Professional Documents

Culture Documents

Cone Calculations - AD Merkblatter

Uploaded by

Sajal KulshresthaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cone Calculations - AD Merkblatter

Uploaded by

Sajal KulshresthaCopyright:

Available Formats

CSPC NANHAI PETROCHEMICALS PROJECT HUIZHOU Loc. (P.R.C.

) Plant

Title

CNOOC/SHELL - Identification Code

Rev

VP-4325-MVSC-0001

TECNIMONT - Identification Code

00

MECHANICAL CALCULATIONS 3163

CD

VM

12

SUPPLIER DOC. NO: MDC 858

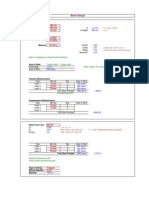

Bottom Cone a) For Design Pressure Design pressure Safety factor at design pressure Stress coefficient at design temp. Factor Cone angle Transition radius Outside diameter of connected cylinder Required wall thickness inside of taper area Required wall thickness outside of taper area Allowance for minus thickness tolerance Wastage allowance Provided cone thickness As per AD-Merkblatt B 2 subclause 8.1.1 [r * S / (15 * K * v)] [ r / Da1] From Fig. 3.4 for j = 16 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [(Dk * r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ sl + r ( 1 - cos j ) + x2 sin j ] = x2 = 0.7 * [ Da1 * ( sl - c1 - c2 ) / cos j ] ^ 0.5 DK x2 [ [ mm mm ] ] 741.5 64.7 [ mm ] 0.003969 0 0.0021 2.6 r S K v j r Da1 sl sg c1 c2 [ [ [ [ [ [ [ [ [ [ [ [ bar N/mm2 mm mm mm mm mm mm mm ] ] ] ] ] ] ] ] ] ] ] ] 0 1 12 6.849 1.5 203 0.85 10 0 764

mm

3.2

Sh. 23 of 32

CSPC NANHAI PETROCHEMICALS PROJECT HUIZHOU Loc. Plant (P.R.C.)

Title

CNOOC/SHELL - Identification Code

Rev

VP-4325-MVSC-0001

TECNIMONT - Identification Code

00

MECHANICAL CALCULATIONS 3163

CD

VM

12

CSPC NANHAI PETROCHEMICALS PROJECT HUIZHOU Loc. Plant (P.R.C.)

Title

CNOOC/SHELL - Identification Code

Rev

VP-4325-MVSC-0001

TECNIMONT - Identification Code

00

MECHANICAL CALCULATIONS 3163

CD

VM

12

SUPPLIER DOC. NO: MDC 858

Bottom Cone b) For Test Pressure ( Equipment in upright condition) Design pressure Height of water column Static pressure of test water = H / 10000 Hydrotest pressure = ( 1.3 * r ) + pStatic Safety factor at test pressure Stress coefficient at 20 deg. C Factor Cone angle Transition radius Outside diameter of connected cylinder Required wall thickness inside of taper area Required wall thickness outside of taper area Allowance for minus thickness tolerance Wastage allowance Provided cone thickness As per AD-Merkblatt B 2 subclause 8.1.1 [r' * S' / (15 * K20 * v)] [r / Da1] From Fig. 3.4 for j = 28 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [(Dk * r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ sl + r ( 1 - cos j ) + x2 sin j ] = x2 = 0.7 * [ Da1 * ( sl - c1 - c2 ) / cos j ] ^ 0.5 DK x2 [ [ mm mm ] ] 1414.1 90.6 [ mm ] 0.003867 0 0.0024 4.5 r H pStatic r' S' K20 v j r Da1 sl sg c1 c2 [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ bar mm bar bar N/mm2 mm mm mm mm mm mm mm ] ] ] ] ] ] ] ] ] ] ] ] ] ] ] 0 1 12 6 26893 2.6893 10.49 1.1 234 0.85 16 0 1464

mm

5.3

Hence provide cone plate thickness 12 mm is OK.

