Professional Documents

Culture Documents

Punch List Civil Jan.13

Uploaded by

Azam Islam KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Punch List Civil Jan.13

Uploaded by

Azam Islam KhanCopyright:

Available Formats

ANNEXURE

JINNAH HYDROPOWER PROJECT PUNCH LIST OF FINISHING WORKS (CIVIL)

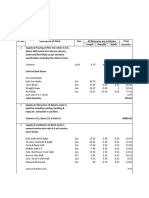

UNLOADING BAY Treatment of cracks in 40 cm wide strip along downstream wall, entrance wall and upstream wall of unloading bay at El. 215 m. Repair of broken edges of entrance columns. Cutting of 8 protruding rebars at upstream wall of unloading bay Cutting of 8 protruding rebars at downstream wall of unloading bay Cutting of protruding rebar at El. 215 m near railing of unloading bay Cutting of 4 rebars that cut from surface level of upstream column of unloading bay Treatment of broken edges under fire alarm cable pipe at downstream column of unloading bay Installation of main gate shutter. General cleaning of unloading bay

ERECTION BAY Repair of broken edges of staircase slabs Repair of broken edges under fire alarm cable pipe at downstream wall of erection bay Repair of broken edges of columns of erection bay Repair of uneven floor surface of erection bay Cutting of 15 protruding rebars and 2 protruding pipes from erection bay at El. 209.4 m Cutting of 1 protruding earthing strips from downstream wall of erection bay at El. 209.7 m Cutting of 45 protruding rebars from upstream wall of erection bay Cutting of 36 protruding rebars from downstream wall of erection bay Cutting of 16 protruding rebars from left side wall of erection bay Cutting of 2 protruding girders from downstream wall of erection bay at El. 215 m Cutting of 4 bolts from downstream wall of erection bay Cutting of protruding rebar near crane beam at downstream wall of erection bay Filling of expansion joint between erection bay and Unit Block # 1 Levelling between floor surfaces of erection bay and Unit Block # 1 Repair of broken edges of main entrance to electrical tool room and lift Levelling of side angles of open area for access to water treatment room and its steel cover to erection bay floor level General cleaning of erection bay

UNIT BLOCK # 01 Treatment of uneven floor surface at El. 209.4 m Levelling and fitting of chequer cover plates of cable trenches to adjacent floor Cutting of 39 protruding rebars from Unit Block # 01 at El. 209.4 m Cutting of 4 protruding earthing strips from Unit Block # 01 at El. 209.4 m

Page 1 of 10

Cutting of protruding metal piece near upstream wall of Unit Block # 01 at El. 209.4 m Cutting of protruding pipe near entrance of generator pit of Unit # 01 at El. 209.4 m Filling of 1 hole at downstream wall inside of Powerhouse at El. + 219 m Proper filling around 5 air grills of Unit Block # 01 Filling of hole near air grill of Unit # 01 Filling of 147 grooves formed due to cutting of anchor bolts in turbine chamber of Unit # 1 Cutting of protruding rubber grout pipes from upstream wall of turbine chamber of Unit # 1 Grinding of uneven surfaces in turbine chamber of Unit # 1 Cleaning of oil stains from chequer cover plates of cable trenches and painting of plates Removing of spider webs from upstream wall of Unit Block # 02 General cleaning of Unit Block # 01

UNIT BLOCK # 02 Filling of expansion joint between Unit Block # 01 and Unit Block # 02 Treatment of uneven floor surface at El. 209.4 m Levelling and fitting of chequer cover plates of cable trenches to adjacent floor Cleaning of oil stains from chequer cover plates of cable trenches and painting of plates Proper filling around 7 air grills of Unit Block # 02 Repair of plaster at downstream wall of Unit # 03 Cutting of protruding rubber grout pipes from upstream wall of Unit Block # 02 and cleaning of adjacent area Cutting of 31 protruding rebars from Unit Block # 02 at El. 209.4 m Removing of spider webs from upstream wall of Unit Block # 02 General cleaning of Unit Block # 02

UNIT BLOCK # 03 Filling of expansion joint between Unit Block # 02 and Unit Block # 03 Treatment of uneven floor surface at El. 209.4 m Levelling and fitting of chequer cover plates of cable trenches to adjacent floor Cleaning of oil stains from chequer cover plates of cable trenches and painting of plates Proper filling around 5 air grills of Unit Block # 03 Cutting of 38 protruding rebars from Unit Block # 03 at El. 209.4 m General cleaning of Unit Block # 03

