Professional Documents

Culture Documents

SAP WM Fundamentals Course Overview

Uploaded by

Ram KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAP WM Fundamentals Course Overview

Uploaded by

Ram KumarCopyright:

Available Formats

Think Tree Technologies, Inc

SAP Warehouse Management

By Dilip K Sadh

Think Tree Technologies, Inc

Dilip K Sadh

Course Prerequisites

SAP Functional Knowledge Overview of Inventory Management Processes Overview of Logistics Execution Processes

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

Course Goals

Understand the basic functions of SAP Warehouse Management (WM) Module e. g. Putaway, Picking and Posting Changes etc. Understand the basic configuration required to configure Warehouse Management functions as per companys requirements. Understand the integration between Inventory Management, Production Processing. Warehouse Management, Planning and Delivery

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

4 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

Understand the Logistics Execution Model Understand basic logistics Execution Processes

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Logistics Execution Process Overview

Vendor Customer

Vendors Warehouse

Distribution Center

Company Warehouse Outbound Inbound Production Plant

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Logistics Execution Integration Process

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Logistics Execution Elements

Logistics LogisticsExecution Execution

Warehouse WarehouseManagement Management

Shipping Shipping

Transportation Transportation

Materials MaterialsManagement Management

Sales Salesand andDistribution Distribution

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: WM Processes in LE

Logistics LogisticsExecution Execution

Inbound Inbound(GR) (GR)

For For Inbound InboundDelivery Delivery Inbound InboundDelivery Delivery Transfer TransferOrder Order Creation Creation Transfer TransferOrder Order Confirmation Confirmation Goods GoodsReceipt Receipt Posting Posting

10

Outbound Outbound(GI) (GI)

For For Outbound Outbound Delivery Outbound OutboundDelivery Delivery Delivery Outbound Outbound Delivery Delivery Transfer TransferOrder Order Creation Creation Transfer TransferOrder Order Confirmation Confirmation Goods GoodsIssue Issue Posting Posting For For Other For ForOther Other Other Transactions Transactions Transactions Transactions Goods GoodsIssue Issue Posting Posting Transfer Transfer Requirement Requirement Transfer TransferOrder Order Transfer TransferOrder Order Confirmation Confirmation

For ForPO, PO,Order Orderand and Other Transactions Other Transactions Goods GoodsReceipt Receipt Posting Posting Transfer Transfer Requirement Requirement Transfer TransferOrder Order Transfer TransferOrder Order Confirmation Confirmation

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Overview to Logistics Execution- Review

The Logistics Execution System covers shipping, goods issue, placing in storage, inbound and outbound transportation processes. The logistics processes include following sub processes:

Sales order processing for goods issues Ordering (purchase order processing) for goods receipts (external procurement) Goods movement process for internal procurement Physically moving goods in the supply chain

11

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

12

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

Understand basic functions of Warehouse Managements. Integration of Warehouse Management with other modules of Logistics Understand how WM handles various types of Inbound and Outbound Goods Movements Knowledge of Information contained in various WM Documents

13

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Warehouse Management Basic Functions

14

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: WM Integration with Other Components

Production ProductionSupply Supply Human HumanResources Resources

Inventory InventoryManagement Management (MM) (MM)

Warehouse Management

Quality Quality Management Management

Shipping Shipping

Delivery DeliveryProcessing Processing (SD) (SD) Remote RemoteData Data Processing Processing

15

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Goods Receipt without ASN - Process in WM

Inventory Management Warehouse Management

Goods Receipt

Transfer Requirement Quant in GR Area

Transfer Order

GR GRArea Area

Confirmation/Differences

Warehouse Warehouse

Transfer to Storage

16 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Goods Receipt with ASN - Process in WM

ERP/IM Warehouse Management

ASN

Transfer Order Creation

Putaway with TO Confirmation -ve Quant in GR Area

GR GRArea Area

GR Posting

Posting of +ve Quant In GR Area

Warehouse Warehouse

Transfer to Storage

17

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Goods Issue for Delivery - Process in WM

Warehouse Warehouse

ERP/IM Warehouse Management

Delivery

Transfer Order Creation

Picking with TO Confirmation +ve Quant in GI Area GI Posting

Transfer from Storage

Posting of ve Quant In GI Area

GI GIArea Area

18

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Other Goods Issue - Process in WM

Warehouse Warehouse

Inventory Management Warehouse Management

Goods Issue

Transfer Requirement Quant in GR Area

Transfer Order

Transfer from Storage

Confirmation/Differences

Common CommonArea Area

19

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Information Contained in a TR

20

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Information Contained in a TO

21

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: WM as a part of LE- Review

Warehouse Management is an integral part of Logistics Execution which controls the goods movement in and out of the companys warehouse Warehouse Management provides various functionalities like stock management to bin level, planning and monitoring tools, control of goods movements, integration with other warehouse control units available. All goods movements (Inbound / Outbound) results in a WM transaction in SAP System. WM transaction can happen before IM transaction or vice versa depending on the type of goods movement in SAP. Transfer Order is created to record the actual movement of goods within the warehouse.

22

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

23

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

24

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Scenarios for WM Implementation

25

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Scenarios for WM Implementation - Review

26

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

27

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

Understand basic organization structure of Warehouse Managements. Understand various possible warehouse structure scenarios of Warehouse Management Understand various controls to be defined while defining Warehouse Managements Organization Elements. Understand the Master data used in warehouse Management Describe the characteristics and Importance of Quant in WM

28

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM WM Organization Structure Elements

Organizational Units

-

Possible Warehouse Organization Structure Scenarios

Master Data Organizational Connection to IM Quant

29

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Organization Structure of a Warehouse in SAP

Plant Plant Storage StorageLocation Location

Configuration

Warehouse Warehouse

Storage StorageType Type

Storage StorageSection/ Section/ Picking PickingArea Area Storage StorageSection/ Section/ Picking PickingArea Area

Storage StorageType Type

Storage StorageSection/ Section/ Picking PickingArea Area Storage StorageSection/ Section/ Picking PickingArea Area

Master Data

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

30

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: A Typical Warehouse Complex

GR GRArea Area

Goods Receipt

High HighRack RackStorage Storage

Bulk BulkStorage Storage

Goods Receipt

Issue IssueArea Area

Goods Issue

Fixed FixedBin BinStorage Storage

31

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Organizational Connection to IM - Customizing

