Professional Documents

Culture Documents

Susuki SY413 - 416 - 418

Uploaded by

Manuel Alonso RomanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Susuki SY413 - 416 - 418

Uploaded by

Manuel Alonso RomanCopyright:

Available Formats

BRAKES

5-7

ON-VEHICLE SERVICE

EXCESSIVE PEDAL TRAVEL CHECK

1) Start engine. 2) Depress brake pedal a few times. 3) With brake pedal depressed with approximately 30 kg (66 lbs) load, measure brake pedal to wall clearance c. Clearance c: Over 80mm (3.15 in.) ... For 1.3 1.6 model 95 mm (3.74 in.) ... For 1.8 model 4) If clearance c is less than specification, the most possible cause is either rear brake shoes are worn out beyond limit or air is in lines. Should clearance c remain less than specification even after replacement of brake shoes and bleeding of system, other possible but infrequent cause is malfunction of rear brake shoe adjusters or booster push rod length out of adjustment. D See BLEEDING BRAKES in this section. D Remove brake drums for adjuster inspection. (See BRAKE DRUM REMOVAL in this section.) If defective, correct or replace.

60G40-5-7-2

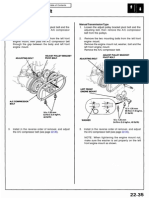

AUTOMATIC TRANSMISSION (4 A / T) 7B1-45

76) Coat new O-ring with A/T fluid. 77) Tighten speedometer driven gear (vehicle speed sensor for speedometer) (with new O-ring installed) with bolt. Tightening Torque (a): 5.5 Nm (0.55 kg-m, 4.0 lb-ft)

1. Speedometer driven gear (Vehicle speed sensor for speedometer) shaft sleeve subassembly.

60G40-7B1-45-1

78) Install transmission range switch assembly. a) Place new rubber plate and new lock washer or shift switch. b) Tighten lock nut. Tightening Torque (a): 7.0 Nm (0.7 kg-m, 5.0 lb-ft) c) Adjust transmission range switch. d) Tighten transmission range switch bolts. Tightening Torque (b): 20 Nm (2.0 kg-m, 14.5 lb-ft) e) Tighten manual shift lever with spring washer and nut. Tightening Torque (b): 20 Nm (2.0 kg-m, 14.5 lb-ft)

1. Shift switch 2. Bolt 3. Lock washer

60G40-7B1-45-3

4. Lock nut 5. Manual shift lever

79) Install oil cooler pipes. Tightening Torque (a): 27 Nm (2.7 kg-m, 19.5 lb-ft) (b): 25 Nm (2.5 kg-m, 18.0 lb-ft) NOTE: Make sure to use new A/T fluid pipe union bolt gaskets to prevent fluid from leaking.

1. Oil cooler pipe 2. New gasket

60G40-7B1-45-4

80) Measure starting torque of differential gear assembly. For detail, refer to step 2) on REMOVAL procedure.

60G40-7B1-45-5

8-4 BODY ELECTRICAL SYSTEM

INSTRUMENTS AND GAUGES

COMBINATION SWITCH

Combination switch incorporates lighting, turn signal, hazard warning light, dimmer, passing light and wiper/washer switches and steering angle sensor.

WIPER TURN DIMMER & PASS LIGHT WASHER

REAR WIPER & WASHER

To J / B

D Terminal arrangement of combination switch coupler viewed from harness coupler.

60G40-8-4-3

A. Horn switch B. Air bag inflator (if equipped) C. Steering sensor (if equipped)

Inspection 1) Disconnect negative () cable at battery. 2) Disconnect combination switch lead wire connectors from junction/fuse box. 3) Use a circuit tester to check the continuity at each switch position. If any continuity is not obtained, replace switch.

60G40-8-4-4

Removal/Installation For removal/installation of combination switch, refer to Section 3C or 3C1 of manual mentioned in FOREWORD of this manual.

NOTE: Some vehicles are not provided with INTERMITTENT position depending on specification.

60G40-8-4-5

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Calculation of Percentage of Oxygen in The Air After The Evaporation of A Volume of Liquid NitrogenDocument2 pagesThe Calculation of Percentage of Oxygen in The Air After The Evaporation of A Volume of Liquid Nitrogenlutfi awnNo ratings yet

- Instrucalc 71Document4 pagesInstrucalc 71অরিজিৎ ঘোষ100% (1)

- Controllability in Process DesignDocument14 pagesControllability in Process DesignKokil JainNo ratings yet

- Separator 1 Sizing Spread Sheets PDF FreeDocument21 pagesSeparator 1 Sizing Spread Sheets PDF FreeHenry WicaksanaNo ratings yet

- Crude Oil Refining UpgradingDocument13 pagesCrude Oil Refining UpgradingBrenda DavisNo ratings yet

- B023 Gas Pipes Calculations - Rev ADocument1 pageB023 Gas Pipes Calculations - Rev AAli BariNo ratings yet

- Getting Start Hysys UnisimDocument38 pagesGetting Start Hysys UnisimBassem BalghouthiNo ratings yet

- Excess Flow ValveDocument2 pagesExcess Flow ValveSyed Waqas HaiderNo ratings yet

