Professional Documents

Culture Documents

Ex13a PDF

Uploaded by

getsweetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ex13a PDF

Uploaded by

getsweetCopyright:

Available Formats

Renewable Energy Technologies I 701-0962-00L Prof. A.

Wokaun

2009-11-23

Exercise 13 Energy from Biomass (fuel production)

Please, solve 2 of the 3 following exercises! Deadline for delivering the exercise: Thursday, 17.12.2009, 10 a.m., only by e-Mail!

Note: - Every student has to give his own solution including auxiliary calculations! - The procedure for calculating must be understandable and clear (In Excel: Formulas, not only values)! - Please use only the OFFICIAL SOLUTION SHEET and deliver it either after this exercise class or by e-mail! - Please write your FULL NAME on all solution sheets!

Tutors: Marcelo Rechulski (marcelo.rechulski@psi.ch), Martin Rdisli (martin.ruedisueli@psi.ch) Address: Paul Scherrer Institut, Laboratory for Energy and Materials Cycles, OLGA/221, 5232 Villigen PSI.

Part 1 Fischer-Tropsch Synthesis (FT-Synthesis)

Purified syngas (mainly CO and H2) from a biomass gasifier (see Table 1) is fed to a Fischer-Tropsch reactor. The aim of the FT-Synthesis is the conversion of hydrogen and carbon monoxide to hydrocarbons (diesel, gasoline, and wax). The distribution of the products depends on the catalyst and the process operation conditions (temperature, pressure, and residence time).

Table 1

Properties of syngas (input to reactor) Molar mass M composition kg/kmol H2 2.016 CO 28.010 H2O 18.015 CO2 44.010 CH4 16.044 HC (-CH2-) incl. CH4 14.28

Heat of combustion HR

kJ/mol 241.75 282.99 0.00 0.00 802.70 -

Molar flow kmol/h

& n

120.0 160.0 10.0 7.5 6.5 0.0

The overall chemical reaction equation for the exothermic Fischer-Tropsch process is based on hydrogen and described by:

3 5 1 2 CO + H 2 ( CH 2 ) + H 2O + CO2 2 6 6 3

HR = -165 kJ/mol

(1)

Question 1a: Calculate the mass, molar, and enthalpy flows (in- and output) for the FT-Synthesis with 85% conversion of hydrogen.

Note: The methane in the output stream should be counted together with the hydrocarbon mass flow. An average molecular weight is given for the hydrocarbons.

Question 1b: The FT-reactor is isothermal and the released heat is used to produce steam. Calculate the heat Qout and the produced steam mass flow. The enthalpy of evaporation for water is 1812 kJ/kg. Question 1c: After the FT-Synthesis, the hydrocarbons will be separated into different fractions (see Table 2). Calculate the mass and enthalpy flows leaving the separation unit.

Seite 1 von 3

Renewable Energy Technologies I 701-0962-00L Prof. A. Wokaun

Table 2 Mass fraction and heating value

2009-11-23

Hydrocarbons Gas (SNG, LPG) Light gasoline Heavy gasoline Diesel Wax C1-C4 C5-C8 C9-C12 C13-C19 > C20

Mass fraction %wt 13% 20% 19% 23% 25%

Heating value LHV [MJ/kg] 42.60 42.45 42.45 42.66 42.80

Question 1d: Real industrial Fischer-Tropsch plants have a chemical conversion efficiency of up to about 55%. Compare this number to the energetic efficiency (in terms of total energy flows) for the useful products of the whole process in this exercise. The gas fraction (C1-C4) shall not be considered as useful energy for this calculation. The input is 4176 kg/h of dry biomass with a heating value of 18.17 MJ/kg.

Part 2 Methane from Wood

The same syngas, as given in Part 1, is now fed to a methanation reactor. In contrary to the FTsynthesis, the desired product is methane (CH4). The exothermic methanation is described by the following equation:

CO + 3H 2 CH 4 + H 2O

HR = -206.28 kJ/mol

(2)

Question 2a: The methanation reaction (2) requires a H2/CO ratio of 3. When the ratio is lower, it can be adjusted by adding water in the methanation reactor. For simplification, the water is added before the methanation reactor to ensure a H2/CO ratio of 3 in the methanation reactor. Calculate the amount of water that must be added, when the water reacts following the water gas shift (WGS) reaction:

CO + H 2O CO2 + H 2

HR = -41.16kJ/mol

(3)

Note: There is already water in the stream that will also be converted! Assumption: The stream after the water gas shift reaction contains no water (complete conversion of water).

Question 2b: Calculate the mass, molar, and enthalpy flows (in- and output) for the water gas shift and methanation reaction with 85% conversion of hydrogen. The water gas shift and the methanation are carried out in two consecutive steps.

