Professional Documents

Culture Documents

Bosch India

Uploaded by

kary290790Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bosch India

Uploaded by

kary290790Copyright:

Available Formats

BOSCH INDIA INNOVATION BLOWBACK INTO EUROPE

Some of the biggest breakthroughs are breathtakingly simple and they come from a complete reframing of a problem or challenge. In 1993, Apple, under its CEO John Sculley, tried creating a Personal Digital Assistant or PDA called Newton that could recognize human handwriting as an input device rather than use a keyboard. It failed miserably at the handwriting recognition. The technology was just not up to it. They had spent nearly $500 million trying to develop it and had failed. Other companies, too, tried to develop a similar handheld device that could recognize handwriting. Nearly a billion dollars spent overall in this endeavor went down the drain. Palm Computing was one of the other companies that failed. But then Jeff Hawkins, the CEO of Palm Computing, reflected on his failure and thought about reframing the challenge. Rather than develop complex software that could enable a machine to recognize all kinds of handwriting styles, why not teach people to write in a way that the machine could understand? He created Graffitti- a kind of writing that requires users to make modified characters with a single pen stroke. Its easy to learn and easy for the machine to recognize. The result was the now iconic Palm Pilot which was launched in 1997. It was developed at a cost of $3 million and by 2000 was generating revenues of over a billion dollars a year. And all because of a reframe! Closer home, a team from Bosch India, the Indian wing of the global engineering giant, the Bosch Group, broke industry norms through a similar reframe in a different context. Stringent emission norms for diesel engines currently require extensive engine modifications to enable them to interact with complex external high-pressure pump that aids in reducing emissions. The team from Bosch India reframed this challenge. Rather than make major and expensive engine modifications to enable it to interact with the high-pressure pump, why not make modifications to the pump to enable it to interact with the existing engine and give the same results? Like all great truths, it seems self-evident today but at the time, the challenge of creating a pump that could enable an existing traditional engine to meet the rigorous emission norms without modifications was seen as so far off the wall as to be almost impossible. No one thought in these terms. They only thought about how and when to convince engine manufacturers to modify their traditional diesel engines. With stricter emission norms coming in, it only seemed a matter of time. But the team at Bosch India began flirting with the idea of creating a pump- since it is the pump or fuel injection system that has the greatest impact on emission. The key challenge was that it was considered impossible to do this with the existing engines. Expensive and extensive modifications would need to be made to the engines. Could the team think radically and find an alternate way of doing this? They did, and now, existing diesel engines can move to the stringent emission norms of Euro IV, V and VI without expensive engine modifications that would cost anywhere from Euros () 3 million to

20 million. All it needs is a 20-Euro pump called the PF-45 that can be modified to fit any existing diesel engine. And the impact has been tremendous. It was launched in 2006 with expected sales of 70,000 units in 2007. Instead, 160,000 units were sold according to company sales figures. And in 2010 one million units are expected to be sold! The impact on the industry is that many engines can continue with the existing design right up to Euro VI- the highest emission norms currently envisaged. THE CHALLENGE: THE BEGINNING It all began in 1989-90. Bosch India had been made the centre of competence for a particular singlecylinder pump called the PF pump used in diesel engines. By 2002, the realization had set in for the R&D group that PF pumps would soon become extinct as the world was moving to tighter emission norms which required a different type of fuel injection system called the common rail system. PF pumps catered to the older kind of engines that could only meet euro II emission norms at best. To go beyond would need a high-pressure pump for the common rail system. Moving to euro IV and higher norms would necessitate all older diesel engines shifting to common rail systems and making extensive modifications to existing diesel engines. The modifications would need to be in both the drive and the crankcase, the most expensive part of the engine. These modifications, especially in developed economies, could cost anything up to 20 million for the manufacturer, depending on the kind and size of engine. This would also mean the end of the PF pump In diesel engines, the key component in reducing emission and pollution is the fuel injection mechanism. The greater the pressure and timing of fuel injection, the more the diesel is burned off completely. Increasing emission norms require increasing pressure in the fuel injection system. Euro II norms could be met with around 500 bars of pressure. But Euro IV necessitates reaching between 1400 and 1600 bars of pressure. Euro V would mean reaching around 2200 to 2400 bars or higher. These are tremendous challenges. An increase in every 100 to 200 bars often needs a relook at existing manufacturing practices. There are two key dimensions to this challenge: Creating a pump that can first generate high pressures of 1600 bars and then withstand the high pressures. The challenges were so radical that over the years a different kind of pump itself has been developed-the Common Rail pump. The pump is large, has three pumping chambers (pressuring units), a metering unit and a drive. Fundamentally, it was a question of survival for the team and production unit. Internally, there was also the feeling that Common Rail (CR) is the present and PF is the past. The CR team in India looked at the PF team as a relic from the past. Even the organization was focused towards CR, while PF was just about tolerated. There were also questions about the contribution of the product development team internally. After all, they were just modifying and tweaking Bosch Germanys products. What was their contribution at all?