- 60G60 - 015 BalenoDocument355 pages60G60 - 015 BalenoFaud NavarreteNo ratings yet

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnNo ratings yet

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinNo ratings yet

- Control Valve SizingDocument5 pagesControl Valve SizingMostafa SharafNo ratings yet

- Glycol Dehydration Unit English LetterDocument4 pagesGlycol Dehydration Unit English LetterRaulCamachoNo ratings yet

- HYSYS Getting Started GuideDocument12 pagesHYSYS Getting Started GuideKokil Jain50% (2)

- Pump RateDocument1 pagePump RateIman Taufik Darajat100% (1)

- Flow Assurance 2005Document35 pagesFlow Assurance 2005Jiso ThomasNo ratings yet

- Siphon Breaker Valves (Accessories)Document2 pagesSiphon Breaker Valves (Accessories)mikeswordsNo ratings yet

- PID Loop SimulatorDocument9 pagesPID Loop SimulatorJavierSanchezNo ratings yet

- Hasil Deepening Gas LiftDocument16 pagesHasil Deepening Gas LiftIrsalina NHNo ratings yet

- BP Peak Oil Demand and Long Run Oil PricesDocument20 pagesBP Peak Oil Demand and Long Run Oil PricesKokil JainNo ratings yet

- VGS Vane Separators Are Recommended ForDocument1 pageVGS Vane Separators Are Recommended ForSanthu PeelaNo ratings yet

- Kunci Jawaban PR 5 Fluida Reservoir 20162017Document8 pagesKunci Jawaban PR 5 Fluida Reservoir 20162017Black CatNo ratings yet

- InstruCalc Relief Device SizingDocument1 pageInstruCalc Relief Device SizinggeorgD2010No ratings yet

- 7335 BulDocument4 pages7335 BulSarah DeanNo ratings yet

- Compressible Flow Bench: Yeditepe University Department of Mechanical EngineeringDocument5 pagesCompressible Flow Bench: Yeditepe University Department of Mechanical EngineeringAhmad AbukhashabehNo ratings yet

- Heat Exchanger Project FinalDocument16 pagesHeat Exchanger Project FinalChristopher CameronNo ratings yet

- September - D 120 P SCSSV and SSV Leak TestDocument1 pageSeptember - D 120 P SCSSV and SSV Leak TestHosseinNo ratings yet

- Valve CV Flow Rate FormlaeDocument1 pageValve CV Flow Rate Formlaelatasharma79No ratings yet

- Che111p Quiz 2ot - 3Q1516Document1 pageChe111p Quiz 2ot - 3Q1516Rejed VillanuevaNo ratings yet

- Sajad FalahDocument12 pagesSajad FalahSajad FalahNo ratings yet

- Pressor CurvesDocument8 pagesPressor CurvesKeyren JuliantoNo ratings yet

- 0420 PV 201 Globe Valve Data SheetDocument12 pages0420 PV 201 Globe Valve Data SheetMohamed Farag MostafaNo ratings yet

- Belt Identification Chart GATESDocument1 pageBelt Identification Chart GATESBenito Ramirez MirandaNo ratings yet

- Pillard - Packlight Buk 117 CDocument2 pagesPillard - Packlight Buk 117 CAlfonso Blanco100% (1)

- Desalters 3Document2 pagesDesalters 3vishnumnair1No ratings yet

- Computer Assisted Design of Thermal Systems: Actual Compressor CalculationsDocument6 pagesComputer Assisted Design of Thermal Systems: Actual Compressor CalculationsmrinalbhadurioNo ratings yet

- Sucker Rod Pump and Accessories-Huaming EnergyDocument9 pagesSucker Rod Pump and Accessories-Huaming EnergyKevin XuNo ratings yet

- Pre-Recorded Information: X X X X XDocument3 pagesPre-Recorded Information: X X X X XOscar BustosNo ratings yet

- Energy and Mass IncinerationDocument11 pagesEnergy and Mass Incinerationnuti_srinivasNo ratings yet

- Oil and Gas Surface Wellhead and Christmas Tree Components Illustration HandbookDocument20 pagesOil and Gas Surface Wellhead and Christmas Tree Components Illustration HandbookazareiforoushNo ratings yet

- Mist Eliminator-ASK2 MfixDocument6 pagesMist Eliminator-ASK2 MfixVismit BansalNo ratings yet

- Subject: - Special Items.: PurposeDocument10 pagesSubject: - Special Items.: PurposeNitin ZoreNo ratings yet

- Instrucalc VDocument33 pagesInstrucalc VNorberto Soto100% (1)

- LP Cold Vent & Closed Drain)Document1 pageLP Cold Vent & Closed Drain)Shibu ThomasNo ratings yet

- Drilling Formulas Calculation Shee V1Document134 pagesDrilling Formulas Calculation Shee V1timz_upNo ratings yet

- Den Con CatalogDocument36 pagesDen Con Catalogbaskaran vNo ratings yet

- 10 1016@j Jngse 2016 01 016Document37 pages10 1016@j Jngse 2016 01 016saiful bahriNo ratings yet

