Professional Documents

Culture Documents

Nmos350 500ConstructionGuide

Uploaded by

trkonjicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nmos350 500ConstructionGuide

Uploaded by

trkonjicCopyright:

Available Formats

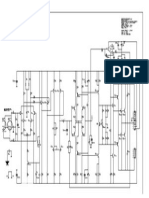

Construction Guide Nmos350 & Nmos500 power amp modules

The following is a guide only and is not intended to cover all variations of construction that may be employed by other hobbyists. It assumes that the constructor has adequate skills to assemble a moderately complex PCB and has basic skills in the use of tools. The guide begins with an un-drilled but otherwise finished blank PCB. The PCB All holes of the PCB should be pre-drilled with a 0.8mm bit. Many of these holes will be drilled again later to accommodate the various component lead sizes. When this is complete rub the track side of the board gently with some fine steel wool to de-burr the holes. Before re-drilling and placing any components you need to use the PCB as a template to mark the heatsink for drilling. This is done by placing the PCB, tracks down onto the heatsink and securing firmly with clamps or strong tape. Use the PCB to mark the drilling holes for the power FET screw holes and the PCB mounts (shown with blue arrows). I used the same 0.8mm bit to provide a drill centre for future drilling. Also mark the hole for T8 the heat sense transistor.

Remove the board and re-drill the holes that will take the larger components. I.e. the FETs, larger capacitors, fuse holders and 5-watt resistors etc. All holes should be correctly drilled before you begin to load the PCB with components. The PCB holes required for the FETs should be the same diameter as the FET mounting hole. Using the board again as a guide make the heatsink for the 4 TO126 transistors. I used a piece of U channel aluminium measuring 64mm long x 12mm wide. Mark and drill the 2 PCB mounting holes plus the 4 transistor mounting holes. De-burr all the holes well. Before components are placed onto the PCB, the tracks should be cleaned well using a small amount of detergent and some fine steel wool (or other abrasive cleaner) then rinsed. Assemble the PCB starting with the wire links, the small resistors, the fuse holders and all the PCB connectors. Then mount the 2 trimmer resistors, all the capacitors and the relay. Then mount all the TO92 transistors except T8. Assemble the 4 TO126 transistors to the small heatsink being mindful of their locations on the PCB. Use the drawing as a guide. Carefully mount the assembly onto the PCB using spacers to raise the heatsink about 6mm. Note there are components underneath that should not be in contact the heatsink. Once the transistor leads are passed through the PCB tighten all the screws. Before you solder check there are no shorts between the heatsink and the collector of each transistor. If there is, disassemble and check the insulating pads and heatsink for burrs or damage. Finally solder all the transistor leads.

The next job is to mount the power FETs. These mount underneath the PCB and involve the use of temporary nuts and bolts to align and secure them prior to soldering. Failure to do this correctly could cause a FET to fracture when PCB is secured to the heatsink. The temporary screws need to be a snug fit so that the FET holes align well with the PCB holes. 1. Measure and bend the FET leads so that they pass through the PCB solder holes and the FET mounting hole aligns with the PCB hole. Note that the metal side of the FET faces the heatsink with the leads bent in the opposite direction. 2. Secure the FETs using the temporary nuts and bolts and tighten taking care that the FETs remain in position. 3. Check to see that the plastic side of the FET is hard against the PCB then solder all the leads. Remove the nuts and bolts. Finally solder the long insulated link connecting the 2 PCB ground points. Solder only at the points shown. Examine the board looking for errors and the tracks for any unintentional shorts between tracks or poorly soldered joints. Your PCB is finished. The Heatsink Using the centre holes marked earlier, drill and tap the heatsink to take whatever mounting bolts you intend to use. Fine thread self tapping screws can also be used. Completely de-burr all the holes using a countersink bit or larger drill bit. This prevents any metal that de-forms during the threading process from piercing the FET insulating pads. Drill the hole for T8 so that it is a snug fit and is deep enough to just take the whole transistor body. T8 is mounted under the board (take care of the pinout orientation) so that it slides into the heatsink hole when the PCB is mounted. This is done by inserting the leads of T8 through the underside of the PCB so that it hangs. Bend the leads a little so that it is retained. Using a few screws and 5mm spacers carefully place the PCB onto the heatsinks so that all the mounting holes line up. Make sure that the T8s body goes in the hole and then on the top side of the PCB bend T8s legs Although taken of a different amplifier this picture shows the mounting of the TO126 transistors. The power FETs and T8. down fully. Lift the PCB off without any side movement then carefully solder one leg only of T8. Re-mount the PCB and check T8s alignement. Once you are satisfied lift the PCB again and solder the remaining 2 legs. Put a little thermal grease in T8s mounting hole, place insulating pads in position under the power FETs and permanently mount the board. Use the photograph as a guide. Tighten all the screws then using a multimeter check for shorts by measuring between the heatsink and the FETs drain (centre) lead. You should see an open circuit. If a short is measured lift the PCB and check for burrs or other damage to the pad.

