Professional Documents

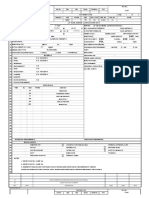

Culture Documents

Process Side: CPDT N H N H

Uploaded by

sahilchemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Side: CPDT N H N H

Uploaded by

sahilchemCopyright:

Available Formats

1.

PROCESS SIDE

1.1 PROCESS SIDE MASS BALANCE

1.1.1 Inlet stream specification

Mol Wt

Molar flow Mass

Component

Mol %

(Lb/lbmol) (Lbmol/hr) (Lb/hr)

N2

2.26

28

159.7

4471.6

H2

1.07

2

75.6

151.2

CH4

20.45

16

1445.1 23121.3

C2H6

0.4362

30

H2O

Ar

CO2

O2

75.31

0.0048

0.469

0

100

18

40

44

32

17.82

30.8

Assuming all hydrocarbons heavier than

C2H6 as C2H6 for the sake of simplicity

924.7

5321.7 95790.7

0.3

13.6

33.1

1458.2

0.0

0.0

7066.4 125931.3

1.1.2 Outlet Stream Specification

Mol Wt

Molar flow Mass

Component

Mol %

(Lb/lbmol) (Lbmol/hr) (Lb/hr)

N2

1.75

28

159.7

4471.6

H2

39.77

2

3629.3

7258.6

CH4

5.69

16

519.3

8308.1

C2H6

0

30

0.0

0.0

H2O

41.386270

18

3776.8 67982.5

Ar

0.00373

40

0.3

13.6

CO2

6.4

44

584.0 25698.1

CO

5

28

456.3 12776.1

O2

0

32

0.0

0.0

100

13.86

Outlet molar flow calculated using

nitrogen as inert

9125.8 126508.6

*There is some problem with the outlet analysis you have provided, sum was not 100%.

*You will notice a difference in inlet and outlet mass flow rate due to assumption mentioned in section 1.1.1 against ethane and also due

to incorrect analysis. In this magnitude these are not going to impact our calculations for efficiency especially for the case you are

referring to.

1.1 PROCESS SIDE HEAT BALANCE

1.1.1 Inlet stream specification

Temperature

900 F

THf

77 F

T2

H n.H

f 77

n CpdT

T1

Component

N2

H2

CH4

C2H6

H2O

Ar

CO2

CO

O2

Enthalpy

979784.33

441325.79

-30927630

-507409.73

-514008790

2080.9579

-5291304.8

0

46184738

-5.03E+08 BTU/hr

900

n.H

f 77

( A BT

CT

DT 3 ) dT

77

n.H

f 77

BT

n AT

2

CT

DT

900

)

77

1.1.1 Outlet stream specification

Temperature

1465 F

THf

77 F

Component

N2

H2

CH4

C2H6

H2O

Ar

CO2

CO

O2

T2

H n.H

Enthalpy

1728892.5

36913062

-5984297.7

0

-341254567

3685.0109

-88668033

-16726344

0

-4.14E+08 BTU/hr

f 77

T1

1465

n.H

f 77

( A BT

CT

DT 3 ) dT

77

n.H

f 77

BT

n AT

2

Net Change in enthalpy across primary reformer (tube side)

2.

n CpdT

CT

DT

8.91E+07

1465

)

77

BTU/hr

FUEL SIDE

2.1 FUEL SIDE MASS BALANCE

2.1.1 Inlet stream specification 1 of 2 (NG)

Mol Wt

Molar flow Mass

Component

Mol %

(Lb/lbmol) (Lbmol/hr) (Lb/hr)