Warehouse PLANT PLANT Storage StorageLocation Location Number

Definition

Assignment

32

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Organization Structure - Warehouse

33

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Organization Structure - Storage Type

34

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Organization Structure Other Org Elements

Warehouse

Door

Staging Area

GR/GI

35

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Possible Warehouse Structure Scenarios

Scenario 1: Inventory Management w/o Warehouse Management Scenario 2: One Storage Location per Plant in One Warehouse Scenario 3: One Warehouse for different Plants under different Companies Scenario 4: Several Storage Locations per Plant in One Warehouse Number

36

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : WM Organization Structure Master Data

Warehouse Warehouse

Storage StorageType Type

Storage StorageSection/ Section/ Picking PickingArea Area Storage StorageSection/ Section/ Picking PickingArea Area

Storage StorageType Type

Storage StorageSection/ Section/ Picking PickingArea Area Storage StorageSection/ Section/ Picking PickingArea Area

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage Bin Type High Bin

Storage Bin Type Low Bin

37

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Storage Bin Structure for Automatic Creation

38

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Storage Bin Data

39

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Quant Where is it placed in WM

Storage StorageType Type

Storage StorageSection/ Section/ Picking PickingArea Area

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage Bin Type High Bin

Storage Bin Type Low Bin Quant Quant

Quant Characteristics

Material Number Stock type or Category Special Stock Assignment Plant and Storage location Batch Number, if applicable

40 SAP WM Fundamentals- | 12/25/2011

Quant Quant

Quant Quant

Think Tree Technologies, Inc

Dilip K Sadh

WM : Material Master Data relevant to WM

41

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Quant Data Details

Material Number Stock type or Category Special Stock Assignment Plant and Storage location Batch Number, if applicable

42

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: WM Organization Structure - Review

Warehouse, Storage Type, Storage Section/Picking Organizational elements of Warehouse Management. Area are

Warehouse Management can be used for a number of different scenarios in terms of physical warehouse structures Master data in Customizing for Warehouse and Storage Type provides number of control functions for various activities in the warehouse. Storage Bin is not a Organization Element of Warehouse Management, but it is master which can be created manually or automatically using templates defined in the Customizing. Quant is the lowest level at which material is maintained in a warehouse. Material movement within warehouse happen in terms of quant.

43

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

44

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

Understand the Key Integration Points between IM and Warehouse Management Understand how Movement type in WM are determined by IM Movement type. Understand the process flow of Goods Movement at IM-WM Interface

45

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : WMs Integration with IM

Integration at Enterprise Structure Level Movement Type Interim Storage Area- Interface

46

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Integration at Enterprise Structure Level

Warehouse PLANT PLANT Storage StorageLocation Location Number

47

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Movement Type

IM Movement Type

Reference Movement Type

WM Movement Type

48

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Movement Type

49

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Movement Type

50

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: WMs Interface with IM - Review

Interface between Inventory Management and Warehouse Management happens whenever there is any Inventory Management Movement which affects data in Warehouse Management.

-

IM WM Interface dont come into picture for internal warehouse goods movements

Enterprise structure definition and assignments are the integration points at first level for setting up IM- WM Integration Movement type is the second level at which IM is integrated to WM Interim Storage Areas act as interface between IM and WM.

-

In other words we can say, Interim storage areas act as bridge between IM and WM.

51

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

52

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM Course Goals

Understand the inbound process with various controls in putting the material in the warehouse Understand various types of stock placement strategies and their functioning Understand and define storage type search followed by storage section and ultimately ending on Storage bin search. Understand the capacity check function during putaway process. Understand various configuration activities for stock putaway Understand handling of differences during putaway process

53

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Inbound Process with Putaway Control

Stock Placement - Overview Type of Putaway Putaway Controls

-

Controls in Storage Type Storage Type Indicator Storage Type Search Sequence Storage Section Search Sequence Control using Storage Unit Type and Storage Bin Type Special Movement Indicator

Putaway Strategies Capacity Check function during Putaway Handling differences during Putaway Process

54

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Stock Placement - Overview

Stock Placement or Goods Receipt Process

-

GR Process is the inbound movement of materials into the warehouse. These movements results as a part of Goods Receipt from an external vendor or from in house production

Types of Goods Receipt Processes Supported in WM

-

GR with reference to a PO GR with reference to a Production Order GR with reference to a delivery GR without any reference( Other receipts)

55

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Types of Putaway

Putaway w/o Sort Variable

02-01-03 01-01-03 01-02-03 03-01-03 03-02-03 03-03-03 3 02-03-03 3-0 02-02-03 0 03 3 0 01-03-03 3 2-0 0 3 3-0 0 - 02 01 3 01-03-03 0 03 2 0 32-0 0 -02 -01 3 3 0 0 01-03-02 01 03 1 0 - 03 2 0 -01 3 -0 01 03

01-01-03

01-02-03

Level 01 to 03

01-01-02

01-02-02

01-01-01

01-02-01

01-03-01

Stack 01 to 03

Cross Line Putaway

01 e l Ais

to

IMG

56

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Storage Type Controls during Putaway

57

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Control Storage Type Indicator

Consider Type Indicator

Consider Stock Category

Consider Special Stock

58

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Control Storage Type Search Sequence

59

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM: Putaway Control Storage Location Control

60

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Control Storage Section Search Sequence

61

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Control Using Storage Unit Type

62

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Control Special Movement Indicator

63

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Strategies- Searching Storage Bins (1)

Fixed bin (F) Open storage (C) Addition to existing stock (I) Next empty bin (L) Near picking bin (K) Pallets/storage unit type (P) Bulk storage (B) Manual Bin User Exit MWMTO003

64

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Strategies- Searching Storage Bins (2)

Fixed bin (F) Open storage (C) Addition to existing stock (I) Next empty bin (L) Near picking bin (K) Pallets/storage unit type (P) Bulk storage (B) Manual Bin User Exit MWMTO003

65

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Strategies- Searching Storage Bins (3)

Fixed bin (F) Open storage (C) Addition to existing stock (I) Next empty bin (L) Near picking bin (K) Pallets/storage unit type (P) Bulk storage (B) Manual Bin User Exit MWMTO003

66

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Putaway Strategies- Searching Storage Bins (4)

Fixed bin (F) Open storage (C) Addition to existing stock (I) Next empty bin (L) Near picking bin (K) Pallets/storage unit type (P) Bulk storage (B) Manual Bin User Exit MWMTO003

67

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Capacity Check function during Putaway

68

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Handling differences during Putaway Process

Differences can be directed to:

-

Source Storage bin of the movement type of the TO Item A dynamic coordinate (with Storage bin as TO Number) in the Interim storage area for differences A dynamic coordinate (with storage bin as Fixed bin Differences) in the interim storage area for differences.

