Professional Documents

Culture Documents

Fabrication of Aspheric Micro-Lens Array using Excimer Laser Micromachining

Uploaded by

Tanweer KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication of Aspheric Micro-Lens Array using Excimer Laser Micromachining

Uploaded by

Tanweer KhanCopyright:

Available Formats

VISVESVARAYA TECHNOLOGICAL UNIVERSITY

BELGAUM, KARNATAKA

A SEMINAR REPORT ON FABRICATION OF ASPHERIC MICRO-LENS ARRAY BY EXCIMER LASER MICRO MACHINING A seminar report submitted in the partial fulfilment for the requirement of Degree in Bachelor of Engineering, MECHANICAL ENGINEERING SUBMITTED BY: TANWEER KHAN 1GA06ME051 Under Guidance Of Dr. M.S.Rajagopal BE, M.tech, PhD, FIE

DEPARTMENT OF MECHANICAL ENGINEERING GLOBAL ACADEMY OF TECHNOLOGY Raja Rajeshwari nagar, Ideal Home Township Bangalore-560098

DEPARTMENT OF MECHANICAL ENGINEERING GLOBAL ACADEMY OF TECHNOLOGY

Ideal Homes Township, Raja Rajeshwari nagar, Bangalore 98

CERTIFICATE

This is to certify that the Seminar report entitled FABRICATON OF ASPHERIC MICRO-LENS ARRAY BY EXCIMER LASER MICRO-MACHINING submitted by TANWEER KHAN bearing 1GA06ME051, bonafide student of GLOBAL ACADEMY OF TECHNOLOGY has successively completed the Seminar work in partial fulfilment for the award of BACHELOR OF ENGINEERING in mechanical Engineering prescribed by Visvesvaraya Technological University, Belgaum.

----------------------Guide and Head of the department Dr M.S. Rajagopal

ACKNOWLEDGMENT

The satisfaction and euphoria that accompany that successful completion of any task would be incomplete without mentioning that the people who made it possible. So with

deep gratitude I acknowledge all those guidance and encouragement served as beacon light and crowned my efforts with success.

I would express my sincere gratitude to Dr. Narendra Viswanath, principal of G.A.T.

With due respect, I sincerely thank to my guide and Head of the Department (HOD) Dr. M.S. Rajagopal BE, M.tech, PhD,FIE, Department of Mechanical Engineering Global Academy of Technology for his encouragement and support during this seminar work.

Lastly, I express my sincere gratitude to all those who directly or indirectly helped throughout this seminar work.

TANWEER KHAN USN: 1GA06ME051

ABSTRACT

This topic presents [1] a unique method for fabrication of aspheric micro-lens array based on a KrF 248 nm excimer laser micromachining with precise surface profile control. Based on a planetary contour scanning laser micro machining method along with a shading metal mask and sample movable stage, an array of micro-lens with precisely controlled surface profiles can be fabricated.

Each lens surface profile can be aspheric and pre-designed. In this experiments have been carried out and the machining accuracy of each lens surface profile is examined. Good surface roughness and profile accuracy are observed.

This paper [2] also demonstrates a newly developed laser scanning method is introduced for machining refractive types of micro lenses, which have pre-designed surface profiles aiming at minimizing the optical focal spot sizes. Optical testing on the fabricated aspheric micro lenses shows significant improvement in focusing capability and the focal spot sizes are approaching optical diffraction limits.

The proposed excimer laser micromachining method is flexible, versatile, and accurate, hence can be very useful and powerful in machining 3D microstructures of complex profiles and demanding profile accuracy.

