Professional Documents

Culture Documents

Gap Analysis - Project Quality Plan

Uploaded by

lewgne08Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gap Analysis - Project Quality Plan

Uploaded by

lewgne08Copyright:

Available Formats

PROJECT QUALITY PLAN GAP ANALYSIS 13800-QA-5798-0001 (AKER SOLUTIONS - PROJECT QUALITY PLAN) DEP 82.00.10.

10-Gen APPENDIX C PROJECT QUALITY PLAN (PQP) STRUCTURE AND FORMAT Contents of the PQP shall follow the following structure and contents (where applicable). A. Purpose and Scope Item 1.1 par. 1 & item 1.2 states the purpose and scope of the PQP. B. Special Terms, Definitions, Acronyms and Abbreviations Item 7 states the definitions of terms, acronyms and abbreviations. Item 1.1 par. 2 mentioned the ISO standards C. References - however there is no reference to DEP 82.00.10.10-Gen specification. Item 1.3 Project Inputs states that all work shall comply with BSP standards, D. Requirements procedures, policies and guidelines including relevant laws of Brunei. 1. Project Codes and Standards 2. Regulatory, Legislation, Permits and Consents Compliance Item 2.4 Overall 0-Philiosophy states the quality startegies, objectives and E. Quality Policy and Objectives processes. item 1.4 the AKER Solutions QA-system were implemented by using the PEM (Project F. QMS Structure Execution Model). It organises each project into phases, controlled by milestones. It specifies strict quality requirements for each milestones, focusing on inter-discipline dependencies to ensure quality in all parts in the project. G. Management Responsibility 1. Management Commitment 2. Management Review H. Quality Organization 1. Roles and Responsibilities and Accountabilities 2. Project Quality Organization and Quality Function Organization Charts 3. Quality Resources 4. Training and Competency I. Information Management 1. Document Control Item 3 shows the ORMC Organization Chart and states the responsibilities of the management team.

Item 2.4 Individual Responsibility states that every managers and employee have a responsibility to assure the quality of own products and services. Item 3 shows the ORMC Organization Chart and states the responsibilities of the management team.

Item 4.19 Information Management - utilise IS applications to support the PEM and ICT to support project organizations. Item 4.27 Document management - Procedure P147 Documentation is use for document controlling. It ensures that all technical internal and external documentation can be traced throughout the project.

2. Quality Records Management and Certification 3. Control of Software J. Communication and Interface Control

Item 3.8 Communication states the project's main communication center and portal is the Project's internal web site. The eNet site is the project's primary communication and working channel. Also, formal meetings with client and internal meetings are schedules regularly and MOM are noted down. - However, the eNet site will be further developed through the project. item 5.3 Change Management will be organized according to P004 Change Control, with a project internal work instruction. Change Control System (CCS) will be used for registration and handling of all change requests. - item 2.4 Project Challenges/Risk management - par.6 the AKER Solutions Quality Policy Statement states the principle for continual improvement by improving the methods and solutions. - Audits, Health checks, corrective and preventive actions, lessons learned and quality metrics were documented, reported, tracked and closure verified in Synergi (AKER Solutions Systems). - Quality Planning will be managed through PEM. - MIPS (Method Integrated Project System) covers all phases of PEM: Material administration Logistic, Procurement, Job Preparation, Fabrication, Mechanical Completion, Commissioning, Completion, Basis for progress reporting. - Using Synergi (AKER Solutions System) where all HSSE and Quality issues and improvement proposals were registered and followed-up. - Also in item 6.1 states the Quality Assurance activities in the project (Contract review, Project Management reviews, milestone check and verifications, vendor audits, follwup incidents, NCR, etc.) item 2.4 Project Challenges/ Risk management - A Risk and oppurtunity register is the basis for input to the Project Performance Report (PPR) including RED and Green flag analyses. Risk register is a part of monthly review and the inputs is also for audits and verifications. item 2.4 par 2. Operational risk is managed through P231 "Risk Management in M&M Frame Agreements". Also refers to the figure 6.1 Risk Classification. - However, there is no Criticality Rating assessment and Quality Intervention programs mentioned in the PQP . - Design/ Engineering has beeen sub-contracted to Petrokon Utama Sdn. Bhd. (PUSB). They are responsible for all engineering activities including identification of SOW, site surveys, drawings & documents including preparation of job packs. The SOW includes all necessary management and supervision work as well as all other support and checking activities to ensure delivery according to all quality requirements put forward in the Contract. - The PEM model is the key deliverables and these are monitored continuously through internal milestone checks based on quality and development.