The R&D team of the PF pump group in India, headed by R. Baskaran, deputy general manager, product engineering, decided to do something about this. If they could find ways to make the PF pump as effective as the conventional Common Rail pump, perhaps extensive engine block modifications would not be required. And engine manufacturers could use existing engines but with higher emission norm capability, thus saving millions of dollars in development costs. This was especially true for India, where were currently on Euro III equivalent emission norms. Once India moves to Euro IV for commercial vehicles, extensive engine modifications would need to take place, perhaps leading to increased vehicle costs. To give an analogy about the scope of the challenge: Look at propeller and jet planes. In the first half of the 20th century, propeller aircraft kept improving and getting better and better. They began to fly higher, farther and faster. But there was always a limit they could not go beyond in terms of speed, distance and height. It needed a jet engine to do this. Similarly, in terms of pressure, there was always a limit the PF pump couldnt go beyond. It needed a Common Rail pump to reach there. What the PF pump team at Bosch India was trying to do in a way was to make the propeller plane perform at the same levels as a jet plane, without the additional costs that a jet plane would entail THE ROAD FROM IDEA TO IMPLEMENTATION In principle, the PF group had an idea that they could create such a pump. But they would need a customer willing to go along with the idea and give it a try. This would also allow Bosch to put in the resources required to develop such a pump. They found a customer not in India but in Germany: the Deutz group that manufactures diesel engines for customers like Volvo and Renault. Deutz was entering a new product category and didnt have a history of using Common Rail systems. The trigger was an order that they got from Volvo for medium-duty trucks. They decided to give this a try. As Dr Thiemann of Deutz says, they didnt want to make extensive design modifications to the existing engine. And when they decided to go with Bosch to co-develop this new pump, there were a lot of concerns within Deutz. First, Common Rail systems were new to the company and they had no experience in this. Second, they were trying to create an exotic system that was unique. Would it work at all? Were they just wasting time and money? The Bosch team from both Germany and India managed to convince Deutz that they would be able to develop such an exotic system. The R&D, of course, would happen in India as the centre of competence for PF pumps was based here. Deutz decided to go ahead and commit to the development and also share developmental costs. A development timetable and budget Whats fascinating about this team is that they didnt shrug their shoulders and say that its inevitable that the world moves from PF to CR as emission norms tighten. They didnt wait for events to overtake them and instead decided to take control and do something within their sphere of influence. And by the way, how much of a sphere of influence do you think a small group in a category out of fashion would

have? They may not have realized at the time, but they had the influence to impact the entire diesel industry across the world. How much of an influence do most of us think we have? Many of us feel fairly helpless and limited in our ability to make an impact. In reality, we may have far more influence and ability to impact the world than we realize.