- Total Dynamic HeadDocument2 pagesTotal Dynamic Headrajbhar_sNo ratings yet

- Basic Practices in Compressors SelectionDocument11 pagesBasic Practices in Compressors SelectionHector RodriguezNo ratings yet

- OIL-SU-02 Rev 0Document34 pagesOIL-SU-02 Rev 0HosseinNo ratings yet

- Asih Ayu Nitiwati - Tugas Surface 2Document8 pagesAsih Ayu Nitiwati - Tugas Surface 2asih ayuNo ratings yet

- Kia Sorento Engine (XM) InfoDocument61 pagesKia Sorento Engine (XM) Inforeluma0% (1)

- Procedimietos CulataDocument15 pagesProcedimietos CulataSERVICIO TECNICO AUTOMOTRIZ TONATONo ratings yet

- Cylinder HeadDocument2 pagesCylinder Headsteven_hoyt8914No ratings yet

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- 94 Integra Ac Belt ReplacementDocument2 pages94 Integra Ac Belt ReplacementRandy TurnerNo ratings yet

- Clutch Actuator & TCM AssemblyDocument13 pagesClutch Actuator & TCM AssemblyVinh XuânNo ratings yet

- 1kz Te Banda de MotorDocument5 pages1kz Te Banda de MotorTaller Energy EnergyNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- SSP 861503 Noise Vibration and HarshnessDocument84 pagesSSP 861503 Noise Vibration and HarshnessMahmoud S NasereddinNo ratings yet

- HPP&HET Apr 2017 - BDocument991 pagesHPP&HET Apr 2017 - Bbudi santosoNo ratings yet

- Coupling: Basic Difference BetweenDocument41 pagesCoupling: Basic Difference BetweenKadiyam VijayNo ratings yet

- Forces (F) QPDocument59 pagesForces (F) QPSam GreenNo ratings yet

- Brakes Description and OperationDocument17 pagesBrakes Description and Operationlilianadiaz.201074No ratings yet

- VW Golf 8 Brochure Nov 2022Document15 pagesVW Golf 8 Brochure Nov 2022kkimhinautoNo ratings yet

- Draft 1 Automobile Handbook 2021Document70 pagesDraft 1 Automobile Handbook 2021khushidhandeNo ratings yet

- D160SDocument22 pagesD160SYakupovmm100% (1)

- Brake System FundamentalsDocument25 pagesBrake System FundamentalsJeff HardyNo ratings yet

- Air Over Hydraulic Brake SystemDocument2 pagesAir Over Hydraulic Brake SystemReyes VargasNo ratings yet

- AURTTB101 LearnersWorkbookDocument36 pagesAURTTB101 LearnersWorkbookMuhammad IrfanNo ratings yet

- Safety of Wind SystemsDocument40 pagesSafety of Wind SystemsBagas ElangNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument53 pagesFastener Tightening Specifications: Application Specification Metric Englishmebarki aberraoufNo ratings yet

- Test Bank For Automotive Technology A Systems Approach 7th Edition ErjavecDocument36 pagesTest Bank For Automotive Technology A Systems Approach 7th Edition Erjavecboggle.muffisheab137100% (40)

- Noise Pollution PresentationDocument128 pagesNoise Pollution PresentationAlagappa MosesNo ratings yet

- KTM RC 250 Moto3/Factory 2012: Material Included in The Bike Sale PackageDocument8 pagesKTM RC 250 Moto3/Factory 2012: Material Included in The Bike Sale PackageJuan Lopez MuñozNo ratings yet

- Cutting Machine Instruction ManualDocument18 pagesCutting Machine Instruction Manualkhaled abdalnaserNo ratings yet

- User Manaul TOP DRIVE JH PDFDocument165 pagesUser Manaul TOP DRIVE JH PDFjoseluisvalera100% (1)

- A35G, A40G: Volvo Articulated Haulers 34.5-39 T 447-475 HPDocument20 pagesA35G, A40G: Volvo Articulated Haulers 34.5-39 T 447-475 HPEdmundas PoškaNo ratings yet

- Brake - PerformanceDocument8 pagesBrake - Performancereza5222No ratings yet

- Brake System Design and Theory PDFDocument5 pagesBrake System Design and Theory PDFal sarNo ratings yet

- Drawworks Technology CatalogDocument20 pagesDrawworks Technology Cataloga_salehi100% (1)

- MECHANICAL Mini ProjectsDocument11 pagesMECHANICAL Mini Projectssanthosh 97No ratings yet

- Tehničke Karakteristike Reduktora 1MW - EngDocument2 pagesTehničke Karakteristike Reduktora 1MW - EngIvana Z. OgnjanovićNo ratings yet

- 3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFDocument14 pages3 Wheel Electric Forklift Trucks 2,500-3,200 LB PDFForklift Systems IncorporatedNo ratings yet

- GR 90 CIRCUIT DIAGRAM 2Document21 pagesGR 90 CIRCUIT DIAGRAM 2Affan fNo ratings yet

- Mathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsDocument5 pagesMathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsInnovative Research PublicationsNo ratings yet

- Ansi Icwm 2012Document65 pagesAnsi Icwm 2012Adam GordonNo ratings yet