and the proprietor is considered as a manager. (iv) Interest considered @ 12% in the project provide for recurring and non-recurring investment. (v) The cost of land, construction charges, cost of machinery and equipment, raw materials and consumables other expenses etc. initiated in the profile are based on the prices

prevailing at the time of project preparation. Therefore, they are subject to necessary changes from time to time based on local conditions. E. IMPLEMENTATION SCHEDULE: Activity Survey for collection of data in respect of demand, raw material, including power and fuel availability of technology, pollution control Arrangement for margin money Preparation of project document and registration and other clearance Financial assistance Selection of site and development of land Make shift office Purchasing of machines & recruitment of staff Construction of building & selection of machinery Installation of machinery & purchase of raw materials Trial production F. TECHNICAL ASPECTS: MANUFACTURING PROCESS The Process involves cutting of acrylic sheets to required length and width, polishing edges for parallel surface. The cut sheets are graduated according to the required accuracy and number marking is done by the automated scale marking machine. The surface is dried and cleaned. The finish polished scales are packed. 2. QUALITY STANDARDS AND SPECIFICATIONS: Graduation marking must be uniform in depth and accuracy to 0.01 mm conform to specification of BIS or other standard. 3. POLLUTION CONTROL: These types of units are is not producing any effluents or any other polluting materials. Therefore pollution control measures are not taken into account. 4. ENERGY CONSERVATION NEEDS: General awareness is to be created for economic use of electricity at all points. Capacitors may be used at suitable points for energy conservation. All machinery and equipment should be properly lubricated and maintained so that they consume less amount of power in use. Period Starting to Completion 0 0 1st 2nd 3rd 3rd 4th 5th 6th 7th 1 Month 1st Months 2nd Months 3rd Months 4th months 4th Months 5th Months 6th Months 7th Months 8th Months

G. FINANCIAL ASPECT: (i) Land & Building: Land and building Rented Covered area 150 sq.mtrs. for Rs. 8,000/- per month. (ii) Fixed Capital on Plant & Machinery: SI.No. Description 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Electrification & installation charges @ 10% of machinery cost Office furniture, almirah, office instruments etc. Total Plant & M/c Cost L.S Automated Scale MarkingMachine complete with accessorries for graduation accuracy 0.01 mm Bench type pentograph engraving machine table size 16" Linear Polishing machine Band saw bench model/ wheel 8" rockwell Bevel edges grinding machine bench type wheel dia 8 " Double ended bench grinder wheel dia 6" Ind/Imported Ind 1 Ind 1 Ind Ind Ind 1 Ind 1 TOTAL 1,54,500 20,000 17,19,500 18,000 7,000 15,45,000 1 1 15,000 8,000 12,000 14,85,000 Qty. (Nos.) Value (Rs.)

(iii) Pre-operative expenses @ 2.0 % -------------- 34,390

TOTAL FIXED CAPITAL (i+ii+iii) ----- 17, 53,890

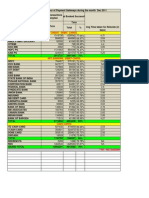

4. WORKING CAPITAL (PERMONTH): 1. Staff & Labour Expenses: (a) Administrative: SI.No. Description 1 2 3 4 5 6 7 Manager Skilled Workers Semi skilled Workers Helper Total Labor Benefits / Perquisite @ 15% of salary Grand Total Nos. 1 2 1 1 Rate (Rs.) 10,000 5,500 4,800 4,500 Amount (Rs.) 10,000 11,000 4,800 4,500 30,300 4,545 34,845

II. Raw Materials (per month): SI.No. Description 1. 2. 3. Acrylic Sheets of thickness 1/8" transparent or milky white Marking Ink, polishing, wheel buffing, clothes Packing Case & Box Cartons & Plastic Bags TOTAL Qty. 500 L.S L.S Value (Rs.) 72,500 5,000 2,500 80,000

III. Utilities (per month): Power @ 3.80/unit for 10 KW Water L.S IV. Other Contingent expenses (P.M.): SI.No. Description 1. 2. 3. 4. Rent Postage and Stationery Telephone Repair and maintenance Values (Rs.) 8,000 500 500 500 Rs 3,800 Rs. 2000

5. 6. 7. 8. 9. 10. 11.

