Professional Documents

Culture Documents

Mayer Stark and Ambrose 2000 Fatigue Design Procedures PDF

Uploaded by

Mas Arman TewoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mayer Stark and Ambrose 2000 Fatigue Design Procedures PDF

Uploaded by

Mas Arman TewoCopyright:

Available Formats

International Journal of Pressure Vessels and Piping 77 (2000) 775781

www.elsevier.com/locate/ijpvp

Review of fatigue design procedures for pressure vessels

H. Mayer a,*, H.L. Stark a, S. Ambrose b,1

b

University of New South Wales, Sydney, Australia Welding Technology Institute of Australia, Australia

Abstract When applying detailed fatigue analysis to welds in pressure vessels, designers encounter practical difculties with the methods required by national standards such as ASME BPV Section VIII Div. 2, BS5500 and AS1210. This paper discusses the main fatigue design stress parameters, being: (a) the stress intensity range and (b) the principal stress range, and evaluates these for their validity over the scope of fatigue conditions they are required to predict. It is concluded that a practical and conservative approach for a given weld detail is to calculate geometric stress parameters at the critical location, evaluate and select the larger of the two parameters above, and to compare this to a fatigue curve based on undressed welded specimens. It is further concluded that an additional fatigue strength reduction factor of 2 be superimposed when the principal stress direction changes signicantly. q 2001 Published by Elsevier Science Ltd.

Keywords: Fatigue design; Pressure vessels; Stress intensity range; Principal stress range

1. Introduction Fatigue design of pressure vessels today, is broadly based on two national standards, those being the ASME Boiler and Pressure Vessel Code (Section 8 Div. 2, and Section 3) [1], and BS5500:1997, Annex C [2]. Until recently the Australian national standard AS 1210 (Supplement 1) [3] has been based on the ASME Code. Difculties in the application in practice of both the American and British approaches have caused those responsible for the Australian code to draft a standard that diverges in important aspects from both the American and British approaches. It is the purpose of this paper to raise these differences for discussion. The ASME approach requires for design, knowledge of the peak alternating stress intensity, that is the peak local value (no matter how small the location) of amplitude of uctuation of the Tresca stress intensity (half the magnitude of uctuation in difference in principal stresses). This is compared with material property data, based on strain cycling experimental data of plain, unwelded plate. Of particular note is the requirement that the uctuations in all three of the principal stresses need to be known, and those need to be known for the most localised of peak stress intensity locations. For

* Corresponding author. 1 Present address: 1A Woods St., North Epping, NSW 2121, Australia. 0308-0161/00/$ - see front matter q 2001 Published by Elsevier Science Ltd. PII: S 0308-016 1(00)00069-7

machined shapes of known geometry this provides no insuperable barriers given the advent of nite element analysis (FEA), however for welds, and specically undressed toes of welds, the designer has little or no hope of determining such localised peaks given the variable geometry of same. Also for the toes of welds (which are the most likely of the stress concentrations to initiate fatigue cracking in practice) there is the further issue of metallurgical damage coincident with the geometric stress concentration. Accordingly the material property approach used in ASME, while readily applicable to dened geometries remote from welds, is not readily applied to weld details. By comparison BS5500:1997 Annex C [2] specically addresses the weld issue and requires knowledge of the maximum range in principal stress at the weld, which is then used with fatigue data based on a range of different weld joint geometries that have been subjected to uniaxial strain cycling. This weld detail categorisation approach considers only uctuations in one of the three principal stresses at the weld. That is, if the largest uctuation in principal stress is across the toe, the principal stress along the weld is ignored. Houston [4] applied each of these procedures to a single example and found these two approaches to differ in fatigue life estimation by a factor of 50. When Houston's calculations were repeated using the currently valid rules [1,2], this factor was reduced to 15.