UNIT BLOCK # 04 Filling of expansion joint between Unit Block # 03 and Unit Block # 04 Treatment of uneven floor surface at El. 209.4 m Levelling and fitting of chequer cover plates of cable trenches to adjacent floor Proper filling around 5 air grills of Unit Block # 02 Cutting of 41 protruding rebars from Unit Block # 04 at El. 209.4 m Cutting of 18 protruding rebars from right side wall of Unit # 08

Page 2 of 10

Cutting of 2 protruding earthing strips from Unit Block # 04 at El. 209.4 m General cleaning of Unit Block # 04

AUXILIARY POWERHOUSE Removing of loose mortar along side walls of Auxiliary Powerhouse at El. 209.4 m Repair of uneven floor surfaces of all rooms and corridor of Auxiliary Powerhouse at El. 209.4 m Removing of polythene sheet cover from all fire fighting doors of Auxiliary Powerhouse at El. 209.4 m Cleaning of spider webs from corridor of Auxiliary Powerhouse Cleaning of footprints marks from walls of Auxiliary Powerhouse Repair of broken plaster edges of wall corners of Auxiliary Powerhouse Proper filling around air grills of Proper filling around 5 air grills White washing of dirty and uneven colour patches on the walls of Auxiliary Powerhouse Grinding of formwork impressions on upstream and downstream walls of Auxiliary Powerhouse Cutting of exposed rebar at entrance from Unit Block # 01 to Auxiliary Powerhouse Repair of crack in AC Chamber wall in front of entrance from Unit Block # 01 Cutting of 14 protruding rebars from Electrical Tool Room Cutting of 12 protruding rebars from Mechanical Tool Room Cutting of 3 protruding earthing strips from Mechanical Tool Room Cutting of 5 protruding rebars from Local Control Unit # 01 Cutting of 11 protruding pipes from Local Control Unit # 01 Cutting of 6 earthing strips from Local Control Unit # 01 Proper covering of opening around panels of Local Control Unit # 01 Cutting of 4 protruding rebars from Local Control Unit # 02 Cutting of 9 protruding pipes from Local Control Unit # 02 Cutting of 1 earthing strips from Local Control Unit # 02 Proper covering of opening around panels of Local Control Unit # 02 Cutting of 13 protruding rebars from Local Control Unit # 03 Cutting of 7 protruding pipes from Local Control Unit # 03 Cutting of 1 earthing strips from Local Control Unit # 03 Proper covering of opening around panels of Local Control Unit # 03 Cutting of 5 protruding rebars from Local Control Unit # 04 Cutting of 3 protruding pipes from Local Control Unit # 04 Cutting of 2 earthing strips from Local Control Unit # 04 Proper covering of opening around panels of Local Control Unit # 04 Cutting of 14 protruding rebars from Local Control Unit # 05 Cutting of 2 earthing strips from Local Control Unit # 05 Proper covering of opening around panels of Local Control Unit # 05 Cutting of 11 protruding rebars from Local Control Unit # 06

Page 3 of 10

Cutting of 4 protruding pipes from Local Control Unit # 06 Cutting of 1 earthing strips from Local Control Unit # 06 Proper covering of opening around panels of Local Control Unit # 06 Cutting of 5 protruding rebars from Local Control Unit # 07 Cutting of 4 protruding pipes from Local Control Unit # 07 Cutting of 3 earthing strips from Local Control Unit # 07 Proper covering of opening around panels of Local Control Unit # 07 Cutting of 8 protruding rebars from Local Control Unit # 08 Cutting of 2 earthing strips from Local Control Unit # 08 Proper covering of opening around panels of Local Control Unit # 08 Cutting of 3 protruding rebars from Ventilation Plant Room # 03 Cutting of 2 protruding pipes from Ventilation Plant Room # 03 Cutting of 3 earthing strips from Ventilation Plant Room # 03 Cutting of protruding metal piece from Ventilation Plant Room # 03 Cutting of 4 protruding rebars from Ventilation Plant Room # 04 Cutting of 4 protruding pipes from Ventilation Plant Room # 04 Proper covering of opening around ducts of Ventilation Plant Room # 04 Cutting of 3 protruding rebars from Excitation Transformer Room (1~4) Cutting of 2 protruding pipes from Excitation Transformer Room (1~4) Cutting of 3 earthing strips from Excitation Transformer Room (1~4) Cutting of 4 protruding rebars from Excitation Transformer Room (5~8) Cutting of 2 protruding pipes from Excitation Transformer Room (5~8) Cutting of 1 earthing strips from Excitation Transformer Room (5~8) Cutting of 2 protruding rebars from 12kv Switchgear Cubical Room Block 1 Cutting of 2 earthing strips from 12kv Switchgear Cubical Room Block 1 Cutting of 12 protruding rebars from 12kv Switchgear Cubical Room Block 2 Cutting of 2 earthing strips from 12kv Switchgear Cubical Room Block 2 Cutting of 7 protruding rebars from 12kv Switchgear Cubical Room Block 3 Cutting of 6 earthing strips from 12kv Switchgear Cubical Room Block 3 Cutting of 9 protruding rebars from 12kv Switchgear Cubical Room Block 4 Cutting of 4 earthing strips from 12kv Switchgear Cubical Room Block 4 Cutting of 1 protruding rebars from Station Service Transformer Room (Transformer No. 1&2) Cutting of 1 earthing strips from Station Service Transformer Room (Transformer No. 1&2) Cutting of 11 protruding rebars from Station Service Transformer Room (Transformer No. 3&4) Cutting of 7 protruding rebars from Station Service Transformer Room (Transformer No. 5) Cutting of 2 protruding pipes from Station Service Transformer Room (Transformer No. 5) Cutting of 2 earthing strips from Station Service Transformer Room (Transformer No. 5) Cutting of 47 protruding rebars from 0.4 kv Switchgear Cubical Room Cutting of 31 earthing strips from 0.4 kv Switchgear Cubical Room