N2

8.230

28

99.3

2779.1

H2

0.000

2

0.0

0.0

CH4

87.971

16

1060.9 16974.9

C2H6

1.775

30

H2O

Ar

CO2

O2

0.000

0.005

2.019

0.000

100

18

40

44

32

17.80

21.4

642.3

Assuming all hydrocarbons heavier than

C2H6 as C2H6 for the sake of simplicity

0.0

0.0 Neglected water coming in with natural gas

0.1

2.3

24.3

1071.4

0.0

0.0

1206 21469.94

2.1.2 Inlet stream specification 2 of 2 (Air)

Mol Wt

Molar flow

Component

Mol %

(Lb/lbmol) (Lbmol/hr)

N2

79.000

28

10582.6

H2

0.000

2

0.0

CH4

0.000

16

0.0

C2H6

0.000

30

0.0

H2O

0.000

18

0.0

Ar

0.000

40

0.0

CO2

0.000

44

0.0

O2

21.000

32

2813.1

100

28.84 13395.6755

Mass

(Lb/hr)

296312.3

0.0 Calculations in section 2.1.2 and 2.1.3 are

0.0 interlinked

0.0

0.0

0.0

0.0

90018.9 Total O2 Moles calculated

386331.3

2.1.3 Outlet stream specification (Flue gas)

Mol Wt

Molar flow

Component

Mol %

(Lb/lbmol) (Lbmol/hr)

N2

73.101

28

10681.8

H2

0.000

2

0.0

CH4

0.000

16

0.0

C2H6

0.000

30

0.0

H2O

14.961

18

2186.1

Ar

0.000

40

0.1

CO2

7.720

44

1128.1

O2

4.218

32

616.3

100.000

27.91

14612.4

Mass

CH 4 2 O 2 CO 2 2 H 2 O

(Lb/hr)

7

299091.4

C 2 H 6 O 2 2 CO 2 3 H 2 O

0.0

2

0.0

0.0

39349.6

2.3

49636.3 Total CO2 & O2 moles calculated

19721.6 O2 (D.B)

4.6 %

407801.2 CO2 (D.B)

8.42 %

Assuming flue gas analysis provided is dry basis

2.2 FUEL SIDE HEAT BALANCE

2.2.1 Outlet stream specification (Flue gas leaving radiant section)

Temperature

1750 F

THf

77 F

Component

N2

H2

CH4

C2H6

H2O

Ar

CO2

CO

O2

Enthalpy

141354911

0

0

0

-190201665

766.04359

-166606558

-21103624

204715968

-3.18E+07 BTU/hr

T2

H n. H

n CpdT

f 77

T1

1750

n. H

f 77

( A BT

CT

DT 3 ) dT

77

n. H

f 77

BT

n AT

2

CT

DT

1750

)

77

2.2.2 Inlet stream specification 1 of 2 (N.G)

Temperature

100 F

Assumed fuel gas temperature to be 100F before primary reformer

THf

77 F

Component

N2

H2

CH4

C2H6

H2O

Ar

CO2

CO

O2

Enthalpy

15952.015

0

-33966367

-773311.19

0

9.3037269

-4120545

0

199398.34

-3.86E+07 BTU/hr

T2

H n.H

f 77

n CpdT

T1

100

n.H

f 77

( A BT

CT

DT 3 ) dT

77

n.H

f 77

BT

n AT

2

CT

DT

100

)

77

2.2.3 Inlet stream specification 2 of 2 (Air)

Temperature

95 F

Assumed Ambient air temperature to be 95F

THf

77 F

Component

N2

H2

CH4

C2H6

H2O

Ar

CO2

CO

O2

Enthalpy

1330721.6

0

0

0

0

0

0

-133519864

1731824.5

-1.30E+08 BTU/hr

T2

H n.H

f 77

n CpdT

T1

95

n.H

f 77

n ( A BT CT

DT 3 ) dT

77

n.H

f 77

BT

n AT

2

CT

DT

95

)

77

Total Enthalpy of two inlet streams =

-1.69E+08 BTU/hr

Net Enthalpy change across reformer (Fuel side) =

1.37E+08 BTU/hr

3.

