Professional Documents

Culture Documents

15 Zero Emissions From FPSOs

Uploaded by

arch_ian0 ratings0% found this document useful (0 votes)

99 views1 pageZero emissions from FPSOs

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentZero emissions from FPSOs

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

99 views1 page15 Zero Emissions From FPSOs

Uploaded by

arch_ianZero emissions from FPSOs

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

GAS TECHNOLOGY

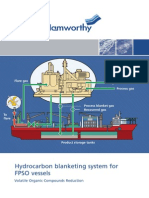

An application of the technology on an FPSO with onboard crude storage tanks. HC (hydrocarbon) process gas is used as blanket gas for the crude storage tanks and is supplied to the tanks when the ship is unloading oil to the shuttle tanker. During production the blanket gas is recovered to the main process and utilized for export, fuel or maybe LNG (Liquefied Natural Gas) or other gas-to-liquid technologies. The recovery system can also be used for recovery of the flare gas.

Zero emissions from FPSOs

New approach to the handling of VOC gases betters strict pollution controls

ABBs novel approach for the handling of VOC (volatile organic compounds) gases stemming from the process and storage facilities on an FPSO (Floating Production Storage and Offloading) vessel gives a 100 percent reduction in all emissions during the equipment uptime, while offering a rapid return on investment, with typical cases of less than two years. As a result, interest for this technology is now being stirred in regions other than the North Sea where it was originally developed, such as offshore West Africa.

Called the HC Blanket Gas System, 100 percent of the VOC emitted from the cargo tanks are recovered in the system and delivered to the existing process system on the FPSO. During offloading the process is reversed and clean process gas refills the cargo tanks while the oil is exported. By its simplicity, this system gives a far better efficiency level than that which is required, for instance, by the Norwegian authorities. Inert vs hydrocarbon blanket gas The purpose of the HC blanket gas system is to replace the use of inert gas with pure HC gas as the blanket gas in the storage tanks and to recover the off gas. Inert gas is used to prevent low pressure and the intrusion of oxygen into the storage tank atmosphere. The advantage of the HC blanket gas system is a pure HC atmosphere, which results in a less problematic approach to the recovery of surplus gas from the storage tanks. Using HC blanket gas also reduces the corrosion problems in the storage tanks and in the tank vent system. VOC gases During the storing and loading of hydrocarbon products, when oil is not being offloaded, "boil-off" vapours in the form of VOC are released. VOC are harmful to ones health, to the environment, represent a considerable economic value and are an asset which should not be wasted. According to the Norwegian Pollution Control Authority (SFT) all FPSOs are required to have VOC recovery installed with a minimum reduction of 78 percent by weight in non-methane VOC emissions (NMVOC). To achieve this, oil companies are required to install systems for collecting VOC from tank farms, terminals and ship loading installations. Legislation in other regions is expected to follow a similar course. ABB supplies skid-based systems after performing feasibility studies and process simulations to assist in the selection of the optimal solution for a given application and provides engineering services for integration into existing process systems.

Synergy 2/2003 15

You might also like

- Coastal Ocean Observing SystemsFrom EverandCoastal Ocean Observing SystemsYonggang LiuNo ratings yet

- Gastech2015 - WSA Case StudyDocument1 pageGastech2015 - WSA Case StudyIlham HakimNo ratings yet

- New Technologies for Emission Control in Marine Diesel EnginesFrom EverandNew Technologies for Emission Control in Marine Diesel EnginesNo ratings yet

- OTC13999 Development For A Deep Sea FPSO Suitable For The GoMDocument8 pagesOTC13999 Development For A Deep Sea FPSO Suitable For The GoMAnil ChananaNo ratings yet

- PT. Pelindo 3 SyndicateDocument32 pagesPT. Pelindo 3 Syndicategalihdiadi-1No ratings yet

- Simulation Result Comparison-LPG Plant JambiDocument1 pageSimulation Result Comparison-LPG Plant JambiMadeMaryasaRobedNo ratings yet

- Technical Safety PDFDocument21 pagesTechnical Safety PDFMochamad Irvan MaulanaNo ratings yet

- 01 Petrobras PDFDocument13 pages01 Petrobras PDFpkannanNo ratings yet

- Largest ScandinavianDocument39 pagesLargest ScandinaviansahirprojectsNo ratings yet

