Professional Documents

Culture Documents

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

Uploaded by

Jèfrì PìnémCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

Uploaded by

Jèfrì PìnémCopyright:

Available Formats

PGEPHOPR0060Rev.

PaddingandBackfillingProcedure

Page 1 of 6

ENGINEERING, PROCUREMENT, CONSTRUCTION AND COMMISSIONING OF EXPORT PIPELINE FOR GARRAF CONTRACT AREA

PaddingandBackfillingProcedure (PGEPHOPR0060)

EPCC CONTRACTOR MIDDLE EAST ENGINEERING

REV

DATE

STATUS

PREPARED BY NAME & SIGN H.H H.H

CHECKED BY NAME & SIGN A.A A.A

QA REVIEW BY NAME & SIGN O.R O.R

APPROVED BY NAME & SIGN O.R

OWNERS COMMENT Approved / Reviewed Approved with Comment

A 0

22-Oct-2011 22-Oct-2011

Issued for internal review Issued for PCIHBV Approval

O.R

Resubmit for Approval Resubmit for Review Name Signature Title Date

EXPORT PIPELINE FOR THE GARRAF CONTRACT AREA P-GEP-HO-PR-0060 Document No.: Revision: 0 Page: 2 of 6

Table of contents Contents

1. 2. 3. 4. 5. PURPOSE ..................................................................................................................................................................... 3 SCOPE........................................................................................................................................................................... 3 DEFINITIONS ............................................................................................................................................................... 3 REFERENCES ............................................................................................................................................................. 3 PADDING ...................................................................................................................................................................... 4 5.1 5.2 5.3 6. 6.1 6.2 6.3 6.4 General .................................................................................................................................................................. 4 Padding Material................................................................................................................................................... 4 Depth of Padding .................................................................................................................................................. 4 General .................................................................................................................................................................. 5 Backfill Material..................................................................................................................................................... 5 Compaction and Crowning.................................................................................................................................. 5 Excess Material .................................................................................................................................................... 6

BACKFILLING............................................................................................................................................................... 5

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

EXPORT PIPELINE FOR THE GARRAF CONTRACT AREA P-GEP-HO-PR-0060 Document No.: Revision: 0 Page: 3 of 6

1. PURPOSE The purpose of this Padding & Backfilling Procedure is to establish the philosophy and plan of padding and backfilling execution such that all work shall be completed in accordance with contract requirements and the PROJECTS Quality Plan and HSE Plan. 2. SCOPE This procedure is applicable to all matters which affect quality, reliability, safety or performance and schedule of the pipeline padding and backfilling execution of the Export Pipeline Project for the Garraf Contract Area. 3. DEFINITIONS PCIHBV MEE PROJECT EPCC HSE Plan PQP CEP ROW Petronas Carigali Iraq Holding B.V. Middle East Engineering Company. EPCC of Export Pipeline Project for the Garraf Contract Area Engineering, Procurement, Construction and Commissioning Health, Safety and Environmental Plan Project Quality Plan Construction Execution Plan Right of Way

4. REFERENCES Exhibit 1- Scope of Work, Section 7.8.18 Padding Exhibit 1- Scope of Work, Section 7.8.24 Backfilling Construction Execution Plan (CEP) Project Quality Plan (PQP) HSE Plan

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

EXPORT PIPELINE FOR THE GARRAF CONTRACT AREA P-GEP-HO-PR-0060 Document No.: Revision: 0 Page: 4 of 6

5. PADDING 5.1 General MEE shall provide trench bottom padding in areas of rock trench, or other areas where material in the bottom of the trench has potential to damage the pipes or external coating following pipes installation. Where trench is on slopes, MEE will install soft plugs to avoid soil run off. MEE shall provide padding to the top and sides of the pipe where material in the backfill has the potential to damage the pipe or external coating following installation and backfilling of the pipe. MEE shall provide trench bottom padding and padding to the top and sides of the pipe where ditch material has been identified as containing graphite. 5.2 Padding Material Material to be employed by MEE for the purposes of padding shall consist only of fine-grained material such as sand, clay or silt. 5.3 Depth of Padding Trench bottom material shall be placed to a minimum compaction thickness of padding material to a required depth above the highest point in the ditch bottom prior to pipe being lowered into the trench and padding shall be placed across full trench width to ensure the pipelines is evenly supported. A required thickness of padding material as per acceptable standard shall be placed from the top and sides of the installed pipeline.