69

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM : Inbound Process and Putaway Control - Review

Putaway process in Warehouse can happen either followed by a GR or an Inbound Delivery Cross line Putaway for storage bins, help in determine a predefined sequence of storage bin search as per custom logic for a storage type. The flow of search for a storage bin happens as follows

-

Step1: Storage Type Search Step2: Storage Section Search Step3: Storage Bin Search using various Putaway Strategies

Capacity check function is required to control /check the capacity of a storage bin while doing putaway activities While searching for storage bins during putaway, there are lot of control functions which provide lot of variety in searching for putting away a material into the warehouse.

70

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WM- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

71

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 Course Goals

Understand the Outbound process with various controls in picking the material in the warehouse Understand various types of stock removal strategies and their functioning Understand and define storage type search followed by picking area and ultimately ending on Storage bin search for picking activities. Understanding various configuration settings relevant to stock removal Understand handling of batches during stock removal process

72

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Outbound Process with Stock Removal Control

Stock removal Process- Overview Stock Removal Controls

-

Controls in Storage Type Storage Type Indicator Storage Type Search Sequence Storage Location Control Special Movement Indicator

Stock Removal Strategies Strategies Batch Management during Stock Removal Process

73

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Stock Removal Process - Overview

Stock Removal or Goods Issue Process

-

GI Process is an outbound movement of material from the warehouse , this outbound movement can be for internal use of material or can be a delivery to a customer

Types of GI Processes Supported

-

Goods Issues to a cost center or project or any other account assignment object Material staging for production Delivery of goods to customers

74

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Storage Type Controls during Stock Removal

75

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Stock Removal Control Storage Type Indicator

Consider Type Indicator

Consider Stock Category

Consider Special Stock

76

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07: Stock Removal Control Storage Type Search Sequence

77

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07: Stock Removal Control Storage Location Control

78

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Stock Removal Control Special Movement Indicator

79

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Removal Strategies- Searching Storage Bins (1)

First in first out (F) Stringent FIFO (***) Last in first out (L) Partial pallet quantity (A) Large/small quantities (M) Expiration date (H) Fixed bin (P) Enhancements MWMTO004 and MWMTO013

80

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Removal Strategies- Searching Storage Bins (2)

First in first out (F) Stringent FIFO (***) Last in first out (L) Partial pallet quantity (A) Large/small quantities (M) Expiration date (H) Fixed bin (P) Enhancements MWMTO004 and MWMTO013

81

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Removal Strategies- Searching Storage Bins (3)

First in first out (F) Stringent FIFO (***) Last in first out (L) Partial pallet quantity (A) Large/small quantities (M) Expiration date (H) Fixed bin (P) Enhancements MWMTO004 and MWMTO013

82

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Removal Strategies- Searching Storage Bins (4)

First in first out (F) Stringent FIFO (***) Last in first out (L) Partial pallet quantity (A) Large/small quantities (M) Expiration date (H) Fixed bin (P) Enhancements MWMTO004 and MWMTO013

83

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07 : Batch Management during Stock Removal

When to use Batch Determination in WM Batch Search in WM Batch Action in WM

84

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_07: WM : Outbound Processes and Stock Removal Control - Review Stock Removal process in Warehouse can happen either followed by a GI or an Outbound Delivery The flow of search for a storage bin happens as follows

-

Step1: Storage Type Search Step3: Storage Bin Search using various Stock Removal Strategies

While searching for storage bins during putaway, there are lot of control functions which provide lot of variety in searching for putting away a material into the warehouse. Summary (For Stock removal)

-

In movement type, the destination bin is available on the lines of Source Bin. Storage section dont come into picture here. Search Sequence is an important parameter to look for picking material On the lines of placement indicator, we have stock removal indicator in this case Destination Interim Storage Area is Determined using WM Mvt TypeReference Mvt typeIM Mvt type Settings

85

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

86 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 Course Goals

Understand the Putaway Process for an Inbound Delivery Understand the Stock Removal Process for an Outbound Delivery Understand the system requirements to enable automatic creation of Transfer orders from Inbound and Outbound Deliveries Understand the processing of returns from inbound and outbound deliveries Understand various options of processing outbound deliveries collectively. Two Step Picking Process

87

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Delivery Processes Using WM

Business Scenarios Inbound Delivery Process using WM

-

Additional Configurations Requirements

Outbound Delivery Process using WM

-

Collective Processing of Outbound Deliveries Two Step Picking

88

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Business Scenario

Inbound Delivery is used for GR Handling in WM, if:

-

Handling Units are required to be captured in the GR Process, because Handling Unit Management in GR Process is only possible through Inbound Delivery

In this situation, TO can be created either with reference to Inbound Delivery or Handling Unit.

Decentralized Warehouse Management System is Used.

89

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08: Inbound Delivery - Process in WM-IM

ERP/IM Warehouse Management

ASN

Transfer Order Creation

Picking with TO Confirmation -ve Quant in GR Area

GR GRArea Area

GR Posting

Posting of +ve Quant In GR Area

Warehouse Warehouse

Transfer to Storage

90

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Methods of TO Creation

Using Inbound Delivery Monitor Manual Creation of TO referencing Inbound Delivery Immediate or Automatically (by assigning output type WMTA in Configuration) In case of SU (Handling Unit)

-

Create TO using Storage Unit Create TO from Stock List

Processing Returns

91

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Setting up Automatic TO for Inbound Delivery

92

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08: Outbound Delivery - Process in WM

Warehouse Warehouse

ERP/IM Warehouse Management

Delivery

Transfer Order Creation

Picking with TO Confirmation +ve Quant in GI Area GI Posting

Transfer from Storage

Posting of ve Quant In GI Area

GI GIArea Area

93

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Collective Processing of Outbound Deliveries

Automatic creation of transfer orders with report RLAUTA20 Collective Processing of Outbound Deliveries using Outbound Delivery Monitor Processing Returns for Outbound Deliveries Grouping Outbound Deliveries Delayed Update of Stock Removal Data in Outbound Delivery

94

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Two Step Picking

Two-Step Picking Advantages of Two Step Picking Two Step Picking Process in WM

95

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08 : Activating Two Step Picking

96

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_08: WM : Delivery Processes using WM - Review

WM Goods Movement Postings are followed by IM Goods Movement postings when Inbound Delivery is used. Automatic Creation of TO is not active by default in the standard system, this is required to be configured in Customizing for Shipping To enable the processing of Returns from Inbound delivery, the relevant item category is required to be activated in Customizing Two Step Picking Process need to be activated at Warehouse level as well as material level. At the same time Customer Exit is also available to define the logic for enabling two step picking in a warehouse.