Sh. 24 of 33

ication Code

Rev

C-0001

12

00

entification Code

0.17453293

ication Code

Rev

C-0001

12

00

entification Code

ication Code

Rev

C-0001

12

00

entification Code

0.27925268

Equipment No.

Mechanical Design Calculations

Design of Top Cone a) For Design Pressure Design pressure r [ Safety factor at designS pressure [ Stress coefficient at design K temp. [ Factor v [ Cone angle j [ Transition radius r [ Da1 Outside diameter of connected cylinder [ sl inside of taper [area Required wall thickness sgoutside of taper Required wall thickness [ area c1 Allowance for minus thickness tolerance [ Wastage allowance c2 Provided cone thickness [ [ bar N/mm2 mm mm mm mm mm mm mm ] ] ] ] ] ] ] ] ] ] ] ]

V 6370

Rev. No.

6.813 1.5 203 0.85 16 0 1464

0 1 12

As per AD-Merkblatt B 2 subclause 8.1.1 [r * S / (15 * K * v)] [r / Da1] From Fig. 3.4 for j = 16 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [ mm ] 0.003948 0 0.00288 5.2

[ mm [(Dk r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ D slK+ r ( 1 - cos j [ ) + x2 sin j ]= mm x2 = 0.7 * [ Da1 * ( sl - cx - c2 ) / cos j ] ^ [ 0.5 12 mm

] ] ]

5.4 1414.1 90.6

CSPC NANHAI PETROCHEMICALS PROJECT

Project No. 120253

V 6370

Rev. No.

Page No. 21 of 65

Equipment No.

Mechanical Design Calculations

Design of Cone b) For Test Pressure ( Equipment in upright condition) Design pressure r [ Height of water column H [ Static pressure of test p water [ Static = H / 10000 Hydrotest pressure p' [ = ( 1.3 * p ) + pStatic Safety factor at test pressure S' [ Kdeg. Stress coefficient at 20 C [ 20 Factor v [ Cone angle j [ Transition radius r [ Da1 Outside diameter of connected cylinder [ sl inside of taper [area Required wall thickness sgoutside of taper Required wall thickness [ area c1 Allowance for minus thickness tolerance [ Wastage allowance c2 [ Provided cone thickness [ bar mm bar bar N/mm2 mm mm mm mm mm mm mm ] ] ] ] ] ] ] ] ] ] ] ] ] ] ]

6 26300 2.63 10.43 1.1 234 0.85 16 0 1464

0 1 12

As per AD-Merkblatt B 2 subclause 8.1.1 [r' * S' / (15 * K20 * v)] 0.003845

[r / Da1] From Fig. 3.4 for j = 28 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [ mm ]

0 0.0024 4.5

[ mm [(Dk * r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ D slK+ r ( 1 - cos j [ ) + x2 sin j ]= mm x2 = 0.7 * [ Da1 * ( sl - cx - c2 ) / cos j ] ^ [ 0.5 12 mm

] ] ]

5.3 1414.1 90.6

Hence provide cone plate thickness 12 mm is OK.

CSPC NANHAI PETROCHEMICALS PROJECT

Project No. 120253

Page No. 21 of 65

0.279253

0.279253

Mechanical Design Calculations

Design of Top Cone a) For Design Pressure Design pressure Safety factor at design pressure Stress coefficient at design temp. Factor Cone angle Transition radius Outside diameter of connected cylinder Required wall thickness inside of taper area Required wall thickness outside of taper area Allowance for minus thickness tolerance Wastage allowance Provided cone thickness As per AD-Merkblatt B 2 subclause 8.1.1 [r * S / (15 * K * v)] [r / Da1] From Fig. 3.4 for j = 28 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [(Dk r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ sl + r ( 1 - cos j ) + x2 sin j ] = x2 = 0.7 * [ Da1 * ( sl - c1 - c2 ) / cos j ] ^ 0.5 DK x2 [ [ mm mm ] ] [ mm ] r S K v j r Da1 sl sg c1 c2 [ bar [ 2 [ N/mm [ [ [ mm [ mm [ [ [ [ [ mm mm mm mm mm ] ] ] ] ] ] ] ] ] ] ] ]

Equipment No. V 6370

Rev. No.