776

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

Nomenclature

s geo

geometric stress. The local primary plus secondary stress intensity at a point which, while including the concentrating effects of joint geometry, excludes the highly localised stress concentration of the weld prole itself. (e.g. for a weld toe this is typically determined by extrapolating to the location of the toe, those stresses at least one half of a plate thickness away from the toe). Ds p range of alternating principal stress Sa amplitude of alternating Tresca stress intensity Sr 2 Sa 2 t plate thickness Tresca stress intensity largest difference between the three principal stresses at a point

ered. Such factors include difference in Young's Modulus, variable stress amplitudes and ratios, the stress parameter to be used (e.g. Tresca stress intensity for multiaxial stresses, or principal stress), mean stress, overload hardening, size effect, environment, surface effects, localised peaks in stress intensity due to geometric stress concentrations and other defects such as those metallurgical defects associated with welds. While many of these factors can be incorporated into the design calculations (using moduli ratio, Miner's rule etc), the highly variable, localised, and unknown (at the design stage) stress concentrations, and metallurgical damage associated with weld toes presents the designer/ stress analyst with severe problems in determining, in practice, a magnitude of peak stress intensity to take to the SN curve. 2.2. Weld detail categorisation SN approach The difculties in application, to fatigue design of welds, of the material property SN approach, and the recognition that any location on a pressure vessel may be welded (e.g. as a result of repairs) have led to the recent advent of the weld detail categorisation approach to fatigue design of pressure vessels (BS5500:1997 Annex C). In essence this approach relies on experimental fatigue data determined not from polished specimens of parent metal but from fatigue testing welded joints. Since there are a great many different geometries of welded joint (butt, tee, cruciate, toe shape, etc), a family of SN curves is required to represent the range of geometries. Accordingly such SN curves include the detrimental effects of weld toe notches and metallurgical damage, such that the designer need only determine the nominal stress range in the vicinity of the weld. This has great practical merit. Gurney [6] and Richards [8], early workers in the UK, introduced this approach for steel structures, with Gurney [9] proposing a set of design rules for welded steel joints based on a number of typical weld details categorised into 8 fatigue classes, each having its own SN curve. These SN curves range from a ground ush butt welded joint (highest fatigue strength, almost equivalent to the material property curve) to a transverse llet welded joint (one third of the fatigue strength of the ground butt weld). Volumes of joint fatigue data were published by Oliver and Ritter [10]. Other investigators constructed complete or near complete pressure vessels, to observe their fatigue behaviour. The results of a number of these tests are presented and discussed in Harrison and Maddox [11]. All joints, except the few constructed into pressure vessels were loaded essentially uniaxially. After Harrison and Maddox [11] and Maddox [12] adapted this approach for pressure vessels, BSI eventually replaced

2. Approaches to component life analysis 2.1. Material property SN approach The material property approach has its origins in the early hler [5] who inveswork carried out by (among others) Wo tigated the fatigue behaviour of rail wagon axles. In essence this approach endeavours to characterise the alternating stress pattern for comparison with the material property, fatigue strength. The material property, fatigue strength, is determined by testing a number of carefully standardised specimens (typically small, polished and usually excluding weld metal) to determine the number of fully alternating (xed amplitude) cycles of stress (or strain) required to generate fatigue failure, usually in a specied environment. While such specimens experience all four stages of fatigue, namely crack nucleation, small crack growth, crack propagation, and complete fracture, because their size is small the crack propagation stage is usually very short, and accordingly the data can be regarded as the material fatigue strength in resisting the formation of cracks. The relationship is usually presented as a graph of stress amplitude (or stress range) versus number of cycles to failure, the SN curve. To allow application of such data to any given design situation, allowance must be made for the differences between the test specimens and the design being consid2 In BS5500 [2], Sr is the notation used for the maximum range of alternating principal stress, wich is Ds p here. Unfortunately, due to the variety of notations used by the codes around the globe, it was not possible to select a set of nomenclature consistent with all the relevant publications. Care should be taken not to confuse the parameters here, or in the published standards.