was chalked out. The pump would need to be developed by 2005. It was 2002. While the developmental timetable had been chalked out, there were organizational, human and technical challenges that the team faced. One organizational challenge was that internally across Bosch there was a great degree of skepticism and also resistance to the idea of new pump. And as Dr Gerhard Ziegler, the VP of engineering application, says, the project had to be kept under the radar in the beginning. If it had been very visible, it could have run into internal hurdles. Once the team demonstrated that the pump was viable and actually emerged with one, it was brought out into public view and the accolades followed, as this was the time at Bosch that a new-to-the world product had been developed in India. In our experience, when internal hierarchical gravities and turfs are very strong, many innovators go under the radar until they can emerge with a tangible success, rather than risk remote organizational heavyweights putting a spanner in the works. The human challenges were around belief in capability. If you think about it, product innovation often flows from the developed world into India. It rarely flows the other way. The belief we have managed to create for ourselves is that we are good at replication and re-engineering. We take anything developed anywhere in the world and create a damned good version of that within a few weeks. For years, we have actually been taking pride in this. But create something new to the world, especially something highly engineered? Forget about it. We dont have the capability. We dont believe we have the capability, and by extension, we create the perception internationally too that we dont have the capability. It is no different at MNCs in India. Indian arms of MNCs are often seen as minor operations that tinker around at the margins. In many cases the Indian arm just makes modifications to products developed in the West. Too often in the Indian arm of an MNC, R&D is a misnomer. More tweak and modify takes place than true research and development. The R&D department just tinkers with an existing product to adapt it to Indian conditions. This was true of Bosch India as well. A team member says that he was very afraid when he took up the project. Earlier he had worked only on the mechanical pumps and there too just tweaking existing products. Here, for the first time, he was expected to develop from scratch. There was a great sense of fear about whether he would be able to do so. Adding to his anxiety was the knowledge that this was a very important project for Bosch India.

The technical challenges were also tremendous. The key constraint was that it would have to be a single-cylinder pump that fitted into the existing engine block and created no changes or modifications in the existing engine. In shape, it would have to look a lot like the existing PF pumps, but in performance it would have to deliver in terms of a conventional Common Rail pump. The key challenge is to deliver the required fuel quantity at 1600 bar pressure with the singlecylinder PF pump. This was possible with the three pumping units in case of conventional Common Rail (CR) pump, but considered impossible with the single-cylinder pump. The maximum a single-cylinder pump could reach was pressures of around 750 bars. To reach Euro IV norms, the pump would need to withstand a pressure of at least 1600 bars. THE INNOVATIONS Now the innovations began. The team was working in a sphere of uncertainty. They didnt know whether this was even possible. To begin with, they decided to challenge every part of the existing Common Rail pump. The conventional CR pump has three key components: a driving unit, three pumping units, and a built-in fuel quantity regulating unit. The key reframe the team attempted here was to unbundle the bundled. They separated the bundled components and decided to challenge each component, beginning with the driving unit. They challenged the fact that the pump required an external drive. Why couldnt it be attached to the engine cam shaft and use that to drive the pump and generate pressure? They did away with the drive unit and the pump is now inside the engine block. The next challenge was to do away with the three sections of the conventional CR pump. The three sections aided in generating pressure. They did this by using the cam lobe in the shape of triangle that really gave a 3-time lift so that as the engine camshaft drove the pump, one revolution in effect lifted and dropped the plunger 3 times. This created the same effect as the 3 sections of a conventional CR pump. The shift they made here was to utilize unutilized assets like the engine cam shaft. If you think about it, what are some unutilized assets in your organization? There are often tremendous assts lying around unutilized which often need just a reframe to utilize them in completely new ways.

Some challenges that seemed very minor took up a huge time and effort. For instance, during trials they found that there were huge stresses on the guide pin at the cam. It took them nearly a year just to find a way to deal with those immense stresses and then to test it. Testing meant making the section go through 107 trials-ten million trials. And that took time and effort. The pump had to work perfectly. One challenge they had committed to was that it would last for 500,000 hours of usage up from the existing 150,000 hours for the conventional CR pump. So nothing could be allowed to go wrong there. Five hundred thousand hours really means a lifespan of twenty years.