6.74 1.5 203 0.85 28 730 3528

0 1 14

0.00391 0.20692 0.0022 8.8

mm

11.7 3207.3 159.5

CSPC NANHAI PETROCHEMICALS PROJECT

Project No. 120253

Page No. 21 of 65

V 6370

Rev. No.

Equipment No.

Mechanical Design Calculations

Mechanical Design Calculations

Design of Cone b) For Test Pressure ( Equipment in upright condition) Design pressure Height of water column Static pressure of test water = H / 10000 Hydrotest pressure = ( 1.3 * p ) + pStatic Safety factor at test pressure Stress coefficient at 20 deg. C Factor Cone angle Transition radius Outside diameter of connected cylinder Required wall thickness inside of taper area Required wall thickness outside of taper area Allowance for minus thickness tolerance Wastage allowance Provided cone thickness As per AD-Merkblatt B 2 subclause 8.1.1 [r' * S' / (15 * K20 * v)] [r / Da1] From Fig. 3.4 for j = 28 , ( sl -c1 -c2 / Da1 ) Hence Required sl = As per AD-Merkblatt B 2 equation 6 Required sg = [(Dk * r ) / (20 * (K/S) * v - r )] * ( 1 / cos j ) + c1 + c2 Where DK = Da1 - 2 * [ sl + r ( 1 - cos j ) + x2 sin j ] = x2 = 0.7 * [ Da1 * ( sl - c1 - c2 ) / cos j ] ^ 0.5 DK x2 [ [ mm mm ] ] [ mm ] r [ H [ pStatic [ p' [ S' K20 v j r Da1 sl sg c1 c2 bar mm bar bar ] ] ] ] ] ] ] ] ] ] ] ] ] ] ]

6 25079 2.5079 10.31 1.1 234 0.85 40 730 3544

[ 2 [ N/mm [ [ [ mm [ mm [ [ [ [ [ mm mm mm mm mm

0 1 22

0.0038 0.20598 0.0024 9.5

mm

11.9 2921.9 218.2

Hence provide cone plate thickness 14 mm is OK.

CSPC NANHAI PETROCHEMICALS PROJECT

Project No. 120253

Page No. 21 of 65

0.4886922

0.6981317

1_THE MACRO TABLE _________ ______________________________________ _________ _________ _________ MACRO DESCRIPTION MACRO NAME KEYSTROKES _________ ______________________________________ _________ _________ _________ \M - Create a Macro {d 5}/rnc\a~~{d 4} /rnc\d~~{d 2}/rnc\e~~{d 2}/rnc\l~~{d 4} /rnc\p~~{d 2}/rnc\s~~{d 2}/rnc\u~~{d 2} /rnc\c~~{d 3}/rncc~~{d 2}/rnc\x~~/wgpe{home} /c{esc}{up}~~{edit}{home}{del} @length("{end}"){calc}{home} @repeat("*",{end}){calc}{home}'~ /wgpd /wgpe /c{esc}{up}~~{edit}{home}{del} @length("{end}"){calc}{home} @repeat("-",{end}){calc}{home}'~ /rp {paneloff}/fs~r /ru /c~b:c35~

\A

- Underline a string using Asterisks

\D \E \L

- Turn global protection OFF - Turn global protection ON - Underline a string using lines

\P \S \U \C

- Protect range(s) - Save the file - Unprotect a range - Copiy cell at location to the cell b:c35 - Copied cell using macro \c

SA-516-70 /cc~~

\X

- Copy the cell at b:c36 to the current pointer location

_________

_________

e~~{d 2}/rnc\l~~{d 4} s~~{d 2}/rnc\u~~{d 2} ~~{d 2}/rnc\x~~/wgpe{home}

You might also like

- Sample Code FM Based ExtractorDocument7 pagesSample Code FM Based ExtractorVikas Gautam100% (2)