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

777

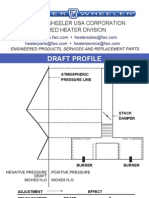

Fig. 1. Stress intensity distribution on pad reinforced nozzle in a cylindrical vessel.

the material property approach by the weld detail categorisation approach with the publication of BS5500:1997 Annex C. While the weld detail categorisation approach relieves some of the designer's problems, there remains in practice two areas of difculty depending on the stress parameter used. ASME, and similar standards today, specify the alternating stress intensity. However, BS5500:1997 considers only the largest range in principal stress. Pressure vessels (unlike typical steel structures) are inevitably subject to stresses that vary multiaxially, not uniaxially, and so for example on the knuckle of a pressure vessel end, high circumferential compression can be combined with high axial tension, causing the variation in stress intensity at that location to be in the order of twice the variation of maximum principal stress. It should be noted that although residual stresses resulting from welding will cause initial stresses in the vicinity of the weld to be tensile, the multiaxiality of the variation in stress can still cause the alternating stress intensity to be signicantly larger than the maximum alternating principal stress. The complex and rapidly varying distributions of primary plus secondary stress intensities typical of the multiaxial stressing in pressure vessels, particularly at the junctions between component shells, nozzles etc. cause the stress analyst

difculty in isolating a magnitude of stress for use with the stress category SN curves. Such stresses need to be close enough to the weld that it represents the stress in the vicinity of the weld but excludes the highly localised stress concentrating effect of the weld toe. While this can be readily done with typical structural steel members such as beams, which are predominantly uniaxially stressed, this can be very difcult to isolate from the full eld view of aggregate stresses given by FEA.

3. Comparison of approaches 3.1. Inside corner of the nozzle (crotch corner) Fig. 1 shows this location and it is of a well dened geometry, remote from welds and as such is amenable to detailed stress analysis using FEA to establish the actual peak stresses. This particular vessel was required to be designed for 5000 cycles (n) of pressure uctuation from 0 to 14.8 MPa internal pressure. At the hot spot on the inner edge of the nozzle the FEA converged to give the three principal stresses at the internal pressure of 14.8 MPa as 1404, 214.8, and 214.8 MPa. Ignoring the small correction for Young's Modulus the following fatigue damage is

778

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

predicted: ASME: Sa amplitude of alt: stress intensity 1=2404 2 214:8 209:4 MPa Giving N 17; 500 from the ASME curve and damage U n=N 5000=17; 500 0:29 BS5500:1997 Annex C: Ds p max principal stress range 404 MPa Giving N 31; 840 from curve C of BS5500:1997 and damage U 5000=31840 0:16: It is of particular note that the ASME approach, using stress intensity, invokes the extremes in principal stress, but BS5500 only uses the maximum range in principal stress. In this example, the difference in the stress range parameter is only about 4%. However, the difference in life of around 80% is due to the difference in curves. Further, on the knuckle of a pressure vessel where the circumferential stress can be compressive of the same order of magnitude as the axial tensile stress that difference could be a factor of 2 (i.e. equivalent to a factor of approximately 8 on life). 3.2. Edge of the compensation plate The weld toe at the edge of the compensation plate presents practical difculties for FEA; some particular small radius has to be assumed for the toe to enable the FEA to converge. Modelling a small radius of curvature in a large model is difcult. The stress results are extremely sensitive to the magnitude of the radius chosen. This radius at the weld toe is highly variable in a real weld. For these reasons it is not practical to attempt to accurately model weld toes using FEA. What can be done is to ignore those stress results within approximately half plate thickness of the toe, and determine the geometric stress at the location of the weld toe by extrapolating from the local stress results. In practice, when plotting the surface stress approaching the discontinuity, a clear change in trend is visible as the effects of peak stress become signicant, so enabling extrapolation to exclude peak stress relatively simply. (extrapolation techniques are given in Ref. [2,13]). This renders the FEA within halft of the weld toe less critical, although it still has to be sufciently nely meshed to give accurate results outside that region. Such a geometric stress represents the primary plus secondary stresses at the location of the weld toe, but excludes the highly localised stress concentration of the weld toe. In this case, two points at a distance of halft and 2t from the weld toe were used and