97

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

98 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 Course Goals

Understand various methods to process posting changes in WM Understand the process of stock transfers in WM Understand customizing required for executing posting changes in WM Understand the process of Stock Replenishment using WM Understand the customizing required for carrying out replenishment in WM

99

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Internal Warehouse Operations

Posting Changes Stock Transfers Replenishment Control

100

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Posting Changes

ERP/IM Warehouse Management

Storage Type Shelf Storage (Before Posting Change)

Quant 1 20 Qty

Posting Change In Inventory Management

e.g. Material X 20 Qty , changed From

Interim Storage Type Posting Change Notice

Quant 2 S 20 Qty Quant 3 -20 Qty

Unrestricted to Blocked stock

Storage Type Shelf Storage

Quant 4 S 20 Qty

101

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Customizing for Posting Changes

IM Movement Type e.g. 301 Reference Movement Types e.g. 301, 302, 309 WM Movement Type e.g. 301, 302, 309

102

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Customizing for Posting Changes (Movement Type)

103

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Stock Transfer

Plant Plant 1000 1000 Plant Plant 1100 1100

SLOC SLOC 1001 1001

SLOC SLOC 1002 1002

SLOC SLOC 1101 1101

SLOC SLOC 1102 1102

Warehouse Warehouse--001 001

Warehouse-002 Warehouse-002

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

Storage StorageBin Bin

104

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Replenishment Control in WM

Replenishment Background Prerequisites for Implementing Replenishment Process Programs Available for carrying out Replenishment

-

RLLNACH1 RLLNACH2 RLLNACH4

Process flow for Replenishment using these programs

-

Check for bin stocks in relevant storage types Check for quantity specifications in the relevant material masters Check for open outbound delivery requirement If there is a need to transfer material to the specified bins, system creates a transfer

105

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Replenishment using Programs

RLLNACH1

-

Quantity to be replenished is in multiples of replenishment quantity till it reaches maximum bin quantity. These Quantities are maintained in the material master.

RLLNACH2

-

Along with above factors, this program also considers the open demand quantity with replenishment quantity

RLLNACH4

-

Random Bin Replacement

106

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09 : Replenishment Control Customizing

This indicator separates normal stock Removal from Replenishment TOs.

107

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_09: Internal WM Operations: Posting Changes and Stock Transfers - Review

Posting changes do not generally involve a physical movement of goods Stock transfers generally involve a physical movement of goods. Replenishment Control function in WM can be executed in various ways which uses information from different parts and decide the replenishment quantity. Stock transfers within WM , do not initiate a IM transaction. In case of posting changes where WM transaction is posted before IM, only-

Stock Category change and change in Special Stock Indicator are allowed

108

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

109 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 Course Goals

Understand the process of Quality Management Relevant Goods Receipts in WM Understand the ways for handling inspection samples in warehouse. Understand the configuration required for setting up WM-QM Interface.

110

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : WM Interface with Quality Management

Overview GR Process in WM with QM Handling Inspection Lots in WM Configuration of WM-QM Interface

111

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : WM Interface with Quality Management- Overview

WM-QM Interface

GR Done in IM

Material Master

Inspection Lot in QM, with an Inspection lot number

Quant with Q in GR Area, This Quant has Inspection Lot number In it.

Usage Decision in QM PCN and Two Quants in Interim Storage Area.

Create TO for the PCN

112

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : GR Process in WM with QM

WM

GR Area

Material MaterialABC ABC 20 PC 20 PC Q Q Inspection InspectionLot LotNumber Number

Multiple Ways to Handle This Inspection Lot

Sample 2 PC

Remaining 18 PCs Inspection Lot Number

Sample Storage Bin 2 PC

Physical Storage Inspection Lot Number 18 PC Q Posting PostingChange ChangeNotice Notice In WM In WM Irrespective Irrespectiveof ofLots Lotslocation location

Usage UsageDecision Decision In QM In QM

113

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : Handling Inspection Lots in WM

Interim storage of inspection samples in a work center Remain in the goods receipt area Put away the inspection lots and the remaining quantities. Pass over transfer requirement items that belong to an inspection lot

114

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : Configuring WM-QM Interface(1)

QM Activation St Type for Inspection St Bin for Inspection Fore/Background Processing Rounding Off Inspection Qty

115

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10 : Configuring WM-QM Interface(2)

116

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_10: WM Interface with Quality Management - Review

Inspection samples can be handled in various ways in WM Sample handling can be done in foreground or background depending on the configuration settings. To activate the QM-WM Interface, storage type search sequence table and interim storage type search table should be activated for Quality Management. While processing posting changes after usage decision, WM takes care of all the quants with that inspection lot number , irrespective of their location in the warehouse.

117

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

118 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 Course Goals

Understand the prerequisites for working with Internal Procurement Process in WM Understand the process of staging components and putting away finished products. Mapping internal procurement process in the system Master data required for Staging

119

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Internal Procurement with WM

WM-PP Interface Staging of Components without WM-PP Interface Staging of Components with WM-PP Interface Putting away Finished Goods Setting up WM-PP Interface through Process Control

-

Master Data (Production Supply Area) Production Control Cycle

120

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : WM-PP Interface

Use of WM-PP Interface Functions at WM-PP Interface

-

Material Staging Goods Receipt from Production

Prerequisites of WM-PP Interface

-

Customizing for WM-PP Interface Control Cycles WM Prerequisites

Assignment of Plant/Sloc to a Warehouse and Plant/warehouse to a Sloc is clear

PP Prerequisites

At least one activity from Production order has been released

121

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Material Staging w/o WM-PP Interface

Goods GoodsIssue Issue For a Work For a WorkOrder Order --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------Transfer Transfer Requirement Requirement