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

EXPORT PIPELINE FOR THE GARRAF CONTRACT AREA P-GEP-HO-PR-0060 Document No.: Revision: 0 Page: 5 of 6

6. BACKFILLING 6.1 General MEE shall backfill the pipe in a manner to prevent damage to the pipe and its coating. Backfilling shall proceed as soon as possible after the lower-in operation, in order to anchor the pipe. MEE shall provide a competent swamper on each piece of backfilling equipment to watch for and prevent rocks and deleterious materials from entering the ditch. Swamper shall be present until pipe is covered with a minimum of 300 mm of fine grained materials. 6.2 Backfill Material Backfill material placed around the pipe and above the top of the pipe shall consist only of fine grained material such as sand, clay or silt. Material such as rock or cobbles shall not be used. Topsoil shall not be used as backfill. If excavated material is predominantly fine grained with occasional rocks or cobbles or lumps, it may be used for backfill provided selective techniques are used for filling around the pipe that allow only fine grained material around, and for a height of 0.15m above the pipe. Where padding is unnecessary, material that has been excavated from the trench shall be used as backfill. Rocks in excess of 0.2m in diameter, width or length, shall not be backfilled into the trench. 6.3 Compaction and Crowning In soils where practicable and prior to crowning, MEE shall consolidate the backfill material by at least one pass of a bulldozer with one track centered on the trench line. The trench shall be left with a crown 0.5 to 1.0 meter high unless otherwise directed by PCIHBV. The crown shall be placed directly above the pipe. The trench crown and the top 0.3 meters of the trench shall be left free of any rock across cultivated or agricultural lands. Openings shall be made in the crown where necessary to permit the passage of surface water. Where backfill material settles, leaving the ditch line at a lower level than the adjacent right-ofway, MEE shall take all steps necessary to restore the trench line to a height consistent with the rest of the ROW. All backfilling done shall be of approved suitable material. Backfill must be compacted in layers of approved thickness. Degree of compaction for each layer shall be a minimum of 95% of the maximum dry density as determined by the British Standard Heavy Compaction Test or Modified Proctor Test. MEE shall carry out appropriate testing to verify the compaction. Field Density Tests of each layer of compacted soil shall be taken by an independent soil testing laboratory appointed by MEE.

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

EXPORT PIPELINE FOR THE GARRAF CONTRACT AREA P-GEP-HO-PR-0060 Document No.: Revision: 0 Page: 6 of 6

6.4 Excess Material Excess material which cannot be used for backfill shall be removed from right-of-way to a location approved by PCIHBV.

- END of DOCUMENT -

P-GEP-HO-PR-0060 Rev.0 Padding and Backfilling Procedure

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Making Soap From WoodDocument6 pagesMaking Soap From WoodmastabloidNo ratings yet

- Homework Helpers - Chemistry PDFDocument311 pagesHomework Helpers - Chemistry PDFTamby100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Specimen 1 ValuationDocument17 pagesSpecimen 1 ValuationLight BearerNo ratings yet

- Norsok Standard M-101Document62 pagesNorsok Standard M-101Popovici Alexandru100% (2)

- داينمك الملزمة كاملةDocument79 pagesداينمك الملزمة كاملةarno assassin33% (3)

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Calculation and Formula GuideDocument15 pagesCalculation and Formula Guidecharles083No ratings yet

- Calculation and Formula GuideDocument15 pagesCalculation and Formula Guidecharles083No ratings yet

- Kathrein 80010375Document2 pagesKathrein 80010375klamar5No ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- Titanic Project Case StudyDocument1 pageTitanic Project Case StudyJèfrì PìnémNo ratings yet

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- Extracted Pages From Mechanical - Estimating - ManualDocument1 pageExtracted Pages From Mechanical - Estimating - ManualJèfrì PìnémNo ratings yet

- ALDocument1 pageALJèfrì PìnémNo ratings yet

- Hydrant Dispenser 1000gpmDocument2 pagesHydrant Dispenser 1000gpmJèfrì PìnémNo ratings yet

- KOIKE Portables and Gas Equipment Catalogue v1.03 - Optimized - OptDocument72 pagesKOIKE Portables and Gas Equipment Catalogue v1.03 - Optimized - OptSergioNo ratings yet

- Rolled Steel Angle Rings: Heavy Gauge Ductwork 171Document1 pageRolled Steel Angle Rings: Heavy Gauge Ductwork 171Jèfrì PìnémNo ratings yet

- Kuda LiarDocument1 pageKuda LiarJèfrì PìnémNo ratings yet

- Productivity TablesDocument18 pagesProductivity TablesabcNo ratings yet

- ETDocument1 pageETJèfrì PìnémNo ratings yet

- Lets PDFDocument20 pagesLets PDFAugusto Manuel Inga SánchezNo ratings yet

- BBJMB Airducts PdsDocument4 pagesBBJMB Airducts PdsJèfrì PìnémNo ratings yet

- GWC BackDocument1 pageGWC BackJèfrì PìnémNo ratings yet

- MTO Piping - Part3Document1 pageMTO Piping - Part3Jèfrì PìnémNo ratings yet

- Schedule Pekerjaan Pembangunan Fix Crusher Pada PT Mifa BersaudaraDocument1 pageSchedule Pekerjaan Pembangunan Fix Crusher Pada PT Mifa BersaudaraJèfrì PìnémNo ratings yet

- Coal SCHDocument3 pagesCoal SCHJèfrì PìnémNo ratings yet

- PDFDocument1 pagePDFJèfrì PìnémNo ratings yet

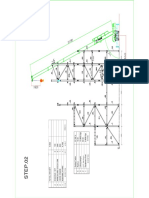

- Steel Structure Erection by 130T Step 02 of 09Document1 pageSteel Structure Erection by 130T Step 02 of 09Jèfrì PìnémNo ratings yet