gave the geometric principal stresses of 1300, 1188 and 0 MPa. ASME: ASME requires a peak stress, and accordingly the geometric stress has to be converted to a peak stress using a stress concentration factor; using a factor of 2.5 (Houston [4]) gives the following result Sa amplitude of alt: stress intensity 1=2404 2 214:8 375 MPa Giving N 3; 000 from the ASME curve and damage U 5000=3; 000 1:67 BS5500:1997 Annex C: Ds p max principal stress range 300 MPa Giving N 38; 518; from curve E (C.3.4.3.2) and damage U 5000=38; 518 0:13: Clearly there is signicant discrepancy between the two approaches for the weld toe, which can be traced to the arbitrary stress concentration factor required to get a peak stress intensity to take to the ASME curve. There is no practical alternative route to get a peak stress intensity for use with the ASME curve using FEA. Accordingly it is the authors' view that the BS5500 approach is the better method to assess fatigue performance at a weld toe. 4. Characterisation of governing stress Each of the two approaches considered above asks for a characteristic uctuating stress. The material property approach requires the maximum alternating stress intensity amplitude, Sa, while the weld detail characterisation approach in BS5500:1997 uses the maximum principal stress range, Ds p. The typical fatigue test specimen is cycled using uniaxial stress, or uniaxial strain of xed amplitude. The loads on a real component may well subject that component to: (i) varying mean stress; (ii) varying amplitude stress; (iii) multiaxial stress; and (iv) out-of-phase loading, (including rotating principal axes). 4.1. Tensile alternating stress with lateral compression The literature contains considerable evidence to the effect that virtually all fatigue and fracture properties of metals and components are signicantly affected by multiaxial loading [7,14,15]. The most damaging case being when tensile stresses normal to a crack plane act in conjunction with compressive stresses parallel to the crack plane. In such a multiaxially stressed case the crack opening due to the

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

779

tensile stress is assisted by the compressive stress, which may or may not itself be cycling. An example of such multiaxial stressing is on the internal surface of a pressure vessel knuckle, where, particularly if the knuckle radius is small in comparison with the crown radius, a substantial circumferential compressive stress accompanies the tensile axial stress. The range of alternating principal stress, Ds p (BS5500:1997), effectively ignores that lateral stresses are present, and, in the case of the knuckle, this parameter would effectively ignore the smaller of the axial tensile stress or the circumferential compressive stress, and so it does not account for the fact that fatigue life is reduced by their combined presence. On the other hand, the alternating stress intensity Sa, (ASME, AS1210), increases because of the presence of the lateral stresses of the opposite sign. Though it is not entirely clear from the literature, it appears that Sa is probably conservative in the case of multiaxial loading. However, it is clear that Ds p, is unconservative in its treatment of multiaxial stresses of mixed sign. 4.2. Biaxial tension Here, the same mechanism allows the crack growth to be inhibited by the presence of the lateral tension. But, because the stresses on the third principal axis are zero, as is generally the case on the outside surface of a pressure vessel, the two parameters are equal to each other, both ignoring the restraining effects of the lateral tension. Hence, both are conservative. 4.3. Triaxial compression In the extreme case where an element is subjected to uctuating hydrostatic pressure, it can be readily theorised that, given three equal principal stresses, the alternating stress intensity, Sa, is zero and, hence, this parameter predicts no crack growth or associated fatigue damage to the element. On the other hand, the parameter Ds p, the

principal stress range, will equal the range in one of the principal stresses regardless of the other two being of equal magnitude, and so it will indicate fatigue damage. The literature indicates that the use of Ds p is probably conservative in that it ignores the restraining effects of triaxial compression. 4.4. Triaxial tension As a direct extension from the biaxial tension case, it is clear that tension parallel to the crack plane in two directions will serve to reduce crack opening even more than tension parallel to the crack plane in only one direction. Here, the Ds p parameter retains the value of the range of the largest principal stress, irrespective of the magnitude of the other two principal stresses and, hence, predicts this case even more conservatively than the biaxial tension case. The value of the Sa parameter is less than in the biaxial tension case, because the shear stress on the element is reduced. In the limiting case, when all principal stress components are equal, and proportional throughout the cycle, Sa is zero at all times and predicts no crack growth. However, the tension still opens the crack and, therefore, the crack will grow, thus making the parameter unconservative in this limiting case. Since it is not known at which point Sa becomes conservative, it must be said to be unconservative in any triaxial tension case. 4.5. Out-of-phase loading In the case of rotating principal axis directions, that is when shear and normal stress alternate out-of-phase, crack growth rates in steel have been observed to increase by a factor of up to ,2.5 under high cycle fatigue conditions [16,17]. This represents a reduction factor of ,1.3 on strength. The effect is much more severe under low cycle fatigue conditions. Both the ASME and BS5500 approaches consider only the largest changes in alternating stress to which an element is subjected, whether or not the loads