(in GI Area) (in GI Area)

Transfer Transfer Order Order

Transfer TransferOrder Order Confirmation Confirmation

122

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Material Staging with WM-PP Interface

Production ProductionOrder Order ----------------------------------------------------------------------------------------------------------------------------------------Components Components --------------------------------------------------------------------Transfer Transfer Requirement Requirement

Transfer Transfer Order Order Goods GoodsIssue Issue For a Work For a WorkOrder Order -----------------------------------------------------------------------------------------------------------------------------------------

(Production Supply (Production Supply Area) Area)

Staged Staged Materials Materials

123

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Putting Away the Finished Goods

Goods Receipt from Production Plant

Inventory Management

Warehouse Management

PP/PI

Goods Receipt

(for Work Order)

Transfer Requirement Quant in GR Area

Transfer Order

GR GRArea Area

Confirmation/Differences

Warehouse Warehouse

Transfer to Storage

124 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (1)

125

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (2) PSA

Work Work Center Center 1 1

Work Work Center Center 2 2

Production Production Supply Supply Area Area

126

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (3) Control Cycle

To Control whether Staging will To Control whether Staging will Happen through TR or Happen through TR or Delivery Delivery

127

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (4) Staging Indicator

No Material Staging (0) Pick Part (1) Crate Part (2) Release Order Part (3) Manual Staging (4)

128

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (5)-Prod Sched. Profile

129

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11 : Setting up WM-PP Interface (6)-Activation

130

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_11: Internal Procurement processes with WM - Review

Goods Issue and receipt to and from Production can be executed WM-PP interface. WM-PP Interface ensures the supply to Production Supply Area GR from production is posted automatically in WM (Interim Storage Area) if WM-PP interface is active, otherwise it has to be carried out manually Creation of Production Supply Area and Setting up Control cycle are two prerequisites for WM-PP Interface To activate automatic material staging for production orders, production scheduling profile is defined in customizing.

131

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN- Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management

Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

132 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 Course Goals

Understand various types of basic methods of carrying out Physical Inventory in the warehouse. Understand the customizing required to use different types of Physical Inventory methods.

133

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Physical Inventory in WM

Physical Inventory Process Physical Inventory Process in Warehouse Management Customizing for Physical Inventory Process in WM

134

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Physical Inventory Process

Physical Inventory Preparation

Physical Inventory Count

Physical Inventory Analysis

135

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Types of Physical Inventory Processes

Periodic Inventory Continuous Inventory (Perpetual Inventory) Cycle Counting Sample Based Inventory

136

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Types of Inventory Methods in WM

Annual Inventory (Counted at a key date or around the key date) Continuous Inventory (Perpetual Inventory) Cycle Counting Inventory on First Putaway (During Putaway) Zero Stock Check (During Stock Removal) Sample Based Inventory

137

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Physical Inventory Process in IM and WM

IM

Create Physical Inventory Doc. Create Physical Inventory Doc.

WM

Block Materials (Manually or Automatically)

Activate Physical Inventory Doc.

Storage Bins Blocked

Print Physical Inventory Doc.

Print Physical Inventory Doc.

Count/Measure Count/Measure Storage Bins Block Lifted Quant (+/-) in Interim Storage Quant (-/+) In Interim Storage

Enter Count Results Enter Count Results

Clear Differences in WM Clear Differences in IM Clear Differences in IM

138

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Physical Inventory Process in WM - Details

Create Physical Inventory Doc (LI01N, LX15, LX16, LX26, LICC)

WM

Activate Physical Inventory Do (LI02N) Print Physical Inventory Doc (LI04) Count/Measure

Storage Bins Blocked

IM

Storage Bins Block Lifted 1. Change in System Stock in Inventory Management 2. Quant2 (-/+) posted to Interim Storage Area 3. Creation of Material Doc. With Movement Type 712

Enter Count Results (LI11N - Count, LI14 Recount) Clear Differences in WM (LI20)

Quant1 (+/-) in Interim Storage Area (-/+) Added to Actual Storage Bin

Clear Differences in IM (LI21)

Quant2 (-/+) in Interim Storage Area

4. Creation of Accounting Document for the material document

139

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Customizing for Physical Inventory Process in WM(1)

140

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12 : Customizing for Physical Inventory Process in WM(2)

141

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_12: Physical Inventory in Warehouse Management - Review In carrying out physical inventory in WM, locking and unlocking of the bins happen automatically There is no accounting document created while posting differences in WM Using warehouse management, there are two more methods available for continuous inventory activities. These are Zero Stock check and, Inventory check during putaway.

142

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN : Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

143

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : Course Goals

Understand the functions of Warehouse Activity Monitor as Planning and Monitoring tools in Warehouse Management

144

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : Warehouse Activity Monitor (1)

Warehouse Activity Monitor Functions of Warehouse Activity Monitor Activating WAM Objects Monitoring Parameters

145

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : Warehouse Activity Monitor (2)

WAM is a Report RLLL0000, for which variants can be created and run for different WAM objects

146

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : Warehouse Activity Monitor (3)

147

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : Warehouse Activity Monitor (4)

Reports for WAM Object Id 01 02 03 04 05 06 07 Object Name Unconfirmed Transfer Orders Open Transfer Requirements Open Posting Change Notices Open Deliveries Negative Stock Interim Storage Stock Critical Stocks for Production Supply Report Name RLLL01SE RLLL02SE RLLL03SE RLLL04SE RLLL05SE RLLL06SE RLLL07SE

148

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_13 : - Review

Warehouse Activity Monitor is a report which can be run with various variants defined suiting individual requirements

149

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN : Course Content

Unit 1: Overview to Logistics Execution Unit 2: Warehouse Management as a Part of Logistics Execution Unit 3: Scenarios for Warehouse Management Implementation Unit 4: WM Organization Structure Unit 5: Warehouse Management's Interface with Inventory Management Unit 6: Warehouse Management: Inbound Processes and Putaway Control Unit 7: Warehouse Management: Outbound Processes and Stock Removal Control Unit 8: Warehouse Management: Delivery Processes using WM Unit 9: Internal Warehouse Operations: Posting Changes and Stock Transfers. Unit 10: WM Interface with Quality Management Unit 11: Internal Procurement processes with WM Unit 12: Physical Inventory in Warehouse Management Unit 13: Warehouse Activity Monitor Unit 14: Technical Topics