CONTENTS

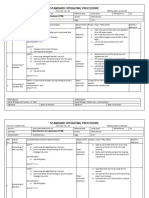

Page No 1: Introduction 2: Literature Survey 3: Technological aspects of laser micro machining 3.1: Definition 3.2: Construction 3.3: Operation 4: Components of typical industrial laser machining system 4.1: Process site 4.2: Laser light source5 4.3: Beam delivery system 4.4: Part handling and motion control system 4.5: Control electronics 4.6: Laser support equipment 4.7: Structure and enclosure 5: Comparing with different types of laser [2] 6: Important Parameters 6.1: Absolute Energy 6.2: Laser Power 6.3: Intensity 6.4: Wave length 7: Configurations of UV excimer laser 7.1: UV excimer laser gases 7.2: UV excimer laser discharge 7.3: Extending laser gas life 8: Photo ablation process [2] 9: Fabrication of Micro lenses [3] 10: Application of Excimer Laser Machine 1 2 3-4 3 3 4 4-6 5 5 5 5 5 6 6 6-7 7-8 7 7 8 8 8-10 8 9 10 11 12 13-16

10.1: Laser Eye (or excimer laser) Surgery 10.2: Biological Matter and Organic Compounds 10.3: Manufacturing of Micro Electronic Chip 10.4: Marking 10.5: Drilling 11: Advantages 11.1: Unique Properties of Excimer Laser Radiation 11.2: Resulting Benefits in Materials Processing 12: Disadvantages 12.1: Discharge Circuit 12.2: Toxic Laser Gas 12.3: Managing high-power UV 13: Future technology 14: Conclusion 15: Reference

13 14 14 15 16 16-17 16 17 17 17 17 17 18 19 20

LIST OF FIGURES

1: Fig.1 High intensity of laser beam 2: Fig.2 Operation of excimer laser micromachining 3: Fig.3 comparing different types of laser [2] 4: Fig.4 Typical excimer laser configuration [1] 5: Fig.5 Discharge of laser 6: Fig.6 The photo ablation process [2] 7: Fig.7 Fabricated micro lenses [4] 8: Fig.8 Shows measured 3D profile of lens [5] 9:Fig.9 Experimental setup [5] 10: Fig.10 Concept of eye surgery 11: Fig.11 marking on ceramic chip 12: Fig.12 marking on nail polish cap 13: Fig.13 drill holes on 75 micron thick plastic 11 12 12 14 15 15 16 3 4 6 8 9 11

You might also like

- Laser Micromachining A Seminar OnDocument27 pagesLaser Micromachining A Seminar OnOmkar KhamkarNo ratings yet

- Micro Machining Using Nanosecond LasersDocument16 pagesMicro Machining Using Nanosecond LasersNOOB GAMINGNo ratings yet

- MOEMS-MEMS 2007: Micro & NanofabricationDocument44 pagesMOEMS-MEMS 2007: Micro & NanofabricationUday kumarNo ratings yet

- Glass MachiningDocument6 pagesGlass MachiningZeko RekoNo ratings yet

- Batch Number 07Document83 pagesBatch Number 07Sabari VenkateshNo ratings yet

- Fabrication of MicrochannelDocument9 pagesFabrication of MicrochannelHarshit AgrahariNo ratings yet

- Golam LaserDocument8 pagesGolam Laserrobo GjNo ratings yet

- A Review Femtosecond Laser-Based Processing Methods and Their Applications in Optical Device ManufacturingDocument11 pagesA Review Femtosecond Laser-Based Processing Methods and Their Applications in Optical Device ManufacturingMinh VuNo ratings yet

- Applied Sciences: Ffects of Laser Fluence and Pulse Overlap OnDocument14 pagesApplied Sciences: Ffects of Laser Fluence and Pulse Overlap Onosama1928No ratings yet

- Pulsed PDFDocument13 pagesPulsed PDFrajeshNo ratings yet

- Electomagnatic Ramming MachineDocument7 pagesElectomagnatic Ramming MachineOfficialRF WRNo ratings yet

- Sem Rep Part 1 and 2 CombinedtDocument24 pagesSem Rep Part 1 and 2 CombinedtDelfinBijuNo ratings yet

- Electromagnetic Breaking SystemDocument27 pagesElectromagnetic Breaking SystemRaj KamalNo ratings yet