- 17.1 - Drillship Class and Stat - FLNG DifferencesDocument38 pages17.1 - Drillship Class and Stat - FLNG Differencesding liuNo ratings yet

- 5NRJHL Saipem FY2020 Results JMEEBODocument42 pages5NRJHL Saipem FY2020 Results JMEEBOsudhakarrrrrrNo ratings yet

- GTDALBDocument154 pagesGTDALBWilson KooNo ratings yet

- Statoil Internal Report On Smeaheia Subsurface 2016 - Selected ExtractsDocument32 pagesStatoil Internal Report On Smeaheia Subsurface 2016 - Selected ExtractsSina Madani100% (1)

- Wartsila 25 The Power To Target Net ZeroDocument8 pagesWartsila 25 The Power To Target Net ZeroAlvin AkbarNo ratings yet

- WisonDocument29 pagesWisonYoon SDNo ratings yet

- Wison: Better Technology, Better LifeDocument27 pagesWison: Better Technology, Better LifeatpworldNo ratings yet

- Safety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsDocument19 pagesSafety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsFoyez AhmadNo ratings yet

- SKK Migas Annual Report 2013Document130 pagesSKK Migas Annual Report 2013郑裕 鸿100% (2)

- BelkinDocument33 pagesBelkinNasrulNo ratings yet

- FDP01 MDM3 Asyyy 14 343008 0001 02Document86 pagesFDP01 MDM3 Asyyy 14 343008 0001 02Khánh TrầnNo ratings yet

- LNG Project Reference Snohvit Success StoryDocument8 pagesLNG Project Reference Snohvit Success StoryKong LingweiNo ratings yet

- Introductiontogastransportation 161222145926 PDFDocument26 pagesIntroductiontogastransportation 161222145926 PDFAl Jawad100% (1)

- Saipem - Baku - YardDocument4 pagesSaipem - Baku - YardXt0ph367% (3)

- Downstream Map LPG in IndonesiaDocument2 pagesDownstream Map LPG in IndonesiaZaenal MutaqinNo ratings yet

- Basic Training For Liquified Gas Tanker and Cargo OperationDocument5 pagesBasic Training For Liquified Gas Tanker and Cargo Operationsreenath MNo ratings yet

- Brief Instruction of FSRUDocument21 pagesBrief Instruction of FSRUwutigarNo ratings yet

- Structural Design of Offshore Ships: Offshore Standard DNV-OS-C102Document44 pagesStructural Design of Offshore Ships: Offshore Standard DNV-OS-C102Arun GuptaNo ratings yet

- Since The Jabiru Venture Became The First Fpso Offshore Australia in 1986, The Requirements For Fpsos Have ChangedDocument10 pagesSince The Jabiru Venture Became The First Fpso Offshore Australia in 1986, The Requirements For Fpsos Have ChangedmasilamaniNo ratings yet

- ME-C Introduction: Total Solution ProviderDocument6 pagesME-C Introduction: Total Solution ProviderАндрейNo ratings yet

- LNG Erminals in USDocument12 pagesLNG Erminals in USManuel Guerrero0% (1)

- Cosl Boss: Keppel Fels "Mod V B Class" Jack-UpDocument2 pagesCosl Boss: Keppel Fels "Mod V B Class" Jack-UpNABIL FIKRIENo ratings yet

- MLA Data Sheet - LNG - RevaDocument6 pagesMLA Data Sheet - LNG - RevaLuis Gonzalez0% (1)

- Petroleum Refining and Economics: Kobbina Awuah (Machinery Engineer/Project Manager, Conocophillips-Bayway Refinery)Document21 pagesPetroleum Refining and Economics: Kobbina Awuah (Machinery Engineer/Project Manager, Conocophillips-Bayway Refinery)GNo ratings yet

- Sustainable Closure and Decommissioning of Oil and Gas Assets in NigeriaDocument32 pagesSustainable Closure and Decommissioning of Oil and Gas Assets in NigeriaSalif DiasNo ratings yet

- Gow Strategy Review March 2011Document15 pagesGow Strategy Review March 2011Shraddha GhagNo ratings yet

- Oil Processing PDFDocument65 pagesOil Processing PDFsegunoyesNo ratings yet

- FPSO SystemsDocument29 pagesFPSO Systemspraving76100% (2)