150 SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_14 : Technical Topics - Content

WM Tables Data flow at Table Level from IM to WM and vice versa BADIs for WM Archiving

151

SAP WM Fundamentals- | 12/25/2011

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_14 : WM Tables

LQUA LTBK LTBP LTAK LTAP LINK LINP T300 T001L T156 T001W T148 MSKA MSPR MKOL Quant Transfer requirement header Transfer requirement item WM transfer order header Transfer order item Inventory document header in WM Inventory document item in WM T300 Storage locations Movement type Plant Special stock Indicator Sales order stock Project stock Special stock from vendor LL01 LL02 LL03 LL04 LL05 LL06 LL07 MGEF NKLV LGAP LEIN MLGT MLGN Hazardous Material Number Ranges in WM Storage bins Storage Unit Header Records Material data for each storage type Material data for each warehouse number WAM Critical Data for different Objects

SAP WM Fundamentals- |

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_14 : Data flow at Table Level from IM to WM and vice versa(1)

MSEG -- Document Segment: Material MBLNR MJAHR ZEILE LGORT MATNR Doc. # Year Item Sto Loc. Material Char 10 Numc 4 Numc 4 Char 4 Char 18

BWART LQNUM Mov. Type Wh No. Char 3 Char 3 "101"/"343"/"501"

TBNUM TBPOS WERKS BWLVS TR No. TR item Plant Mv.Ty.WM Numc 10 Numc 4 Char 4 Numc 3

MKPF -Material Document MBLNR MJAHR CPUDT CPUTM Doc. # Year Date Time Char 10 Numc 4 Dats 8 Tims 6

LTBP -- Transfer Requirement Item TANUM LGNUM TBNUM TBPOS TO No. Wh No. TR No. TR item Numc 10 Char 3 Numc 10 Numc 4

LTAP -- Transfer order item VLPLA QZEIT QDATU Sto.Bin Time Date Char 10 Tims 6 Dats 8

MATNR Material Char 18

TANUM TO No. Numc 10

LGNUM Wh No. Char 3

TAPOS TO item Numc 4

T001W -- Plants/Branches Name1 SPRAS WERKS Name Language Plant Char 30 Lang 1 Char 4 Sy-langu

SAP WM Fundamentals- |

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_14 : Data flow at Table Level from IM to WM and vice versa(2)

LTAK (WM transfer order header) LGNUM TANUM Warehouse Transfer order Num/complex number Char/3 Numc/10 LTAP (WM transfer order item) LGNUM TANUM Warehouse Transfer order Num/complex number Char/3 Numc/10 T001W (Plants/Branches) WERKS Plant Char/4

TBNUM Transfer requirement number Numc/10

BETYP Requirement type Char/1 J QZEIT Confirmation time of transfer order Tims/6

WERKS Plant Char/4

QDATU Confirmation date of transfer order Dats/8 in previous week

MATNR Material number Char/18

VLPLA Source storage bin Char/10

LTBK (Transfer requirement header) LGNUM TBNUM Warehouse Transfer requirement Num/complex number Char/3 Numc/10

BETYP Requirement type Char/1 J

BDATU Creation date of transfer request Dats/8

BZEIT Creation time of transfer request Tims/6

T300 (WM Warehouse Numbers) LGNUM Warehouse Num/complex Char/3

SAP WM Fundamentals- |

Think Tree Technologies, Inc

Dilip K Sadh

WMFUN_14 : Business Add-Ins

LE_WM_LE_QUANT BADI for Quant Determination LE_WM_STORAGETYPE_HU BADI for Determining Storage Type LE_WM_SUTYPE_HU BADI for Determining Storage Unit Type LE_WM_INV_WM_IM BADI for Entering Inventory Data in IM LE_WM_LATER_DN BADI for Influencing Delayed Delivery Update

155

SAP WM Fundamentals- | 12/25/2011

You might also like

- The Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemFrom EverandThe Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemNo ratings yet

- Step-by-Step Approach for Configuring Warehouse ManagementDocument44 pagesStep-by-Step Approach for Configuring Warehouse ManagementMukesh100% (4)

- SAP WM configuration essentials under 40 charsDocument6 pagesSAP WM configuration essentials under 40 charsamit76meerut100% (3)

- Sap WM in DetailDocument93 pagesSap WM in Detailkurrysuchit100% (5)

- Basic Customizing For Handling UnitDocument12 pagesBasic Customizing For Handling UnitPranaya Barik100% (5)

- Concept of Warehouse Management System ConfigurationDocument62 pagesConcept of Warehouse Management System Configurationrasgeetsingh100% (7)

- Handling Unit Management in SAP Packing During Outbound ProcessDocument48 pagesHandling Unit Management in SAP Packing During Outbound ProcessManibudh Sankasem0% (1)

- CookBook WM On ECC - 5Document91 pagesCookBook WM On ECC - 5Anirban Laha100% (5)

- WM-End User DocumentDocument4 pagesWM-End User Documentkalyan7sapabap71% (7)

- SAP WM Interview Questions and AnswersDocument21 pagesSAP WM Interview Questions and AnswersBipul KumarNo ratings yet

- Understanding Material Master WM1 and WM2 ViewsDocument4 pagesUnderstanding Material Master WM1 and WM2 Viewsrajesh98765100% (1)

- WM PPTDocument12 pagesWM PPTpraveennbsNo ratings yet

- WM-PP Interface Guide for Pick Parts StagingDocument3 pagesWM-PP Interface Guide for Pick Parts Stagingramakrishna100% (1)

- Advance Returns Management SetupDocument14 pagesAdvance Returns Management SetupParinit Agarwal100% (2)

- SAP IM Vs WM, How To Choose Use and OptimizeDocument56 pagesSAP IM Vs WM, How To Choose Use and Optimizehalwanv100% (1)

- Important SAP EWM TablesDocument4 pagesImportant SAP EWM Tableszinefine0% (1)

- Configure Embedded EWM in SAP S/4 HANADocument35 pagesConfigure Embedded EWM in SAP S/4 HANAAruna DasNo ratings yet

- LO530 4.6 - Basic Processes in WMDocument337 pagesLO530 4.6 - Basic Processes in WMamitava_bapi100% (3)