Final Set up And Adjustment No attempt should be made to set up or test a power amplifier module that is not correctly mounted on a heatsink. Make sure the main power supply is fused and the work area is clear. First check all your work and make sure the output devices are insulated from heatsink. The set up is done without an input or a load connected to the power amplifier. 1. Check the power supply is operating correctly and verify the rail voltages. Switch the power supply off and check with a multimeter that the rail capacitors have discharged. 2. Correctly connect the ground, positive and negative leads to the power amp module. 3. Remove the PCB fuses and replace with 100 ohm 5 watt resistors. Connect a multimeter that is set to the 20 volt scale across the positive rail 100 ohm resistor. 4. Check that the power supply connections are correct one last time and switch on. If the multimeter reading goes off-scale, turn off immediately and find the problem. Check also the 100 ohm 5 watt resistors; they may have gone open cct. 5. If everything seems ok adjust VR2 to set the output stage bias current, by measuring the voltage across the positive rail resistor. Adjust for a reading of 3 volts per output FET pair. I.e. For a 6 FET board set for a voltage of 9 volts. This equates to a bias current of 30mA per FET pair or 90 mA total. For a 10 FET board set for a voltage of 15 volts. 6. If everything seems ok, check the output offset voltage and adjust VR1 to achieve an offset of less than 10 mV. 7. All being well switch off, back off the bias control trimmer (VR2) and replace the 100 ohm resistors with 10 ohm 1 watt resistors. Switch on again and re-adjust VR2 to get 0.3 volts per per FET pair across the positive rail 10 ohm resistor. 8. Switch off, remove the resistors and put the fuses back in. Switch on, re-check the offset voltage and adjust with VR1 if necessary. The amp module is ready, connect the input and output and enjoy.

You might also like

- Actrk400 600 Construction GuideDocument3 pagesActrk400 600 Construction GuideClaudio MartinsNo ratings yet

- EB27A construction hintsDocument8 pagesEB27A construction hintsPisu Miau Pisu MiauNo ratings yet

- 15 Watt FET FM Amp Rev 2 Assembly InstructionsDocument7 pages15 Watt FET FM Amp Rev 2 Assembly InstructionsStephen Dunifer100% (4)

- FRB 15 Watt Instruction PacketDocument8 pagesFRB 15 Watt Instruction PacketStephen Dunifer100% (1)

- Firefly PCB Assembly Guide - Build Your Own Tube AmplifierDocument16 pagesFirefly PCB Assembly Guide - Build Your Own Tube AmplifierRenier Orlando BlancoNo ratings yet

- 10 Watt PLL New Version Assembly InstructionsDocument11 pages10 Watt PLL New Version Assembly InstructionsStephen Dunifer100% (8)