- 360 Vault Installation Quick Start: Installing The Network License ManagerDocument4 pages360 Vault Installation Quick Start: Installing The Network License ManagerCarlos Condor A100% (1)

- Introduction to Korea's Employment Insurance PlanDocument176 pagesIntroduction to Korea's Employment Insurance PlanCarlos Andrés NeyraNo ratings yet

- Abcdefg XDocument1 pageAbcdefg XJèfrì PìnémNo ratings yet

- Mech & Piping - List ofDocument1 pageMech & Piping - List ofJèfrì PìnémNo ratings yet

- Introduction to Korea's Employment Insurance PlanDocument176 pagesIntroduction to Korea's Employment Insurance PlanCarlos Andrés NeyraNo ratings yet

- Acad DPGDocument184 pagesAcad DPGBharathi RajaNo ratings yet

- 43-101 Technical Report Quimsacocha, February 2009Document187 pages43-101 Technical Report Quimsacocha, February 2009Marco Vinicio SotoNo ratings yet

- BR A Consumables Catalog ElecDocument31 pagesBR A Consumables Catalog Elecdweil1552No ratings yet

- Chapter 31. Current and Resistance Chapter 31. Current and Resistance Current and ResistanceDocument11 pagesChapter 31. Current and Resistance Chapter 31. Current and Resistance Current and ResistanceArwaa AlmaghrabiNo ratings yet

- Alternator NotesDocument24 pagesAlternator Notesarunima arunimaNo ratings yet

- Moral Theories: Presented By: Sedrick M. MallariDocument27 pagesMoral Theories: Presented By: Sedrick M. MallariAlyssa De PaduaNo ratings yet

- Spcr-TagbayaganDocument76 pagesSpcr-TagbayaganReycia Vic QuintanaNo ratings yet

- Systematic Literature Review and Mapping of The Prediction of Pile CapacitiesDocument12 pagesSystematic Literature Review and Mapping of The Prediction of Pile CapacitiesCaio Augusto Lemke CostaNo ratings yet

- AUS Triboard ManuaDocument112 pagesAUS Triboard ManuaWan RidsNo ratings yet

- Kinematics Problem SetDocument1 pageKinematics Problem SetMohammad JubranNo ratings yet

- Sensing System Assisted Novel PID Controller For Efficient Speed Control of DC MDocument4 pagesSensing System Assisted Novel PID Controller For Efficient Speed Control of DC Mu2005044No ratings yet

- HYKDDocument15 pagesHYKDAri RamadhanNo ratings yet

- Exercise Questions (Materials) .: BFT 112 Introduction To EngineeringDocument1 pageExercise Questions (Materials) .: BFT 112 Introduction To EngineeringSK DarsyanaaNo ratings yet

- Chefs at HomeDocument4 pagesChefs at Homezbdv2kyzv7No ratings yet

- Pricelist Mobil Area Jabodetabek Semester 2 2022 TerbaruDocument108 pagesPricelist Mobil Area Jabodetabek Semester 2 2022 TerbarutonymuzioNo ratings yet

- 32776Document6 pages32776Muqtar KhanNo ratings yet

- Analytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeDocument2 pagesAnalytical Chemistry Lecture Exercise 2 Mole-Mole Mass-Mass: Sorsogon State CollegeJhon dave SurbanoNo ratings yet

- TED BENTON: Is Capitalism Sustainable?Document2 pagesTED BENTON: Is Capitalism Sustainable?api-25932856No ratings yet

- Starter Unit Basic Vocabulary: Smart Planet 3Document21 pagesStarter Unit Basic Vocabulary: Smart Planet 3Rober SanzNo ratings yet

- BS 7941-1-2006Document20 pagesBS 7941-1-2006Willy AryansahNo ratings yet

- Anhydrous Ammonia Unloading Station & Storage/Vaporizer SystemDocument2 pagesAnhydrous Ammonia Unloading Station & Storage/Vaporizer SystemWalter Rigamonti100% (1)

- Projects in the Autonomous Region in Muslim MindanaoDocument4 pagesProjects in the Autonomous Region in Muslim MindanaoMark montebonNo ratings yet

- Uv Spectrophotometric Estimation of Carvedilol Hydrochloride by First Order Derivative and Area Under Curve Methods in Bulk and PH PDFDocument7 pagesUv Spectrophotometric Estimation of Carvedilol Hydrochloride by First Order Derivative and Area Under Curve Methods in Bulk and PH PDFMeilia SuhermanNo ratings yet

- Production of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesDocument13 pagesProduction of Natural Bamboo Fibers-1: Experimental Approaches To Different Processes and AnalysesrabiulfNo ratings yet

- Basicline BL 21t9stDocument28 pagesBasicline BL 21t9stgabriel6276No ratings yet

- Eb4069135 F enDocument13 pagesEb4069135 F enkalvino314No ratings yet