The fuel quantity regulating unit of the conventional CR pump was separated and placed elsewhere so that it didnt take up precious space in the engine block. The next challenge was to create an external body that could withstand tremendous pressures and temperatures. This was done using a monoblock, but then the team found that the plunger seized because the temperature was so high that the body became deformed. They needed to work on this further. One solution was to coat the interior with anti-friction and anti-wear carbon-impregnated coating. Finally, the radical pump was created. It was developed within budget and within time. Deutz got the pump in the time frame they had wanted it. It collected a patent along the way and took constant innovations at every level and in every part of the pump as each new challenge required an innovation to crack it. The biggest constraints to a product are those that enable it to succeed. For instance, the biggest enabler to propeller planes was the propeller. And until that was removed, the jet didnt happen. Similarly, the biggest enablers to the usual CR pump were the external drive and the three pressure chambers. Once these were removed, the innovative PF-45 pump happened. What are some key enablers of your product that you can eliminate? THE IMPACT The impact has been tremendous. Business has boomed. And since the pump is now so incredibly simple, the assembly, installation and maintenance costs have crashed. A large part of servicing costs in Common Rail pumps has always been pump servicing by highly trained technicians. This has been all but eliminated. The pump needs no servicing and lasts more than three times as long as a conventional CR. And at around 20 Euros, at a fourth the cost of a conventional CR pump, its really great value for money. The impact on Bosch India has been incredible. There has always Really, if you think about it, talent is like capital. It flows to the place of highest utilization. At Bosch India, every year, around thirty new engineering graduates join and they get to choose which department they want to join. Usually, only about five or six join R&D. but last year, twenty-four out of thirty graduates wanted to join R&D! Once the R&D team began producing breakthrough innovations, it began attracting talent. A similar story is found at Titan after it created the worlds slimmest water resistant watch and at Tata Motors after the Nano challenge. A new kind of talent is seeking out these companies. The newspapers are full of the reverse brain-drain or brain-gain with Indians who had migrated to the US coming back home. This really is a manifestation of talent going to the place of highest utilization. So really, if you are not satisfied with your in-house talent, the catch is that you are not going to attract new talent without demonstrating fundamental breakthroughs with

your existing talent. And these breakthroughs will largely come from an orbit-shifting challenge like the one the Bosch team took up.

been a fear that manufacturing and development could shift to China to take advantage of costs. With nothing to differentiate between Indian and China, the fear was that this would just be a matter of time. Today, with the innovations that India is producing around the pump, this fear has, for the time being at least, reduced. The potential impact on the diesel engine industry is huge. Engine manufacturers and commercial vehicle buyers have got a new lease of life as they dont have to go in for expensive engine modifications to meets the next level of emission norms. Instead, they can get the same benefit for a fraction of the cost. This pump can also be upgraded to meet Euro VI norms that will come into force in 2013 in Europe and 2020 in India (India lags behind Euro norms by around eight years). The impact on the internal team has been awesome. The India competency centre has suddenly become extremely visible not only to the Bosch world, but to the entire diesel world. The R&D department is attracting talent. Last year, 80 per cent of new engineering trainees at Bosch India wanted to join R&D, up from 20 per cent in previous years. Internal motivation and confidence have skyrocketed. As a team member said, I feel like a boy whos won a gold medal. Another said, I now feel confident about taking on any challenge. The PF-45 experience has really motivated us and boosted our confidence. There is a deep sense of pride. As a team member said, We have always felt that we Indians cannot do any development. Everything can only be developed in Europe and brought to India a decade later when the world has shifted to other products and technologies. We get the hand-me-downs to lead. The usual block to innovation in a developing country like India is the question: Has anyone done it before? If no one has done it before how can we do it? This often leads to fitting-in and modifying rather than creating new-to-the-world innovations. Today we have shown the world that we can conceive, develop and manufacture terrific innovations. The mindset shift has been from we are just applicators for Bosch Germanys products, therefore make minimal tweaks after extensive permission-seeking to we create technology that nobody in the world has done. We are thought leaders. The team has overcome the traditional developing country mindset of deference to the West or Japan. The same team has now developed the next-generation pump called PF-51 which is a much smaller version of the current one. As Amarnath from sample manufacturing said, the pump is the epitome of simplicity and performance. It does what a PF-45 does at one-fourth its dimensions and weight. And the fascinating factor, according to the project champion Baskaran, is that now, new

engine manufacturers are designing their engines around the pump rather than the usual pump manufacturers designing the pump around the engine. This next generation pump has created tremendous breakthroughs in design, cost reduction and size. But perhaps the greatest impact is the innovation blowback effect. A pump originally conceived for India, keeping in mind the reluctance of most Indian commercial vehicle customers to spend anything extra on vehicle costs, is now sweeping the European continent. What began as an idea to make a painless transition to higher emission norms in India has now impacted the Western hemisphere. Increasingly, innovations from India, developed to meet the uniquely Indian challenges of extreme low-cost solutions along with great quality are impacting the West. The PF-45 pump is one such innovation. And it all began when one powerless team decided to take control of its own destiny and began by reframing something the whole diesel world had begun to take for granted.