Page 4 of 10

General Cleaning of Auxiliary Powerhouse

WATER TREATMENT ROOM Cutting of 16 protruding pipe fitting supports from Water Treatment Room at El. 203.5 m Cutting of 19 protruding rebars from Water Treatment Room at El. 203.5 m Cutting of 11 earthing strips from Water Treatment Room at El. 203.5 m Levelling of steel mesh covers of pipe ducts to adjacent floor

COOLING WATER SUPPLY GALLERY Cutting of 14 protruding rebars from staircases of Cooling Water Supply Gallery near Lift Repair of uneven floor surfaces of Cooling Water Supply Gallery Grinding of formwork impressions on upstream and downstream walls of Cooling Water Supply Gallery Cutting of 47 protruding rebars from Cooling Water Supply Gallery at El. 205.5 m Cutting of 5 protruding pipes from Cooling Water Supply Gallery at El. 205.5 m Cutting of 4 earthing strips from Cooling Water Supply Gallery at El. 205.5 m Proper filling around 16 air grills on upstream and downstream walls of Cooling Water Supply Gallery Proper filling of expansion joints of Cooling Water Supply Gallery at El. 205.5 m

UPSTREAM OF POWERHOUSE Cutting of 3 protruding rebars from top face of upstream wave wall of Powerhouse at El. 216.4 m Cutting of 11 protruding rebars from upstream of Powerhouse at El. 215 m Cutting of protruding pipe from upstream of Powerhouse at El. 215 m Placement of covers of LDs (vertical displacement benchmark) at upstream and downstream of Powerhouse Repair of vertical joints at outside of upstream Powerhouse wall between monoliths above El. 215 m Cutting of protruding metal strip along upstream wall of Powerhouse at El. 215 m Proper filling between expansion joint of monoliths at upstream of Powerhouse at El. 215 m Treatment of 3 diagonal cracks on upstream, right side wave wall of Powerhouse Treatment of cracks near start of Trash Rack Cleaning Machine Rail Grinding of plastering surface at upstream left side retaining wall to make smooth Rain water drainage arrangement along upstream side of upstream Powerhouse wall and upstream wave wall at El. 215 m General cleaning of upstream of Powerhouse

DOWNSTREAM OF POWERHOUSE Cutting of 24 protruding rebars from downstream of Powerhouse at El. 215 m Cutting of 5 protruding earthing strips from downstream of Powerhouse at El. 215 m Cutting of 3 protruding girders from downstream of Powerhouse at El. 215 m Drainage ditches under the downstream gantry crane rail need proper finishing

Page 5 of 10

Scaffolding holes at downstream wall of Powerhouse are roughly filled need grinding Repair of vertical joints at outside of downstream Powerhouse wall between monoliths above El. 215 m Treatment of expansion joints at downstream floor of Powerhouse at El. 215m to stop leakage of rain water down to local control unit rooms at El. 209.4 Treatment of cracks at floor at El. 215 m in front of downstream wall of Central Control Building Treatment of cracks at outer face of downstream wall of Central Control Building Treatment of cracks between Beams, Columns and plastered brick masonry portions at outer face of downstream wall of Powerhouse Proper filling of expansion joint in front of downstream wall of Central Control Building Rectification of settled floor in front of downstream wall of Central Control Building Rectification of skirting along outside of right wall of Central Control Building Rectification of skirting along outside face of downstream wall of Powerhouse Treatment of 4 cracks along expansion joints of monoliths at downstream floor of Powerhouse at El. +215 m Treatment of 16 minor cracks at downstream floor of Powerhouse at El. + 215 m Proper stairs to the top of Powerhouse