- Sap Le - WMDocument14 pagesSap Le - WMRavindra Sadar JoshiNo ratings yet

- TK Reddy - Understanding Stock Types in SAP EWMDocument7 pagesTK Reddy - Understanding Stock Types in SAP EWMhalwanv100% (1)

- WM UsermanualDocument35 pagesWM Usermanualmunmun_neogi100% (7)

- Storage Bin StrategiesDocument9 pagesStorage Bin StrategiesLucas DantasNo ratings yet

- Embeded Warehouse1Document71 pagesEmbeded Warehouse1Navjyot Singhvi100% (4)

- MM - Warehouse ManagementDocument29 pagesMM - Warehouse ManagementSaroshNo ratings yet

- Sap WM Kanban ProcessDocument8 pagesSap WM Kanban ProcessAbhijit100% (1)

- Understanding SAP EWM in Comparison With SAPDocument9 pagesUnderstanding SAP EWM in Comparison With SAPGent-Nguyễn Phước Toàn100% (1)

- SAP WM Vs eWMDocument6 pagesSAP WM Vs eWMBIROJI VENKAT RAMANANo ratings yet

- Basic Settings For SAP EWM in SAP S - 4HANA 1709 - SAP BlogsDocument31 pagesBasic Settings For SAP EWM in SAP S - 4HANA 1709 - SAP BlogslavleenlesyaNo ratings yet

- WM PPInterfaceDocument11 pagesWM PPInterfacechokx008No ratings yet

- Embedded EWM in SAP A Functional ComparisionDocument5 pagesEmbedded EWM in SAP A Functional ComparisionRajesh SinghNo ratings yet

- RF in SAP Warehouse ManagementDocument12 pagesRF in SAP Warehouse Managementsathyakalyan86% (7)

- SAP Warehouse Management WM Introduction 26125078Document44 pagesSAP Warehouse Management WM Introduction 26125078Uday L100% (1)

- S4 HANA Simple Logistics Training Videos - Materials - Course Content DetailsDocument2 pagesS4 HANA Simple Logistics Training Videos - Materials - Course Content DetailsAKbarNo ratings yet

- What Happens During Inbound Processing in SAP Embedded EWM?: External ProcurementDocument8 pagesWhat Happens During Inbound Processing in SAP Embedded EWM?: External ProcurementMohanish MurkuteNo ratings yet

- Subcontracting process configuration in S4 HANA MMDocument13 pagesSubcontracting process configuration in S4 HANA MMSapnote100% (4)

- EWM Manual PDFDocument16 pagesEWM Manual PDFcutemmaa63% (8)

- DOC2 - Storage Type Customizing - Control ParametersDocument34 pagesDOC2 - Storage Type Customizing - Control ParametersBIROJI VENKAT RAMANA100% (1)

- Sap WM TcodesDocument7 pagesSap WM TcodesVenkat Ram Reddy UppulaNo ratings yet

- Is-Retail Replenishment Vs Multi-Step ReplenishmentDocument9 pagesIs-Retail Replenishment Vs Multi-Step ReplenishmentNoppawan BuangernNo ratings yet

- Configure ITSmobile in SAP EWM SCM7Document2 pagesConfigure ITSmobile in SAP EWM SCM7suseevNo ratings yet

- Sap MM Im WM Slides Class EightDocument124 pagesSap MM Im WM Slides Class EightMd Saif100% (2)

- Handling Unit ManagementDocument15 pagesHandling Unit Managementinpbm06330100% (2)

- SAP Handling Unit ManagementDocument61 pagesSAP Handling Unit ManagementSuvendu Bishoyi91% (23)

- Sap WMDocument6 pagesSap WMAkhil MehtaNo ratings yet

- Lean WM PDFDocument17 pagesLean WM PDFrajasekeranmad75% (8)

- SAP EWM Value Added Services: Kit-to-Order ProcessDocument16 pagesSAP EWM Value Added Services: Kit-to-Order Processkristian yotovNo ratings yet

- BBP SAP WM Implementation LuminousDocument33 pagesBBP SAP WM Implementation LuminousNaveen Kumar100% (6)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- SAP IS-Retail Interview Questions, Answers, and ExplanationsFrom EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsRating: 3 out of 5 stars3/5 (11)

- SAPCOOKBOOK Training Tutorials: SAP MM Inventory ManagementFrom EverandSAPCOOKBOOK Training Tutorials: SAP MM Inventory ManagementRating: 4 out of 5 stars4/5 (13)

- Warehouse Management Systems A Complete Guide - 2019 EditionFrom EverandWarehouse Management Systems A Complete Guide - 2019 EditionNo ratings yet

- SAP Variant Configuration: Your Successful Guide to ModelingFrom EverandSAP Variant Configuration: Your Successful Guide to ModelingRating: 5 out of 5 stars5/5 (2)

- SAP Service Management: Advanced ConfigurationFrom EverandSAP Service Management: Advanced ConfigurationRating: 4.5 out of 5 stars4.5/5 (3)

- Computer ServersDocument8 pagesComputer ServersRam KumarNo ratings yet

- DosDocument9 pagesDosluckyvinoNo ratings yet

- Application Packaging GuideDocument1,138 pagesApplication Packaging Guidesurkal100% (3)

- Chirala, Andhra PradeshDocument7 pagesChirala, Andhra PradeshRam KumarNo ratings yet

- The Importance of Due Diligence in Commercial Transactions - AvoidDocument37 pagesThe Importance of Due Diligence in Commercial Transactions - AvoidRam KumarNo ratings yet

- Step by Step Sap SD Configuration GuideDocument40 pagesStep by Step Sap SD Configuration Guideseetanal94% (16)

- DosDocument9 pagesDosluckyvinoNo ratings yet

- FAQ On MSI Packaging and Repackaging Ver 0.0.2Document35 pagesFAQ On MSI Packaging and Repackaging Ver 0.0.2Harry PatelNo ratings yet

- Application PackagingDocument69 pagesApplication PackagingRam Kumar100% (1)

- BMC Blade Logic Client Automation Application Packager User GuideDocument454 pagesBMC Blade Logic Client Automation Application Packager User Guidedilpreet_sohanpal100% (1)

- Solution Guide Rubik's KubikDocument12 pagesSolution Guide Rubik's KubikneiramedicNo ratings yet

- Machiavelli's The Prince Part II Full PDFDocument30 pagesMachiavelli's The Prince Part II Full PDFRam KumarNo ratings yet