Oils & Lubricants Consumable stores Transport charges Insurance Sales expenses Misc Expenses Total

2,500 2,000 1,500 500 800 500 17,300

V. Total recurring expenditure (per month): 1. Staff and labor 2. 3. 4. Raw material Utilities Other contingent expenses Total

34,845 80,000 5,800 17,300 1,37,945

VI. Total working capital (3 months basis) 5. Total capital investment: 1. Machinery and equipment 2. Working Capital Total 6. Financial Analysis: 1. Cost of Production (Per Year) : 1. Total recurring cost per year 2. 3. 4.

4,13,835

17,53,890 4,13,835 21,67,725

16,55,340 1,54,500 4,000 2,60,127 20,73,967

Depreciation on plant and machinery @ 10% Depreciation on office equipments @ 20% Interest on total capital investment @ 12% Total

2. Total Sales (per year): Annual Production of 4,00,000 Engineering Scales Total Annual sales 4,00,000 * 7.00 = Rs. 28,00,000 By sale of scrap (L.S) = Rs. 5,000 Total = Rs. 28,05,000 3. Net Profit (per year) Before tax = Total sales Cost of production = 28,05,000 20,73,967 = 7,31,033 4. Profit Ratio:= Net profit x 100 / Total turn over = 7,31,033 x 100 / 28,05,000 = 26.06 % 5. Rate of Return: = Net profit x 100 / Total Capital Investment = 7,31,033 x 100 / 21,67,725 = 33.72% 6. Break Even Point: a) Fixed cost (per year): 1. Rent 2. 3. 4. 5. 6. Interest @12 % Depreciation of machinery & equipments, tools, fixtures @10 % Depreciation of office equipment @ 20 % 40% of salaries and wages 40% of other expenses including utilities and excluding rent Total fixed cost (FC) BEP = FC x 100/ FC + Profit = 7,54,363 x 100 / ( 7,54,363 + 7,31,033 ) = 50.79 % ADDRESSES OF MACHINERY & EQUIPMENT SUPPLIERS: 1. M/s. Batliboi & Co., Parliament Street, New Delhi-110001 2. M/s. Ashoka Machine Tools Corpn., A-15, Mayapuri Indl. Area, New Delhi. 3. M/s. Amteep Machine Tools (P) Ltd., 17/7, Mathura Road, Faridabad. 4. M/s Rita Pad Printing Systems Ltd. Plot No. 44 & 45 , Sector - 18, Gurgaon NAMES AND ADDRESSES OF RAW MATERIALS SUPPLIERS: Raw material can be purchased from the local suppliers available in the market.

96,000 2,60,127 1,54,500 4,000 1,67,256 72,480 7,54,363

You might also like

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- AAC Sample Project Profile Universal-Ver-2Document7 pagesAAC Sample Project Profile Universal-Ver-2N Gangadhar Reddy100% (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Desk Top Publishing DTP CenterDocument9 pagesDesk Top Publishing DTP CentersuryanathNo ratings yet

- Project Profile - Magnetic ButtonsDocument7 pagesProject Profile - Magnetic ButtonsSai PrashanthNo ratings yet

- Design Handbook MAchine DesignDocument5 pagesDesign Handbook MAchine DesignsouravNo ratings yet

- Offset Printing Press (Job Work) : NtroductionDocument4 pagesOffset Printing Press (Job Work) : NtroductionMMjagpreetNo ratings yet

- Almirah Enterprenuership Project 2Document11 pagesAlmirah Enterprenuership Project 2Debadatta Ratha50% (6)