K. Management of Change

L. Continuous Improvement 1. Audits 2. Health Checks 3. Corrective and Preventive Actions 4. Lessons Learned 5. Quality Metrics and KPIs M. Project/Product Realization 1. Quality Planning

2. Quality Risk Assessment

3. Equipment Criticality Rating

4. Design/Engineering Management (If applicable) I. Design Planning II. Engineering Deliverables III. Design Reviews IV. Technical Assurance a) Technical Integrity Verification b) Design and Novel Technology Validation V. Technical Deviations VI. Weight Control (if applicable)

PROJECT QUALITY PLAN GAP ANALYSIS DEP 82.00.10.10-Gen 5. Contracting and Procurement (If applicable) I. Prequalification Requirements II. Contract Quality Requirements III. Tender Documentation and Assessment IV. Post Contract Award Requirements V. Performance Monitoring 6. Fabrication, Construction, Assembly, Mechanical Completion (if applicable) I. Material Management a) Control of Principal Supplied Materials b) Packaging and Preservation requirements 13800-QA-5798-0001 (AKER SOLUTIONS - PROJECT QUALITY PLAN) - PEM embraces all philosophies, principles and methodologies for project execution, including guidelines for planning/scheduling, procedures and work instructions for design development and assurance, materials procurement and management, work preparation, prefabrication and construction/integration.

item 4.12 Materials Control - All material control activities will be performed in MIPS. item 4.12.2 Procured materials and equipment will be received and certificates controlled by BSP/STL. Material receipt and control will be documented in MIPS. item 4.17 Preservation and preparation for shipment - This will apply for items both procured and fabricated by AKER Solutions. Company's preservation requirements will be included in procurement specifications and supplier's adherance. Preservation maintenance schedule/ program will incorporate supplier requirements and registered in MIPS. Item 4.15 QUALITY CONTROL - states the development of ITP that will be established for fabrication and it will be adapted to the Company's specifications and requirements.

7. Inspection and Testing I. Inspection and Test Plan II. Inspection and Test Execution and Monitoring III. Verification Activities by Principal IV. Inspection Function and Competency V. Pre-inspection and Quality Alignment VI. Inspection and Test Records VII. Control of Measuring and Testing Equipment 8. Hook-Up, Commissioning, Start-up and Handover (If applicable). I. Commissioning Planning II. Commissioning Execution III. Completion and Handover N. Non-Conformance Management and Control O. Appendices (as needed)

item 4.9 par. 3, Network Planning - Commissioning will be defined according to established commissioning packages with a minimum of one activity per package.

- item 6.2 Non-Conformance were documented, reported, tracked and closure verified in the Synergi (AKER Solutions Systems). - None