- RFID-Enabled Integrated Inbound and Outbound ScenarioDocument17 pagesRFID-Enabled Integrated Inbound and Outbound Scenariojayakrishna.kNo ratings yet

- Sappress Treasury and RiskDocument62 pagesSappress Treasury and RisksaldsimaNo ratings yet

- SAP Treasury and Risk Management Within SAP ERP FinancialsDocument28 pagesSAP Treasury and Risk Management Within SAP ERP FinancialsAgung Terminanto Jkt100% (4)

- Alan Shawn Feinstein Graduate School Resume ExamplesDocument6 pagesAlan Shawn Feinstein Graduate School Resume ExamplesRam KumarNo ratings yet

- (EN) Uclgcrisis (Eng)Document54 pages(EN) Uclgcrisis (Eng)Ram KumarNo ratings yet

- Apple Inc. v. Samsung Electronics Co. Ltd.Document7 pagesApple Inc. v. Samsung Electronics Co. Ltd.Ram Kumar100% (1)

- An Analysis of OTC Interest RateDocument23 pagesAn Analysis of OTC Interest RateRam Kumar100% (1)

- 2000 01Document11 pages2000 01Ram KumarNo ratings yet

- 2012 q2 Northern Trust Corp Y9Document66 pages2012 q2 Northern Trust Corp Y9Ram KumarNo ratings yet

- Exam 1 Test BankDocument36 pagesExam 1 Test BankRam Kumar75% (4)

- 18.sachin KhandareDocument4 pages18.sachin KhandareRam KumarNo ratings yet

- 90 Day Treasury Bill Yields in U.SDocument1 page90 Day Treasury Bill Yields in U.SRam KumarNo ratings yet

- Sap Fico InterviewDocument16 pagesSap Fico InterviewRam KumarNo ratings yet

- SAP FICO SyllabusDocument1 pageSAP FICO SyllabusMaurya ShantanuNo ratings yet

- What Is SAPDocument8 pagesWhat Is SAPRam KumarNo ratings yet

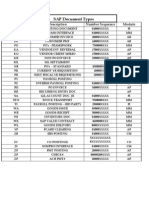

- SAP document types and descriptionsDocument1 pageSAP document types and descriptionshembeck119No ratings yet

- INTRO SapDocument144 pagesINTRO SapmatzoneNo ratings yet

- Komunikacija Između Mikrokontrolera. Uart, Spi, I2C AD I DA KonverzijaDocument18 pagesKomunikacija Između Mikrokontrolera. Uart, Spi, I2C AD I DA KonverzijaHury999No ratings yet

- Chapter 12Document7 pagesChapter 12Xynith Nicole RamosNo ratings yet

- PWC'S Insurance Insights: Analysis of Regulatory Changes and Impact Assessment For March 2018Document11 pagesPWC'S Insurance Insights: Analysis of Regulatory Changes and Impact Assessment For March 2018Bhan WatiNo ratings yet

- Spykar JeansDocument6 pagesSpykar Jeansshjvd72100% (1)

- DD311 40Document154 pagesDD311 40luis naupari100% (1)

- EXPERIMENT 2: Absorption of Carbon Dioxide in WaterDocument4 pagesEXPERIMENT 2: Absorption of Carbon Dioxide in WaterAzrol Azmir Long67% (6)

- Solved Using A Contents Search in Intelliconnect S Standard Federal Tax ReporterDocument1 pageSolved Using A Contents Search in Intelliconnect S Standard Federal Tax ReporterAnbu jaromiaNo ratings yet

- Csec It 2016 Paper 2Document18 pagesCsec It 2016 Paper 2Jennique S.No ratings yet

- #2succession law_sy 2023-24 1S_lectures notes1_arts. 774 - 856_updated 20231025 4.46 pm (1)Document284 pages#2succession law_sy 2023-24 1S_lectures notes1_arts. 774 - 856_updated 20231025 4.46 pm (1)JUAN GABONNo ratings yet

- 330B Excavators Hydraulic Systems: 3YR1-UP 5LR1-UP 4RS1-UP 5LS1-UPDocument2 pages330B Excavators Hydraulic Systems: 3YR1-UP 5LR1-UP 4RS1-UP 5LS1-UPJim LiebNo ratings yet

- Directory Analyzer Admin GuideDocument204 pagesDirectory Analyzer Admin Guidenipi99No ratings yet

- Difference Between API 650 & API 620Document5 pagesDifference Between API 650 & API 620job saputraNo ratings yet

- 24 Rapiscan 632XR DatasheetDocument2 pages24 Rapiscan 632XR DatasheetlinaNo ratings yet

- Pas 10 - Events After The Reporting PeriodDocument11 pagesPas 10 - Events After The Reporting PeriodBritnys Nim100% (1)

- Materi Kesatu Apt Ari - Webinar Hisfarsi Jatim 9Document86 pagesMateri Kesatu Apt Ari - Webinar Hisfarsi Jatim 9Fara Ester100% (1)

- DATA MANAGEMENT FOR LOCAL GOVERNMENT PLANNING AND DEVELOPMENT Bkfinal Edited Version PDFDocument92 pagesDATA MANAGEMENT FOR LOCAL GOVERNMENT PLANNING AND DEVELOPMENT Bkfinal Edited Version PDFactiveabbasNo ratings yet

- Entrepreneurs Are Great WorksheetsDocument9 pagesEntrepreneurs Are Great WorksheetsSilvia MontesNo ratings yet

- Fresh Fruits and VegetablesDocument6 pagesFresh Fruits and VegetablesNicole LeongNo ratings yet

- Product Service Bulletin: ACPSB24 TCI Analog Card Transistor Q7 Testing and RepairDocument13 pagesProduct Service Bulletin: ACPSB24 TCI Analog Card Transistor Q7 Testing and RepairEmilio Cortes T.No ratings yet

- Names and Occupations: 1 Match The Occupations With The Pictures Write The Letter On The LineDocument17 pagesNames and Occupations: 1 Match The Occupations With The Pictures Write The Letter On The LineElga Orosco CanidoNo ratings yet

- 197-Article Text-384-1-10-20220215Document6 pages197-Article Text-384-1-10-20220215RaymondDomingoNo ratings yet

- EquinoxZ2 FirmwareUpdate Instructions 022321 WebDocument4 pagesEquinoxZ2 FirmwareUpdate Instructions 022321 WebNowy NowyNo ratings yet