Professional Documents

Culture Documents

Presentacion Motores

Uploaded by

Pedro Arrambidez HernandezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Presentacion Motores

Uploaded by

Pedro Arrambidez HernandezCopyright:

Available Formats

Rockwell Automation- Allen Bradley Motors

Allen Bradley Control Matched Motors

Mario Monsivais Application Engineer

Rockwell Automation- Allen Bradley

The Complete Line of Control Matched Motors

CM202 Motors CM203 Motors CM100 and CM110

CM300 and CM310

Custom Large AC

8-2

Rockwell Automation-Allen Bradley

Specification Considerations

Issues and Information Required to quote motors Especially Variable Speed Motors

8-3

Rockwell Automation-Allen Bradley

What is the basic rating required:

HP and Base speed in RPM

Torque is KEY concern based on HP& base speed

T RPM HP = 5252

T = Torque (ft-lbs.) RPM = Motor Rotation/minute 5252 = constant (33,000ft lbs/min/2() rad/rev)

Voltage/Power

460V, 230/460V, 208-230/460V, 575V 60Hz 380V, 400V, 415V, - 50 Hz

Efficiency Requirement

Energy Efficient (EE) Premium Efficient (PE) Nema Premium (NP)

8-4

Rockwell Automation-Allen Bradley

Is it going to be used on inverter or as a fixed speed motor (on sine wave)? For Inverter fed motors

What is the performance required below base speed (only valid for inverter fed motors)?

Constant Torque or Variable Torque (Pumps, Fans) CT 1000:1, CT 10:1, CT 4:1, CT 2:1, VT 2:1

Is there a need for a constant horse power range (CHP)?

Constant horsepower range is the speed above the base speed rating that motor will run and still have the rated amount of HP.

8-5

Rockwell Automation-Allen Bradley

Specification Considerations

Enclosures Application and Framing Considerations Insulation/Temperature Rise Ambient Altitude SF Constant Torque Range Environment, Modifications Severe Duty Features

8-6

Rockwell Automation-Allen Bradley

Motor Enclosures

Motor Construction Motor Cooling Method

8-7

Rockwell Automation-Allen Bradley

AC or DC Motor Totally Enclosed Non-Vent (TENV) Enclosure

Prevents entry of dust, grit or moisture Cooling only through radiation

8-8

Rockwell Automation-Allen Bradley

AC Totally Enclosed Fan Cooled (TEFC) Enclosure

Fan mounted on Opposite Drive End shaft Turns at the same speed as motor rotates Cooling air goes around the motor, not through the motor Prevents entry of dust, grit or moisture

8-9

Rockwell Automation-Allen Bradley

AC or DC Motor Totally Enclosed Blower Cooled (TEBC) Enclosure

Blower mounted on Opposite Drive End. Blower needs separate power feed with motor starter. Cooling air goes through channels in the frame of the motor. No cooling air goes through the stator of the motor. Prevents entry of dust, grit or moisture.

8 - 10

Rockwell Automation-Allen Bradley

AC TEAO-P/B Enclosure

(Totally Enclosed Air Over Piggy Back)

Can change TEBC Inline to TEAO-P/B in order to mount brake and encoder Prevents entry of dust, grit or moisture

8 - 11

Rockwell Automation-Allen Bradley

AC or DC Motor Drip Proof Separate Vent (DPFV) Enclosure

Most Compact Design Low Inertia for fast response Air goes through the center of the motor Most efficient cooling method Filters can be added on blower Blower can be removed, and customer provide clean air piped into motor (DPSV) Designed to accept accessories; Brakes, Encoders, etc.