- 0 0750 0043 02 WebDocument2 pages0 0750 0043 02 WebisaacNo ratings yet

- Shipboard Operational Energy Efficiency:: Regulations, Standards & OpportunitiesDocument18 pagesShipboard Operational Energy Efficiency:: Regulations, Standards & OpportunitiesRaluca UcaNo ratings yet

- DF 2005 2 PDFDocument16 pagesDF 2005 2 PDFAnonymous yRpebGJGaNo ratings yet

- Otc 10711 MSDocument12 pagesOtc 10711 MSAnonymous pNgdUM2x8No ratings yet

- PT Saipem Indonesia Karimun Island Yard: Work in PR OgressDocument4 pagesPT Saipem Indonesia Karimun Island Yard: Work in PR OgressAndysAfendsNo ratings yet

- HW 1 SolutionDocument5 pagesHW 1 SolutionNisargPatelNo ratings yet

- CE707-Lec08-Layout and Functional Requirement of PortDocument13 pagesCE707-Lec08-Layout and Functional Requirement of Portraaaaajjjjj100% (1)

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- OGTSIMForum Yinson-Inprocess Lifecycle ModelingforFPSODocument32 pagesOGTSIMForum Yinson-Inprocess Lifecycle ModelingforFPSOSaditte Manrique ContrerasNo ratings yet

- African LNGDocument5 pagesAfrican LNGM SidinaNo ratings yet

- 11 - Overview of SOQRATESDocument25 pages11 - Overview of SOQRATESsNo ratings yet

- Asia Pac Slides PDFDocument28 pagesAsia Pac Slides PDFjayryansantosNo ratings yet

- 1308spm Yard BOSCONGDocument4 pages1308spm Yard BOSCONGFabMaNo ratings yet

- Selecting: A Suitable ProcessDocument6 pagesSelecting: A Suitable ProcesstermdoxaNo ratings yet

- Explosion - Cidade de Sao Mateus FPSO - Rev 01Document1 pageExplosion - Cidade de Sao Mateus FPSO - Rev 01MukeshNo ratings yet

- CT Cleans Sand Deepwater Well WoDocument7 pagesCT Cleans Sand Deepwater Well Woabdulrahman abbasNo ratings yet

- Intecsea Lm-FpsoDocument40 pagesIntecsea Lm-FpsomuhamadsaffuanNo ratings yet

- Otc 21292 FPSO Motion CriteriaDocument7 pagesOtc 21292 FPSO Motion CriteriaJean David ChanNo ratings yet

- Engine Retrofit Guide v8Document70 pagesEngine Retrofit Guide v8Romulo AlvarezNo ratings yet

- 2018 AnnualReport PolychemIndonesiaTbk PDFDocument299 pages2018 AnnualReport PolychemIndonesiaTbk PDFDandy Riski FirdausNo ratings yet

- Hydrocarbon Gas BlanketingDocument2 pagesHydrocarbon Gas Blanketingna_pariNo ratings yet

- Benzene Vapour RecoveryDocument4 pagesBenzene Vapour Recoverymark_59No ratings yet

- Green TechnologiesDocument3 pagesGreen TechnologiesPriyanka GopinathanNo ratings yet

- MSC.245 (83) Cross FloodingDocument11 pagesMSC.245 (83) Cross Floodingarch_ian100% (2)

- Deliverable D1.1a v03Document131 pagesDeliverable D1.1a v03arch_ianNo ratings yet

- EulaDocument1 pageEulaarch_ianNo ratings yet

- Import 2011 06 22T22 53 40Document143 pagesImport 2011 06 22T22 53 40arch_ianNo ratings yet

- Delta PresentationDocument36 pagesDelta Presentationarch_ianNo ratings yet

- Deutz F12L413F Diesel Engine For Engineering - Deutz Engine WholesalerDocument2 pagesDeutz F12L413F Diesel Engine For Engineering - Deutz Engine WholesalerFederico Nah50% (2)

- Ship Recognition Manual CardassianDocument98 pagesShip Recognition Manual CardassianCody Lees100% (9)

- Schengen Visa PresentationDocument17 pagesSchengen Visa PresentationRizwan Anjum ChaudhryNo ratings yet