- Assembly Instructions for the Gozouta Kit (40 charactersDocument17 pagesAssembly Instructions for the Gozouta Kit (40 charactersJuahanNo ratings yet

- SymAsym PCB Assembly GuideDocument8 pagesSymAsym PCB Assembly GuideWojciechNo ratings yet

- Diy Minipro DC/DC ConverterDocument14 pagesDiy Minipro DC/DC Convertermrcinek01No ratings yet

- Vintage New U47 Build GuideDocument16 pagesVintage New U47 Build Guidepiretto77No ratings yet

- The Digital Frequency Meter KitDocument11 pagesThe Digital Frequency Meter KitAllah RakhaNo ratings yet

- Flexible Voltage Regulator LayoutDocument9 pagesFlexible Voltage Regulator LayoutMahesh PhapaleNo ratings yet

- The Electronic Diagram of The Monophonic FM Receiver Made With TDA7088T Is Shown On PicDocument5 pagesThe Electronic Diagram of The Monophonic FM Receiver Made With TDA7088T Is Shown On PicBhatiaEktaNo ratings yet

- 5E3 Manual de MontagemDocument39 pages5E3 Manual de MontagemFabio NevesNo ratings yet

- KAT-KIT Deacy Amp Assembly and Test InstructionsDocument22 pagesKAT-KIT Deacy Amp Assembly and Test InstructionsAntony Sebastián Villalobos CataldoNo ratings yet

- 1 Watt Amp AssemblyDocument5 pages1 Watt Amp AssemblyStephen Dunifer100% (2)

- PWMcircuit 08Document10 pagesPWMcircuit 08kcarringNo ratings yet

- Kit MC34063Document11 pagesKit MC34063Enéas BaroneNo ratings yet

- Double 14500 VV Regulated Mod Parts ListDocument16 pagesDouble 14500 VV Regulated Mod Parts ListAlvin SugueNo ratings yet

- Building Circuits On BreadboardsDocument23 pagesBuilding Circuits On Breadboardsniyop4allNo ratings yet

- FRB No-Tune 1 Watt PLL Transmitter KitDocument5 pagesFRB No-Tune 1 Watt PLL Transmitter KitStephen DuniferNo ratings yet

- Klipsch Pro Media Ultra 2.0 Volume FixDocument7 pagesKlipsch Pro Media Ultra 2.0 Volume FixMisterBSNo ratings yet

- BYOC E.S.V. 2-Knob Bender Kit InstructionsDocument19 pagesBYOC E.S.V. 2-Knob Bender Kit Instructionsrick_marcominiNo ratings yet

- E Plus Kit ManualDocument27 pagesE Plus Kit ManualJCMNo ratings yet

- 70 Watt FET FM Amp Assembly InstructionsDocument5 pages70 Watt FET FM Amp Assembly InstructionsStephen Dunifer100% (7)

- An Ultimate Guide To Transistor PinoutsDocument15 pagesAn Ultimate Guide To Transistor PinoutsjackNo ratings yet

- A Simple Inverter For Flour..Document8 pagesA Simple Inverter For Flour..Daniel Vladimir MaciucaNo ratings yet

- Tri Boost Kit Instructions: Click Here For Older Triboost Version Instructions (No 3-Way LED)Document17 pagesTri Boost Kit Instructions: Click Here For Older Triboost Version Instructions (No 3-Way LED)rick_marcominiNo ratings yet

- Intercom Project Assembly GuideDocument3 pagesIntercom Project Assembly GuideJohn OrokNo ratings yet

- Blue Ring TesterDocument8 pagesBlue Ring Testers12originalNo ratings yet

- PM 2500 v3.2Document16 pagesPM 2500 v3.2orangepi65No ratings yet

- Tesla Coil TunerDocument4 pagesTesla Coil TunerkishbudNo ratings yet

- Smart Kit 1009 (1W Transmitter)Document5 pagesSmart Kit 1009 (1W Transmitter)Zeljko VukovicNo ratings yet