RIGHT SIDE OF POWERHOUSE Filling and levelling of gravel material around the patches of cable trenches Repair of plinth protection at downstream side of diesel generator room Repair of plaster at top right side corner of transformer oil treatment room

LEFT SIDE OF POWERHOUSE Cutting of 4 protruding bolts and 4 nails at outside of Powerhouse left side wall Cutting of rebar at outer face of control building left side wall Cutting of protruding bolt from outer face of left side wall of Central Control Building Alignment of 38 expansion joints of pavement panels between main gate and Powerhouse entrance

BOUNDARY WALL OF POWERHOUSE Filling of 3 holes in downstream side of Powerhouse boundary wall Repair of cracks over the expansion joints between monoliths in downstream side of Powerhouse boundary wall Repair of horizontal crack in front of downstream wall of Central Control Building Repair of 2 vertical cracks in switchyard side boundary wall near cable trench of Powerhouse

SWITCHYARD Bent up rebars to be straightened Switchyard gate to be improved to stop entry of animals like dogs and cats Repair of vertical crack at left side wall of switchyard boundary wall Filling of hole at left side wall of switchyard boundary wall

Page 6 of 10

CABLE TRENCH Repair of cracks in cable trench of switchyard Repair of damaged concrete slabs of cable trench Repair of side wall of cable trench near downstream boundary wall

TAILRACE WORKING BRIDGE Rectification of settled and cracked approach slabs at right side of Tailrace Working Bridge

CONTROL & OFFICE BUILDING

Ground Floor of Central Control Building EL. 215 m

Corridor Replacement of 3 defective panels of false ceiling outside of Operation Engineer Office Replacement of 12 cracked floor tiles in corridor at El. 215 m Replacement of 3 cracked floor tiles near main exit door Provision of proper cover around pipes carrying cables to Power Supply Box Proper filling between skirting tiles and floor tiles Rectification of damaged skirting tiles along upstream and downstream walls of corridor Filling of hole around pipe carrying cables for fire alarm system outside Central Control Room Treatment of vertical crack near Power Supply Box Filling of gap in roof around pipes carrying cables from Power Supply box Cutting of protruding pipe from upstream wall of corridor Filling of empty power socket at upstream wall of corridor Finishing of floor tiles in corridor in front of Central Control Room Repair of broken edges of tiles at entrance of Central Control Room Re-fixing of skirting tiles in corridor to maintain uniform thickness along the wall Doors of Central Control building are substandard need to be replaced Installation of good quality lock in exit door in corridor Repair of damaged plaster around fire hydrant between toilets and lift entrance Replacement of defective door closure of entrance door of Central Control Room Treatment of entrance wall vertical crack at corner of right side wall of central control building and lift

Treatment of vertical crack at corner of right side wall of central control building and wall in front of lift entrance (upstream)

Central Control Room Treatment of vertical crack at right side wall Finishing and painting of plaster patch near right downstream corner Proper filling between skirting tiles and antistatic floor tiles Replacement of 9 cracked antistatic floor panels Alignment of sliding panel of one window in Central Control Room Filling of empty power socket at downstream wall

Page 7 of 10

Filling of opening at left side wall of Central Control Room Proper covering of gaps around electrical panels Painting of dirty patches of walls of Central Control Room

Computer Room Replacement of 30 cracked antistatic floor panels Proper filling between skirting tiles and antistatic floor tiles Proper covering of gaps around electrical panels Proper covering of gap around cable tray at floor and roof level Cutting of protruding earthing strip near exit door Painting of dirty patches of walls of Computer Room Painting of dirty patches of walls of Computer Room Rectification of damaged skirting tile near exit door

Operation Engineer Office Filling of opening at left wall of Operation Engineer Office Filling of opening at upstream wall of Operation Engineer Office Filling of 2 openings around cables at floor of Operation Engineer Office at El. 215 m Painting of dirty patches of walls of Operation Engineer Office

Toilets Replacement of defective tap of wash basin Proper drainage of wash basin to avoid standing of water Proper drainage measures in toilets to avoid standing of water Painting the walls of Toilets where tiles are not fixed Fixing of cover on drainage hole in water sump Fixing of tiles at bottom of water sump Treatment of electric cables near water sump Cleaning of toilets