- Design of Single-Notched Small Square Ring Monopole Antenna For UWB ApplicationsDocument72 pagesDesign of Single-Notched Small Square Ring Monopole Antenna For UWB ApplicationsKumarJinneNo ratings yet

- Report CompleteDocument57 pagesReport CompleteEmmanuel Babu PaulNo ratings yet

- Seminar Report 3GN17ME055Document27 pagesSeminar Report 3GN17ME055Rahul KullkarniNo ratings yet

- Report FullDocument71 pagesReport FullVeera HasanNo ratings yet

- TEAM 7 - Mechanical Engineering Final Year ProjectDocument79 pagesTEAM 7 - Mechanical Engineering Final Year ProjectMurasoli palaniNo ratings yet

- A Systematic Review On MEMS GyroscopeDocument6 pagesA Systematic Review On MEMS GyroscopeArjun KapoorNo ratings yet

- Direct Femtosecond Laser Fabricated Photon SieveDocument14 pagesDirect Femtosecond Laser Fabricated Photon SieveArathyNo ratings yet

- JMF OnlineDocument8 pagesJMF OnlinePinal RanaNo ratings yet

- Study of Cryogenically Treated Molybdenum Wire's Mechanical PropertiesDocument70 pagesStudy of Cryogenically Treated Molybdenum Wire's Mechanical Propertieswinter soldierNo ratings yet

- Non-Traditional Micromachining Processes: Golam Kibria B. Bhattacharyya J. Paulo Davim EditorsDocument431 pagesNon-Traditional Micromachining Processes: Golam Kibria B. Bhattacharyya J. Paulo Davim EditorsAnkur PandeyNo ratings yet

- Femtosecond Laser Fabrication of SiC Microlens Arrays As Integrated Light Homogenizer and SplitterDocument4 pagesFemtosecond Laser Fabrication of SiC Microlens Arrays As Integrated Light Homogenizer and SplitterGergő BárdosNo ratings yet

- Liu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1043 032037Document11 pagesLiu 2021 IOP Conf. Ser. Mater. Sci. Eng. 1043 032037ntik 23No ratings yet

- NanoroboticsDocument34 pagesNanoroboticsSheraz Cr7No ratings yet

- "CNC - Laser Cutting Technology": A Technical SeminarDocument36 pages"CNC - Laser Cutting Technology": A Technical SeminarOmprakash ChoudharyNo ratings yet

- Electrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyFrom EverandElectrochemical Micromachining for Nanofabrication, MEMS and NanotechnologyRating: 4 out of 5 stars4/5 (1)

- Pneumatic Speed Breaker With Day Night Control (PSB)Document40 pagesPneumatic Speed Breaker With Day Night Control (PSB)Giri TharanNo ratings yet

- MEMS mirror enables low cost laser scannersDocument34 pagesMEMS mirror enables low cost laser scannersvitavanish0% (1)

- FINALDocument57 pagesFINALSai kumarNo ratings yet

- AIMTDR2016 - Full - Length PaperDocument6 pagesAIMTDR2016 - Full - Length PaperMM GoudNo ratings yet

- MICROMACHININGDocument34 pagesMICROMACHININGChandu Sunag100% (1)

- Submarine RadomeDocument75 pagesSubmarine RadomeKarthikeya ReddyNo ratings yet

- Fabrication of Actuator For Nanopositioning Using Laser Micro-MachiningDocument4 pagesFabrication of Actuator For Nanopositioning Using Laser Micro-MachiningBrian FreemanNo ratings yet

- PSNS-Thesis - Complete Thesis 25Document266 pagesPSNS-Thesis - Complete Thesis 25venkatesh maduthuriNo ratings yet

- Dini Tech SeminarDocument23 pagesDini Tech SeminarDinesh arNo ratings yet

- template [Autosaved]Document7 pagestemplate [Autosaved]Sriram SrinivasanNo ratings yet

- Technical Seminar SUNIL KUMARDocument39 pagesTechnical Seminar SUNIL KUMARsunil kumarNo ratings yet