EFFICIENCY CALCULATIONS

Efficiency

64.94 %

process

fuel

The efficiency number is low, I dont know if there is a problem with any flow meter or temperature meter or

analysis etc.

You cannot introduce heat of reaction into your calculation while working with heat of formations

as the heat of reaction is automatically covered in heat of formation.

This is not intended to calculate exactly the efficiency of your reformer but to explain as an example so that you

can identify your fault.

Once you have understood these calculations use HYSYS instead as its physical property data bank

is much better than of what you were using (David.M. Himmelblau)

ERRORS AND OMISSIONS ARE EXPECTED AS THIS HAS NOT BEEN CROSS CHECKED AT ALL

From David.M. Himmelblau

Heat Capacity Data (Cp = A+BT+CT2+DT3) BTU/Lbmol-F

Component

N2

H2

CH4

C2H6

H2O (g)

Ar

CO2

CO

O2

Heat of formation

@ 77 Deg.F

BTU/Lbmol

0

0

-32226.104

-36457.6102

-104130.2756

0

-169445.406

-47589.912

0

A

6.931

6.89276

8.20009

11.79943

7.99694

6.931

8.63029

6.91905

6.9549

B

0.000525561

1.82835E-05

0.01068091

0.0332688

0.00164432

0.000525561

0.01011687

0.00098229

0.00276762

C

1.3678E-06

7.85832E-07

8.74979E-07

-1.39002E-05

1.81736E-06

1.3678E-06

-6.89993E-06

8.47972E-07

-1.45001E-06

D

-6.86169E-10

-2.07882E-10

-2.629E-09

1.73992E-09

-8.58727E-10

-6.86169E-10

1.7839E-09

-5.3058E-10

3.13329E-10

You might also like

- Horizontal SeparatorDocument64 pagesHorizontal SeparatorKathleen RoldanNo ratings yet

- Sizing Hydrocracking ReactorDocument2 pagesSizing Hydrocracking ReactorMeidinaSekarNadistiNo ratings yet

- Ta 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorDocument8 pagesTa 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorShella Theresya PandianganNo ratings yet

- G01 20 VD 101 (Sizing Sheet) 3 PhaseDocument6 pagesG01 20 VD 101 (Sizing Sheet) 3 PhaseWickyNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Volume Calculation For BlowdownDocument6 pagesVolume Calculation For BlowdownrohitkushNo ratings yet

- Ammonia Absorber CalculationDocument5 pagesAmmonia Absorber CalculationKvspavan KumarNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNo ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- Fdocuments - in Separator Sizing SpreadsheetDocument31 pagesFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaNo ratings yet

- 20120507091359 (1)Document6 pages20120507091359 (1)Noman Abu-FarhaNo ratings yet

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- 1 Pieza PSV-3X4Document4 pages1 Pieza PSV-3X4jose ocanaNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Petro ChemDocument68 pagesPetro ChemDivyansh Singh ChauhanNo ratings yet

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNo ratings yet

- Ammonia Equvments DrawingDocument43 pagesAmmonia Equvments DrawingSaad KhanNo ratings yet

- Hydraulic Cal - Tanks Vent To FlareDocument1 pageHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

- Air Separation Unit Atmospheric AirDocument2 pagesAir Separation Unit Atmospheric Airv.satyanarayana EthaNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- 1055 Crude Stailization Systems-SperoidsDocument0 pages1055 Crude Stailization Systems-SperoidsgshdavidNo ratings yet

- Distillation Theoretical Stages CalculatorDocument1,557 pagesDistillation Theoretical Stages Calculatorgautam_96948069No ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- M M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / HDocument1 pageM M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / Hahm3d16nNo ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomoNo ratings yet

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel SizingzamijakaNo ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- Reactor DesignDocument31 pagesReactor DesignMortada OthmanNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- CCB DE000121701 P&ID Bean Treatment Rev. ADocument2 pagesCCB DE000121701 P&ID Bean Treatment Rev. AJean-philippe DenouNo ratings yet