Table 1 Performance of design parameters under various loading conditions

780

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

are alternating out-of-phase. Hence, this effect is not considered and both codes may be unconservative in such cases. 4.6. Load state discussion The conclusions above are collated in Table 1. The table reveals immediately that both parameters can be unconservative in some load states. This implies that each of the two approaches, ASME BPV-VIII-2 and BS5500:1997 Annex C, can lead to unconservative estimates of fatigue life. Of particular concern is the BS5500:1997 use of the range of principal stress, Ds p, where tension normal to a crack plane acts in conjunction with compression parallel to that plane, such as in the knuckle regions of a vessel. It is also evident from Table 1, that either one or the other parameter is conservative in all states of in-phase cyclic loading, which implies that between the two parameters conservative estimation of fatigue life can nevertheless be achieved. It is a simple exercise to calculate both parameters once the stresses at the point of interest are known. Hence, to be conservative, the designer may simply apply the larger (and more conservative) of the two parameters. In consideration of out-of-phase loading, a fatigue strength reduction factor of 2 is proposed. 5. A new approach in AS1210 supplement 1-2000 A revised version of AS1210 was being drafted at the time of completion of this paper. Among other modications, a new approach to detailed fatigue analysis is proposed. This new approach, is based on the arguments presented in this paper, and is subject to public comment. Consequently, the published version of AS1210 may vary in detail from this approach, which is summarised as follows. There are now two lters aimed at removing the need for fatigue analysis. These two lters are much simplied from the previous code and so minimise design costs for those cases clearly not in need of detailed fatigue analysis. Where there is need for detailed fatigue analysis the following applies. If there is no structural singularity such as a weld toe, but simply rolled plate or forging without repair welds, the three principal stresses are established using elastic analysis at the location of the peak stressing. Both the maximum range of principal stress, Ds p, and the maximum range of stress intensity, Sr, are established for that point. The larger of these two parameters is then chosen as the design parameter, and corrected for Young's Modulus (for both material and temperature). The permissible number of cycles, N, is then established from a design curve, which is equivalent to curve C from BS5500 Annex C, so allowing the calculation of the fatigue damage, U. If the peak stress region is a weld toe, then the three principal stresses are established at the location of the

weld toe by extrapolation from the surrounding local stress analysis results (linear elastic FEA or equivalent) beyond a perimeter that is half plate thickness from the weld toe. The procedure is then as before, excepting that a second design curve, which is equivalent to Curve E from BS5500 Annex C, is used to determine N. Curves C and E of BS5500:1997 are the ones being considered at the time of writing. Slightly different curves may be used in the published document (to cater for ASME parent metal). As an alternative, consideration is being given to presenting the fatigue curves in a strain form. The advantages of such a presentation being that the curves can be presented as common for all metals and temperatures. Further, such a strain presentation of the curves enables the practitioner to use non-linear FEA, and the SN data can be represented with two curves only, being one for welded material & another for non-welded material. If the detail is poorer in fatigue performance than a weld toe, such as for example the root of a partial penetration llet weld, then the procedure is to use the average stress determined across the weld throat further applying a stress concentration factor of 2 to the design stress parameter before going to curve E. In those cases where the principal stress directions vary, that is where the principal stresses uctuate signicantly out of phase, then a further fatigue strength reduction factor of 2 is applied. 6. Conclusion Practical difculties arise for the designer in the fatigue analysis of welds in pressure vessels. For example, the geometry of weld toes are effectively singularities for the purposes of elastic nite element stress analysis. Yet, most national standards, such as ASME, require an elastically derived peak stress intensity at the highly localised peak stress location. Other standards, such as BS5500, allow categorisation of the weld detail, but rely on the range of maximum principal stress, without apparently taking account of multiaxial stresses. When calculating the fatigue life of some components, the two codes differed by a factor on life of greater than 10. The major fatigue design stress parameters: (i) the stress intensity range, Sr, and (ii) the principal stress range, Ds p, were evaluated for their performance over the scope of fatigue conditions they were required to predict, and for their ability to be calculated. It was concluded that a practical and conservative fatigue analysis approach for a given weld detail is to use for the stress parameter the larger of Sr and Ds p, and to avoid the difculty with the singularity at the weld toe by extrapolating from the surrounding values to give a geometric stress at the singularity. The alternating stress parameter so evaluated is compared to one of two fatigue curves. A curve based