You might also like

- Case 2 & 3 - Cashing Our & Indian Sugar IndustryDocument8 pagesCase 2 & 3 - Cashing Our & Indian Sugar Industrymohitrameshagrawal100% (2)

- Mother Dairy CompetitorsDocument1 pageMother Dairy CompetitorsPrakharNo ratings yet

- BPCLDocument17 pagesBPCLTausif KhanNo ratings yet

- The Case On Tata Nano - The People's CarDocument4 pagesThe Case On Tata Nano - The People's CarAsm TowheedNo ratings yet

- Fake Brand AssignmentDocument5 pagesFake Brand AssignmentMeetu RawatNo ratings yet

- Reva StrategyDocument18 pagesReva Strategyjames40440No ratings yet

- BRL Hardy: Globalizing An Australian Wine CompanyDocument6 pagesBRL Hardy: Globalizing An Australian Wine CompanyTusharNo ratings yet

- NestleDocument9 pagesNestleRamiz ShahidNo ratings yet

- Innovation Simulation: Breaking News: HBP Product No. 8678Document9 pagesInnovation Simulation: Breaking News: HBP Product No. 8678Karan ShahNo ratings yet

- Process Selection and Design OptimizationDocument34 pagesProcess Selection and Design OptimizationAlex Francis0% (1)

- Goli Vada Pav Is A VadaDocument7 pagesGoli Vada Pav Is A Vadaabramasw86No ratings yet

- Tata Daewoo Deal1Document5 pagesTata Daewoo Deal1Ashwinikumar KulkarniNo ratings yet

- Economics Assignment 4Document3 pagesEconomics Assignment 4Shivnath KarmakarNo ratings yet

- Analyze Dry Idea's Market Position and Consumer Behavior DriversDocument5 pagesAnalyze Dry Idea's Market Position and Consumer Behavior DriversShachin ShibiNo ratings yet

- Group5 - B 3rd CaseDocument2 pagesGroup5 - B 3rd CaseRisheek SaiNo ratings yet

- Balaji Group1Document7 pagesBalaji Group1Abhigya MaheshwariNo ratings yet

- BMW 7-Series Project Process ChangesDocument27 pagesBMW 7-Series Project Process ChangesSambit RoyNo ratings yet

- Montreaux Chocolate Section E Group 2Document10 pagesMontreaux Chocolate Section E Group 2Swastika DashNo ratings yet

- Adani GroupDocument20 pagesAdani GroupKetan DeshpandeNo ratings yet

- Jaguar Land Rover Acquisition Part 1Document12 pagesJaguar Land Rover Acquisition Part 1Ankur Dinesh PandeyNo ratings yet

- Duracell Case FINALDocument5 pagesDuracell Case FINALRob ZhangNo ratings yet

- DR Reddy CaseDocument3 pagesDR Reddy Casesubhendu maharanaNo ratings yet

- Tata Nano : ONE LakhDocument24 pagesTata Nano : ONE Lakharunaghanghoria2803No ratings yet

- Case-1 - MM1 - Vora and Company - Anirban Kar - EPGP-12A-022Document6 pagesCase-1 - MM1 - Vora and Company - Anirban Kar - EPGP-12A-022Anirban KarNo ratings yet

- First Generation Indian Entrepreneur Case Study on ID Fresh Food CEODocument9 pagesFirst Generation Indian Entrepreneur Case Study on ID Fresh Food CEOHimanshu RaoNo ratings yet

- Beechnut Nutrition Corporation Faces Supplier IssuesDocument4 pagesBeechnut Nutrition Corporation Faces Supplier Issueszain1234567No ratings yet