- Stompbox WorkshopDocument18 pagesStompbox Workshopchris_holden249580% (10)

- Robo-Roller Mkii: A "Two-Motor" Sun Powered VehicleDocument3 pagesRobo-Roller Mkii: A "Two-Motor" Sun Powered Vehiclestraf238No ratings yet

- 4Z4TJDocument16 pages4Z4TJBimal Chutia100% (1)

- Transistor Radio PDFDocument4 pagesTransistor Radio PDFAnonymous tT1L9eNo ratings yet

- Dentron MLA-2500 GI7B Modification Procedure 3Document27 pagesDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoNo ratings yet

- 30 Watts, 1240 To 1300 MHZ Linear Amplifier PCB Kit or Complete KitDocument6 pages30 Watts, 1240 To 1300 MHZ Linear Amplifier PCB Kit or Complete Kitwa3yueNo ratings yet

- NEXTSTATION Turbo Color Capacitor ReplacementDocument8 pagesNEXTSTATION Turbo Color Capacitor ReplacementPiotr TwareckiNo ratings yet

- From Schematic To VeroboardDocument12 pagesFrom Schematic To Veroboardcracker01No ratings yet

- Qrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverDocument10 pagesQrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverAltan KomanNo ratings yet

- Lfo Assembly GuideDocument15 pagesLfo Assembly GuideArkadiusz Qrchack RozmusNo ratings yet

- Quasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General DescriptionDocument6 pagesQuasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General Descriptionapi-3864578No ratings yet

- Pigrig v2Document17 pagesPigrig v2ffwwfNo ratings yet

- Using standard probes and replacing battery on Tektronix 222PS oscilloscopeDocument13 pagesUsing standard probes and replacing battery on Tektronix 222PS oscilloscopemarius virtosu65No ratings yet

- Gold PicDocument6 pagesGold PicBalbalaManiukNo ratings yet

- Construction Hints and TechniquesDocument8 pagesConstruction Hints and Techniquesbayman66No ratings yet

- ADA MP-1 Stock Gain ModDocument19 pagesADA MP-1 Stock Gain ModAndrei PopaNo ratings yet

- mm-c414-build-guide-1.2Document23 pagesmm-c414-build-guide-1.2Pule123No ratings yet

- H440 InstructionsDocument28 pagesH440 InstructionsAnonymous WgpXi9ANo ratings yet

- Pacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsDocument6 pagesPacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsedosviracNo ratings yet

- PicoKeyer Plus 080501Document10 pagesPicoKeyer Plus 080501diney m e willemenNo ratings yet

- Quasar Kit No. 1052 3-Input Mono Mixer: General DescriptionDocument4 pagesQuasar Kit No. 1052 3-Input Mono Mixer: General DescriptionFernando FigueroaNo ratings yet

- Build Your Own Light MeterDocument17 pagesBuild Your Own Light Meterassis_campos8950No ratings yet

- Banggood IRF 530 PA Instructions V1.4Document16 pagesBanggood IRF 530 PA Instructions V1.4Jorge MarinNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityFrom EverandHow Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityNo ratings yet

- Hypertrophic Cardiomyopathy (Beyond The Basics) - UpToDateDocument13 pagesHypertrophic Cardiomyopathy (Beyond The Basics) - UpToDatetrkonjicNo ratings yet

- Prails Guitar PlayerDocument1 pagePrails Guitar PlayertrkonjicNo ratings yet

- 2020 05 29 20102335v1 Full PDFDocument36 pages2020 05 29 20102335v1 Full PDFtrkonjicNo ratings yet

- Lampemetre 2Document12 pagesLampemetre 2trkonjic100% (1)

- Noise Reduction Systems: Guitar Buzz Solution Model 1 - Fender Strat/ Tele (5.5k - 6.3k)Document3 pagesNoise Reduction Systems: Guitar Buzz Solution Model 1 - Fender Strat/ Tele (5.5k - 6.3k)trkonjicNo ratings yet