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNo ratings yet

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Common Ions Anions and CationsDocument2 pagesCommon Ions Anions and CationsSajal KulshresthaNo ratings yet

- PHY2061 Enriched Physics 2 Lecture Notes: Coulomb's LawDocument7 pagesPHY2061 Enriched Physics 2 Lecture Notes: Coulomb's LawRavi Kanth M NNo ratings yet

- 1.operations ResearchDocument36 pages1.operations ResearchPiuShan Prasanga Perera100% (1)

- Computational Physics - Fortran Version - Koonin PDFDocument660 pagesComputational Physics - Fortran Version - Koonin PDFJosé Roberto LessaNo ratings yet

- Design of AgitatorDocument6 pagesDesign of AgitatorVishalNo ratings yet

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Design of AgitatorDocument3 pagesDesign of AgitatorManish PatelNo ratings yet

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Asme Viii Uhx Tubesheet CalcsDocument3 pagesAsme Viii Uhx Tubesheet CalcsjdfdfererNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- 350 V Pressure Vessel Strength CalculationDocument3 pages350 V Pressure Vessel Strength CalculationTanCM100% (1)

- Heat ExchangerDocument11 pagesHeat ExchangerMangesh MandgeNo ratings yet

- Design-Calculation Acid Wash TankDocument5 pagesDesign-Calculation Acid Wash TankWiz DomNo ratings yet

- Agitated Thin Film Dryer ClaculationDocument12 pagesAgitated Thin Film Dryer ClaculationakaashNo ratings yet

- Pressure Vessel Cone Design ToolDocument1 pagePressure Vessel Cone Design ToolssierroNo ratings yet

- Shell and Tube Heat Exchanger CalculationDocument9 pagesShell and Tube Heat Exchanger CalculationKuldeep28883No ratings yet

- Process Industry Basket StrainersDocument27 pagesProcess Industry Basket StrainersmartinnovelNo ratings yet

- Design of AgitatorDocument12 pagesDesign of AgitatorPatil HemantNo ratings yet

- Dimpled Jacket 2Document4 pagesDimpled Jacket 2grincheu7050% (2)

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Aeration System and Oxygen RequirementDocument7 pagesAeration System and Oxygen Requirementdzari6738No ratings yet

- Design of paddle type agitator for effluent agitationDocument4 pagesDesign of paddle type agitator for effluent agitationuttam prabhuNo ratings yet

- 8KL FERMENTER DESIGN CALCULATIONSDocument3 pages8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNo ratings yet

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVANo ratings yet

- Autopipe Vessel Guide 1-5Document5 pagesAutopipe Vessel Guide 1-5fiuto_rights_1404802No ratings yet

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoDocument2 pagesScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisNo ratings yet

- Cpp-Tank DSGN Calc-Rev CDocument42 pagesCpp-Tank DSGN Calc-Rev CnamasralNo ratings yet

- Agitator DesignDocument6 pagesAgitator DesignrcchhajedNo ratings yet

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationdhavaleshNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Actual Plate Thickness: Material H/LDocument8 pagesActual Plate Thickness: Material H/LSruthish SasindranNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datNo ratings yet

- Hemispherical Head Blank DiameterDocument1 pageHemispherical Head Blank DiameterdombipinNo ratings yet

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Cone Development CalculationsDocument5 pagesCone Development CalculationssaudimanNo ratings yet

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)amaNo ratings yet

- Gas Scrubbers: DescriptionDocument14 pagesGas Scrubbers: DescriptionPitiporn HasuankwanNo ratings yet

- Heat Exchanger DesignDocument7 pagesHeat Exchanger Designsiva sankarNo ratings yet

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- Orifice CalculationDocument3 pagesOrifice Calculationchandramohan muruganNo ratings yet

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Document2 pages9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Ahmad Badsha QuadriNo ratings yet

- Base Ring and SkirtDocument8 pagesBase Ring and Skirtduazo2009No ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignLam TranNo ratings yet