First Floor of Central Control Building

Corridor Installation of 3 panels of false ceiling outside of battery room Replacement of 3 defective panels of false ceiling outside of battery room Proper sealing around fire hydrant pipe in front of battery room Fixing of floor tile around fire hydrant pipe opening Replacement of 3 cracked floor tiles outside of battery room Replacement of 3 cracked floor tiles near main exit door

Page 8 of 10

Replacement of 5 cracked floor tiles outside of power supply room Replacement of cracked floor tile near power supply room having hole Replacement of 5 cracked floor tiles outside of communication room Replacement of cracked floor tile outside of toilets Replacement of 2 cracked floor tiles outside of lift opening Provision of proper cover around pipes carrying cables to inspection power box in front of communication room Painting on wall behind pipe in front of power supply room and straightening of the pipe Proper filling between skirting tiles and floor tiles Repair of plaster at inside wall of corridor near exit door Treatment of vertical crack between exit door wall and left side wall of central control building Treatment of 2 vertical cracks at outside wall of battery room Filling of holes and repair of damaged plaster at outside wall of battery room Cleaning of foot print marks from corridor wall Treatment of vertical crack between battery room and power supply room Filling of hole around pipe carrying cables for fire alarm system outside power supply room Filling of 2 vertical cracks between power supply room and communication room Treatment of damaged plaster around inspection power box Treatment of horizontal crack on wall in front of communication room Treatment of 2 vertical cracks between communication room and toilets Treatment of horizontal and vertical cracks on wall in front of toilets (upstream) and lift opening Treatment of 2 vertical cracks between right side wall of central control building and lift entrance Treatment of entrance wall vertical crack at corner of right side wall of central control building and lift

Treatment of vertical crack at corner of right side wall of central control building and wall in front of lift entrance (upstream) Repair of damaged plaster around fire hydrant between toilets and lift entrance Fixing of bottom cover of 4 ceiling lights in corridor Cleaning of spider webs from corridor Stopping entry of rats to avoid accumulation of dung Cleaning of stains from tiles of corridor General cleaning of corridor

Communication Room Fixing of missed skirting tile at entrance of communication room Proper filling between skirting tiles and antistatic floor tiles Proper filling around power switch boards Cleaning of foot marks from communication room walls Painting of cement sand mortar patches provided to fill openings around AC plant pipes

Page 9 of 10

Painting of cement sand mortar patch provided to fill exhaust fan opening Replacement of 106 cracked antistatic floor panels Proper covering of gaps around electrical panels Cleaning of spider webs

Power Supply Panel Room Replacement of all cracked antistatic floor panels Proper covering of gaps around electrical panels Painting of cement sand mortar patches Proper filling between skirting tiles and antistatic floor tiles

Toilets Proper filling of holes at bottom and top of fire hydrant pipe and fixing of tile around pipe carrying water to corridor Fixing of tap cap of wash basin Provision of water supply connection to wash basin Fixing of cover on drainage hole in water sump Fixing of tiles at bottom of water sump Treatment of electric cables near water sump Fixing of 4 bottom covers of ceiling lights Provision of water connection in toilets Filling around holes carrying water supply pipes in toilets room Cleaning of toilets

Note:Elimination of all protruding rebars, pipes, beams and anchoring bolts etc., must be done below the concrete surface and the resulting hole properly finished. Grinding of formwork impressions must be done properly to create smooth surface.

Page 10 of 10

You might also like

- A Qac Pro 000 38951Document30 pagesA Qac Pro 000 38951Amin GNo ratings yet

- 5 Formwork ChecklistDocument81 pages5 Formwork ChecklistAlphaNo ratings yet

- Installation of LV Cables: Inspection and Test Plan ForDocument1 pageInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNo ratings yet

- Sp3-3 - Reinforced Concrete SpecDocument11 pagesSp3-3 - Reinforced Concrete SpecJon WadsworthNo ratings yet

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- Cracking Concrete SurfacesDocument2 pagesCracking Concrete SurfacesCivilEngClubNo ratings yet

- Inspection & Test Plan (Itp) : Road WorkDocument1 pageInspection & Test Plan (Itp) : Road WorkLOPA THANDARNo ratings yet

- Method Statement For Electrcial Work Construc1Document69 pagesMethod Statement For Electrcial Work Construc1herene7621No ratings yet

- QM Plan ProcedureDocument13 pagesQM Plan ProcedureHans JonesNo ratings yet

- Module 9. Soil Foundation Materials and Types of FoundationsDocument7 pagesModule 9. Soil Foundation Materials and Types of Foundationslester aceNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- CEMENT PLASTERING CHECKLISTDocument1 pageCEMENT PLASTERING CHECKLISTsankuj5354No ratings yet