& for the water gas shift and methanation reactor. Both Question 2c: Calculate the released heat Q out reactors are isothermal. Determine the produced steam, when the enthalpy of evaporation for water is 1812 kJ/kg.

Question 2d: Real industrial Methane from Wood plants have a chemical conversion efficiency of up to about 65%. Compare this number to the energetic efficiency (in terms of total energy flows) for the reactor in this exercise. The input is 4176 kg/h dry biomass with a heating value of 18.17 MJ/kg. The heating value of methane is 44.56 MJ/kg.

Seite 2 von 3

Renewable Energy Technologies I 701-0962-00L Prof. A. Wokaun

2009-11-23

Part 3 Biofuels for automotive applications

One of the great opportunities of biofuels is their application in the automotive sector. Particularly, in this sector the replacement of fossil fuels with renewable energy carriers is still a great challenge for the future. Question 3a: Regarding biofuels, a clear distinction between first and second generation biofuels must be made. Name one fuel of each group with the corresponding type of conversion and give some advantages and disadvantages of each group. Question 3b: A natural gas car (compressed natural gas = CNG) consumes 5.5 kgCNG/100 km. How much fresh wood do you have to bring to the Methane from Wood plant (gasification + methanation) to receive enough fuel such that you can drive your car for 20 km? Fresh wood shows a water content (w) of 30%. Dry wood has a heating value of 18.17 MJ/kg. To produce 1 MJ of CNG, you require 0.25 MJ to dry the wood and 0.3 MJ to supply the gasifier with heat. The efficiency of the methanation process step (without gasification) is 85%. Furthermore, calculate the energetic efficiency of the gasifier and of the whole process. Data: LHVCNG LHVwood Methanation hLV = 44.56 MJ/kg = 18.17 MJ/kg = 85% = 2.441 MJ/kg (lower heating value) (lower heating value based on dry wood) (efficiency) (heat of evaporation for water)

Influence of water content:

LHVwet = LHVdry (1 w) h LV w

Seite 3 von 3

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Media Lecture Notes S5B1C6Document17 pagesMedia Lecture Notes S5B1C6getsweetNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Renewable Theoretical Summary - Mona - MidtermDocument11 pagesRenewable Theoretical Summary - Mona - MidtermgetsweetNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Review Problems Soln PDFDocument10 pagesReview Problems Soln PDFgetsweetNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- General Overview Boilers and FlowDocument22 pagesGeneral Overview Boilers and FlowLiam MoylanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Review ProblemsDocument5 pagesReview ProblemsgetsweetNo ratings yet

- Bearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°Document1 pageBearing Housing: 1. All Unspecified Radii To Be 0.5 MM 2. All Unspecified Chamfers To Be 0.5/45°getsweetNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lesson 4 XPDocument30 pagesLesson 4 XPmaglalang_dexter_024No ratings yet

- Air Pollution Examples Stability Classes ConcentrationsDocument50 pagesAir Pollution Examples Stability Classes ConcentrationsgetsweetNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Solar 2 - Solar Power PlantsDocument60 pagesSolar 2 - Solar Power PlantsgetsweetNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- ITEC Application Form 2014-15Document8 pagesITEC Application Form 2014-15Mangalah Gauari MahaletchnanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- How To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic SystemDocument2 pagesHow To Design Solar PV System - Guide For Sizing Your Solar Photovoltaic Systemgetsweet100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesEngineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Sustainable BackgroundDocument111 pagesSustainable BackgroundgetsweetNo ratings yet

- Worksheet Week7Document2 pagesWorksheet Week7getsweet0% (1)

- ST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmaDocument2 pagesST RD: Engineering Drawing & CAD Page 1 of 2 Sanjay SharmagetsweetNo ratings yet

- Proposal Tips HintsDocument4 pagesProposal Tips HintsAravindan NatarajanNo ratings yet

- NEWChapter - 3-Mass Balance PDFDocument10 pagesNEWChapter - 3-Mass Balance PDFAbdelhaleem KhaderNo ratings yet

- Oblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsDocument2 pagesOblique Projection Worksheet - Draw Cylinder & Shapes in 2 ViewsgetsweetNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Problem 01 Problem 02: Community College of Allegheny CountyDocument1 pageProblem 01 Problem 02: Community College of Allegheny CountygetsweetNo ratings yet

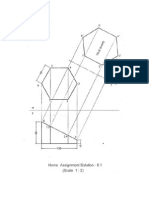

- Home Soln 8Document4 pagesHome Soln 8getsweetNo ratings yet

- CCAC Mechanical Drawing Worksheet 01 ProblemsDocument1 pageCCAC Mechanical Drawing Worksheet 01 ProblemsgetsweetNo ratings yet

- Multi-view drawing with dimensions of given objectDocument3 pagesMulti-view drawing with dimensions of given objectgetsweetNo ratings yet