- Duokit 2Document12 pagesDuokit 2trkonjicNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,259,318 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 7,259,318 B2trkonjicNo ratings yet

- RFT El34Document1 pageRFT El34trkonjicNo ratings yet

- 1 PB PDFDocument7 pages1 PB PDFtrkonjicNo ratings yet

- Aortic Dimension & The Risk of DissectionDocument6 pagesAortic Dimension & The Risk of Dissectionraghesh VNo ratings yet

- Dummy Coils For PickupsDocument2 pagesDummy Coils For PickupsRoland CziliNo ratings yet

- P90 Additional Instructions: Through GuitarDocument1 pageP90 Additional Instructions: Through GuitartrkonjicNo ratings yet

- 13136paneurysm PDFDocument12 pages13136paneurysm PDFtrkonjicNo ratings yet

- 1d0o1a4jl 100302Document1 page1d0o1a4jl 100302trkonjicNo ratings yet

- tv7 RegeneratorDocument1 pagetv7 RegeneratortrkonjicNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 7,259,318 B2Document11 pagesUlllted States Patent (10) Patent N0.: US 7,259,318 B2trkonjicNo ratings yet

- At54 Line 6 Variax GuitarDocument2 pagesAt54 Line 6 Variax GuitartrkonjicNo ratings yet

- P90 Additional Instructions: Through GuitarDocument1 pageP90 Additional Instructions: Through GuitartrkonjicNo ratings yet

- P90 Additional Instructions: Through GuitarDocument1 pageP90 Additional Instructions: Through GuitartrkonjicNo ratings yet

- 2018 Yamaha Guitars Catalog PDFDocument24 pages2018 Yamaha Guitars Catalog PDFJose Luis Rodriguez InterianoNo ratings yet

- Bassking I T (2-0163) (Rev. A, 29-03-1968) SchematicDocument1 pageBassking I T (2-0163) (Rev. A, 29-03-1968) SchematictrkonjicNo ratings yet

- Akai GX 260 D BrochureDocument4 pagesAkai GX 260 D BrochuretrkonjicNo ratings yet

- Sumo Nine Plus Version CDocument1 pageSumo Nine Plus Version CtrkonjicNo ratings yet

- Warning / Disclaimer: MouserDocument15 pagesWarning / Disclaimer: MousertrkonjicNo ratings yet

- Fretboard Radius Templates for Guitar NecksDocument1 pageFretboard Radius Templates for Guitar NeckstrkonjicNo ratings yet

- Making A Guitar BodyDocument11 pagesMaking A Guitar Bodytrkonjic100% (2)

- Futterman Otl 3 Power Amplifier SchematicDocument1 pageFutterman Otl 3 Power Amplifier SchematictrkonjicNo ratings yet

- Electrocompaniet Aw120 Power Amplifier SchematicDocument1 pageElectrocompaniet Aw120 Power Amplifier Schematictrkonjic100% (1)

- PocketPOD PresetsDocument1 pagePocketPOD PresetsDavid DetherageNo ratings yet

- Nut Slot TemplatesDocument1 pageNut Slot TemplatestrkonjicNo ratings yet

- Markard Et Al. (2012) PDFDocument13 pagesMarkard Et Al. (2012) PDFgotrektomNo ratings yet

- Slimline: Switch Disconnector Fuse, SR 63-630 ADocument46 pagesSlimline: Switch Disconnector Fuse, SR 63-630 AЕвгений МатвеевNo ratings yet

- A Light Sculling Training Boat PDFDocument8 pagesA Light Sculling Training Boat PDFLuis BraulinoNo ratings yet

- MCT-MST Formative Report Form 2bashaer AwadDocument9 pagesMCT-MST Formative Report Form 2bashaer Awadapi-315648941No ratings yet

- Populist Movement (Anant)Document7 pagesPopulist Movement (Anant)Siddhi JoshiNo ratings yet