- Bubble and Dew PointDocument6 pagesBubble and Dew PointMawaddah Nur TambakNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDocument3 pagesPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasNo ratings yet

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaNo ratings yet

- CalculationDocument13 pagesCalculationajit kumarNo ratings yet

- Separator SizingDocument16 pagesSeparator SizingMichael J. BaneNo ratings yet

- Knock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet NozzleDocument11 pagesKnock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet Nozzlejazeel alaviNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- DJM MBA PCS CA 011 de Butanizer Accumulator REV 1Document6 pagesDJM MBA PCS CA 011 de Butanizer Accumulator REV 1DIANTORONo ratings yet

- PT FLASH CALCULATION (Using Peng Robinson EOS) : Chemical Engineer's GuideDocument88 pagesPT FLASH CALCULATION (Using Peng Robinson EOS) : Chemical Engineer's GuidevasudhaNo ratings yet

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertNo ratings yet

- Acetic 2520acid 2520 - Design 2520of 2520equipments PDFDocument41 pagesAcetic 2520acid 2520 - Design 2520of 2520equipments PDFTanuj HandaNo ratings yet

- Line Sizing Criteria As Per Different International StandardsDocument12 pagesLine Sizing Criteria As Per Different International StandardsbadelitamariusNo ratings yet

- Distillation Column: Major Equipment DesignDocument45 pagesDistillation Column: Major Equipment Designrubesh_rajaNo ratings yet

- Colum Specification SheetDocument6 pagesColum Specification SheetEddy RainNo ratings yet

- Basic Design of A Heat ExchangerDocument10 pagesBasic Design of A Heat ExchangerKvspavan KumarNo ratings yet

- Template (Vessel Sizing-2phase)Document2 pagesTemplate (Vessel Sizing-2phase)mNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Flare RadiationDocument27 pagesFlare RadiationgrabettyNo ratings yet

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainNo ratings yet

- Beta CaroteneDocument2 pagesBeta CaroteneChou ChouNo ratings yet

- Data Reference: Merk: FG-Wilson, Model: P700-1, 2014 Fuel ConsumptionDocument22 pagesData Reference: Merk: FG-Wilson, Model: P700-1, 2014 Fuel ConsumptionIrene 'septiriana'No ratings yet

- Jumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenDocument4 pagesJumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenJanelle M. JumadiaoNo ratings yet

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsFrom EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffineNo ratings yet

- Msds of OxygenDocument7 pagesMsds of OxygensahilchemNo ratings yet

- Metric and US Conversion FormulasDocument2 pagesMetric and US Conversion FormulassahilchemNo ratings yet

- Msds ChlorineDocument9 pagesMsds ChlorinesahilchemNo ratings yet

- MSDS Natural GasDocument5 pagesMSDS Natural GasRadhakrishna MadabhushiNo ratings yet

- Msds Ldpe en UsDocument3 pagesMsds Ldpe en UssahilchemNo ratings yet

- Material Safety Data Sheet 1.: Chemical Product & Manufacturer'S DetailsDocument0 pagesMaterial Safety Data Sheet 1.: Chemical Product & Manufacturer'S DetailssahilchemNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationsahilchemNo ratings yet

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustrysahilchemNo ratings yet

- Material Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationsahilchemNo ratings yet

- MSDS - Sulphur 90%: Section 1. Product InformationDocument3 pagesMSDS - Sulphur 90%: Section 1. Product InformationsahilchemNo ratings yet

- Sinha LechatelierprinDocument9 pagesSinha LechatelierprinsahilchemNo ratings yet

- L7 8Document44 pagesL7 8huyphuca2No ratings yet

- Material and Energy BalanceDocument26 pagesMaterial and Energy Balancezest321No ratings yet

- Material Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/UndertakingDocument7 pagesMaterial Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/UndertakingsahilchemNo ratings yet