- Rakesh Seminar Report2Document18 pagesRakesh Seminar Report2Siriganti RakeshNo ratings yet

- Final PDFDocument57 pagesFinal PDFSai kumarNo ratings yet

- Performance Study of Pesticide Sprayer Using Solar EnergyDocument39 pagesPerformance Study of Pesticide Sprayer Using Solar EnergyPRAVIN KUMAR NNo ratings yet

- Project Work FinalDocument50 pagesProject Work FinalRanjith KumarNo ratings yet

- Pulsed Laser Ablation and Micromachining of 4H and 6H SiC Wafers PDFDocument113 pagesPulsed Laser Ablation and Micromachining of 4H and 6H SiC Wafers PDFagiles6No ratings yet

- Fracture Toughness Inconel 625Document10 pagesFracture Toughness Inconel 625gacm98No ratings yet

- A Tool-Based Hybrid Laser-Electrochemical Micromachining ProcessDocument21 pagesA Tool-Based Hybrid Laser-Electrochemical Micromachining ProcessChoy Hau YanNo ratings yet

- Fabrication of Cylindrical Micro Tools by Micro Electrochemical Form Turning OperationDocument9 pagesFabrication of Cylindrical Micro Tools by Micro Electrochemical Form Turning OperationPrapto PraptNo ratings yet

- Finishing of Micro-EDMed Surface Based On ScanningDocument6 pagesFinishing of Micro-EDMed Surface Based On ScanningOmkar DashNo ratings yet

- MPR Seminar Report 1Document22 pagesMPR Seminar Report 1abhiramks222No ratings yet

- Modeling and Simulation of Frequency Reconfigurable Microstrip Patch Antenna For Wimax ApplicationsDocument54 pagesModeling and Simulation of Frequency Reconfigurable Microstrip Patch Antenna For Wimax Applicationskasi sirishaNo ratings yet

- A 2D Resonant MEMS Scanner With An Ultra-Compact Wedge-Like Multiplied Angle Amplification For Miniature LIDAR ApplicationDocument3 pagesA 2D Resonant MEMS Scanner With An Ultra-Compact Wedge-Like Multiplied Angle Amplification For Miniature LIDAR ApplicationUğur ÇelikNo ratings yet

- Design and Analysis of Two Wheller Disk BrakeDocument57 pagesDesign and Analysis of Two Wheller Disk BrakeVignesh VaranNo ratings yet

- Laser Ignition: A Promising Alternative to Spark PlugsDocument24 pagesLaser Ignition: A Promising Alternative to Spark PlugsSantosh TotagerNo ratings yet

- Design and Fabrication Power Generation Using Speed BreakerDocument25 pagesDesign and Fabrication Power Generation Using Speed BreakerAabal Sylo100% (1)

- JMNM 001 03 031002Document8 pagesJMNM 001 03 0310024029MOHIT KUMAR DASNo ratings yet

- Front PageDocument11 pagesFront PageSHAKHT FAUJI FAUJINo ratings yet

- Design and Fabrication of a Solar Grass Cutter with Water Spraying VehicleDocument78 pagesDesign and Fabrication of a Solar Grass Cutter with Water Spraying VehicleAbi YadavNo ratings yet

- Design and Fabrication of Modified Crop HarvesterDocument13 pagesDesign and Fabrication of Modified Crop HarvesternkchandruNo ratings yet

- 102040Document1 page102040Tanweer KhanNo ratings yet

- April Line Walk ReportDocument5 pagesApril Line Walk ReportTanweer KhanNo ratings yet

- 19- Replacement of Horizontal Gear BoxDocument7 pages19- Replacement of Horizontal Gear BoxTanweer KhanNo ratings yet

- CapaDocument1 pageCapaTanweer KhanNo ratings yet

- 17353 Union Roadways- Feedback FormDocument1 page17353 Union Roadways- Feedback FormTanweer KhanNo ratings yet

- 32 HR Late Vehicle-17353Document6 pages32 HR Late Vehicle-17353Tanweer KhanNo ratings yet