PROJECT QUALITY PLAN GAP ANALYSIS No. CONTRACT 1 Organigram - describing the organization to be employed for the execution of the work. 2 List of QA/QC procedures - Quality System Controls - Material Control procedures - Construction Control procedures - Quality Control procedures AKER PQP Item 3. ORGANIZATION AND RESPONSIBILITIES describes the management organization for the ORMC project. Item 4. TOOLS, PROCEDURES AND REQUIREMENTS - describes the way to execute and deliver projects by using the Project Execution Model (PEM). - MIPS (Method Integrated Project System) covers all phases of PEM: Material administration Logistic, Procurement, Job Preparation, Fabrication, Mechanical Completion, Commissioning, Completion, Basis for progress reporting. - Using Synergi (AKER Solutions System) where all HSSE and Quality issues and improvement proposals were registered and followed-up. - Also in item 6.1 states the Quality Assurance activities in the project (Contract review, Project Management reviews, milestone check and verifications, vendor audits, follow-up incidents, NCR, etc.) - There is no work specifications/ standards listed in the PQP however in item 1.3 Projects Inputs states that all work shall comply will all BSP standards, Procedures, Policies and guidelines and in item 4.15 QUALITY CONTROL mentioned the adaptation of Company's specifications and requirements in the preparation of ITP's. Item 4.15 QUALITY CONTROL - states the development of ITP that will be established for fabrication and it will be adapted to the Company's specifications and requirements.

3 Work Specification/ Standards

4 Quality Control Plans

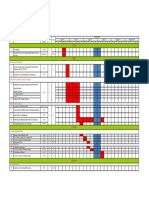

PROJECT QUALITY PLAN GAP ANALYSIS NO. 1 2.4 Project Quality Plan DEP 82.00.10.10-Gen.

3 2.3. Management Reesponsibility - (Commitment and review)

2.4.3.3 Training and competency

2.5 MEASUREMENT, ANALYSIS AND IMPROVEMENT 2.5.1 General 2.5.4 Lessons Learned and corrective and preventive actions --2.5.3 Quality Audits --2.5.2 Quality performance monitoring and continuous improvement - (KPI)

7 8

PROJECT QUALITY PLAN GAP ANALYSIS AKER SOLUTIONS INTRODUCTION 1.1. Quality Plan 1.2. Scope 1.3. Project Inputs 1.4. QA VS Project Execution Model PROJECT VISION, MISSION AND STRATEGY 2.1. Aker Solutions Vision and Values 2.2. Project Mission and Vision 2.3. Contract Strategy 2.4. Project Challenges / Risk Management 2.5. Health, safety and Environment ORGANIZATION AND RESPONSIBILITIES 3.1. Management 3.2. Authorization Matrix 3.3. Project Location 3.4. Human Resources and Competence 3.5. Confidentiality 3.6. Training 3.7. Overtime and Business Travel 3.8. Communication TOOLS, PROCEDURES AND REQUIREMENTS 4.1. Project Execution Model (PEM) 4.2. Method Statement General 4.3. Details Method Description 4.4. MC Check Lists and Check Records 4.5. Constructability, Installation, Maintainability, Accessibility and Availability in Design 4.6. Reduce Offshore Hot Work and Minimize Influence on Operation 4.7. MIPS (Method Integrated Project System) 4.8. Organization 4.9. Network Planning 4.10. Planning Hierarchy 4.11. Onshore Fabrication 4.12. Materials 4.13. Pre-fabrication and Pre-outfitting 4.14. Painting 4.15. Quality Control 4.16. Storage 4.17. Preservation and Preparation for Shipment 4.18. Reconciliation 4.19. Information Management (IM) 4.20. IM System Tools General 4.21. Systems in Use 4.22. Aker Business Services 4.23. Infrastructure, Operation and Application Management 4.24. Companys IT Security Requirements and Policy 4.25. Network 4.26. Collaboration 4.27. Document Management

CONTROL OF WORK 5.1. Design Basis 5.2. Contract Review 5.3. Change Management 5.4. Sub-contractors and Suppliers MEASUREMENT, ANALYSIS AND IMPROVEMENT 6.1. Quality Assurance Activities in the Project 6.2. Non-conformance, Corrective and Preventive Actions 6.3. Handling of Major Quality Incidents 6.4. Audit and Verification Plan 6.5. Experience Transfer

DEFINITIONS ENCLOSURES

You might also like

- 2010 KPI Milestone Chart 07 08 09Document21 pages2010 KPI Milestone Chart 07 08 09Abas AsmanNo ratings yet

