Professional Documents

Culture Documents

L1746

Uploaded by

Medhat ElhagrasiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L1746

Uploaded by

Medhat ElhagrasiCopyright:

Available Formats

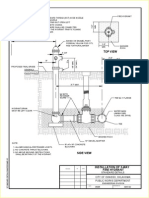

FIRE AND CEILING RADIATION DAMPERS

IN DRYWALL TYPE CONSTRUCTION 1 HOUR AND 2 HOUR RATED

TYPE-A

INSTALLATION INSTRUCTIONS FOR FIRE DAMPERS

UL CLASSIFIED Refer to figures 1, 2 and 3 for details of opening preparation and fire damper installations in wood (SEE COMPLETE stud and steel stud 1 hr. and 2 hr. rated walls.

MARKING ON PRODUCT)

VERTICAL MOUNTING

WALL COLLAR (SLEEVE)

See notes 2 and 3 for joint detail. Damper shall be secured to sleeve with # 10 sheet metal screws 6" on center, 1/4" diameter nuts and bolts, welding, 3/16" steel pop rivets or clinching (toggle). Angles shall be a minimum of 1-1/2" x 1-1/2" x 16 gauge and may be of a unit type construction. Fasten to sleeve with 1/4" diameter nuts and bolts, welding 8" on center, # 8 sheet metal screws 8" on center, or 3/16" steel pop rivets. (See NOTE 4 for clearance and overlap). NOTES 1. Sleeves shall be of the SAME GAUGE or heavier as the duct to which it is attached. Gauges shall conform to SMACNA or ASHRAE duct standards. Collars shall extend approximately 3" on either side of wall or floor to facilitate the joining of the collar to the duct. In cases where the width of the retaining angle is such that it would inhibit joining the collar to the duct, the collar may extend approximately 2" beyond the edge of the angles. See Note 3. 2. The following duct-sleeve connections may be used on all systems. Inside slip Angle slip Plain S slip Double S slip Hemmed S slip Cup slip Bar slip Drive slip Alternate bar slip (standing slip) Pocket lock Reinforced bar slip (cleat)

DUCT

VERTICAL MOUNTING

TYPE-B

COLLAR (SLEEVE)

Refer to separate Breakaway Connection sheet for further information. 2 A. Duct-sleeve connections may be of the rigid or fixed type when fire dampers are installed in sleeves that are 16 ga. up to 36" W x 24" H or 14 ga. for size exceeding 36" W x 24" H. 3. 4. When the duct work terminates at the damper, retaining angles on the opposite side of the opening may be reversed providing the size of the opening is increased by an amount equal to twice the combined thickness of the angle and the height of the screw or bolthead to maintain expansion clearance. (See note 4) In this case the collar at the open end may be made flush with the edge of the retaining angle. Clearance between the sleeve and wall/floor opening shall be a maximum 1/8" per foot on height and width of sleeve to a maximum of 1-1/2" (e.g. damper 47-3/4" x 47-3/4", collar 48" x 48", opening 49-1/2" x 49-1/2". Minimum clearance shall be 1/4. Perimeter angles shall overlap the wall/floor by a minimum of 1".

VERTICAL MOUNTING

DUCT

TYPE-C

5. As with all joints, contractor must seal duct-collar connection in field, after installation. IMPORTANT Do Not Cast Damper In Place Do Not Fasten Retaining Angles Or Damper Directly To Wall Cycle Damper After Installation To Insure Free Movement Do Not Install Damper Out Of Square Or Out Of Flat Install Damper In Plane Of Fire Separation

COLLAR (SLEEVE)

DUCT

DETAIL OF OPENING PREPARATION AND FIRE DAMPER INSTALLATION WALL RATING - 1 HR.

1/2" GYPSUM WALLBOARD 2-1/2" STUD OR RUNNER RETAINING ANGLE DAMPER SLEEVE FIRE DAMPER NOTE: THE RETAINING ANGLES ON BOTH SIDES OF THE FIRE DAMPER MAY BE INVERTED IN ORDER TO ACCOMODATE A REGISTER OR GRILLE. SEE FIG. 2

DUCT

1/2" THICK FILLER PIECES - 2-1/2" WIDE TO BE INSTALLED AROUND ENTIRE OPENING - SCREWED 12" O.C. TO WEB OF RUNNERS AND STUDS. NOTE: REQUIRED FOR WOOD STUD TYPE CONSTRUCTION ONLY.