- Program: MBA-Master in Business Administration: Student: Mislav MatijevićDocument4 pagesProgram: MBA-Master in Business Administration: Student: Mislav MatijevićMislav MatijevićNo ratings yet

- Case Millennium TSS J v1Document6 pagesCase Millennium TSS J v1killer drama100% (1)

- Supply and Value Chain of Zara and P&GDocument8 pagesSupply and Value Chain of Zara and P&GDarshini DarshuNo ratings yet

- Give IndiaDocument5 pagesGive Indiamohitegaurv87No ratings yet

- Case Analysis: Sustainability at MilliporeDocument1 pageCase Analysis: Sustainability at MilliporeJulie SousaNo ratings yet

- Precise Software Solutions Case ROI and Pricing AnalysisDocument2 pagesPrecise Software Solutions Case ROI and Pricing AnalysisRevappa YeddeNo ratings yet

- Bharti Airtel in Africa: Group - 11Document15 pagesBharti Airtel in Africa: Group - 11Srijani DharaNo ratings yet

- IKEA's Wood Sustainability and 2020 Growth TargetDocument3 pagesIKEA's Wood Sustainability and 2020 Growth Targetneha reddyNo ratings yet

- IIM Kozhikode EPGP Business Laws End-Term ExamDocument4 pagesIIM Kozhikode EPGP Business Laws End-Term ExamAbhay AgarwalNo ratings yet

- Bharat MatrimonyDocument15 pagesBharat Matrimonychetankhanna93No ratings yet

- Clearion Software 1Document13 pagesClearion Software 1Dewashish RaiNo ratings yet

- SCM CaseletDocument10 pagesSCM CaseletSreejith P MenonNo ratings yet

- RCF's Supply Chain Management StrategiesDocument24 pagesRCF's Supply Chain Management Strategiesmalik_samnani100% (1)

- ABB and Caterpillar (A) : Key Account Management: Case ReportDocument2 pagesABB and Caterpillar (A) : Key Account Management: Case ReportSonaliCaffreyNo ratings yet

- HP-Cisco FinalPPTDocument15 pagesHP-Cisco FinalPPTKarthikeyan Gopal100% (1)

- BRLHardy Group5Document4 pagesBRLHardy Group5saurav1202No ratings yet

- GROFERSDocument4 pagesGROFERSsiddhants3108No ratings yet

- Tata Group's Global Expansion StrategyDocument14 pagesTata Group's Global Expansion Strategybali_jepalliNo ratings yet

- Barilla Case Study SolutionDocument6 pagesBarilla Case Study Solution王睿No ratings yet

- Mother Dairy PresentationDocument5 pagesMother Dairy PresentationAKANSHANo ratings yet

- TATA - STEEL - Group 5Document7 pagesTATA - STEEL - Group 5Sidhant NayakNo ratings yet

- STAMYPOR MANAGEMENT OF INNOVATIONDocument15 pagesSTAMYPOR MANAGEMENT OF INNOVATIONrockysanjitNo ratings yet

- Dominion Motors and Controls Ltd. - Case AnalysisDocument7 pagesDominion Motors and Controls Ltd. - Case Analysisdhiraj agarwalNo ratings yet

- Dabur RepositioningDocument11 pagesDabur RepositioningsaurabhNo ratings yet

- Case Study Mahindra PDFDocument18 pagesCase Study Mahindra PDFGourav ChoudhuryNo ratings yet

- CAPSIM Capstone Strategy 2016Document21 pagesCAPSIM Capstone Strategy 2016Khanh MaiNo ratings yet

- Case Analysis: Havells - India - Sylvania AcquisitionDocument12 pagesCase Analysis: Havells - India - Sylvania AcquisitionMohit ChorariaNo ratings yet

- Parle Vs Britannia NewDocument24 pagesParle Vs Britannia Newl_krish07100% (2)

- Barilla SpA Case Study: Improving Supply Chain Management Through JITDDocument5 pagesBarilla SpA Case Study: Improving Supply Chain Management Through JITDShiva KashyapNo ratings yet

- BoschDocument12 pagesBoschmicakojic100% (2)

- Standing On The Shoulders of GiantsDocument19 pagesStanding On The Shoulders of Giantschakib salekNo ratings yet