- Communication Matrix: # Process Area Activity Type What To Communcate? (Information)Document10 pagesCommunication Matrix: # Process Area Activity Type What To Communcate? (Information)CQMS 5S DivisionNo ratings yet

- Ivv 17 Internal Quality Audits - Ver Ac - 10-25-2017Document10 pagesIvv 17 Internal Quality Audits - Ver Ac - 10-25-2017qualiman1No ratings yet

- Documentation Matrix DS QMS 00 R2Document19 pagesDocumentation Matrix DS QMS 00 R2DhinakaranNo ratings yet

- FRM-MR-01 Management Review Sept 03Document6 pagesFRM-MR-01 Management Review Sept 03Ranjit RoyNo ratings yet

- Qhi Classroom Training List PDFDocument2 pagesQhi Classroom Training List PDFPrakash kumarTripathiNo ratings yet

- Calibration PlanDocument1 pageCalibration Plansemaphore6No ratings yet

- Example of Quality KPIDocument1 pageExample of Quality KPISanjeev NairNo ratings yet

- ProceduresDocument22 pagesProceduresRajVardhan100% (1)

- 316 - Procedure - 0-Record Filing, Maintenance, Retrieval, and RetentionDocument6 pages316 - Procedure - 0-Record Filing, Maintenance, Retrieval, and RetentionagaricusNo ratings yet

- Master List of Records 1Document2 pagesMaster List of Records 1Anonymous i3lI9MNo ratings yet

- Quality Assurance For Service IndustriesDocument16 pagesQuality Assurance For Service IndustriesDr Srinivasan Nenmeli -K100% (11)

- Iso 9001:2000 Sample Audit Plan Schedule (Registrar)Document0 pagesIso 9001:2000 Sample Audit Plan Schedule (Registrar)Muhammad ShafiNo ratings yet

- Quality Assurance Plan ChecklistDocument8 pagesQuality Assurance Plan ChecklistJanell Parkhurst, PMP100% (8)

- Quality ObjectivesDocument3 pagesQuality ObjectivesMuhammad ImranNo ratings yet

- Monitoring and Assessment Quality Objectives - Form - Admin.2Document3 pagesMonitoring and Assessment Quality Objectives - Form - Admin.2Vanny Joyce BaluyutNo ratings yet

- 12 Software Validation LogDocument1 page12 Software Validation LogRina AnitaNo ratings yet

- EGA2 Lessons Learned QualityDocument4 pagesEGA2 Lessons Learned QualityfaizanAkhtar100% (3)

- MDSAP QMS P0013.004 Continual Improvement Procedure 2019-01-11Document7 pagesMDSAP QMS P0013.004 Continual Improvement Procedure 2019-01-11Tariq Tlafha100% (1)

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaNo ratings yet

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- Communications Plan Template: Project Name: Prepared By: DateDocument1 pageCommunications Plan Template: Project Name: Prepared By: DatevyerramallaNo ratings yet

- Swarda Tools & Dies: Company Wide Quality Objectives ApDocument3 pagesSwarda Tools & Dies: Company Wide Quality Objectives ApSangram KandekarNo ratings yet

- Measurement Quality Objectives and Validation TemplatesDocument48 pagesMeasurement Quality Objectives and Validation TemplatesksbbsNo ratings yet

- Context & Interested Party Analysis RIODocument7 pagesContext & Interested Party Analysis RIOMuhamad HaykalNo ratings yet

- 10.1 Internal Audit Report App 1Document6 pages10.1 Internal Audit Report App 1SethNo ratings yet

- Gap Analysis TemplateDocument13 pagesGap Analysis TemplateYan Ferizal100% (1)

- Setting KPIs and Quality ObjectivesDocument48 pagesSetting KPIs and Quality ObjectivesSharaf AgeedNo ratings yet