FIG. 1

DETAIL OF OPENING PREPARATION AND FIRE DAMPER INSTALLATION WALL RATING - 2 HR.

1/2" GYPSUM WALLBOARD 2-1/2" STUD OR RUNNER RETAINING ANGLE DAMPER SLEEVE FIRE DAMPER

NOTE: THE RETAINING ANGLES ON BOTH SIDES OF THE FIRE DAMPER MAY BE INVERTED IN ORDER TO ACCOMODATE A REGISTER OR GRILLE.

DUCT 1/2" THICK FILLER PIECES - 2-1/2" WIDE TO BE INSTALLED AROUND ENTIRE OPENING - SCREWED 12" O.C. TO WEB OF RUNNERS AND STUDS. NOTE: REQUIRED FOR WOOD STUD TYPE CONSTRUCTION ONLY.

FIG. 2

METAL OR WOOD STUD FRAMING FOR FIRE DAMPERS IN WALLBOARD PARTITIONS

NOTE: Gypsum Wallboard screwed to all stud and runner flanges. 12 O.C. maximum, surrounding opening

2-1/2" RUNNER SCREWS CEILING RUNNER SECTION "A-A" 2-1/2" STUDS

NOTE: DOUBLE STUDDING MUST BE USED ON THE VERTICAL SIDES OF THE OPENING. NOT REQUIRED ON OPENINGS 36"X36" OR SMALLER.

24" ON CENTER

16"

16" A A

12" RUNNER 90 BEND

97-1/2" MAXIMUM

109-1/2" MAXIMUM

2 EACH PANHEAD SCREWS

2" 2"

FLOOR RUNNER

FIG. 3

MAXIMUM SIZE TABLE

MODEL MFD MFD3 MDFD MDFD3 MFDS MFDS3 MDFDS MDFDS3 MFDUS MFDUS3

Multiple Section Vertical Horizontal Vertical Horizontal Max. Width Max. Height Max. Width Max. Height Max. Width Max. Height Max. Width Max. Height 60 60 40 40 120 120 80 40 48 48 40 40 80 40 36 36 18 18 36 36 36 36 18 18 36 36 48 48 48 48 48 48 48 48 36 36 18 18 36 36 36 48 48 36 48 48 18 18 36 36 -

Single Section

NOTE: For maximum single section sizes refer to maximum size table. For openings larger than given for single section, multiple dampers are required. For openings larger than given in multiple sections a 12 wide brick or reinforced mullion must be provided between adjacent assemblies.

Litho in U.S.A.

2011 Metal-Fab, Inc. Form No. L1746 - 11/11 8881

You might also like

- DESCRIPTIONS Garbage ChuteDocument12 pagesDESCRIPTIONS Garbage ChuteYasser Fathy AlyNo ratings yet

- Fire Fighting Pipe Sizing UAEDocument2 pagesFire Fighting Pipe Sizing UAEgiemy george100% (1)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocument3 pagesGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNo ratings yet

- SPRINKLER Zone Control ValveDocument4 pagesSPRINKLER Zone Control ValveIonut SomneaNo ratings yet

- Regulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainDocument10 pagesRegulation DD-9.0: Drainage: 9.1 Domestic Drainage 9.2 Water Supply 9.3 Rainwater Drainage 9.4 A/C DrainSarathNo ratings yet

- Damper Manual - AMCADocument6 pagesDamper Manual - AMCASaransh GuptaNo ratings yet

- Rules and Rules of Thumb For Duct SystemsDocument1 pageRules and Rules of Thumb For Duct SystemsNguyễn Xuân ĐiệpNo ratings yet

- Chapter 6 Water Supply and DistributionDocument20 pagesChapter 6 Water Supply and Distributionapi-131679190No ratings yet

- Where and How to Install Refuse ChutesDocument2 pagesWhere and How to Install Refuse ChutesMoloy Das100% (1)

- Design Report (HK)Document22 pagesDesign Report (HK)Ravi Bhushan100% (1)

- Romold TrapDocument2 pagesRomold Traprajkumar_chinniah100% (1)

- Tornatech Brochure JPYDocument2 pagesTornatech Brochure JPYedward baskara100% (1)

- WHA Water Hammer ArrestorsDocument5 pagesWHA Water Hammer ArrestorsvitgahiNo ratings yet