H. Mayer et al. / International Journal of Pressure Vessels and Piping 77 (2000) 775781

781

on parent material property data is used when the location in question is free of any welded material, and another curve based on butt welded, unground specimens, is used when welded joints may be present at the location at any time in the vessels life. These details may vary slightly in the nal published AS1210. It is further proposed, that an additional fatigue strength reduction factor of 2 be applied where the component stresses in a multiaxially stressed location uctuate out of phase signicantly. References

[1] ASME BPV-VIII-2. Boiler and pressure vessel code: section VIII Rules for construction of pressure vessels: division 2 alternative design rules. Appendix 5. New York: The American Society for Mechanical Engineers, 1995. [2] BS5500:1997. British standard specication for unred fusion welded pressure vessels. Annex C. UK: British Standards Institution. [3] AS1210 Supplement 1-1990. Unred pressure vessels Advanced design and construction (supplement to AS1210-1989). Appendix C. Sydney: Standards Australia. [4] Houston R. British standards institution boiler and pressure vessel design criteria. In: Nichols RW, editor. Pressure vessel codes and standards. Amsterdam: Elsevier, 1987 (chap. 5). hler, A. Versuche u ber die Festigkeit der Eisenbahnwagenachsen. [5] Wo r Bauwesen, 1860. In: ASM handbook, vol. 19: fatigue Zeitshrift fu and fracture. OH: ASM International, 1996. p. 15.

[6] Gurney TR. Fatigue of welded structures. Cambridge: Cambridge University Press, 19681979. [7] Beaver PW. Biaxial fatigue and fracture of metals: a review. Metals Forum, Australia, vol. 8, no. 1, Summer, 1985. [8] Richards KG. Fatigue strength of welded structures. Cambridge: Abington Hall, 1969. [9] Gurney TR. Fatigue design rules for welded joints. The Welding Institute Research Bulletin 1976;May:11524. [10] Oliver, Ritter. Catalogue of SN curves of welded joints in structural sseldorf: Deutscher Verlag fur Schweisstechnick, 1979. steel. Du [11] Harrison JD, Maddox SJ. Derivation of design rules for pressure vessels. The International Institute of Welding Document, XIII-94180, 1980. [12] Maddox SJ. Fatigue design rules for pressure vessels. The International Institute of Welding Document, XIII-1215-86, 1986. [13] IIW Group XIII-XV. Fatigue design of welded joints and components. The International Institute of Welding Document, XIII-153996/XV-845-96, 1996. [14] Leevers PS, Radon JC, Culver LE, (1977). In: Beaver PW, editor. Biaxial fatigue and fracture of metals: a review. Metals Forum, Australia, vol. 8, no. 1, 1985. [15] Charat IMH, Garrat GG, (1980). J Test Eval JTEVA, 8,9. In: Beaver PW, editor. Biaxial fatigue and fracture of metals: a review. Metals Forum, Australia, vol. 8, no. 1, Summer, 1985. [16] Kanazawa K, Miller KJ, Brown MW, (1977). J Engng Mater Technol (Trans. ASME, Series H), 99, 222. In: Beaver PW, editor. Biaxial fatigue and fracture of metals: a review. Metals Forum, Australia, vol. 8, no. 1, Summer, 1985. [17] Kitagawa H, Yuuki R, Tohgo K., (1979). Fatigue Engng Mater Struct, 2, 195. In: Beaver PW, editor. Biaxial fatigue and fracture of metals: a review. Metals Forum, Australia, vol. 8, no. 1, Summer, 1985.