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonNo ratings yet

- RC Beam Design To EC2Document3 pagesRC Beam Design To EC2suman_civilNo ratings yet

- E4.5 Flange Cover CalcDocument10 pagesE4.5 Flange Cover CalcTanCM100% (1)

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous 9iK0i8h0dPNo ratings yet

- Fin Plate - Beam To ColumnDocument78 pagesFin Plate - Beam To ColumnHemant Ramesh NarkarNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsIbrahim El SharNo ratings yet

- DG Consulting Engineers: Job NoDocument52 pagesDG Consulting Engineers: Job NosthakshyNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design SheetsAnonymous nwByj9L100% (2)

- 8BJXX7CICWDocument6 pages8BJXX7CICWAnonymous nfHBPXz178No ratings yet

- CBD Credit Card Cashback T&CsDocument2 pagesCBD Credit Card Cashback T&CsSajal KulshresthaNo ratings yet

- FAB Yearend Spend Campaign Oct Jan2020 TnC1Document1 pageFAB Yearend Spend Campaign Oct Jan2020 TnC1Satyanarayana MukkuNo ratings yet

- Strainer Information PDFDocument6 pagesStrainer Information PDFmahdiNo ratings yet

- Modal Mass IDocument8 pagesModal Mass ISajal KulshresthaNo ratings yet

- Grade 1Document2 pagesGrade 1Sajal KulshresthaNo ratings yet

- Close Bank Account RequestDocument1 pageClose Bank Account RequestlogisrinivasNo ratings yet

- Arabian Oryx Physical FeaturesDocument4 pagesArabian Oryx Physical FeaturesSajal KulshresthaNo ratings yet

- Enjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andDocument1 pageEnjoy 2% Cashback: Use Your Samba Credit Card at Kalyan Jewellers andSajal KulshresthaNo ratings yet

- Grade 1 Science WorksheetDocument3 pagesGrade 1 Science WorksheetSajal KulshresthaNo ratings yet

- Strainer Information PDFDocument6 pagesStrainer Information PDFmahdiNo ratings yet

- Ellipsoidal Head Dimensional CharacteristicsDocument2 pagesEllipsoidal Head Dimensional CharacteristicsSajal KulshresthaNo ratings yet

- Form No. 15 H: Bar Code: PanDocument2 pagesForm No. 15 H: Bar Code: PanSajal KulshresthaNo ratings yet

- Hotl ListDocument1 pageHotl ListSajal KulshresthaNo ratings yet

- FirstRewardsCatalogue PDFDocument9 pagesFirstRewardsCatalogue PDFSajal KulshresthaNo ratings yet

- Trunnion PDFDocument7 pagesTrunnion PDFSajal KulshresthaNo ratings yet

- The Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentDocument1 pageThe Damage Could Have Been Greater Had He Not Stopped Himself From Paying The Fourth and Final InstalmentSajal KulshresthaNo ratings yet

- Form 15G TDS waiverDocument2 pagesForm 15G TDS waiverPalaniappan Meyyappan83% (6)

- Spark Resistance HoistDocument4 pagesSpark Resistance HoistSajal KulshresthaNo ratings yet

- Walnut CakeDocument1 pageWalnut CakeSajal KulshresthaNo ratings yet

- WRC 107Document3 pagesWRC 107Aqeel BismaNo ratings yet

- Harrington Manual Trolleys and Hoists Product Specification FormDocument1 pageHarrington Manual Trolleys and Hoists Product Specification FormSajal KulshresthaNo ratings yet

- Input EchoDocument10 pagesInput EchoSajal KulshresthaNo ratings yet

- AccountClosureRequest NewDocument1 pageAccountClosureRequest NewSajal KulshresthaNo ratings yet

- WJM Technologies: Excellence in Material JoiningDocument5 pagesWJM Technologies: Excellence in Material JoiningA K SinghNo ratings yet

- Seismic Design Lec 2 PDFDocument32 pagesSeismic Design Lec 2 PDFGuillermo Cordero100% (1)