- FP ManualDocument81 pagesFP Manualshekharvkate100% (4)

- Hot Water Storage Systems GuideDocument11 pagesHot Water Storage Systems GuideNadeesha BandaraNo ratings yet

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- VRV-S Catalogue (New)Document72 pagesVRV-S Catalogue (New)Skill IndiaNo ratings yet

- Foam System - V.0 - WS PDFDocument82 pagesFoam System - V.0 - WS PDFSajjadNo ratings yet

- External Building DrainageDocument11 pagesExternal Building Drainagevelayuthan_s9168No ratings yet

- Fire Fighting Specifications SummaryDocument50 pagesFire Fighting Specifications SummaryPabbathi VinayNo ratings yet

- Fire Fighting IntroDocument15 pagesFire Fighting IntroNaimah Derani100% (1)

- Jet FansDocument8 pagesJet FansTin ThanNo ratings yet

- Hot and Cold Water Supply FinalDocument40 pagesHot and Cold Water Supply FinalAmit Kumar YadavNo ratings yet

- PalDuct Phenolic Datasheet MEDocument2 pagesPalDuct Phenolic Datasheet MERamadan RashadNo ratings yet

- Interceptors: S-WD-INTER-1 0812Document11 pagesInterceptors: S-WD-INTER-1 0812Athirah Amer HamzahNo ratings yet

- A Guide To Ventilation Exhaust FansDocument4 pagesA Guide To Ventilation Exhaust FansLoter BelautNo ratings yet

- Sizing An Exhaust FanDocument1 pageSizing An Exhaust Fanomar mohd zainiNo ratings yet

- Hygienic Air Handling Technical SpecsDocument7 pagesHygienic Air Handling Technical SpecsMuhammad IlyasNo ratings yet

- TCVN 7336-2003 Sprinkler Systems in English VersionDocument24 pagesTCVN 7336-2003 Sprinkler Systems in English Versionlimch91% (11)

- Fire Hydrant Detail PDFDocument1 pageFire Hydrant Detail PDFmarcojaimeperez100% (1)

- ASPE PSD - Fire Pump InstallationDocument4 pagesASPE PSD - Fire Pump InstallationNiong DavidNo ratings yet

- PLUMBING SYSTEM-WPS OfficeDocument10 pagesPLUMBING SYSTEM-WPS OfficeLea MaligsayNo ratings yet

- Sprinkler Sloped - Ceilings - 2010 PDFDocument7 pagesSprinkler Sloped - Ceilings - 2010 PDFnrodinis7No ratings yet

- Designing efficient centralized hot water systemsDocument36 pagesDesigning efficient centralized hot water systemsAbhik BhattacharjeeNo ratings yet

- HDPE Tender DocumentDocument4 pagesHDPE Tender Documentabhijithaval100% (1)

- NFPA 820 Wastewater Treatment Facility Area ClassificationsDocument36 pagesNFPA 820 Wastewater Treatment Facility Area ClassificationsKarim El ShamashergyNo ratings yet

- Scope of chiller maintenance worksDocument3 pagesScope of chiller maintenance worksnoormuddassirkhan100% (1)

- Design Calculation Sheet: Water Demand & Drainage FlowDocument5 pagesDesign Calculation Sheet: Water Demand & Drainage FlowAhmadNo ratings yet

- Left Elevation: AroomDocument4 pagesLeft Elevation: AroomMUBASHIRNo ratings yet

- NN 100 Nitrogen Gas Fire Suppression SystemDocument4 pagesNN 100 Nitrogen Gas Fire Suppression SystemJulius BravoNo ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- Chiller and cooling equipment scheduleDocument53 pagesChiller and cooling equipment scheduleRaju KsnNo ratings yet

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeDocument21 pagesSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91No ratings yet

- JFDocument28 pagesJFrajarathnam.kNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- NBC vs. NFPADocument12 pagesNBC vs. NFPAMGHIRBI HAYKELNo ratings yet

- Water Pipes and FittingsDocument26 pagesWater Pipes and Fittingsgshazaidi100% (2)

- Hot Water-Plumbing Lect - 2015 BAUDocument60 pagesHot Water-Plumbing Lect - 2015 BAUAbed BaayounNo ratings yet

- Fire Hose Reel SystemDocument7 pagesFire Hose Reel SystemRedford DonguyaNo ratings yet