- QC Check Sheet for Earthworks ExcavationDocument1 pageQC Check Sheet for Earthworks ExcavationPrasanna KumarNo ratings yet

- Bangsar Rising - M&E ChecklistDocument13 pagesBangsar Rising - M&E ChecklistchanjunkaiNo ratings yet

- Concrete Post-Pour Inspection ReportDocument1 pageConcrete Post-Pour Inspection ReportKamal FitriNo ratings yet

- Basement Floor Screed ConcreteDocument5 pagesBasement Floor Screed ConcreteQAQC NandanamNo ratings yet

- Block Masonary Work: Method StatementDocument5 pagesBlock Masonary Work: Method StatementAneel KumarNo ratings yet

- Quality Control Inspection Checklist: Gamuda BerhadDocument2 pagesQuality Control Inspection Checklist: Gamuda BerhadSyerifaizal Hj. MustaphaNo ratings yet

- MS Site and FenceDocument11 pagesMS Site and FenceSahabzada AamirNo ratings yet

- Quality Control - Works Inspection: Glazed DoorsDocument1 pageQuality Control - Works Inspection: Glazed DoorsParasNo ratings yet

- ColumnDocument2 pagesColumnUday Kumar Das100% (1)

- Itp For Gravel Surfacing and Dust PreventionDocument7 pagesItp For Gravel Surfacing and Dust PreventionShewale PravinNo ratings yet

- Structural Steel Work Check ListDocument1 pageStructural Steel Work Check ListAhmad Bilal100% (1)

- PC-ITP-001 - Backfilling and ExcavationDocument2 pagesPC-ITP-001 - Backfilling and ExcavationHusam zayedNo ratings yet

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- Checklist For Excavation & Backfilling WorkDocument2 pagesChecklist For Excavation & Backfilling WorkHimanshu ChaudharyNo ratings yet

- Water Proofing SpecificationDocument1 pageWater Proofing Specificationprabhu81No ratings yet

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호No ratings yet

- PQP Flow ChartDocument1 pagePQP Flow ChartFIRMANSYAHNo ratings yet

- Method Statement Embankment: 1. GeneralDocument11 pagesMethod Statement Embankment: 1. GeneralReny AkmaliaNo ratings yet

- Termite Treatment ChecklistDocument4 pagesTermite Treatment ChecklistMd.Naimur rahaman juelNo ratings yet

- Check List For Block Brick WorkDocument4 pagesCheck List For Block Brick Workvenugopal mvvNo ratings yet

- 10.method Statement Piling WorkDocument6 pages10.method Statement Piling Workشاز إياسNo ratings yet

- Focus Dimension Target Purpose Action Persons Involve Estimate Budget Time Frame Production ResultsDocument4 pagesFocus Dimension Target Purpose Action Persons Involve Estimate Budget Time Frame Production ResultsEsh YoNo ratings yet

- Construction Method Statement PDFDocument22 pagesConstruction Method Statement PDFFaruk AtalarNo ratings yet

- Crystalline waterproofing for concrete structuresDocument2 pagesCrystalline waterproofing for concrete structuresRuel Buntog100% (1)

- Elcometer 456 User Manual PDFDocument76 pagesElcometer 456 User Manual PDFchaparal100% (1)

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- Bill of Quantities (BOQ)Document1 pageBill of Quantities (BOQ)Azil14No ratings yet

- Method Statement of Mass Concrete Block Precast WorksDocument41 pagesMethod Statement of Mass Concrete Block Precast WorksShams JogNo ratings yet

- Lavatex 2000...Document2 pagesLavatex 2000...ArifNo ratings yet

- Itp For U-G2Document7 pagesItp For U-G2Ramzi MusthafaNo ratings yet

- Building InspectionsDocument2 pagesBuilding InspectionsSuresh DevarajanNo ratings yet

- 01 - Codes ListDocument6 pages01 - Codes ListSanthoshKumarSharmaCHNo ratings yet

- Hollow Core Slab PDFDocument4 pagesHollow Core Slab PDFStraus WaseemNo ratings yet

- 11a Checklist For Tiling (Floor) AlfredoDocument1 page11a Checklist For Tiling (Floor) AlfredoalfieNo ratings yet

- Methodology For Convreting WorksDocument7 pagesMethodology For Convreting WorksLokesh SaranNo ratings yet