- Project of Rexin BagDocument11 pagesProject of Rexin BagShayan Pitruja100% (1)

- P P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumDocument10 pagesP P O P C (P - IV) : Roject Rofile N Ersonal Omputer EntiumNiju K ANo ratings yet

- Project Profile On Repair & Servicing of Electrical AppDocument11 pagesProject Profile On Repair & Servicing of Electrical AppKavi RehabianNo ratings yet

- Project On Hollow BricksDocument13 pagesProject On Hollow BricksSindhu Amal100% (1)

- Sample Project ProfileDocument9 pagesSample Project ProfileAnushaa BharadwajNo ratings yet

- A Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inDocument8 pagesA Project Profile On Saddlery & Harness: Dcdi-Agra@dcmsme - Gov.inroufzargarNo ratings yet

- Project Profile: Manufacturing of Staple PinDocument8 pagesProject Profile: Manufacturing of Staple PinAbhijeet ChauhanNo ratings yet

- Voltage StabilizerDocument11 pagesVoltage StabilizerShreekant KashyapNo ratings yet

- Disposable SyringeDocument5 pagesDisposable SyringePrabhu KoppalNo ratings yet

- Bleaching and Dyeing of Cotton Knitted Fabric Project ReportDocument9 pagesBleaching and Dyeing of Cotton Knitted Fabric Project ReportRajesh Kumar PandeyNo ratings yet

- Ac PDFDocument5 pagesAc PDFBest BetterNo ratings yet

- Plastic Industry Project ReportDocument6 pagesPlastic Industry Project Reportloveaute15100% (1)

- Project Profile - Gems Clip A. Introduction:: Market PotentialDocument8 pagesProject Profile - Gems Clip A. Introduction:: Market PotentialGopal SinhaNo ratings yet

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiDocument9 pagesIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreNo ratings yet

- Mobile Phone Repairing and ServicingDocument9 pagesMobile Phone Repairing and Servicingsvkatkar0% (1)

- Auto Leaf SpringDocument11 pagesAuto Leaf SpringVijayKrishnaAmaraneniNo ratings yet

- Electronic Weighing ScaleDocument17 pagesElectronic Weighing ScaleVicky KaloniaNo ratings yet

- Aluminum Fabrication PDFDocument11 pagesAluminum Fabrication PDFdishku50% (4)

- Electronics CCTV CameraDocument10 pagesElectronics CCTV CameraShanza ManzoorNo ratings yet

- Project Profile On Computerized Machine (Job Work) : Such Specification For This ProductDocument8 pagesProject Profile On Computerized Machine (Job Work) : Such Specification For This ProductParijat RaiNo ratings yet

- CH 22Document5 pagesCH 22ProfNDAcharyaNo ratings yet

- Hand Gloves Project EportDocument4 pagesHand Gloves Project Eportktgururaj0% (1)

- Project Profile On DVR: CCTV CameraDocument11 pagesProject Profile On DVR: CCTV CameraBest BetterNo ratings yet

- Paper CupsDocument13 pagesPaper CupsVeena KohliNo ratings yet

- MSME Project ReportDocument8 pagesMSME Project Reportchaudhary1604No ratings yet

- Water ProjectDocument5 pagesWater ProjectJayaprakash KanagarajNo ratings yet

- Project Report Battery Manufacturing PlantDocument14 pagesProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Ec Imp QuestionsDocument21 pagesEc Imp Questionswhitefang0606No ratings yet

- Cotton Knitted Undergarments (Briefs, Panties, Vests) : 1. Procurement of Knitted FabricDocument6 pagesCotton Knitted Undergarments (Briefs, Panties, Vests) : 1. Procurement of Knitted FabricPaka ManojNo ratings yet

- Cost EstimationDocument7 pagesCost Estimationrubesh_rajaNo ratings yet

- Monolithic RefractoriesDocument11 pagesMonolithic RefractoriesZafr Cetn100% (1)