- IMSP 21 Operational Control EMSDocument3 pagesIMSP 21 Operational Control EMSEvonne LeeNo ratings yet

- Iso 9001 2008 Document Kit PDFDocument8 pagesIso 9001 2008 Document Kit PDFsytrelle100% (1)

- Interested Party AnalysisDocument3 pagesInterested Party AnalysisArun Byakod100% (1)

- R-11 Intrested PartiesDocument5 pagesR-11 Intrested PartiesSandeep PhatakNo ratings yet

- T&D-HSE-PRC-0060 Non Conformity and Corrective Action ProcedureDocument10 pagesT&D-HSE-PRC-0060 Non Conformity and Corrective Action ProcedureDamalieNo ratings yet

- IMS APEX Manual Final LOCODocument64 pagesIMS APEX Manual Final LOCOMarjorie Dulay Dumol100% (1)

- Quality Control Key Steps - ConstructionDocument26 pagesQuality Control Key Steps - ConstructionDarwin MarceloNo ratings yet

- Proyect Sheduling Iso 9001 2015Document1 pageProyect Sheduling Iso 9001 2015roellyNo ratings yet

- Insert Your Company Logo/Name Here: InstructionsDocument4 pagesInsert Your Company Logo/Name Here: InstructionsJamal BahriNo ratings yet

- ISO 9001-2015 Implementation TimelineDocument1 pageISO 9001-2015 Implementation TimelineGiovanniNo ratings yet

- Communication MatrixDocument1 pageCommunication Matrixrohini kadamNo ratings yet

- Quality Objective PRSDocument1 pageQuality Objective PRSKurt ClaveriaNo ratings yet

- Lessons Learned Document TemplateDocument3 pagesLessons Learned Document TemplateChairimanNo ratings yet

- Iso 9001 Toolkit File ListDocument3 pagesIso 9001 Toolkit File ListEl KhanNo ratings yet

- GAP AnalysisDocument9 pagesGAP AnalysisrokyomNo ratings yet

- Control Copy Issue RegisterDocument30 pagesControl Copy Issue Registerpundir_vineetNo ratings yet

- Evaluation Checklist For PM ToolsDocument16 pagesEvaluation Checklist For PM ToolskosarajuNo ratings yet

- Eeam-Q-009 Quality ManagementDocument15 pagesEeam-Q-009 Quality ManagementSyed Shoaib RazaNo ratings yet

- AE-QA-09 - Master List of Instrument Cum Calibration PlanDocument3 pagesAE-QA-09 - Master List of Instrument Cum Calibration PlanKarthi ThiyagarajanNo ratings yet

- QP0225-0 Continual Improvement ProcedureDocument6 pagesQP0225-0 Continual Improvement ProcedureNyadroh Clement MchammondsNo ratings yet

- Project Checklist of ISO 9001Document2 pagesProject Checklist of ISO 9001Rajat Jain100% (1)

- GTGC-RID-IMS-MAN-00 Integrated Management System Manual PDFDocument64 pagesGTGC-RID-IMS-MAN-00 Integrated Management System Manual PDFMaria Magdalena Palacios Hernandez100% (1)

- 10 IMS - DocumentationDocument4 pages10 IMS - DocumentationantivariNo ratings yet

- PR020 Control of Non Conformances ProcedureDocument6 pagesPR020 Control of Non Conformances ProcedureSandraNo ratings yet

- Control of Tech. DocumentsDocument7 pagesControl of Tech. DocumentsDeepak Kumar DuttaNo ratings yet

- MRM - Jan-2015Document8 pagesMRM - Jan-2015RajVardhanNo ratings yet

- InProcess Rejection PPM.Document72 pagesInProcess Rejection PPM.Vikas KashyapNo ratings yet

- USI-QSF-19.1 - Internal AuditChecklist & ReportDocument49 pagesUSI-QSF-19.1 - Internal AuditChecklist & ReportPritam MitraNo ratings yet