- 02-Jun-21 - TSL Programm Issue - FDocument11 pages02-Jun-21 - TSL Programm Issue - FTanweer KhanNo ratings yet

- Allow Late Payment EntryDocument1 pageAllow Late Payment EntryTanweer KhanNo ratings yet

- TSL PROGRAMM ISSUEDocument25 pagesTSL PROGRAMM ISSUETanweer KhanNo ratings yet

- Transport Person Name Mobile NoDocument1 pageTransport Person Name Mobile NoTanweer KhanNo ratings yet

- RKFL Quote The Outgoing RateDocument1 pageRKFL Quote The Outgoing RateTanweer KhanNo ratings yet

- TPL Url OsDocument2 pagesTPL Url OsTanweer KhanNo ratings yet

- Violation Previous Invoice or Penalty New Invoice or PenaltyDocument3 pagesViolation Previous Invoice or Penalty New Invoice or PenaltyTanweer KhanNo ratings yet

- Deduction List of Himtec Sales PVT Ltd.Document7 pagesDeduction List of Himtec Sales PVT Ltd.Tanweer KhanNo ratings yet

- Amps Engg & Equipment Pvt. LTD Out Standing ListDocument2 pagesAmps Engg & Equipment Pvt. LTD Out Standing ListTanweer KhanNo ratings yet

- MF & VH (Apr'21-Mar'22)Document1 pageMF & VH (Apr'21-Mar'22)Tanweer KhanNo ratings yet

- Himtec Actual Diduction ListDocument30 pagesHimtec Actual Diduction ListTanweer KhanNo ratings yet

- Fabrication of Aspheric Micro-Lens Array using Excimer Laser MicromachiningDocument6 pagesFabrication of Aspheric Micro-Lens Array using Excimer Laser MicromachiningTanweer KhanNo ratings yet

- Letter For Bank StatementDocument1 pageLetter For Bank StatementTanweer KhanNo ratings yet

- Monthly PPE ChecklistDocument2 pagesMonthly PPE ChecklistTanweer Khan100% (1)

- Himtection DiduDocument6 pagesHimtection DiduTanweer KhanNo ratings yet

- Mechanical Engineer Resum1e For FresherDocument4 pagesMechanical Engineer Resum1e For FresherAhmad Faiz MohamadNo ratings yet

- Seminar WordDocument26 pagesSeminar WordTanweer KhanNo ratings yet

- MechnicalDocument20 pagesMechnicalTanweer KhanNo ratings yet

- Recommendations for Lubricating Oil SelectionDocument7 pagesRecommendations for Lubricating Oil SelectionSergei KurpishNo ratings yet

- Halogen+Compound+ +PYQ+by+PC+SirDocument4 pagesHalogen+Compound+ +PYQ+by+PC+SirSuraj SinghNo ratings yet

- 3 - Gravimetric Analysis of Calcium and Hard Water - S PDFDocument6 pages3 - Gravimetric Analysis of Calcium and Hard Water - S PDFJon CranNo ratings yet

- Maharaja Agrasen Vidyalaya: Viscosity of FluidDocument18 pagesMaharaja Agrasen Vidyalaya: Viscosity of FluidAagam ShahNo ratings yet

- Co(III) Coordination Compounds Synthesis ReactionsDocument28 pagesCo(III) Coordination Compounds Synthesis ReactionsRahul GogiaNo ratings yet

- DP Chem Unit 3 PerodicityDocument5 pagesDP Chem Unit 3 PerodicityPatrick AbidraNo ratings yet

- Ammonia and Urea Plants PDFDocument48 pagesAmmonia and Urea Plants PDFbenon100% (1)

- The Effects of Rotary Kiln Operating Conditions and Design On Burden Heating Rates As Determined by A Mathematical Model of Rotary Kiln Heat Transfer PDFDocument9 pagesThe Effects of Rotary Kiln Operating Conditions and Design On Burden Heating Rates As Determined by A Mathematical Model of Rotary Kiln Heat Transfer PDFSHRAVAN KUMARNo ratings yet