8 - 12

Rockwell Automation-Allen Bradley

Motor Specifications

Application Requirements Framing Considerations Insulation/Temperature Rise Ambient Altitude SF Constant Torque Range

8 - 13

Rockwell Automation-Allen Bradley

Motor Specifications

Key Factors in Sizing Motors for an Application Torque/Speed Determines Standard Frame Size Specify Overload Torque Requirements at Specific Speeds and for Specific Durations Accelerations & Decelerations E-Stop Conditions Specify Continuous Torque Requirements through Specific Speed Range Fast Run Conditions Continuous Duty Slow Run Conditions Continuous Duty

8 - 14

Rockwell Automation-Allen Bradley

Motor Specifications

Frame Size Adjusted to Manage Temperature Components Potential to Over Size Frames to Manage Ambient Altitude Service Factor Constant Torque Range Frame Size is Largest Determining Factor in Cost

8 - 15

Rockwell Automation-Allen Bradley

Maximum Total Temperature C of Insulation Systems Based on Measurement by Resistance for AC Motors

Insulation Class A 105C B 130C F 155C H 180C

AC

Standard Insulation on CM202

Standard Insulation CM203

8 - 16

Rockwell Automation-Allen Bradley

AC Temperature Components (C)

Class B 40C 80C 10C 130C Class F 40C 105C 10C 155C Class H 40C 130C 10C 180C

Ambient Rise/Rest. Hot Spot Total

8 - 17

Rockwell Automation-Allen Bradley

Motor Specifications

Ambient Altitude Service Factor

8 - 18

Rockwell Automation-Allen Bradley

Constant Torque

For Force Vent, Blower Cooled and Non-Vent Enclosures Constant Speed Blower, no problem. For Fan Cooled Enclosures Fan turns at shaft speed At lower RPM lower fan speed less cooling Harder to dissipate heat generated from losses

8 - 19

Rockwell Automation-Allen Bradley

Environmental Modifications

Severe Duty Features Motor Features

Cast-iron construction - frame, conduit box, end shields, fan cover, inner caps (Frame for CM203 is Laminated Steel) PLS positive bearing lubrication system Silicone rubber sealed fits Diagonally split, neoprene-gasketed, rotatable conduit box with NPT threaded lead hole Conduit box-mounted, UL listed, clamp-type grounding lug Rust-inhibitive, nonwashing lubricant Antistatic, polypropylene, corrosion-resistant bidirectional fan Stainless steel nameplates with NEMA nominal efficiency, guaranteed efficiency, AFBMA bearing numbers and lubrication instructions Zinc-plated, hex-head hardware Stainless steel "T" drains in both end brackets Stator and rotor completely epoxy-coated for corrosion protection Nonmetallic, V-ring shaft slinger Alemite grease fittings with protective covers

8 - 20

Rockwell Automation-Allen Bradley

Environmental Modifications

IEEE 841XL Features

All Severe Duty Features PLUS

8 - 21

Rockwell Automation- Allen Bradley Motors

Component Class

For use on inverter for variable torque and constant torque (less than 10:1) applications, no encoder capability, thermostats

Inverter Duty General Purpose Series

Inverter Duty Harsh Environment Series

Architecture Class

For use on inverter only for high performance applications, encoder capable, thermostats

Industrial Environment Series

Sine Wave Class

For use on sine wave power for fixed speed applications such as conveyors, blowers, pumps

or fans

General Purpose Series Harsh Environment Series

8 - 22

Rockwell Automation- Allen Bradley

Component Class

For use on inverter for variable torque and constant torque (less than 10:1) applications, no encoder capability, thermostats

Inverter Duty General Purpose Series

CM101 - Enclosed Energy Efficient Rolled Steel CM102 - Enclosed Energy Efficient Cast Iron CM103 Totally Enclosed EE, PE, NP CM106 Open Energy Efficient Rolled Steel CM107 Open EE, PE, NP

Inverter Duty Harsh Environment Series

CM111 Severe Duty

CM112 IEEE 841 XL

CM113 Aggregate Duty

CM115 Wash Down Duty

CM118 Stainless Steel

8 - 23

Rockwell Automation- Allen Bradley

CM113 841XL Cast Iron

EPAct Efficient, Premium Efficient, NEMA Premium Modifiable Severe duty 1/6 - 300 HP

CM111 Severe Duty

EE, PE, NP XT for harsh environ. Modifiable 1 - 300 HP

CM103

Price

EPAct Efficient Steel Frames Non-modifiable 1/4 - 30 HP

CM102

EPAct Efficient Cast Iron Frame Non-modifiable 1/4 - 50 HP

CM101 and CM106

Value

8 - 24

Rockwell Automation- Allen Bradley Motors

CM101 and CM106 EPAct Compliant with Light Weight and Rugged Construction

Stock product only Heavy guage rolled steel frame 1.0 on VFD SF Class F Insulation Permanently lubricated for life bearings 10:1 VT, varying CT based on HP/Frame Insulation meets MG-1 part 31 for up to 480 volt VFD Oversize terminal box, rotatable in 90 degree increments Removable eyebolt for easy lifting

Available Features Mounting Enclosure Type Efficiency HP Range

Foot Mtd ODP EPACT 1/4 - 30

C-Face TEFC

8 - 25

Rockwell Automation- Allen Bradley Motors

CM102 EPAct Compliant with Light Weight and Rugged Construction

Stock product only, limited modifications Cast Iron Frames 1.0 on VFD SF Class F Insulation 10:1 VT, varying CT based on HP/Frame Permanently lubricated for life bearings Insulation meets MG-1 part 31 for up to 480 volt VFD Oversize terminal box, rotatable in 90 degree increments Removable eyebolt for easy lifting

Available Features Mounting Enclosure Type Efficiency HP Range

Foot Mtd TEFC EPACT 1/4 - 50

C-Face TEFC

8 - 26

Rockwell Automation- Allen Bradley Motors

CM103 - EE Cast Iron

Cast Iron frame and end brackets Stainless steel nameplate 1.0 on VFD Service Factor Insulation meets MG-1 part 31 for up to 480 volt VFD Bearing system (182-215T) Permanently Lubricated (250-449T) Re-greaseable

8 - 27

Rockwell Automation- Allen Bradley Motors

CM103 PE and NP Cast Iron:

Highest Level of Energy Efficient Operation

Cast iron frame and end brackets Bearing Systems (140-449) regreaseable 1.0 SF on inverter Class F insulated Insulation meets MG-1 part 31 for up to 480 volt VFD Warranty 3 year

Available Features* Mounting Enclosure Type Efficiency Hp Range

Foot Mtd ODP Premium 3 - 350

C-Face D-Flange TEFC NEMA Premium

8 - 28

Rockwell Automation- Allen Bradley Motors

CM111 Severe Duty Features: Meeting Tough Application Environments, IP54

56-140 Plated steel frame, fan cover, and conduit box Cast iron endshields Double sealed bearings 180-440 Cast iron frame, fan cover, conduit box and endshields Available Features PLS bearing system Mounting Enclosure Type 56-440 Efficiency Class F Insulation & 1.15 SF Horsepow er Range Stainless steel nameplate Stainless steel T-drain Neoprene lead separator gasket Epoxy coated rotor and stator Shaft slinger

All TEFC TENV EE, PE, NP 1/4-400

8 - 29

Rockwell Automation- Allen Bradley Motors

CM112 841XL: Exceeds the IEEE 841 Standard for Chemical Duty

1.15SF with class B rise Quiet operation -- below 90dba sound power Reduced vibration (.08in/sec max) Precision cast and machined frame Lead lugs Available Features All cast iron construction Mounting Enclosure Type Bearing isolators both ends Efficiency Horsepower Range PLS -- Positive lubrication system Routine & vibration test report 5 year conditional warranty

Foot Mtd TEFC Premium 1-250

C-Face D-Flange

8 - 30

Rockwell Automation- Allen Bradley Motors

Per NEC 2005 Adjustable speed drive system shall protect against motor over temp conditions. Achieved through use of thermostats in the motors, or special circuitry in the drives. All CM100 and CM200 are provided standard with thermostats Thermostats can be removed from the CM100 motors by using the modification code to deduct them

8 - 31

Rockwell Automation- Allen Bradley Motors

Architecture Class

For use on inverter only for high performance applications, encoder capable

CM201 Vector Duty Enclosed Small AC Motors

1000:1 CT Capable, TENV and TEFC Enclosures

CM205 DC Motors

CM202 Vector Duty Totally Enclosed Cast Iron NEMA AC Motors

1000:1 Capable, TEFC and TENV Enclosures

Industrial Environment Series

Designed with laminated square frame for more performance in smaller frames DPG-FV and TEFC enclosures

CM206 Small DC Motors

Designed for reliability and long life in variable speed applications, TEFC and TENV Enclosures

CM203 Vector Duty Laminated AC Motors

1000:1 Capable; DPFV, TEBC, TENV, and TEFC Enclosures

8 - 32

Rockwell Automation- Allen Bradley Motors

CM202 - Performance & Price in a Cast Iron Variable Speed Motor

Vector Duty TE Cast Iron NEMA AC Motor

8 - 33

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

Blower Cooled Performance in a Fan Cooled (TEFC) Motor Constant Torque from 0 to Base Speed (1000:1) 2 HP to 450 HP in NEMA Standard Fixed Speed TEFC & TENV Frames Catalog Numbers for 1800 and 1200 rpm Base Speeds

8 - 34

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

All Cast Iron Frames & End Shields From 180T to L440T Three Thermostats - One Per Phase 200% Overload Torque for 1 Minute Optimized Electrical Designs for Inverter Power, not for Across the Line Power Design A

8 - 35

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

Constant Horsepower Operation to 1.5 Times Base Speed Encoder Mounting Provisions Class F Insulation Class F Temperature Rise 40 deg C Ambient 1.0 Service Factor on Inverter Power

8 - 36

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

Re-greaseable Bearings Stainless Steel Nameplate Insulated Bearing on Opposite Drive End is Standard on All 440T Frames Starts with 100 HP @ 1200 rpm Reduces shaft currents and increases bearing life.

8 - 37

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

CM202 TEFC & TENV Enclosures Cost Less to Install & Increases Reliability Does Not Require the Customer to Purchase, Install and Interlock a Blower Motor Starter. Does Not Require Installation of Three Phase Power Leads for Blower Motor

8 - 38

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

Designed Specifically for Hollow Shaft Encoders

No Machined Fan Covers Required Install Stub Shaft Kit, Slide Hollow Shaft Encoder Over Stub Shaft and Attach Anti-Rotational Arm to Standard Fan Cover Encoders Available through Stock Modification Center or Production: BEI, Avtron and Lakeshore

8 - 39

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

Many Traditional Modifications Available from Stock Center or Production

XT, Extra-Tough Features 841XL Mechanical Features C-Face and D-Flanges Special Encoders Brakes

8 - 40

Rockwell Automation- Allen Bradley Motors

CM202 Vector Duty TE Cast Iron NEMA AC Motor

2 to 20 HP Stocked with C-Face & Feet 3 to 300 HP, 1800 rpm, - Stocked Catalog numbers assigned for 2 to 450 HP, 1200 & 1800 rpm Standard NEC Full Load Amp Ratings Warranty 3 years from date of manufacture or 2 years of operation, whichever occurs first

8 - 41

Rockwell Automation- Allen Bradley Motors

New for 2005 CM202 - Division 2 Self Certified

Self Certified - Athens production motors only (stock mod coming soon). 1000:1 CT in Standard Frame Sizes (No Constant HP range) Division 2, Class 1 Groups A,B,C & D Temperature code T2A (280 degree C) through T2C (230 degree C) environments. N/P T2C Class F rise with class F sealed thermostats, 40 degree C ambient. PWM (IGBT) drive with 2 kHz carrier or higher.

8 - 42

Rockwell Automation- Allen Bradley Motors

New for 2005 CM202 - Division 2 Self Certified

The following will appear on customer quotations:

Attention: The internal and external surface temperatures of the motor will not exceed 230 degree C when the motor is operated properly within the rated conditions (HP, SF, Voltage, Frequency) shown on the nameplate on the PWM inverter power with a minimum carrier frequency of 2 KHz. For all other conditions see user manual.

8 - 43

Rockwell Automation- Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

8 - 44

Rockwell Automation- Allen Bradley Motors

If you could start with a clean piece of paper : How would you design a motor for Variable Speed, Inverter Duty operation?

Make it square

8 - 45

Rockwell Automation- Allen Bradley Motors

CM203 is a laminated frame design that is optimized for operation on inverter power supplies. The only laminated frame AC inverter duty motor made in North America Concept first introduced on D-C in 1967

Today, third generation of square laminated frames on CM205

AC -Evolved to meet high performance DC variable speed market needs Similar benefits on A-C Inverter Drives

Ability to be standard or custom design

Special base speeds, high speeds, custom flanges, brakes and feedback devices

8 - 46

Rockwell Automation- Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Clamp laminations in a high pressure press Permanently riveted with eight through-studs to cast iron end rings Frame is now a rigid single structure

8 - 47

Rockwell Automation- Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Rugged, High Mechanical Performance

Mounting feet located on the end brackets Short, direct path from bearing load Inherent planity with the mounting surface for greater vibration resistance and stability Improved mechanical stiffness, higher critical speeds, enables high speed operation

8 - 48

Rockwell Automation-Allen Bradley Motors

Higher power density for better space utilization

More copper & magnetic steel in square frame design Inactive Cast Iron Frame - Reduced Heat transfer between stator and frame Larger rotor diameter produces higher torque

8 - 49

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

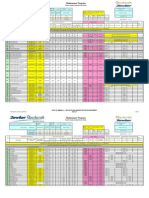

HP @1750 Standard RPM A-C RPM A-C

RPM 5 10 20 30 75 125 150 250 400 500 1000

TEFC 215 250 280 360 440 440 440 440 500 580

TEBC

DPFV -

Frame Size Comparison

CM203 vs Standard NEMA TEFC

250 320 360 360 400 440 440 250 280 280 320 360 400 440

1000 Hp in 440 frame

8 - 50

Rockwell Automation- Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Rugged, High Mechanical Performance

PLS (Positive Lubrication System) Use cooler operating open bearings protected against contamination Bearing cavity designed to provide proper lubrication regardless of mounting position Designed to prevent damage from over greasing Generously-sized bearings for long service life

8 - 51

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

High Dynamic Performance

Lower Rotor Inertia than round frame motor of same HP provides better torque to inertia ratios for faster response to speed changes Optimized square frame, more active material and Through-theframe ventilation design dissipates heat faster and more efficiently than round frame motors High grade materials and an advanced rotor design minimize hot spots for maximum performance

8 - 52

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Motor Insulation System

Insulation is required anywhere in the motor where there is a difference of electrical potential between two conductors. Insulation system consists of Magnet wire insulation Resin insulation Slot insulation Coil head insulation (phase paper)

8 - 53

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Insulation System

A-C controller designs use fast-switching IGBTs Inverter grade insulation system designed and tested for full compatibility on adjustable frequency power Meets and exceeds NEMA MG1 Part 31 Minimum 1600V peak CIV for 460v systems, at rated operating temperature (higher for 575v)

8 - 54

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Insulation System

Class H materials Copper magnet wire with high film build Multiple dips and bakes of Class H varnish VPI option

8 - 55

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Versatile Operations

1000:1 constant torque on vector controller Provides 100% full load torque to zero speed continuously on a vector control. Wide selection of base speeds - RPM - to optimize your variablespeed application requirements

8 - 56

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

DPG-FV/TESV

Most compact vector 5-1000 HP Lowest inertia Wide speed range 1000 : 1 constant torque, wide c. HP 100% Torque @ Zero Speed Continuous Coolest bearings Replace AC and DC Match anyones shaft height and footprint

8 - 57

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

TEBC, Totally Enclosed Blower Cooled, In line Blower

Wide speed range 1000 : 1 constant torque, wide c. HP 100% Torque @ Zero Speed Continuous Replace AC and DC Match shaft height and footprint

Through - the frame cooling ducts

8 - 58

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Totally-enclosed, air-over, blower cooled enclosures

Available with either an in-line or piggy-back blower Accommodates mounting accessories at either end of motor

8 - 59

Rockwell Automation-Allen Bradley Motors

CM203 Vector Duty Laminated Frame AC Motors

Totally-enclosed, nonventilated enclosures

Prevents entry of dust, grit or moisture Available with XT (Extra Tough) features for severe environments Modifications available for outdoor or washdown duty

8 - 60

Rockwell Automation-Allen Bradley

Sine Wave Class

For use on sine wave power for fixed speed applications such as conveyors, blowers, pumps or fans

General Purpose Series

CM301 - Enclosed Energy Efficient Rolled Steel CM302 - Enclosed Energy Efficient Cast Iron CM303 Totally Enclosed EE, PE, NP CM306 Open Energy Efficient Rolled Steel CM307 Open EE, PE, NP

Harsh Environment Series

CM311 Severe Duty

CM312 IEEE 841 XL

CM313 Aggregate Duty

CM315 Wash Down Duty

CM318 Stainless Steel

8 - 61

Rockwell Automation-Allen Bradley

CM300 Sine Wave Motors General Purpose Series

CM301 & CM306 Rolled Steel, Most Economical motor choice CM302 Most Economical Cast Iron TE motor, limited modifications CM303 & CM307 Energy Efficient, Premium Efficient, and NEMA Premium for General Purpose Applications TE and Open motors

8 - 62

Rockwell Automation-Allen Bradley

CM310 Sine Wave Motors Harsh Environment Series

CM311 Severe Duty Features Designed with features for long life in severe environments such as chemical plants, petroleum refineries, and paper mills CM312 IEEE 841XL Exceeds IEEE841 mechanical requirements. Built extra tough for durability in harsh environments

8 - 63

Rockwell Automation-Allen Bradley motors

Large AC Custom Motors

8 - 64

Rockwell Automation-Allen Bradley Motors

LAC Motors Custom Motors

Approximately 300 to 3500 HP AC induction machines Frame sizes from 449 to 9600 Voltages up to 7kV Random and Form wound windings Horizontal and vertical mounting Sleeve and anti-friction bearings available Single speed, multi-speed or variable speed designs Open, totally enclosed and explosion proof enclosures

8 - 65

Rockwell Automation-Allen Bradley Motors

LAC Motors Custom Motors

Voltage

Low (Form/Random Wound) Up to 1000V Medium (Form Wound) 1.1kV - 5kV High (Form Wound) 5.1kV - 7kV Anti-Corona protection std

Frequency

60Hz & 50Hz Special Hz on request Variable Frequency from VFDs

8 - 66

Rockwell Automation-Allen Bradley Motors

LAC Motors Custom Motors

Complete Product Line (and growing) HPs, Enclosures, Complexity, etc. Premium Insulation System that passes H2O test True TEFC capability to 2250 HP High quality cast rotors Extensive variable speed product/application capability

8 - 67

Rockwell Automation-Allen Bradley Motors

Thank You for Your Attention

8 - 68

You might also like

- Iasimp Qr023 en eDocument6 pagesIasimp Qr023 en ePedro Arrambidez HernandezNo ratings yet

- Topology OverviewDocument10 pagesTopology OverviewPedro Arrambidez HernandezNo ratings yet

- DC To AC Conversion - 01Document35 pagesDC To AC Conversion - 01Pedro Arrambidez HernandezNo ratings yet

- Infrastructure ProductService Overview Oct2008Document39 pagesInfrastructure ProductService Overview Oct2008Pedro Arrambidez HernandezNo ratings yet

- DCD 2Document28 pagesDCD 2MancamiaicuruNo ratings yet

- DC Digital DriveDocument338 pagesDC Digital DriveFadFadNo ratings yet

- DCD 2Document28 pagesDCD 2MancamiaicuruNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Air CarDocument22 pagesAir Carrakesh sNo ratings yet

- Ref Del Us 72 AktuellDocument48 pagesRef Del Us 72 AktuellMohammad HosseiniNo ratings yet

- Flywheel Energy FormulaDocument9 pagesFlywheel Energy Formulaalexbusinesss100% (1)

- DENSO Diesel Common Rail Sell Sheet D1070 PDFDocument2 pagesDENSO Diesel Common Rail Sell Sheet D1070 PDFFernando Garcia CortesNo ratings yet

- Manual de Servicio Motor Cummins X2.5G4Document69 pagesManual de Servicio Motor Cummins X2.5G4Almy Rose100% (2)

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- Hydraulic & Pneumatic Actuators-Product Catalogues-EnglishDocument4 pagesHydraulic & Pneumatic Actuators-Product Catalogues-Englishcosmin75No ratings yet

- EC210B LC EC210B NC/EC210B NLC: Volvo ExcavatorDocument16 pagesEC210B LC EC210B NC/EC210B NLC: Volvo Excavatormutawakkil9majidNo ratings yet

- Carnot Battery Technology: A State-Of-The-Art ReviewDocument17 pagesCarnot Battery Technology: A State-Of-The-Art ReviewPaul MatteschkNo ratings yet

- Kubota Kx71Document6 pagesKubota Kx71Nerijus SaldunasNo ratings yet

- Citroen Berlingo BrochureDocument29 pagesCitroen Berlingo BrochurereadalotbutnowisdomyetNo ratings yet

- A180 Service ManualDocument213 pagesA180 Service ManualramiroNo ratings yet

- Magnetic Chip Detectors - Inspection/Check: Reference DesignationDocument38 pagesMagnetic Chip Detectors - Inspection/Check: Reference DesignationAdrian LauNo ratings yet

- Electric Bicycle (E-BIKE)Document16 pagesElectric Bicycle (E-BIKE)k rajendraNo ratings yet

- Filipino Inventors and Their InventionsDocument18 pagesFilipino Inventors and Their InventionsCarlo Revs100% (1)

- 9 Tonne Front Tip Specs: MACH2090 Dimensions & CapacitiesDocument2 pages9 Tonne Front Tip Specs: MACH2090 Dimensions & CapacitiesQuelmis De La Cruz Vilca AmesquitaNo ratings yet

- SO-1136-d Part 1 Engine Room Simulator MAN B&W 5L90MC-L11Document22 pagesSO-1136-d Part 1 Engine Room Simulator MAN B&W 5L90MC-L11Stipe TurićNo ratings yet

- 1103C-33TG2 (47KW)Document2 pages1103C-33TG2 (47KW)Rafael LopezNo ratings yet

- PK18500 S.N 100111848Document28 pagesPK18500 S.N 100111848Rauf GebreelNo ratings yet

- Xa-Uir 22052 Prog Mtto Jun-01-2010Document39 pagesXa-Uir 22052 Prog Mtto Jun-01-2010Carlo VillegasNo ratings yet

- Classification of Internal Combustion EnginesDocument22 pagesClassification of Internal Combustion Enginesoureducation.inNo ratings yet

- RWYL102 Operation Manual (FABRICA)Document10 pagesRWYL102 Operation Manual (FABRICA)bifok96010No ratings yet

- KTH Stirling Engine PDFDocument37 pagesKTH Stirling Engine PDFdedy supriadiNo ratings yet

- Ventilation and Cooling Comparison Between Diesel and Electric Mining EquipmentDocument128 pagesVentilation and Cooling Comparison Between Diesel and Electric Mining EquipmentJavier Rico PaezNo ratings yet

- Third DPSU Indigenization ListDocument17 pagesThird DPSU Indigenization ListAshutoshGuptaNo ratings yet

- Hyundai Heavy Industries: With Tier 4 Interim Engine InstalledDocument24 pagesHyundai Heavy Industries: With Tier 4 Interim Engine InstalledSoban ReddyNo ratings yet

- 7fdl Brochure LocomotiveDocument2 pages7fdl Brochure LocomotiveFukyma Morgan100% (2)

- 2013 Technical Service Bulletin No 06 enDocument3 pages2013 Technical Service Bulletin No 06 enSaeed BarzegarNo ratings yet

- Fuel System Engine Control System Hydraulic sYSTEMDocument3 pagesFuel System Engine Control System Hydraulic sYSTEMlamborghini1991No ratings yet

- ISRO 2021 Syllabus - Mechanical Engineering - Scientist - Engineers SC - Crackon - inDocument11 pagesISRO 2021 Syllabus - Mechanical Engineering - Scientist - Engineers SC - Crackon - inJohn WickNo ratings yet