You might also like

- Aluminum Brazed HEX Chart 015Document4 pagesAluminum Brazed HEX Chart 015Mas Arman TewoNo ratings yet

- Presentation PVP 2008 Fastener Preload GuidanceDocument19 pagesPresentation PVP 2008 Fastener Preload GuidanceMas Arman TewoNo ratings yet

- Flexitallic Joint Integrity CalculationsDocument7 pagesFlexitallic Joint Integrity Calculationslotra1979No ratings yet

- Torque Charts and Pump Tutorial 3Document7 pagesTorque Charts and Pump Tutorial 3Mas Arman TewoNo ratings yet

- Torque of Stainless Steel, Non Ferrous TorqueDocument1 pageTorque of Stainless Steel, Non Ferrous TorqueMas Arman TewoNo ratings yet

- ABSA News 008-V13-Iss1Document4 pagesABSA News 008-V13-Iss1Mas Arman TewoNo ratings yet

- ABSA Failure Alert IB06-003Document1 pageABSA Failure Alert IB06-003Mas Arman TewoNo ratings yet

- CH 37 Waste Water GEDocument22 pagesCH 37 Waste Water GEMas Arman TewoNo ratings yet

- Engineering Critical Analyses To BS 7910Document15 pagesEngineering Critical Analyses To BS 7910Mas Arman TewoNo ratings yet

- BS 7910Document12 pagesBS 7910Mas Arman Tewo50% (2)

- 1386 - FM Front Page Industrial Burner HandbookDocument14 pages1386 - FM Front Page Industrial Burner HandbookMas Arman Tewo0% (1)

- Ethylene Heat Flux John ZinkDocument4 pagesEthylene Heat Flux John ZinkMas Arman Tewo100% (1)

- 01 Script Hydrodynamic Layout PDFDocument0 pages01 Script Hydrodynamic Layout PDFMas Arman TewoNo ratings yet

- Earthquake Loading Specified in GDocument3 pagesEarthquake Loading Specified in GMas Arman TewoNo ratings yet

- Tall Vertical ColumnsDocument2 pagesTall Vertical ColumnsMas Arman TewoNo ratings yet

- A Step by Step Introduction To FEADocument7 pagesA Step by Step Introduction To FEAMas Arman TewoNo ratings yet

- Mechanical Design Internals Column Notes PDFDocument14 pagesMechanical Design Internals Column Notes PDFMas Arman TewoNo ratings yet

- Practical Fracture MechanicsDocument2 pagesPractical Fracture MechanicsMas Arman TewoNo ratings yet

- FEA 107 Validation ExperimentDocument7 pagesFEA 107 Validation ExperimentMas Arman TewoNo ratings yet

- Finite Element Analysis For Pressure Vessel Design - by - MichelDocument4 pagesFinite Element Analysis For Pressure Vessel Design - by - MichelaruatscribdNo ratings yet

- Sample FEA ReportDocument13 pagesSample FEA ReportMario Tirabassi100% (1)

- SCL Through Areas of Peak StressDocument14 pagesSCL Through Areas of Peak StressetyuyNo ratings yet

- Causal Factor Chart and Fault Tree TemplateDocument7 pagesCausal Factor Chart and Fault Tree TemplateMas Arman TewoNo ratings yet

- Fired Heater Checklist FW PDFDocument2 pagesFired Heater Checklist FW PDFMas Arman Tewo100% (2)

- Behind The Pretty Pictures (Speaker Information) PDFDocument1 pageBehind The Pretty Pictures (Speaker Information) PDFMas Arman TewoNo ratings yet

- Causal Factor Chart and Fault Tree TemplateDocument7 pagesCausal Factor Chart and Fault Tree TemplateMas Arman TewoNo ratings yet

- Ethylene Safety Incidents PDFDocument88 pagesEthylene Safety Incidents PDFMas Arman TewoNo ratings yet

- Part 2 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFDocument18 pagesPart 2 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFMas Arman Tewo0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- New Document (116) New Document (115) New Document (1Document9 pagesNew Document (116) New Document (115) New Document (1Manav PARMARNo ratings yet