- Tut 12 Multiple Char Reactions TutorialDocument19 pagesTut 12 Multiple Char Reactions TutorialRubén Alfonso Pérez JeldresNo ratings yet

- Oxidation States of ManganeseDocument4 pagesOxidation States of ManganesexbokyxNo ratings yet

- The Cell: Prepared By: Tio Magdalena Manurung, B.SCDocument31 pagesThe Cell: Prepared By: Tio Magdalena Manurung, B.SCvvNo ratings yet

- StyreneDocument28 pagesStyreneAbuBakar Saleem75% (4)

- Chemistry of The Elements (2nd Edition)Document14 pagesChemistry of The Elements (2nd Edition)mycomiccityNo ratings yet

- Scarlett .. - .: "An Introduction To Printed Circuit Board Technology"Document8 pagesScarlett .. - .: "An Introduction To Printed Circuit Board Technology"امين الدينNo ratings yet

- Day 2-5 Dynamic Response of Tall BuildingsDocument41 pagesDay 2-5 Dynamic Response of Tall BuildingsMIHDI PALAPUZ100% (1)

- Differential Drive KinematicsDocument8 pagesDifferential Drive KinematicsPratik PatelNo ratings yet

- Baeyer-Villiger Oxidation of 8-Aryl Substituted Unsaturated Carbonyl Compounds With Hydrogen Peroxide and Catalytic Selenium DioxideDocument15 pagesBaeyer-Villiger Oxidation of 8-Aryl Substituted Unsaturated Carbonyl Compounds With Hydrogen Peroxide and Catalytic Selenium DioxidejavasoloNo ratings yet

- Test Specification Table Type of Test: MCQ No of Items: 40 QuestionsDocument5 pagesTest Specification Table Type of Test: MCQ No of Items: 40 QuestionsAhmad ZaidiNo ratings yet

- Heat 1Document36 pagesHeat 1ZainabNo ratings yet

- Materials Today: Proceedings: N.H. Sabri, N.H.A. Rani, N.F. Mohamad, N.A.S. Mohd Muhsen, M.S. MD ZainiDocument8 pagesMaterials Today: Proceedings: N.H. Sabri, N.H.A. Rani, N.F. Mohamad, N.A.S. Mohd Muhsen, M.S. MD ZainiMuchammad AdriyanNo ratings yet

- 31.2-General Wave Popeties-Cie Igcse Physics Ext-Theory-QpDocument12 pages31.2-General Wave Popeties-Cie Igcse Physics Ext-Theory-Qpnityam bajajNo ratings yet

- Araldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFDocument8 pagesAraldite FT CY205IN Aradur HY905IN DY040 DY061 Si02 Eur e PDFneerajaNo ratings yet

- Youcai-Chenglong2017 Book PollutionControlAndResourceReuDocument447 pagesYoucai-Chenglong2017 Book PollutionControlAndResourceReuMartin DuarteNo ratings yet

- 1 s2.0 S2214785322035441 MainDocument7 pages1 s2.0 S2214785322035441 MainMohammad Irfan AliNo ratings yet

- Schedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)Document161 pagesSchedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)sagar mukulNo ratings yet

- Adblue Diesel Exhaust Fluid-PI SheetDocument2 pagesAdblue Diesel Exhaust Fluid-PI SheetAntonio AriasNo ratings yet

- Claus Plants Prove FlexibleDocument3 pagesClaus Plants Prove Flexiblebakhtiari_afNo ratings yet

- Cuison Chapter 2Document41 pagesCuison Chapter 2Reinzo GallegoNo ratings yet

- APITECH 03 DecryptedDocument23 pagesAPITECH 03 Decryptedjokerveloz100% (2)

- About Soda Ash - ANSACDocument2 pagesAbout Soda Ash - ANSAChabib1234No ratings yet

![template [Autosaved]](https://imgv2-1-f.scribdassets.com/img/document/720057690/149x198/3cd9db0a66/1712248134?v=1)