- AlgurgDocument1 pageAlgurgSajal KulshresthaNo ratings yet

- Exchanger CostingDocument2 pagesExchanger CostingSajal KulshresthaNo ratings yet

- Prime Form: Music Set Transformation Transposition InversionDocument3 pagesPrime Form: Music Set Transformation Transposition InversionAvicena Albiruni100% (1)

- 2.8 Index of Refraction LabDocument4 pages2.8 Index of Refraction LabsashaNo ratings yet

- Math 323: Solutions To Homework 9Document8 pagesMath 323: Solutions To Homework 9AlbertoAlcaláNo ratings yet

- 02page SageDocument140 pages02page SageSergio MontesNo ratings yet

- Gtu Micro Processor PracticalDocument79 pagesGtu Micro Processor Practicalbaba100% (1)

- Acceleration and DecelerationDocument28 pagesAcceleration and DecelerationCt RahayuNo ratings yet

- 5 2 A A Geometric Constraints 1Document3 pages5 2 A A Geometric Constraints 1api-248595624No ratings yet

- (-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice AnotherDocument4 pages(-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice Anotherbilal5202050No ratings yet

- James Mcivor: A B C BDocument4 pagesJames Mcivor: A B C BMatthew StevenNo ratings yet

- 10 Questions for Stephen Hawking about the UniverseDocument2 pages10 Questions for Stephen Hawking about the UniverseYihuan ZouNo ratings yet

- MATH 6 PPT Q3 - Translation of Real-Life Verbal Expressions and Equations Into Letters or SymbolsDocument28 pagesMATH 6 PPT Q3 - Translation of Real-Life Verbal Expressions and Equations Into Letters or SymbolsAlbert MarzanNo ratings yet

- Mathematical Induction ConceptsDocument11 pagesMathematical Induction ConceptsMehak ElahiNo ratings yet

- Determining Beta Factor For A 2N2222 TransistorDocument2 pagesDetermining Beta Factor For A 2N2222 TransistorJuan Carlos Morales ParraNo ratings yet

- Chapter 3 - Stories Categorical Data TellDocument15 pagesChapter 3 - Stories Categorical Data TellBryant BachelorNo ratings yet

- Physics Gutka - Allen's 2021 Side BookDocument192 pagesPhysics Gutka - Allen's 2021 Side BookDhyey PatelNo ratings yet

- TLS Point Cloud RegistrationDocument55 pagesTLS Point Cloud RegistrationLipkowskiNo ratings yet

- Naive Bayes Classifier: Coin Toss and Fair Dice ExampleDocument16 pagesNaive Bayes Classifier: Coin Toss and Fair Dice ExampleRupali PatilNo ratings yet

- Ac7101 3DDocument24 pagesAc7101 3DNamelezz ShadowwNo ratings yet

- Real Number Properties WorksheetsDocument4 pagesReal Number Properties Worksheetsapi-150536296No ratings yet

- Quantile Regression (Final) PDFDocument22 pagesQuantile Regression (Final) PDFbooianca100% (1)

- Strategy Formulation FrameworkDocument26 pagesStrategy Formulation FrameworkSibin PiptiNo ratings yet

- Linear Algebra Resupply Date Iv. Direct Sum Vs DimensionDocument7 pagesLinear Algebra Resupply Date Iv. Direct Sum Vs Dimension詹子軒No ratings yet

- Syllabi Master of TechnologyDocument63 pagesSyllabi Master of TechnologyRanjit Kumar ShahNo ratings yet

- Tabulation of Error Function Values PDFDocument1 pageTabulation of Error Function Values PDFReyes DanaeNo ratings yet

- Adilet Imambekov - Strongly Correlated Phenomena With Ultracold Atomic GasesDocument200 pagesAdilet Imambekov - Strongly Correlated Phenomena With Ultracold Atomic GasesItama23No ratings yet

- LECTURE (NOTE) - Module 01 - MeasurementDocument86 pagesLECTURE (NOTE) - Module 01 - Measurement821A 45RajNo ratings yet