- Okrs That Clarify, Inspire and Motivate: A Framework and SamplesDocument12 pagesOkrs That Clarify, Inspire and Motivate: A Framework and SamplesJuan Manuel MauroNo ratings yet

- Joou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - EdoujinDocument25 pagesJoou No Gohoubi - Tate No Yuusha No Nariagari 288869 Doujin - Edoujinaura.nazhifa10020% (1)

- LAB-Histopath Midterms 01Document5 pagesLAB-Histopath Midterms 01Jashmine May TadinaNo ratings yet

- Module 3 - Subsequent To AcquisitionDocument8 pagesModule 3 - Subsequent To AcquisitionRENZ ALFRED ASTRERONo ratings yet

- The 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoDocument18 pagesThe 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoKarla BangFerNo ratings yet

- Teamcenter 10.1 Business Modeler IDE Guide PLM00071 J PDFDocument1,062 pagesTeamcenter 10.1 Business Modeler IDE Guide PLM00071 J PDFcad cad100% (1)

- Product Placement in Movies- Impact on SalesDocument3 pagesProduct Placement in Movies- Impact on SalesBhavya DiddeeNo ratings yet

- Installation Guide for lemonPOS POS SoftwareDocument4 pagesInstallation Guide for lemonPOS POS SoftwareHenry HubNo ratings yet

- Key plan and area statement comparison for multi-level car park (MLCPDocument1 pageKey plan and area statement comparison for multi-level car park (MLCP121715502003 BOLLEMPALLI BINDU SREE SATYANo ratings yet

- Easa Ad 2023-0133 1Document6 pagesEasa Ad 2023-0133 1Pedro LucasNo ratings yet

- Assessment Nursing Diagnosis Scientific Rationale Planning Intervention Rationale EvaluationDocument9 pagesAssessment Nursing Diagnosis Scientific Rationale Planning Intervention Rationale Evaluationclydell joyce masiarNo ratings yet

- Quick Healthcare Stencil: SketchDocument2 pagesQuick Healthcare Stencil: SketchNafiz Hannan NabilNo ratings yet

- Combined LoadingsDocument23 pagesCombined LoadingsVinaasha BalakrishnanNo ratings yet

- Bla Irv RanchDocument84 pagesBla Irv RanchArturo Palma RamírezNo ratings yet

- Aegon Life Insurance Marketing Strategy AnalysisDocument22 pagesAegon Life Insurance Marketing Strategy AnalysissalmanNo ratings yet

- Environment Health: European Research OnDocument73 pagesEnvironment Health: European Research OnDaiuk.DakNo ratings yet

- J S S 1 Maths 1st Term E-Note 2017Document39 pagesJ S S 1 Maths 1st Term E-Note 2017preciousNo ratings yet

- Fmi Code GuideDocument82 pagesFmi Code GuideNguyễn Văn Hùng100% (4)

- User'S Manual: 1 - Installation 2 - Technical SpecificationsDocument8 pagesUser'S Manual: 1 - Installation 2 - Technical SpecificationsGopal HegdeNo ratings yet

- Gas Turbine MaintenanceDocument146 pagesGas Turbine MaintenanceMamoun1969100% (8)

- Predict CambodianDocument11 pagesPredict CambodianMd Ibrahim KhalilNo ratings yet

- Keyence cv700 - Man2Document232 pagesKeyence cv700 - Man2kamaleon85No ratings yet

- Biomechanics of Knee Joint - 20 Questions-2Document5 pagesBiomechanics of Knee Joint - 20 Questions-2rehab aymanNo ratings yet

- CH 9 - Spontaneity, Entropy, and Free EnergyDocument65 pagesCH 9 - Spontaneity, Entropy, and Free EnergyCharbel RahmeNo ratings yet

- Lista 30 JulioDocument2 pagesLista 30 JulioMax Bike MartinezNo ratings yet