- The Model T Ford: Case StudiesDocument3 pagesThe Model T Ford: Case Studiesedris9788No ratings yet

- Project Report On Ford Motor Company PDFDocument15 pagesProject Report On Ford Motor Company PDFHargun VirkNo ratings yet

- Garrett EV ThermalDocument4 pagesGarrett EV ThermalDivyanshu JhaNo ratings yet

- Program ContentDocument2 pagesProgram Contentkary290790No ratings yet

- Case Study On Product DissectionDocument6 pagesCase Study On Product Dissectionkary290790No ratings yet

- Case Study 3 On Product BenchmarkingDocument3 pagesCase Study 3 On Product Benchmarkingkary290790No ratings yet

- Transforming Organizational ChangeDocument42 pagesTransforming Organizational Changekary290790No ratings yet

- Man ChangeDocument72 pagesMan Changekary290790No ratings yet

- Case Study 1 - Benchmarking at XeroxDocument3 pagesCase Study 1 - Benchmarking at Xeroxkary290790100% (1)

- Article On BenchmarkingDocument10 pagesArticle On Benchmarkingkary290790No ratings yet

- Article - Benchmarking Understanding The BasicsDocument4 pagesArticle - Benchmarking Understanding The Basicskary290790No ratings yet

- Article On Benchmarking by Kenneth CrowDocument17 pagesArticle On Benchmarking by Kenneth Crowkary290790No ratings yet

- Article - Benchmarking IntroDocument5 pagesArticle - Benchmarking Introkary290790No ratings yet

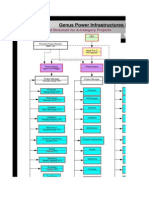

- Organizational Structure and Design FundamentalsDocument27 pagesOrganizational Structure and Design Fundamentalskary2907900% (1)

- Organizational Structure for Operations and Supply Chain ManagementDocument1 pageOrganizational Structure for Operations and Supply Chain Managementkary290790No ratings yet

- Co-Creation For Sustained ValueDocument15 pagesCo-Creation For Sustained Valuekary290790No ratings yet

- The Engagement ExchangeDocument2 pagesThe Engagement Exchangekary290790No ratings yet

- World Class R&D Structure, Projectised Structure & InfrastuctureDocument65 pagesWorld Class R&D Structure, Projectised Structure & Infrastucturekary290790No ratings yet

- Total Quality Management As The Basis For Organizational TransforDocument412 pagesTotal Quality Management As The Basis For Organizational Transforkary290790No ratings yet

- Transforming Your OrganizationDocument17 pagesTransforming Your Organizationjimmy0000007No ratings yet

- PWC Looking Ahead Driving Co Creation in The Auto Industry PDFDocument12 pagesPWC Looking Ahead Driving Co Creation in The Auto Industry PDFkary290790No ratings yet

- Employee CoDocument5 pagesEmployee Cokary290790No ratings yet

- Culture Transformation Viewpoint 2012Document8 pagesCulture Transformation Viewpoint 2012kary290790100% (1)

- CoDocument5 pagesCokary290790No ratings yet

- How IBMDocument3 pagesHow IBMkary290790No ratings yet

- Mailchimp Grants EmployeesDocument6 pagesMailchimp Grants Employeeskary290790No ratings yet

- 118 226 1 PBDocument19 pages118 226 1 PBkary290790No ratings yet

- How One Company Taught Its Employees How To Be HappierDocument5 pagesHow One Company Taught Its Employees How To Be Happierkary290790No ratings yet

- Strategy Case Studies (Catalogue II)Document77 pagesStrategy Case Studies (Catalogue II)kary290790No ratings yet

- Employee Engagement Maximizing Organizational PerformanceDocument25 pagesEmployee Engagement Maximizing Organizational Performancekanwarsingh100% (1)

- ShellyDocument11 pagesShellykary290790No ratings yet

- Presentation 2Document8 pagesPresentation 2kary290790No ratings yet

- BS Swingo200 EN 2016 04 PDFDocument20 pagesBS Swingo200 EN 2016 04 PDFCiprian Varlan0% (2)

- Technical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Document205 pagesTechnical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Dev JainNo ratings yet