- Concrete Pre Pour Planning For Civil ProjectsDocument6 pagesConcrete Pre Pour Planning For Civil ProjectshemantrulzNo ratings yet

- Raft foundation guideDocument7 pagesRaft foundation guide18 FAISAL SHAH100% (1)

- Fire Fighting PipesDocument1 pageFire Fighting PipesMIDHUN RAJNo ratings yet

- Skid Mounted Unit InstallationDocument2 pagesSkid Mounted Unit Installationric leonisoNo ratings yet

- High Strength Epoxy Bonding Agent CICO BOND EPODocument2 pagesHigh Strength Epoxy Bonding Agent CICO BOND EPOPraveenk000No ratings yet

- NUI PHAO MINING BRICK WALL INSPECTIONDocument1 pageNUI PHAO MINING BRICK WALL INSPECTIONHongducBuiNo ratings yet

- 005-Sample Method Statement CivilDocument2 pages005-Sample Method Statement CivilS.C.Satish Chander100% (1)

- PENDING PUNCH POINTS FOR SUBSTATIONDocument3 pagesPENDING PUNCH POINTS FOR SUBSTATIONshivendra singhNo ratings yet

- Fabrication and installation of offshore HVAC systemsDocument5 pagesFabrication and installation of offshore HVAC systemsAli Aimran100% (1)

- Equipment Erection and Alignment in Vertical and Horizontal Furnace SectionsDocument138 pagesEquipment Erection and Alignment in Vertical and Horizontal Furnace SectionsPA PROJECTS PVT LTDNo ratings yet

- Bill of MaterialsDocument7 pagesBill of MaterialsTerancen RajuNo ratings yet

- 002 Surah Baqarah - Tafheem Ul Quran (Urdu)Document183 pages002 Surah Baqarah - Tafheem Ul Quran (Urdu)Truthfinder20000% (1)

- 10 25 APP STDocument29 pages10 25 APP STAzam Islam KhanNo ratings yet

- FIDIC Conditions of Contract For Construction, Vesion 1999Document15 pagesFIDIC Conditions of Contract For Construction, Vesion 1999Azam Islam KhanNo ratings yet

- Indus Waters Treaty 1960-India & PakistanDocument24 pagesIndus Waters Treaty 1960-India & PakistanSampath BulusuNo ratings yet

- Push for lifeDocument22 pagesPush for lifeAzam Islam KhanNo ratings yet

- PC 1Document2 pagesPC 1Azam Islam KhanNo ratings yet

- The Law of Contract in PakistanDocument9 pagesThe Law of Contract in PakistanFarhan ShariffNo ratings yet

- STAAD Truss Analysis Job Information and Member PropertiesDocument1 pageSTAAD Truss Analysis Job Information and Member PropertiesAzam Islam KhanNo ratings yet

- Pakistan LawDocument3 pagesPakistan LawAzam Islam KhanNo ratings yet

- The Law of Contract in PakistanDocument9 pagesThe Law of Contract in PakistanFarhan ShariffNo ratings yet

- Indus Basin TreatyaaDocument11 pagesIndus Basin TreatyaaAzam Islam KhanNo ratings yet

- Detailed Design Calculations of 132kv Transformer Foundation 1Document9 pagesDetailed Design Calculations of 132kv Transformer Foundation 1Azam Islam Khan100% (3)

- Glorify The Islamic CivilizationDocument1 pageGlorify The Islamic CivilizationAzam Islam KhanNo ratings yet

- Design of Structures and Foundations For Vibrating Machines PDFDocument39 pagesDesign of Structures and Foundations For Vibrating Machines PDFsaputrafrandy_958992No ratings yet

- Design Steps For FootingDocument1 pageDesign Steps For FootingAzam Islam KhanNo ratings yet

- Design Steps For FootingDocument1 pageDesign Steps For FootingAzam Islam KhanNo ratings yet

- Design Steps For FootingDocument1 pageDesign Steps For FootingAzam Islam KhanNo ratings yet

- Glorify The Islamic CivilizationDocument1 pageGlorify The Islamic CivilizationAzam Islam KhanNo ratings yet

- English Al-IslamDocument31 pagesEnglish Al-IslamAzam Islam KhanNo ratings yet

- Strip FootingDocument10 pagesStrip FootingAzam Islam KhanNo ratings yet

- Glorify The Islamic CivilizationDocument1 pageGlorify The Islamic CivilizationAzam Islam KhanNo ratings yet

- Basis of Structural Design: Course 3 Structural Action: Trusses and BeamsDocument15 pagesBasis of Structural Design: Course 3 Structural Action: Trusses and BeamsCristian BlanaruNo ratings yet