- Chapter 08 2Document64 pagesChapter 08 2Subhi MohamadNo ratings yet

- U U U P T: Quick Visit To Bernoulli LandDocument9 pagesU U U P T: Quick Visit To Bernoulli LandAkash SodhaNo ratings yet

- Create The Following Solid Models Using Solidworks.: ExerciseDocument1 pageCreate The Following Solid Models Using Solidworks.: ExercisegetsweetNo ratings yet

- Pyrolysis LectureDocument30 pagesPyrolysis Lecturevkchintu53No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 300 MicroglassDocument2 pages300 MicroglassDavid BaylissNo ratings yet

- 4167-GH2 Projects DownloadDocument54 pages4167-GH2 Projects DownloadFrancesco Giuseppe LadisaNo ratings yet

- Biomass PowerPoint PresentationDocument37 pagesBiomass PowerPoint Presentationlahiani yassinNo ratings yet

- Lurgi S FBDB GasificationDocument30 pagesLurgi S FBDB Gasificationrajnish14feb8516100% (1)

- Uso Da Espectrofotometria UV-Vis para DiferenciarDocument6 pagesUso Da Espectrofotometria UV-Vis para DiferenciarCarlos Aguilar TorresNo ratings yet

- Paklaring Muhammad Andry - DraftDocument2 pagesPaklaring Muhammad Andry - DraftHazairin As-Shiddiq RahmanNo ratings yet

- Biogas From HuskDocument10 pagesBiogas From HuskRaghavendra RaghavNo ratings yet

- Alternative Fuel Power System DistributionDocument3 pagesAlternative Fuel Power System DistributionnikunjNo ratings yet

- Biobased Energy in Flanders, Belgium: Rslag Biobased Economie PDFDocument7 pagesBiobased Energy in Flanders, Belgium: Rslag Biobased Economie PDFTiinaKoolNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Potential Development of Wood Pellets As Renewable Fuel, Case Study of Wonosobo DistrictDocument12 pagesPotential Development of Wood Pellets As Renewable Fuel, Case Study of Wonosobo DistrictAhmad ZulfikarNo ratings yet

- Bio-Fuel: BY: K. Pramod E11-0031Document29 pagesBio-Fuel: BY: K. Pramod E11-0031Nurul HudaNo ratings yet

- Entropy 22 01286 v2Document17 pagesEntropy 22 01286 v2scribduserme123No ratings yet

- Advances On Seawater ElectrolysisDocument28 pagesAdvances On Seawater Electrolysismsantosu000No ratings yet

- Biomass and Bioenergy - LectureDocument58 pagesBiomass and Bioenergy - LectureCarl Jan SolitoNo ratings yet

- Hydrogen Production From Natural GasDocument18 pagesHydrogen Production From Natural Gasmojicap100% (3)

- Density of Sugar Factory ProductsDocument1 pageDensity of Sugar Factory ProductsJose GarciaNo ratings yet

- MI Renewable Methanol Pathways White Paper FinalDocument26 pagesMI Renewable Methanol Pathways White Paper Finalthajoka23No ratings yet

- Biomass EnergyDocument11 pagesBiomass EnergyBandana Pha Go LimbooNo ratings yet

- Methanol TechnologyDocument25 pagesMethanol TechnologyWillyOroscoMariscalNo ratings yet

- Thyssenkrupp gH2 - 202104Document26 pagesThyssenkrupp gH2 - 202104Ananda LagoNo ratings yet

- Biofuel - Wikipedia, The Free EncyclopediaDocument22 pagesBiofuel - Wikipedia, The Free EncyclopediaJohny KurubilaNo ratings yet

- Bioethanol - The Advantages and Disadvantages - UK: What Is Bioethanol and How Is It Produced?Document2 pagesBioethanol - The Advantages and Disadvantages - UK: What Is Bioethanol and How Is It Produced?Gabriele NeriNo ratings yet

- BiomassDocument6 pagesBiomassSaddang SaputraNo ratings yet

- Bio Energy Conversion Question BankDocument6 pagesBio Energy Conversion Question BankGeorge OliverNo ratings yet

- 3.6 Comparison Between Traditional and Modern Fuel VehiclesDocument16 pages3.6 Comparison Between Traditional and Modern Fuel VehiclesNaina AgrawalNo ratings yet

- ReadingDocument6 pagesReadingTUTOR IELTSNo ratings yet

- Hydrogen Facts: Power To Change The WorldDocument2 pagesHydrogen Facts: Power To Change The WorldJohn KellyNo ratings yet

- Bab 1 Perbaikan OkeyDocument18 pagesBab 1 Perbaikan OkeyFariz Al HafizNo ratings yet

- Simulation of Single-Step Dimethyl Ether Synthesis From SyngasDocument5 pagesSimulation of Single-Step Dimethyl Ether Synthesis From SyngasshaNo ratings yet

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (586)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)