- Attery: User Guide Dict Release 2020Document47 pagesAttery: User Guide Dict Release 2020diegoNo ratings yet

- Electronic Load FundamentalsDocument16 pagesElectronic Load FundamentalsMiguel PenarandaNo ratings yet

- Defending A Dogma: Between Grice, Strawson and Quine: Elvis ImafidonDocument10 pagesDefending A Dogma: Between Grice, Strawson and Quine: Elvis ImafidonYang Wen-LiNo ratings yet

- Congental Abdominal Wall DefectsDocument38 pagesCongental Abdominal Wall DefectsAhmad Abu KushNo ratings yet

- Scribe FormDocument2 pagesScribe FormsiddharthgamreNo ratings yet

- Stroke Practice GuidelineDocument274 pagesStroke Practice GuidelineCamila HernandezNo ratings yet

- India Marine Insurance Act 1963Document21 pagesIndia Marine Insurance Act 1963Aman GroverNo ratings yet

- RA 9344 As Amended by RA 10630 - HandoutsDocument9 pagesRA 9344 As Amended by RA 10630 - HandoutsJan Re Espina CadeleñaNo ratings yet

- VestibuleDocument17 pagesVestibuleDeepti MangalNo ratings yet

- Southeast Asian Fabrics and AttireDocument5 pagesSoutheast Asian Fabrics and AttireShmaira Ghulam RejanoNo ratings yet

- CHAPTER 4 (B)Document6 pagesCHAPTER 4 (B)Jon Lester De VeyraNo ratings yet

- Arsu and AzizoDocument123 pagesArsu and AzizoZebu BlackNo ratings yet

- Danculos - M1 - L3 - Activity TasksDocument2 pagesDanculos - M1 - L3 - Activity TasksAUDREY DANCULOSNo ratings yet

- Life in The Past - Year 6 WorksheetsDocument11 pagesLife in The Past - Year 6 WorksheetstinaNo ratings yet

- Analysing Worship in The Pentateuch and Its ApplicationDocument12 pagesAnalysing Worship in The Pentateuch and Its ApplicationDaniel Solomon100% (1)

- Forecast Error (Control Chart)Document2 pagesForecast Error (Control Chart)Jane OngNo ratings yet

- De Thi Hoc Ki 2 Lop 3 Mon Tieng Anh Co File Nghe So 1Document3 pagesDe Thi Hoc Ki 2 Lop 3 Mon Tieng Anh Co File Nghe So 1huong ngo theNo ratings yet

- 8 Powerful Methods People Use To Bounce Back From FailureDocument7 pages8 Powerful Methods People Use To Bounce Back From FailureGrego CentillasNo ratings yet

- Binding of IsaacDocument10 pagesBinding of IsaacBraz SouzaNo ratings yet

- Biometric Security ConcernsDocument27 pagesBiometric Security ConcernsprinceuchenduNo ratings yet

- The Bible Does Not Condemn Premarital SexDocument16 pagesThe Bible Does Not Condemn Premarital SexKeith502100% (3)

- Unsung Ancient African Indigenous Heroines and HerosDocument27 pagesUnsung Ancient African Indigenous Heroines and Herosmsipaa30No ratings yet

- Tugas, MO - REVIEW JURNAL JIT - Ikomang Aditya Prawira Nugraha (1902612010304)Document12 pagesTugas, MO - REVIEW JURNAL JIT - Ikomang Aditya Prawira Nugraha (1902612010304)MamanxNo ratings yet

- Nursery Rhymes Flip ChartDocument23 pagesNursery Rhymes Flip ChartSilvana del Val90% (10)

- Unit 2-ED (Theory)Document13 pagesUnit 2-ED (Theory)chakramuNo ratings yet

- Measure For Measure AngeloDocument1 pageMeasure For Measure AngeloRoger Knight100% (1)

- TOEIC® Practice OnlineDocument8 pagesTOEIC® Practice OnlineCarlos Luis GonzalezNo ratings yet

- STEM BeesDocument36 pagesSTEM BeesHitesh YadavNo ratings yet

- Spyderco Product Guide - 2016Document154 pagesSpyderco Product Guide - 2016marceudemeloNo ratings yet