- Weekly Quality MetricsDocument287 pagesWeekly Quality Metricsrmdarisa100% (1)

- 15 IMS Performance AsssesmentDocument4 pages15 IMS Performance AsssesmentantivariNo ratings yet

- 15 IMS Performance AsssesmentDocument4 pages15 IMS Performance AsssesmentPriyasha Ray100% (1)

- COA007 PD Sidempuan 3 Combat - PSP588 Padang Sidempuan 3, MLE-15St To MLCN-15X, 0.6 (Existing), 4E1 To 100 MBPS, 1+0 - PS Local PDFDocument1 pageCOA007 PD Sidempuan 3 Combat - PSP588 Padang Sidempuan 3, MLE-15St To MLCN-15X, 0.6 (Existing), 4E1 To 100 MBPS, 1+0 - PS Local PDFlewgne08No ratings yet

- Increasing P91 Welding Productivity With FCAW: Page 1 of 40Document40 pagesIncreasing P91 Welding Productivity With FCAW: Page 1 of 40lewgne08No ratings yet

- PSP534 Lubuk Barumun - PSP682 Rep - Sihiuk, MLE-7St To MLCN-7X, 0.6 (Existing), 16E1 To 100 MBPS, 1+0Document4 pagesPSP534 Lubuk Barumun - PSP682 Rep - Sihiuk, MLE-7St To MLCN-7X, 0.6 (Existing), 16E1 To 100 MBPS, 1+0lewgne08No ratings yet

- KPD285 Sibabangun - KPD978 Sibabangun Kota, MLCN-23Xu, 0.6, 50 MBPS, 1+0Document4 pagesKPD285 Sibabangun - KPD978 Sibabangun Kota, MLCN-23Xu, 0.6, 50 MBPS, 1+0lewgne08No ratings yet

- KPD285W, Sibabangun, RBS6601 DUW30 RRUS2100 EnclDocument7 pagesKPD285W, Sibabangun, RBS6601 DUW30 RRUS2100 Encllewgne08No ratings yet

- Brunei Road SignDocument2 pagesBrunei Road Signlewgne0894% (18)

- Basic Operation of A LatheDocument8 pagesBasic Operation of A Lathelewgne08No ratings yet

- Brochure For Training Courses ScheduleDocument2 pagesBrochure For Training Courses Schedulelewgne08No ratings yet

- SMAW-Shielded Metal Arc Welding: AdvantagesDocument1 pageSMAW-Shielded Metal Arc Welding: Advantageslewgne08No ratings yet

- Pipeline Hydro Test Pressure Determination - Pipeline & Gas JournalDocument4 pagesPipeline Hydro Test Pressure Determination - Pipeline & Gas Journallewgne08No ratings yet

- Training Flyer - IsO 9001 Public Trainings Rev2Document1 pageTraining Flyer - IsO 9001 Public Trainings Rev2lewgne08No ratings yet

- Internal Auditor ISO 9000: Quality Management SystemDocument3 pagesInternal Auditor ISO 9000: Quality Management Systemlewgne08No ratings yet

- Argon Specification - AIR LIQUIDEDocument2 pagesArgon Specification - AIR LIQUIDElewgne08No ratings yet

- Stork Cooperheat Consumables and Spares Brochure1Document16 pagesStork Cooperheat Consumables and Spares Brochure1lewgne08No ratings yet

- Inspection Report TemplateDocument2 pagesInspection Report Templatelewgne08No ratings yet

- Stork Cooperheat Consumables and Spares Brochure1Document16 pagesStork Cooperheat Consumables and Spares Brochure1lewgne08No ratings yet

- Procedure For Calibration of Machines WeldingDocument3 pagesProcedure For Calibration of Machines Weldinglewgne08100% (6)

- 4th Periodical Test in Math 2022 2023 1Document8 pages4th Periodical Test in Math 2022 2023 1Jasmin Ibarra VillaflorNo ratings yet