- KI0120182ENN enDocument2,290 pagesKI0120182ENN enDaiuk.DakNo ratings yet

- Manual of FUA India V 1.0Document109 pagesManual of FUA India V 1.0Ambrish YadavNo ratings yet

- Aviation IndustryDocument16 pagesAviation IndustryRajesh RaghavanNo ratings yet

- Tijuana A MexicoDocument1 pageTijuana A MexicoLance LamperougeNo ratings yet

- Audit Checklist SampleDocument150 pagesAudit Checklist SampleNikka LopezNo ratings yet

- Hitachi Package Oil Free BEBICON G2 SeriesDocument15 pagesHitachi Package Oil Free BEBICON G2 SeriesSilk RoadNo ratings yet

- New Holland T7.235 (EN)Document538 pagesNew Holland T7.235 (EN)George Stoican100% (2)

- @magazinesy Autocar UK - 6 April 2022Document84 pages@magazinesy Autocar UK - 6 April 2022Wndah CahyaniNo ratings yet

- Technical Note: I - Subject: Apm and Ebs 5 (Operation and Diagnostics)Document13 pagesTechnical Note: I - Subject: Apm and Ebs 5 (Operation and Diagnostics)mebarki aberraoufNo ratings yet

- CESMM3 OcrDocument122 pagesCESMM3 OcrKhaled RahimNo ratings yet

- 650 Point To Point Bolt ListDocument14 pages650 Point To Point Bolt ListDanny ArimaNo ratings yet

- GMDSS GantiolerDocument104 pagesGMDSS GantiolerSimou NassimNo ratings yet

- Bourbon 2017 Registration DocumentDocument244 pagesBourbon 2017 Registration DocumentAR El Patron KadryNo ratings yet

- Moore, Malcom - Seventeenth-Century Vehicle of The Middle Passage, Archaeological and Historical Investigations On The Henrietta Marie Shipwreck SiteDocument19 pagesMoore, Malcom - Seventeenth-Century Vehicle of The Middle Passage, Archaeological and Historical Investigations On The Henrietta Marie Shipwreck SiteutvrdaNo ratings yet

- Unmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaDocument8 pagesUnmatched Boldness. Unrivaled Dominance.: Presenting The Imposing New Innova CrystaSatya JiNo ratings yet

- Despiece Estanque CombustibleDocument3 pagesDespiece Estanque CombustibleRicardo HarringtonNo ratings yet

- Event ManagementDocument25 pagesEvent ManagementRohan Sharma100% (1)

- Controlling A Growing International AirportDocument41 pagesControlling A Growing International Airportbluesw42No ratings yet

- P2.1 Forces and Their Effects Mark SchemeDocument2 pagesP2.1 Forces and Their Effects Mark SchemeAli khan7No ratings yet

- Intruder PolicyDocument3 pagesIntruder PolicyVARUN KUMAR CHINTALANo ratings yet

- Rro-N1/63 115: Government of India Ministry of Railways Railway BoardDocument14 pagesRro-N1/63 115: Government of India Ministry of Railways Railway BoardshakNo ratings yet

- Boarding Pass Dar Z in S Einar S 1504946115216Document1 pageBoarding Pass Dar Z in S Einar S 1504946115216Anonymous mficOTNo ratings yet

- Hec Mba - Case BookDocument139 pagesHec Mba - Case Bookfaredj rsNo ratings yet

- Town Planning Unit 4Document18 pagesTown Planning Unit 4Ayushi AgarwalNo ratings yet

- AeromexicoDocument3 pagesAeromexicoSergio LeniNo ratings yet

- Chile Import-Export Procedures: Section 11Document6 pagesChile Import-Export Procedures: Section 11Fabián A. Barraza RochaNo ratings yet

- Alam Jaya IIDocument2 pagesAlam Jaya IIStephanie LambertNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsFrom EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsRating: 4 out of 5 stars4/5 (9)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Basic Digital Signal Processing: Butterworths Basic SeriesFrom EverandBasic Digital Signal Processing: Butterworths Basic SeriesRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (26)

- Piping Design for Industrial Facilities: Understanding Codes and StandardsFrom EverandPiping Design for Industrial Facilities: Understanding Codes and StandardsRating: 4 out of 5 stars4/5 (1)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet