Professional Documents

Culture Documents

CP7818 - Fuel Pressure Tester Kit Instructions: Vehicle Application List

Uploaded by

Engine Tuning UpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CP7818 - Fuel Pressure Tester Kit Instructions: Vehicle Application List

Uploaded by

Engine Tuning UpCopyright:

Available Formats

CP7818 Fuel Pressure Tester Kit INSTRUCTIONS

Vehicle Service Information:

The following is a list of publishers who have manuals containing electronic fuel injection system information. Some manuals may be available at auto parts stores, your local dealer, or your local public library. For others, you need to write for availability and prices, specifying the make, model and year of your vehicle.

Fuel pressure testing involves some contact with pressurized fuel. Do not use the Fuel Pressure Tester Kit on Diesel or Flex Fuel engines. Only use the Fuel Pressure Tester Kit on Gasoline powered engines. Helps diagnose driveability problems due to abnormally high or low fuel pressure.

Aftermarket Vehicle Service Manuals: Chilton Book Company Chilton Way Radnor, PA 19089

Haynes Publications 861 Lawrence Drive Newbury Park, CA 91320 Cordura Publications Mitchell Manuals, Inc. Post Office Box 26260 San Diego, CA 92126 Motors Auto Repair Manual Hearst Company 250 W. 55th Street New York, NY 10019

Vehicle Service Manuals from General Motors Corporation:

Buick Tuar Company Post Office Box 354 Flint, MI 48501 Oldsmobile Lansing Lithographers Post Office Box 23188 Lansing, MI 48909 Cadillac, Chevrolet, Pontiac Helm Incorporated Post Office Box 07130 Detroit, MI 48207

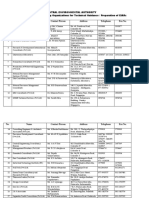

VEHICLE APPLICATION LIST

The Fuel Pressure Tester Kit works on most domestic fuel injected vehicles having a schrader valve test port on the fuel rail. This includes Ford high pressure central fuel injection and GM, Ford, and Chrysler multiport fuel injection. Multi-port means one fuel injector per cylinder.

Domestic FORD, LINCOLN, MERCURY

High Pressure Central Fuel Injected (CFI) Vehicles 1981-86 Country Squire, Crown Victoria, LTD, Colony Park, Grand Marquis, & Marquis 1985-86 Mustang & Capri 1985-87 Thunderbird & Cougar 1981-85 Continental, Town Car, Mark VI & Mark VII 1980 Versailles Most Multi-Port Fuel Injected Vehicles 1983 to 1996. Not Including: 1.3L Festiva & Aspire 1.6L Capri 1.8L Escort & Tracer 2.0L, 2.2L & 2.5L Probe 3.0L Villager

Domestic CHRYSLER, PLYMOUTH, DODGE

Multi-Port Fuel Injected Passenger Vehicles

Year 1995-96 1984-93 1995-96 1984-92 1987-96 1993-96 1987-93

Engine 8th VIN Digit 2.0L C or Y 2.2L Turbo E 2.4L X 2.5L Turbo J 3.3L R 3.5L F 3.8L L

Vehicle Service Manuals from Ford Motor Company: Ford Publication Department Helm Incorporated Post Office Box 07150 Detroit, MI 48207

Vehicle Service Manuals from Chrysler Corporation:

Chrysler Corporation Dyment Distribution Service Service Publication 12200 Alameda Drive Strongsville, Ohio 44136

Multi-Port Fuel Injected Trucks & Vans Year Engine 8th VIN Digit 1996 2.4L B 1989 2.5L Turbo J 1992-96 3.3L R 1994-96 3.8L L 1992-96* 3.9L X 1992-96* 5.2L Y 1993-96 5.9L 5 or Z 1994-96 8.0L W

Customer Service

For product information or customer service please call 1-800-ACTRON-7 (1-800-228-7667) Monday through Friday, between 8:30 a.m. and 4:30 p.m. Eastern time or fax anytime at (216) 651-2388. Actron can also be reached by Email or on the Internet. Email address: sunpro@actron.com Internet home page: http://www.actron.com

One Year Warranty

If within one year from the date of purchase this equipment fails due to defect in materials or workmanship, return it to Actron and Actron will repair it free of charge. This warranty gives you specific legalights, and you may also have other rights which may vary from state to state.

Domestic GENERAL MOTORS

Most Multi-Port Fuel Injected Vehicles 1984 to 1996. Not Including: 1988 1.6L Nova 1988-89 1.5L Spectrum 1987-90 Sprint Turbo

JEEP

Multi-Port Fuel Injected Vehicles Year Engine 8th VIN Digit 1991-95 2.5L P 1987-96* 4.0L S 1993-96* 5.2L Y

Note

All information, illustrations and specifications contained in this manual are based on the latest information available from industry sources at the time of publication. No warranty (expressed or implied) can be made for its accuracy or completeness, nor is any responsibility assumed by Actron Manufacturing Co. or anyone connected with it for loss or damages suffered through reliance on any information contained in this manual or misuse of accompanying product. Actron Manufacturing Co. reserves the right to make changes at any time to this manual or accompanying product without obligation to notify any person or organization of such changes.

Domestic EAGLE

Multi-Port Fuel Injected Vehicles Year Engine 8th VIN Digit 1995-96 2.0L Y 1993-96 3.3L T 1993-96 3.5L F * Some 1996 engines may not have a schrader valve fuel rail test port.

Instructions for Fuel Pressure Tester Kit

Safety Precautions

To prevent accidents that could result in serious injury and/or damage to your vehicle or test equipment, carefully follow these safety rules and test procedures at all times when working on vehicles. Always wear approved eye protection. Never use Fuel Pressure Tester Kit on Diesel or Flex Fuel engines! Never attach Fuel Pressure Tester to any place other than the fuel rail test port. Do not confuse Air Conditioning schrader valves with the fuel rail test port. Never attach or remove Fuel Pressure Tester Kit from fuel rail test port with the ignition key on. Always place end of 6 ft. bleed-off hose in an approved container for fuel during testing and when bleeding off fuel pressure. Never smoke or have open flames near vehicle. Vapors from fuel and charging battery are highly flammable and explosive. Never permit fuel to spill on hot engine parts. If a spill or leak occurs, immediately turn ignition key off, and clean up fuel. Only use the Fuel Pressure Tester Kit for measuring fuel pressure on vehicles having schrader valves as their fuel rail test port. Do not use this kit for any other purpose! Always operate the vehicle in a well ventilated area. Do not inhale exhaust gases or fuel vapors - they are very hazardous! Always keep yourself, tools and test equipment away from all moving or hot engine parts. Always make sure the vehicle is in PARK (Automatic transmission) or NEUTRAL (manual transmission) and that the parking brake is firmly set. Block the drive wheels. Never lay tools on vehicle battery. You may short the terminals together causing harm to yourself, the tools or the battery. Never leave vehicle unattended while running tests. Always keep a fire extinguisher suitable for fuel/electrical/chemical fires handy. Always use extreme caution when working around the ignition coil, distributor cap, ignition wires, and spark plugs. These compo-

nents contain High Voltage when the engine is running. Complete all Pre-Testing Checks before beginning fuel pressure testing. Always follow vehicle manufacturers warnings, cautions and service procedures.

button is pressed. Never use a bleed-off hose shorter than 6 ft. Important: Always make sure end of bleed-off hose is in an approved container for fuel at all times during testing and when bleeding off fuel pressure!! 4. Gauge Hose: Hose that carries fuel to the gauge so that pressure can be measured.

Fig. 2

FUEL INJECTORS FUEL PRESSURE REGULATOR PRESSURE LINE

CAUTION: Some vehicles are equipped with safety air bags. You must follow vehicle service manual cautions when working around the air bag components or wiring. If the cautions are not followed, the air bag may open up unexpectedly, resulting in personal injury. Note that the air bag can still open up several minutes after the ignition key is off (or even if the vehicle battery is disconnected) because of a special energy reserve module.

5. GM/Chrysler Test Port Adapter: This Ford CFI adapter is used to connect the gauge Throttle Body hose to GM and Chrysler vehicles equipped with a schrader valve test FUEL FUEL RAIL INJECTORS port on the fuel rail. TEST PORT 6. Ford Test Port Adapter: This adapter is used to connect the gauge hose to Ford vehicles equipped with a schrader valve test port on the fuel rail.

RETURN LINE

FUEL PRESSURE REGULATOR

FUEL RAIL

Fuel Pressure Tester Description

1. Dial Face: Measurement scale that shows amount of fuel pressure present in fuel system. 2. Pressure Relief Button: Used to relieve fuel pressure in the gauge hose before disconnecting the gauge hose from the fuel rail. 3. Bleed-Off Hose: A 6-ft. hose that bleeds off fuel pressure when the pressure relief

Fuel Injection System Theory

40

300 400

60

Fig. 1

1

80

20

200 100

kPa psi

500 600 700

100

There are two basic types of fuel injection systems currently being used by GM, Ford, and Chrysler. The first type is called port or multi-port fuel injection. In this system, GM Multi-Port the fuel injectors spray fuel directly into the Fuel Injection FUEL INJECTORS intake manifold behind the intake Fig. 3 valve. These sysFUEL RAIL FUEL PRESSURE TEST PORT tems typically have REGULATOR FUEL FUEL INJECTORS one fuel injector per RAIL cylinder. The second type is commonly called Throttle Body Injection (TBI) for GM and Chrysler vehicles or Central Fuel Injection (CFI) for Ford vehicles. PRESSURE VACUUM LINE PORT These systems use RETURN one or two fuel injecFUEL INJECTORS LINE tors mounted on top of the intake manifold. They spray fuel FUEL FILTER into the throttle body similarly to a conventional carburetor. See Fig. 2 for illusFUEL TANK trations of both types FUEL PUMP FILTER of fuel systems. FUEL PUMP

PRESSURE LINE RETURN LINE

Fuel System Components

6 Before doing any fuel pressure testing, it is a good idea to understand how fuel system components work and how they relate to one another. The fuel pump pumps fuel from the fuel tank to the fuel pressure regulator and fuel injectors. The fuel pressure regulator

divides fuel between the pressure line and the return line. The fuel in the pressure line goes to the fuel injectors, while the fuel in the return line is returned to the fuel tank. Fig. 3 shows the orientation of fuel system components in a typical port fuel injection system.

Fuel Tank: A large container that holds your vehicles supply of fuel. Fuel Pump Filter: A filter that is usually located in the fuel tank. Its function is to prevent foreign particles from reaching the fuel pump. A clogged or restricted fuel pump filter can cause low fuel pressure readings. When replacing a fuel pump it is a good idea to clean or replace the fuel pump filter. Fuel Pump: An electric motor that pumps fuel into the fuel system at a constant pressure. It is mounted in the fuel tank or on the frame. Some vehicles have more than one fuel pump. Return Line: Path way for excess fuel to return to the fuel tank. Pressure Line: A pressurized fuel line that carries fuel from the fuel tank to the fuel injectors. Fuel Filter: A filter that is located in-line with the pressure line. Its function is to prevent foreign particles from reaching the fuel injectors. A clogged or restricted fuel filter can also cause low fuel pressure readings. This is the only fuel system component that requires periodic replacement. Refer to vehicle owners manual for replacement interval. Fuel Rail Test Port: A schrader valve located on the fuel rail (Fig. 4) that allows easy connection of a fuel pressure gauge to measure fuel pressure. Do not confuse this valve with the schrader valves that are used for recharging air conditioning systems. Fuel Pressure Regulator: The fuel pressure regulator (Fig. 5) is connected across the pressure line and return line. It contains a spring loaded valve assembly that opens to allow fuel to move into the return line, when the pressure line fuel pressure is exceeded. It is used to keep a constant fuel pressure drop across the fuel injectors. Some fuel pressure regulators have a vacuum port so fuel pressure can be adjusted based on engine load. These are commonly called vacuum actuated (compensated) fuel pressure regulators. A leaking fuel pressure regulator can cause low fuel pressure readings and hard starting problems. Fuel Rail: The fuel rail assembly is bolted to the intake manifold. Its purpose is to hold the fuel injectors in place and to deliver pressurized fuel to the fuel injectors. Fuel Injectors: A precision valve that is controlled by a solenoid. Fuel injection is controlled by the amount of fuel pressure,

Fig. 4

FUEL RAIL TEST PORT FUEL RAIL PROTECTIVE CAP

Typical GM Multi-Port Fuel Injection System Fig. 5

VACUUM PORT

9. If engine will not start, check ignition system for spark. If no ignition spark is present, refer to vehicle service manual for No Start Diagnostics.

Fig. 6

40

300 400

60

20

200 100

kPa psi

500 600 700

80

100

Fuel Pressure Testing Procedures

RETURN LINE

PRESSURE LINE

Vacuum Actuated (Compensated) Fuel Pressure Regulator

and the size and duration of the valve opening. Fuel injectors contain a filter used to prevent very small particles from clogging the valve. Leaking fuel injectors will cause fuel pressure to slowly decrease when the ignition key is on and engine is off.

This test procedure explains how to make fuel pressure measurements on vehicles while the ignition key is on and while the engine is at idle. The procedure also explains the safest way to connect and disconnect the fuel pressure tester kit from vehicles equipped with schrader valves as their fuel rail test ports. If the fuel pressure readings measured in this test procedure are not within your vehicles manufacturing specification, then you must use your vehicle service manual along with the fuel pressure tester kit to service the problem. This test procedure does not contain any vehicle specific diagnostics. 1. Read all SAFETY PRECAUTIONS and PRE-TESTING CHECKS. 2. Apply a lightweight household oil to the rubber O rings inside both test port adapters. 3. Turn Ignition Key OFF. 4. Locate fuel rail test port and remove protective cap. (See Fig. 4.)

END OF BLEED-OFF HOSE MUST BE PLACED IN AN APPROVED FUEL CONTAINER

SHOP RAG

FUEL RAIL TEST PORT

Bleed-off hose must remain in container until testing is complete. 6. Turn all accessories OFF. (i.e. Radio, A/C, Blower Fan, Headlights, Windshield Wipers...) 7. Turn ignition key ON. Do the following checks... Listen for fuel pump. Pump should run for approximately 2 seconds. Check fuel system for leaks. If leaks found, turn ignition key OFF and wipe up fuel immediately! Read fuel pressure from dial face. Pressure should rise to manufacturers specification and hold steady even after fuel pump stops running. Refer to vehicle service manual for fuel pressure specifications. If fuel pressure is not within manufacturers specification, than service vehicle according to vehicle service manual. When repair is completed and key-onengine-off fuel pressure is now within manufacturers specification, then proceed to Step 8. For instructions on how to safely disconnect the Fuel Pressure Tester Kit from the fuel rail test port, proceed to Step 9. 8. Start engine Let idle. If your vehicles fuel system uses a vacuum actuated (compensated) fuel pressure regulator then fuel pressure should drop approximately 3-10 psi, depending on manifold vacuum.

Pre-Testing Checks

1. Read Safety Precautions. 2. Do a thorough visual and hands-on inspection of the engine and fuel system. Look for loose or cracked electrical wiring, battery cables, ignition wires, and fuel or vacuum lines. 3. Verify that the battery is fully charged and fuel tank has an adequate supply of fuel. 4. Verify that the inertia switch on certain Ford/Lincoln/Mercury vehicles has not been tripped. (The inertia switch is usually located in the trunk.) 5. Verify that all fuel system fuses are good. 6. Verify fuel vapor recovery system and gas cap are in good condition. 7. Verify that manifold vacuum is within manufacturers specification which is typically 18-20 in. at idle. 8. Look for fuel leaks and wipe up any spilled fuel immediately.

For Ford/Lincoln/Mercury Vehicles...

Screw Ford test port adapter to fuel rail test port until finger tight. Screw GM/Chrysler test port adapter to the Ford test port adapter until finger tight.

For GM/Chrysler Vehicles...

Screw GM/Chrysler test port adapter to fuel rail test port until finger tight.

Note: Always wrap a shop rag around fuel rail test port when attaching test port adapters. This is a precaution in case a small amount of fuel leaks out while attaching adapters.

5. Place end of 6 ft. bleed-off hose in an approved container for fuel.

If your vehicles fuel system uses a fuel pressure regulator without a vacuum port than fuel pressure should remain constant during both key-on-engine-off and idle. Read fuel pressure from dial face. If fuel pressure is not within manufacturers specification, than service vehicle according to vehicle service manual. When repair is completed and idle fuel pressure is now within manufacturers specification, then proceed to Step 9. To safely disconnect the Fuel Pressure Tester Kit from the fuel rail test port and perform repairs at a later time, proceed to Step 9. 9. Turn Ignition Key OFF. 10.Verify that 6 ft. bleed-off hose is still in an approved container for fuel. 11.Fully DEPRESS and HOLD the pressure relief button until dial face pointer is resting on stop pin. 12.Shake bleed-off hose to make sure that all fuel went into approved container. 13.Remove gauge hose from fuel rail test port.

For GM/Chrysler Vehicles...

Wrap a shop rag around fuel rail test port in case a small amount of fuel drips out while unscrewing test port adapters. Unscrew GM/Chrysler test port adapter from fuel rail test port. Wrap a shop rag around GM/Chrysler test port adapter so any fuel dripping from gauge hose is absorbed. Remove bleed-off hose from approved fuel container and hold gauge hose over container so any remaining fuel will drip into container. 14.Store shop rags in an approved container so they cannot cause personal injury or a hazardous situation. 15.Store Fuel Pressure Tester in a well ventilated area where it cannot cause personal injury or a hazardous situation.

General Fuel Pressure Diagnostics

Fuel pressure checking is an essential part of fuel injection system troubleshooting. High fuel pressure will make an engine run rich, while low fuel pressure will make an engine run lean or not at all. Fuel pressure readings that are higher than manufacturers specifications are generally caused by a problem in the return line fuel components. Conversely, fuel pressure readings that are lower than manufacturers specifications are generally caused by a problem in the pressure line fuel components. If fuel pressure readings are not within manufacturers specifications, then refer to a vehicle service manual for step-by-step diagnostic procedures that will pinpoint the faulty component for your specific vehicle.

Care and Maintenance

Apply a lightweight household oil to the rubber O rings inside both the GM/Chrysler and Ford test port adapters before each use.

Possible causes of high fuel pressure readings are the following: Faulty fuel pressure regulator. Restriction in return line. Faulty fuel line couplings at fuel tank. Possible causes of low fuel pressure readings are the following: Clogged or restricted fuel filter. Restriction in pressure line. Faulty fuel pump. Faulty fuel pump relay. Bad fuel pump fuse. Faulty fuel pump wiring. Clogged or restricted fuel pump filter. Faulty fuel pressure regulator. Leaking fuel injectors. Faulty fuel line couplings at fuel tank.

For Ford/Lincoln/Mercury Vehicles...

Wrap a shop rag around fuel rail test port in case a small amount of fuel drips out while unscrewing test port adapters. Unscrew GM/Chrysler test port adapter from Ford test port adapter. Wrap a shop rag around GM/Chrysler test port adapter so any fuel dripping from gauge hose is absorbed. Remove bleed-off hose from approved fuel container and hold gauge hose over container so any remaining fuel will drip into container. Unscrew Ford test port adapter from fuel rail test port.

ACTRON MANUFACTURING CO. 9999 Walford Avenue Cleveland, Ohio 44102

You might also like

- Alto High Performance CatalogDocument48 pagesAlto High Performance CatalogEvs SrhNo ratings yet

- Borgeson Steering JointsDocument29 pagesBorgeson Steering JointsKerry Murray100% (1)

- Automotive Electrical SystemsDocument101 pagesAutomotive Electrical SystemsMos CraciunNo ratings yet

- Energysuspension CatalogDocument76 pagesEnergysuspension CatalogwillyhuaNo ratings yet

- Lubrication and Maintenance: Engine OilDocument18 pagesLubrication and Maintenance: Engine Oilprueba5No ratings yet

- Decode Jeep XJ computer codesDocument2 pagesDecode Jeep XJ computer codesoğuzhan_tekceNo ratings yet

- Camaro Special Editions: Includes pace cars, dealer specials, factory models, COPOs, and more: Includes pace cars, dealer specials, factory models, COPOs, and moreFrom EverandCamaro Special Editions: Includes pace cars, dealer specials, factory models, COPOs, and more: Includes pace cars, dealer specials, factory models, COPOs, and moreNo ratings yet

- Axle InfoDocument120 pagesAxle InfoposttonNo ratings yet

- 00 - Lubrication and MaintenanceDocument12 pages00 - Lubrication and MaintenanceMarkitos LopezNo ratings yet

- 182 185Document4 pages182 185jharl100% (1)

- Eaton Performance Differential Application Guide enDocument32 pagesEaton Performance Differential Application Guide enAbhishek BansalNo ratings yet

- PutcoProductCatalog-2014 v38CDocument40 pagesPutcoProductCatalog-2014 v38CKPNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Mitsubishi Electric HD Technicians GuideDocument52 pagesMitsubishi Electric HD Technicians Guideadi22-22100% (1)

- Installation Instructions TH700-R4 (4L60) TranskitDocument19 pagesInstallation Instructions TH700-R4 (4L60) TranskitEddy QueroNo ratings yet

- 454 Short Block Crate Engine 12498778Document18 pages454 Short Block Crate Engine 12498778fariaseulisesNo ratings yet

- Laminated Composite Stiffened Panels Application and BehaviourDocument46 pagesLaminated Composite Stiffened Panels Application and BehaviourHemendra Jain100% (1)

- Lubrication and MaintenanceDocument8 pagesLubrication and MaintenanceJahanzeb KhanNo ratings yet

- GM 2007 LD General InformationDocument37 pagesGM 2007 LD General InformationschraeubleNo ratings yet

- This Is TestDocument20 pagesThis Is TestramapeddintiNo ratings yet

- PARTS CATALOG & TECHNICAL GUIDE FOR STEERING & SUSPENSIONDocument36 pagesPARTS CATALOG & TECHNICAL GUIDE FOR STEERING & SUSPENSIONWijayanto BekasiNo ratings yet

- Front and Rear Light Axle Parts, Kits and Applications Chrysler/Dodge, Ford, General Motors/Chevrolet and Jeep Model Years 1978-1998Document379 pagesFront and Rear Light Axle Parts, Kits and Applications Chrysler/Dodge, Ford, General Motors/Chevrolet and Jeep Model Years 1978-1998Engine Tuning UpNo ratings yet

- 350-HO Long Block SpecsDocument30 pages350-HO Long Block SpecsClif CunninghamNo ratings yet

- 199r10487 1rev6Document12 pages199r10487 1rev6Alfonso JaureguiNo ratings yet

- ST37182 Chevrolet Diesel Fuel Systems ManualDocument99 pagesST37182 Chevrolet Diesel Fuel Systems ManualtefNo ratings yet

- 9.4. Lubrication and MaintenanceDocument15 pages9.4. Lubrication and MaintenanceChristian Icaza SamaniegoNo ratings yet

- V8 Tpi Speed SensorsDocument18 pagesV8 Tpi Speed SensorsRay Ray RayNo ratings yet

- Smashing e8ook Series. #í Proíessional Web DesignDocument242 pagesSmashing e8ook Series. #í Proíessional Web DesigntintrangNo ratings yet

- Household Electricity End-Use ConsumptionDocument22 pagesHousehold Electricity End-Use ConsumptionEva ViskadourakiNo ratings yet

- Elgin-Product-Catalog (2021 - 01 - 27 20 - 16 - 46 UTC)Document89 pagesElgin-Product-Catalog (2021 - 01 - 27 20 - 16 - 46 UTC)wade.hynesoutlook.comNo ratings yet

- LS9 Crate Engine 19244099Document17 pagesLS9 Crate Engine 19244099Karanveer SinghNo ratings yet

- 2013 MRG Catalog 74780GDocument164 pages2013 MRG Catalog 74780GRoberto ClamdNo ratings yet

- Ussocom 006Document52 pagesUssocom 006RTSLLCNo ratings yet

- Giignl Custody Transfer Handbook 6.0 - May 21 0Document195 pagesGiignl Custody Transfer Handbook 6.0 - May 21 0Александр КарташовNo ratings yet

- Underfloor Wheelset Lathe: Operating / Maintenance ManualDocument84 pagesUnderfloor Wheelset Lathe: Operating / Maintenance ManualMinh Canh100% (1)

- Impact of Gadgets on Learning in Senior High StudentsDocument16 pagesImpact of Gadgets on Learning in Senior High StudentsBlessing Joy Capiz83% (36)

- Static Electricity and Charge AccumulationDocument75 pagesStatic Electricity and Charge AccumulationArjav DesaiNo ratings yet

- LHR IndstryDocument84 pagesLHR Indstryabubakar09ect50% (2)

- Ship Rudder Types and Design FeaturesDocument10 pagesShip Rudder Types and Design FeaturesAurvin SinghNo ratings yet

- Service Booklet: Passenger CarsDocument0 pagesService Booklet: Passenger CarsEngine Tuning Up100% (1)

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)From EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)No ratings yet

- GHGHFDocument35 pagesGHGHFMetin BlackshotNo ratings yet

- AU TO M OT I V E & T R U C K / S U V APPLICATIONS, SPECIFICATIONS & DISTRIBUTOR PRICE GUIDEDocument60 pagesAU TO M OT I V E & T R U C K / S U V APPLICATIONS, SPECIFICATIONS & DISTRIBUTOR PRICE GUIDEArif WidayuniNo ratings yet

- Gear Axle Lubricants MOPARDocument3 pagesGear Axle Lubricants MOPARzobrevillesNo ratings yet

- Vortec 8.1L: POWERTRAIN Industrial EnginesDocument2 pagesVortec 8.1L: POWERTRAIN Industrial EnginesphalksturmNo ratings yet

- Differential Axle IdentificationDocument1 pageDifferential Axle IdentificationAbbode HoraniNo ratings yet

- 5.7L HEMI Engine RemanufacturingDocument2 pages5.7L HEMI Engine Remanufacturingd-fbuser-98752598No ratings yet

- March Mini 8-07Document20 pagesMarch Mini 8-07cameldiverNo ratings yet

- 08XKDocument510 pages08XKscribd2162No ratings yet

- Twin Turbo Power GuideDocument24 pagesTwin Turbo Power GuideawalsumNo ratings yet

- 500,000 Extended Maintenance GuideDocument3 pages500,000 Extended Maintenance GuideHarry WeiNo ratings yet

- Chevrolet Camaro 2010 ProspektDocument4 pagesChevrolet Camaro 2010 ProspektJoe Niederberger100% (1)

- 1 - 208129978 Hemi EnginesDocument18 pages1 - 208129978 Hemi EnginesBoya Raj NaikNo ratings yet

- Thule ClipOn 9104 Recommendations v14Document12 pagesThule ClipOn 9104 Recommendations v14Aner KurtovicNo ratings yet

- ERA CarDocument34 pagesERA CarMarcos SoarNo ratings yet

- OtroDocument216 pagesOtrobj42No ratings yet

- Specification Application Metric English: Engine Mechanical Specifications Y Car - LS1Document6 pagesSpecification Application Metric English: Engine Mechanical Specifications Y Car - LS1Jean Paul BésNo ratings yet

- 97jamopar PDFDocument743 pages97jamopar PDFAngel MorenoNo ratings yet

- New Wrangler New Defender ... Only One WinnerDocument9 pagesNew Wrangler New Defender ... Only One Winnerjasperj_au2027No ratings yet

- GTLegends Driving Guide Vol3Document13 pagesGTLegends Driving Guide Vol3kloppobotNo ratings yet

- 1953 1954 1955 Corvette Operations ManualDocument71 pages1953 1954 1955 Corvette Operations ManualDavid EvansNo ratings yet

- TM Suzuki Manual de Taller Suzuki Vitara 1991 en Ingles PDFDocument835 pagesTM Suzuki Manual de Taller Suzuki Vitara 1991 en Ingles PDFCarlos Alberto Romero MendezNo ratings yet

- Xfer Case IdentificationDocument9 pagesXfer Case IdentificationErickMaki0% (1)

- 2009 Tahoe Capacities PDFDocument1 page2009 Tahoe Capacities PDFAnonymous YIV4T8t8dNo ratings yet

- Al To Standard Clutch CatalogDocument136 pagesAl To Standard Clutch Catalogrobertoperez525No ratings yet

- Steeda CatalogDocument96 pagesSteeda Catalogbladeliger22100% (1)

- 200 4R PDFDocument96 pages200 4R PDFbyungchul kimNo ratings yet

- 615Document32 pages615ccbulgariaNo ratings yet

- Project Charger: The Step-By-Step Restoration of a Popular Vintage CarFrom EverandProject Charger: The Step-By-Step Restoration of a Popular Vintage CarNo ratings yet

- 2000 Maintenance ManualDocument0 pages2000 Maintenance ManualEngine Tuning UpNo ratings yet

- 2004 2005 EclassDocument0 pages2004 2005 EclassEngine Tuning UpNo ratings yet

- Maintenance Booklet: 2005 Passenger CarsDocument0 pagesMaintenance Booklet: 2005 Passenger CarsEngine Tuning UpNo ratings yet

- 2001 Light TruckDocument0 pages2001 Light TruckEngine Tuning UpNo ratings yet

- 2004 2005 EclassDocument0 pages2004 2005 EclassEngine Tuning UpNo ratings yet

- FG Bov Ktss20Document3 pagesFG Bov Ktss20Engine Tuning UpNo ratings yet

- 2003 Passenger CarsDocument0 pages2003 Passenger CarsEngine Tuning UpNo ratings yet

- 2002 Light TruckDocument0 pages2002 Light TruckEngine Tuning UpNo ratings yet

- HowtoDocument7 pagesHowtoEngine Tuning UpNo ratings yet

- High definition micro printing with the Domino PinpointTMDocument2 pagesHigh definition micro printing with the Domino PinpointTMEngine Tuning UpNo ratings yet

- Road Test: Test Four-Selector in Overdrive (4Th Gear)Document2 pagesRoad Test: Test Four-Selector in Overdrive (4Th Gear)Engine Tuning UpNo ratings yet

- HTTP WWW - Allisontransmission.com Servlet DownloadFile Dir Publications Pubs&FileToGet SA5429ENDocument4 pagesHTTP WWW - Allisontransmission.com Servlet DownloadFile Dir Publications Pubs&FileToGet SA5429ENpewald123100% (1)

- 06 Chassis ElectricalDocument365 pages06 Chassis ElectricalEngine Tuning UpNo ratings yet

- Useful InfoDocument2 pagesUseful InfoEngine Tuning UpNo ratings yet

- Evaluating Oscilloscope FundamentalsDocument24 pagesEvaluating Oscilloscope Fundamentalsgaru1991No ratings yet

- AURETR2007 Demonstrate Knowledge of Automotive Electrical Circuits and Wiring SystemsDocument9 pagesAURETR2007 Demonstrate Knowledge of Automotive Electrical Circuits and Wiring SystemsEngine Tuning UpNo ratings yet

- Twenty Things A Mom Should Tell Her SonDocument3 pagesTwenty Things A Mom Should Tell Her SonEngine Tuning UpNo ratings yet

- ABBs Water Coops Award MeDocument2 pagesABBs Water Coops Award MeEngine Tuning UpNo ratings yet

- Automotive Relays: General CatalogDocument71 pagesAutomotive Relays: General CatalogEngine Tuning UpNo ratings yet

- High definition micro printing with the Domino PinpointTMDocument2 pagesHigh definition micro printing with the Domino PinpointTMEngine Tuning UpNo ratings yet

- 11 NextGenPoliceIntercepBrochure2 LRDocument32 pages11 NextGenPoliceIntercepBrochure2 LREngine Tuning UpNo ratings yet

- JAC Diagnostics List: (Note:For Reference Only)Document4 pagesJAC Diagnostics List: (Note:For Reference Only)Engine Tuning UpNo ratings yet

- ABBs Water Coops Award MeDocument2 pagesABBs Water Coops Award MeEngine Tuning UpNo ratings yet

- EC 351 AC Analog Communication Lab ManualDocument117 pagesEC 351 AC Analog Communication Lab Manualhodibaaba1No ratings yet

- Acoples Lovejoy (Rejilla - Grid, 8 Pág.)Document8 pagesAcoples Lovejoy (Rejilla - Grid, 8 Pág.)marcelo castilloNo ratings yet

- Design of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingDocument9 pagesDesign of Foundations On Sensitive Champlain Clay Subjected To Cyclic LoadingRamiro ChairezNo ratings yet

- List of Organisations SAR147 Apr2012Document2 pagesList of Organisations SAR147 Apr2012Tan Lian KiatNo ratings yet

- Naval Arch - Incline TestDocument11 pagesNaval Arch - Incline TestDheerajKaushalNo ratings yet

- AMSOIL 10W40 and 10W30 Synthetic Metric Motorycle Oils (MCT - MCF)Document2 pagesAMSOIL 10W40 and 10W30 Synthetic Metric Motorycle Oils (MCT - MCF)amsoildealerNo ratings yet

- As3000 Service Manual PDFDocument180 pagesAs3000 Service Manual PDFsambadeeNo ratings yet

- Lars Part Ix - Safety Managment System Requirements-SmsDocument24 pagesLars Part Ix - Safety Managment System Requirements-SmssebastienNo ratings yet

- Sangshad BhabanDocument21 pagesSangshad Bhabanuniqueboy6050% (2)

- FRL GoyenDocument12 pagesFRL GoyenAbigael92No ratings yet

- Firestop Product ApplicationsDocument18 pagesFirestop Product Applicationsc1565No ratings yet

- CLC Blocks ProposolDocument5 pagesCLC Blocks ProposolGyi TawNo ratings yet

- Thermocouple & PRT Cable Selection GuideDocument15 pagesThermocouple & PRT Cable Selection Guidetees220510No ratings yet

- Nexans - MPRX (2002)Document63 pagesNexans - MPRX (2002)Dan Ghimbasanu0% (1)

- New Consultant List 20177 For Cea Website 10.02.2016Document4 pagesNew Consultant List 20177 For Cea Website 10.02.2016hxian.y9333No ratings yet

- Database transactions, recovery, and concurrencyDocument30 pagesDatabase transactions, recovery, and concurrencyIvan Jan AvigueteroNo ratings yet

- Romanian Power Grid Substation Refitting StrategyDocument16 pagesRomanian Power Grid Substation Refitting StrategyParmeshwar MbNo ratings yet

- Transmission Line Surveyors Face Challenges in Projecting Data onto MapsDocument3 pagesTransmission Line Surveyors Face Challenges in Projecting Data onto MapsTATAVARTHYCH HANUMANRAONo ratings yet

- Vend RegDocument49 pagesVend RegProcaeHexdofNo ratings yet

- Inverting Power Supply Using A TPS54202 BuckDocument25 pagesInverting Power Supply Using A TPS54202 Buckg4okkNo ratings yet

- Galaxy Electrical: Zener DiodesDocument3 pagesGalaxy Electrical: Zener Diodesdragon-red0816No ratings yet