- Organisation MGMT - NICMAR NCP-21Document19 pagesOrganisation MGMT - NICMAR NCP-21madhuwadi100% (1)

- 500va Inverter: Small Industries Service Institute, AgartalaDocument10 pages500va Inverter: Small Industries Service Institute, AgartalaAvishek DuttaNo ratings yet

- Msme-Development INSTITUTE, 107, Industrial: Estate, Kanpur - 208012Document10 pagesMsme-Development INSTITUTE, 107, Industrial: Estate, Kanpur - 208012Sethu SparkNo ratings yet

- Hacksaw BladeDocument12 pagesHacksaw BladeShankar GNo ratings yet

- Stainless Steel Cooking UtensilsDocument9 pagesStainless Steel Cooking UtensilsGopal AgrawalNo ratings yet

- Estimation and CostingDocument44 pagesEstimation and CostingSuhasini Pranay100% (2)

- About Us Nstedb Events Feedback Contact Us: Fly Ash BricksDocument6 pagesAbout Us Nstedb Events Feedback Contact Us: Fly Ash BricksShantanu.s.deshpandeNo ratings yet

- Quality Control and Standards: Sl. Activity No. Period Starting Period CompletionDocument5 pagesQuality Control and Standards: Sl. Activity No. Period Starting Period Completionanand_shrivastavNo ratings yet

- Engeco Chap 02 - Cost Concepts and Design EconomicsDocument37 pagesEngeco Chap 02 - Cost Concepts and Design EconomicshannankuNo ratings yet

- Gents T-Shirts: NtroductionDocument8 pagesGents T-Shirts: Ntroductionharish_kavetiNo ratings yet

- Men's Readymade GarmentsDocument5 pagesMen's Readymade Garmentsmorshed.mahamudNo ratings yet

- Jute BagDocument9 pagesJute Bagafham84No ratings yet

- P P O C C: Roject Rofile N Omputer Entre For Website Design and DevelopmentDocument10 pagesP P O C C: Roject Rofile N Omputer Entre For Website Design and DevelopmentSatish KumarNo ratings yet

- Ridj Offset PrintingDocument9 pagesRidj Offset Printingsanjit laishramNo ratings yet

- CH 25Document19 pagesCH 25Shanawar AzamNo ratings yet

- General Engineering WorkshopDocument3 pagesGeneral Engineering WorkshopSudhir Kushwaha0% (1)

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningFrom EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- CDocument6 pagesCAmshgautamNo ratings yet

- SocialSC Supp MA PoliticalSC 01Document2 pagesSocialSC Supp MA PoliticalSC 01AmshgautamNo ratings yet

- MA PoliticalSc Admn List IDocument6 pagesMA PoliticalSc Admn List IAmshgautamNo ratings yet

- M.A. Political Science Entrance ExamDocument75 pagesM.A. Political Science Entrance ExamshaninxyzNo ratings yet

- Credit / Debit CardsDocument3 pagesCredit / Debit CardsAmshgautamNo ratings yet

- Master M Des List of Candidate & ScheduleDocument4 pagesMaster M Des List of Candidate & ScheduleAmshgautamNo ratings yet

- List of Candidate & ScheduleDocument21 pagesList of Candidate & ScheduleAmshgautamNo ratings yet

- National Air Express Ch-01Document2 pagesNational Air Express Ch-01Amshgautam0% (1)

- 17 Modelica in SimulationX 3 5Document9 pages17 Modelica in SimulationX 3 5AmshgautamNo ratings yet

- Kishore M. Daswani - ResumeDocument3 pagesKishore M. Daswani - ResumeKishore DaswaniNo ratings yet

- Construction Companies in MauritiusDocument4 pagesConstruction Companies in MauritiusJowaheer Besh100% (1)