- Tips and Tricks For Using STAADDocument13 pagesTips and Tricks For Using STAADAzam Islam KhanNo ratings yet

- Rational Surface Water ManagementDocument67 pagesRational Surface Water ManagementAzam Islam KhanNo ratings yet

- Housner GW 1954Document42 pagesHousner GW 1954Carlos RoblesNo ratings yet

- Civil and Structura 116850aDocument10 pagesCivil and Structura 116850aSiva SenthilNo ratings yet

- Bermuda TriangleDocument3 pagesBermuda TriangleAzam Islam KhanNo ratings yet

- Tips and Tricks For Using STAADDocument13 pagesTips and Tricks For Using STAADAzam Islam KhanNo ratings yet

- Tips and Tricks For Using STAADDocument13 pagesTips and Tricks For Using STAADAzam Islam KhanNo ratings yet

- YEZ-Conical Brake MotorDocument3 pagesYEZ-Conical Brake MotorMech MallNo ratings yet

- Basicline BL 21t9stDocument28 pagesBasicline BL 21t9stgabriel6276No ratings yet

- Value-Instruments Cat2012 enDocument58 pagesValue-Instruments Cat2012 enAnonymous C6Vaod9No ratings yet

- 3P61 Service Manual PDFDocument17 pages3P61 Service Manual PDFgulaab786No ratings yet

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDocument5 pagesSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)

- Disney Channel JRDocument14 pagesDisney Channel JRJonna Parane TrongcosoNo ratings yet

- Allcargo Corporate BrochureDocument12 pagesAllcargo Corporate BrochureallinonecargologisticsNo ratings yet

- Transmission ImpairmentsDocument49 pagesTransmission ImpairmentsLaurentiuStanciuNo ratings yet

- CAT775GDocument32 pagesCAT775GAndy Chan100% (1)

- P108Document1 pageP108teban09No ratings yet

- Module 8 SAHITA ConcreteDocument11 pagesModule 8 SAHITA ConcreteHarrybfnNo ratings yet

- Axial Shortening of Column in Tall Structure.Document9 pagesAxial Shortening of Column in Tall Structure.P.K.Mallick100% (1)

- HT Series: 73-136Kw I Up To 12 Mppts Three PhaseDocument2 pagesHT Series: 73-136Kw I Up To 12 Mppts Three PhasesyamprasadNo ratings yet

- Factors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDDocument70 pagesFactors Affecting Purchase Intentions in Generation Z Towards Hipster Cafe in Kelantan LOCKEDlassan199358No ratings yet

- 4c - Expanded - RevisedDocument132 pages4c - Expanded - RevisedMartín Serena75% (4)

- Dsd-060 Earthquake Shutdown Unit: DescriptionDocument2 pagesDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifNo ratings yet

- Advanced Excel FormulasDocument25 pagesAdvanced Excel Formulasskmohit singhalNo ratings yet

- Template Icme 13 PosterDocument1 pageTemplate Icme 13 PosterZulma Xiomara Rueda GarciaNo ratings yet

- Panasonic WJ FS616Document62 pagesPanasonic WJ FS616triliteNo ratings yet

- Recovering Valuable Metals From Recycled Photovoltaic ModulesDocument12 pagesRecovering Valuable Metals From Recycled Photovoltaic ModulesNguyễn TriếtNo ratings yet

- Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesDocument3 pagesMobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 Series Mobil Pegasus™ 1100 SeriesMudabbir Shan AhmedNo ratings yet

- Auto BestBuys MAKATI CITY September ListingDocument5 pagesAuto BestBuys MAKATI CITY September ListingWill GeronaNo ratings yet

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- Presentation On BAJAJDocument19 pagesPresentation On BAJAJVaibhav AgarwalNo ratings yet

- Process Thermodynamic Steam Trap PDFDocument9 pagesProcess Thermodynamic Steam Trap PDFhirenkumar patelNo ratings yet

- Pink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalDocument28 pagesPink Fun Doodles and Blobs Math Online Class Creative Presentation SlidesCarnivalraine castorNo ratings yet

- Strength of A440 Steel Joints Connected With A325 Bolts PublicatDocument52 pagesStrength of A440 Steel Joints Connected With A325 Bolts Publicathal9000_mark1No ratings yet

- Method of MomentsDocument114 pagesMethod of MomentsankladhaNo ratings yet

- UFED Solutions Brochure WebDocument4 pagesUFED Solutions Brochure Webwilly irawanNo ratings yet

- # 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilDocument3 pages# 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilPrakash KumarNo ratings yet