- DAF FluidsDocument142 pagesDAF FluidsMumko100% (1)

- The Chassis OC 500 LE: Technical InformationDocument12 pagesThe Chassis OC 500 LE: Technical InformationAbdelhak Ezzahrioui100% (1)

- EUROCARGO Bodybuilders InstructionsDocument226 pagesEUROCARGO Bodybuilders Instructionsdarko miladinovicNo ratings yet

- RRL 1Document9 pagesRRL 1JannenNo ratings yet

- Ipol Stu (2021) 690888 en PDFDocument64 pagesIpol Stu (2021) 690888 en PDFAbiodun IbrahimNo ratings yet

- Sensors For Everyday LifeDocument326 pagesSensors For Everyday LifeMax EliotNo ratings yet

- PEER Stage2 10.1016 J.applthermaleng.2010.09.023Document37 pagesPEER Stage2 10.1016 J.applthermaleng.2010.09.023Yezid RokhmatulahNo ratings yet

- Toyota Hilux 2013 Brochure TCM 11 169512Document46 pagesToyota Hilux 2013 Brochure TCM 11 169512CONFERENCIER100% (3)

- Adblue Emulator V4 Nox Installation StepsDocument2 pagesAdblue Emulator V4 Nox Installation StepsJulito CastellanosNo ratings yet

- Catalogue 2016Document67 pagesCatalogue 2016Rok ŠalamunNo ratings yet

- Dr. Prapat - PM2-5-covid-2 PDFDocument31 pagesDr. Prapat - PM2-5-covid-2 PDFDj ClarrioNo ratings yet

- (Pre-Final) Significant Improvement in Air Quality in PhilippinesDocument17 pages(Pre-Final) Significant Improvement in Air Quality in PhilippinesMarkNo ratings yet

- MAN EngineDocument50 pagesMAN Engine1ramsai86% (22)

- Stability of Biodiesel: Heinrich PranklDocument10 pagesStability of Biodiesel: Heinrich PranklIAMANDU COSTANo ratings yet

- DENSO Common Rail Isuzu 6HK1 6SD1 Service Manual PagesDocument9 pagesDENSO Common Rail Isuzu 6HK1 6SD1 Service Manual PagesAmadeus De La Cruz67% (9)

- Air Pollution by VehiclesDocument18 pagesAir Pollution by VehiclesFurqan Fazili88% (33)

- EURO 2 3 RHD - 300dpiDocument419 pagesEURO 2 3 RHD - 300dpinikos.spanakakisNo ratings yet

- Sprinter BrochureDocument56 pagesSprinter BrochureHieuDinhNo ratings yet

- Road TransportDocument16 pagesRoad TransportCedo CeddNo ratings yet

- ICCT Annual Report 2020Document36 pagesICCT Annual Report 2020The International Council on Clean Transportation100% (1)

- Renault TRAFIC: Powerful, Clever and DynamicDocument56 pagesRenault TRAFIC: Powerful, Clever and Dynamicediartmobe100% (1)

- Man TGX.: Efficiency in Long-Haul TransportDocument21 pagesMan TGX.: Efficiency in Long-Haul TransportNadeem Mohd100% (1)

- Booklet Powertrain YMZ 2017Document13 pagesBooklet Powertrain YMZ 2017Michele GuerriniNo ratings yet

- Master Plan For Automotive IndustryDocument109 pagesMaster Plan For Automotive IndustryAvilash100% (1)

- L1-CHE-STD-007 v8 - Track VehiclesDocument14 pagesL1-CHE-STD-007 v8 - Track VehiclesCK TangNo ratings yet

- Exhaust Gas Treatment: (CPF For EURO4)Document13 pagesExhaust Gas Treatment: (CPF For EURO4)SergeyNo ratings yet

- BS4 BS6 Paper Ijstm19691398886200Document14 pagesBS4 BS6 Paper Ijstm19691398886200sanjay50% (2)

- Volvo's Hybrid Double-Deckers Cutting Emissions in LondonDocument20 pagesVolvo's Hybrid Double-Deckers Cutting Emissions in Londonrakeshpa_2078662No ratings yet