- Travel Insurance CertificateDocument9 pagesTravel Insurance CertificateMillat PhotoNo ratings yet

- BPI Lesson 1 - Surveys & Investigation PDFDocument60 pagesBPI Lesson 1 - Surveys & Investigation PDFMayNo ratings yet

- Bsee25 Lesson 1Document25 pagesBsee25 Lesson 1Renier ArceNoNo ratings yet

- Islam and PatriarchyDocument21 pagesIslam and PatriarchycarolinasclifosNo ratings yet

- Aims of The Big Three'Document10 pagesAims of The Big Three'SafaNo ratings yet

- 2020 Macquarie University Grading and Credit Point System PDFDocument2 pages2020 Macquarie University Grading and Credit Point System PDFRania RennoNo ratings yet

- Shes Gotta Have It EssayDocument4 pagesShes Gotta Have It EssayTimothy LeeNo ratings yet

- Development of Modern International Law and India R.P.anandDocument77 pagesDevelopment of Modern International Law and India R.P.anandVeeramani ManiNo ratings yet

- Sibayan, Patrick Jorge - Weekly Accomplishment (July 8-14, 2019)Document2 pagesSibayan, Patrick Jorge - Weekly Accomplishment (July 8-14, 2019)Patrick Jorge SibayanNo ratings yet

- Types of Quiz-2-QDocument9 pagesTypes of Quiz-2-QAhmed Tamzid 2013028630No ratings yet

- Jordan Leavy Carter Criminal ComplaintDocument10 pagesJordan Leavy Carter Criminal ComplaintFOX 11 NewsNo ratings yet

- Declarations On Higher Education and Sustainable DevelopmentDocument2 pagesDeclarations On Higher Education and Sustainable DevelopmentNidia CaetanoNo ratings yet

- Mini Manual CompiereDocument20 pagesMini Manual Compiereapi-3778979100% (1)

- Information Security NotesDocument15 pagesInformation Security NotesSulaimanNo ratings yet

- Maharashtra Government Dilutes Gunthewari ActDocument2 pagesMaharashtra Government Dilutes Gunthewari ActUtkarsh SuranaNo ratings yet

- Why Some Platforms Thrive and Others Don'tDocument11 pagesWhy Some Platforms Thrive and Others Don'tmahipal singhNo ratings yet

- Lecture 1Document12 pagesLecture 1asiaNo ratings yet

- HANDOUT Writing 6Document2 pagesHANDOUT Writing 6Huân Nguyễn DuyNo ratings yet

- Unit 7:: Intellectual PropertyDocument52 pagesUnit 7:: Intellectual Propertyمحمد فائزNo ratings yet

- Sir Gawain and The Green Knight: A TranslationDocument39 pagesSir Gawain and The Green Knight: A TranslationJohn AshtonNo ratings yet

- Pronunciation SyllabusDocument5 pagesPronunciation Syllabusapi-255350959No ratings yet

- Sample TRF For Master TeacherDocument10 pagesSample TRF For Master TeacherBernard TerrayoNo ratings yet

- Music of The Medieval PeriodDocument33 pagesMusic of The Medieval PeriodEric Jordan ManuevoNo ratings yet

- Tan Vs PeopleDocument1 pageTan Vs PeopleGian Tristan MadridNo ratings yet

- "The Old Soldier'S Return": Script Adapted FromDocument6 pages"The Old Soldier'S Return": Script Adapted FromMFHNo ratings yet

- Country in A Box ProjectDocument6 pagesCountry in A Box Projectapi-301892404No ratings yet

- Supply Chain and Logistics Management: Distribution PoliciesDocument8 pagesSupply Chain and Logistics Management: Distribution PoliciesKailas Sree ChandranNo ratings yet

- Nurlilis (Tgs. Bhs - Inggris. Chapter 4)Document5 pagesNurlilis (Tgs. Bhs - Inggris. Chapter 4)Latifa Hanafi100% (1)