- GulfSea HT Oil 32 PDFDocument1 pageGulfSea HT Oil 32 PDFObydur RahmanNo ratings yet

- $RKNVNODDocument8 pages$RKNVNODhoangleeicftNo ratings yet

- Psy 1 Chap 3 Human DevelopmentDocument24 pagesPsy 1 Chap 3 Human Developmentjeanette8riosNo ratings yet

- Vessel Nozzle PDFDocument30 pagesVessel Nozzle PDFEugenia LorenzaNo ratings yet

- Ass AsDocument2 pagesAss AsMukesh BishtNo ratings yet

- The+Conversational+Hypnosis+Code+Digital Book PDFDocument681 pagesThe+Conversational+Hypnosis+Code+Digital Book PDFRudolfSianto100% (2)

- Case Study ResearchDocument20 pagesCase Study ResearchManish PuttyahNo ratings yet

- BTP ReportDocument27 pagesBTP ReportAayush Ghosh ChoudhuryNo ratings yet

- It (Cesec - Form 4 - 5) OutlineDocument7 pagesIt (Cesec - Form 4 - 5) Outlineapi-287025606No ratings yet

- Annotated BibliographyDocument10 pagesAnnotated Bibliographyapi-457225775No ratings yet

- 5 HPHT API 6x - FowlerDocument13 pages5 HPHT API 6x - Fowlerchau nguyenNo ratings yet

- Chemistry 102 Experiment 8 ColorimetryDocument7 pagesChemistry 102 Experiment 8 ColorimetryDaniel MedeirosNo ratings yet

- 2010-2011 CatalogDocument339 pages2010-2011 CatalogSimon TabNo ratings yet

- CA Cooling TowerDocument19 pagesCA Cooling TowerKeshia WiseNo ratings yet

- Maxwell's EquationsDocument1 pageMaxwell's EquationsAlemKomićNo ratings yet

- Arrays in C++Document13 pagesArrays in C++weggie alcarazNo ratings yet

- CMC Ludhiana Prospectus UGDocument80 pagesCMC Ludhiana Prospectus UGAnweshaBoseNo ratings yet

- Doc 01 DE 20190115144751 PDFDocument20 pagesDoc 01 DE 20190115144751 PDFAdi MNo ratings yet

- Imp Ob QuestionsDocument2 pagesImp Ob QuestionsPrabhakar RaoNo ratings yet

- Lecture 1 - Surveying FieldworkDocument16 pagesLecture 1 - Surveying FieldworkArchitect ArchitectNo ratings yet

- Indian Oil Corporation LTD Guwahati RefineryDocument27 pagesIndian Oil Corporation LTD Guwahati Refineryelectram67% (6)

- Elena Alina Popa: Key StrengthsDocument3 pagesElena Alina Popa: Key StrengthsElena Alina PopaNo ratings yet

- Social Psychology-E BookDocument4 pagesSocial Psychology-E BookShamilka Fernando60% (5)

- Samakande A UnprotectedDocument190 pagesSamakande A Unprotectedathilla27No ratings yet

- A Survey On Sentiment Analysis of (Product) Reviews: A. Nisha Jebaseeli E. Kirubakaran, PHDDocument4 pagesA Survey On Sentiment Analysis of (Product) Reviews: A. Nisha Jebaseeli E. Kirubakaran, PHDvarunendraNo ratings yet

- Alfred Nobel and The Nobel PrizesDocument17 pagesAlfred Nobel and The Nobel PrizesElizabethDarcyNo ratings yet

- Information On Resource Allocation Within NetbackupDocument17 pagesInformation On Resource Allocation Within NetbackupAbhishek PondicherryNo ratings yet

- No. 119 - March 2005Document68 pagesNo. 119 - March 2005European Southern ObservatoryNo ratings yet

- Indonesia Fertilisers 2009Document5 pagesIndonesia Fertilisers 2009George Van BommelNo ratings yet