- General Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Document10 pagesGeneral Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Ryan SutherlandNo ratings yet

- Horizontal Sidewall Sprinklers Technical Data SheetDocument6 pagesHorizontal Sidewall Sprinklers Technical Data SheetAhrian BenaNo ratings yet

- Linear Slot DiffuserDocument15 pagesLinear Slot DiffuserhyderabadNo ratings yet

- Rectify issues from site visitDocument1 pageRectify issues from site visitSaqib_Manzoor__9876No ratings yet

- AHU Vs FCU Comparison PDFDocument5 pagesAHU Vs FCU Comparison PDFamirin_kingNo ratings yet

- Rainwater DesignDocument64 pagesRainwater DesignarifzakirNo ratings yet

- Fire Sprinkler Design-Part1Document2 pagesFire Sprinkler Design-Part1Henry SuarezNo ratings yet

- Refrigeration and Air Conditioning Systems ExplainedDocument6 pagesRefrigeration and Air Conditioning Systems ExplainedYash TewariNo ratings yet

- Fire Damper Installation InstructionsDocument4 pagesFire Damper Installation Instructionsanwer_quadri100% (1)

- "Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperDocument4 pages"Out of Wall/Partition": Fire Damper and Combination Fire/Smoke DamperMariIacomiNo ratings yet

- Air Curtain PDFDocument8 pagesAir Curtain PDFabidch143No ratings yet

- Heatexchanger TestDocument6 pagesHeatexchanger Testabidch143No ratings yet

- Schedule QDocument31 pagesSchedule Qabidch143100% (9)

- Saudi Labor LawDocument64 pagesSaudi Labor LawSaudi ExpatriatesNo ratings yet

- Fire Rated Door CertificateDocument1 pageFire Rated Door Certificateabidch143No ratings yet

- Design of Air Conditioning DuctsDocument15 pagesDesign of Air Conditioning Ductsabidch143No ratings yet

- National Factory 3 Way DiffusersDocument16 pagesNational Factory 3 Way Diffusersabidch143No ratings yet

- CLimate DEsign Condition - ASHRAEDocument1 pageCLimate DEsign Condition - ASHRAEabidch143No ratings yet

- 3 Ways To Align A Centrifugal Pump PDFDocument4 pages3 Ways To Align A Centrifugal Pump PDFabidch143No ratings yet

- Guidelines for mounting ceiling diffusersDocument2 pagesGuidelines for mounting ceiling diffusersabidch143No ratings yet

- Kitchen Hoods GeneralDocument55 pagesKitchen Hoods Generalabidch143No ratings yet

- Duct DesignDocument67 pagesDuct DesignShahrukh Ansari100% (1)

- Duct Area Diagram and Area Calculation FormulaDocument49 pagesDuct Area Diagram and Area Calculation FormulaSanthosh Kumar75% (4)

- Titus Diffusers PDFDocument64 pagesTitus Diffusers PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Labour LawDocument5 pagesSaudi Labour Lawrashid hussainNo ratings yet

- Complete Finish ChartDocument1 pageComplete Finish Chartjcmendez506No ratings yet

- IAQ Handbook 2011 A4 5001020-WebDocument31 pagesIAQ Handbook 2011 A4 5001020-Webabidch143No ratings yet

- Moisture Barrier On Metal Jacketing & Kraft PaperDocument2 pagesMoisture Barrier On Metal Jacketing & Kraft Paperabidch143No ratings yet

- Ashrae For Noise Level PDFDocument1 pageAshrae For Noise Level PDFabidch143No ratings yet

- HVAC Formula GuideDocument5 pagesHVAC Formula GuidezakirnagarNo ratings yet

- SBC 601 2007 - Saudi Building Code (Energy Conservation)Document13 pagesSBC 601 2007 - Saudi Building Code (Energy Conservation)abidch143No ratings yet

- Velocity of Water in PipeDocument4 pagesVelocity of Water in Pipeabidch143100% (1)

- Climate Systems Inc ASHRAE - StandardsDocument21 pagesClimate Systems Inc ASHRAE - Standardsabidch143No ratings yet

- Scope Management PlanDocument7 pagesScope Management Planabidch143No ratings yet

- SOW Kitchen HvacDocument3 pagesSOW Kitchen Hvacabidch143No ratings yet

- Work Breakdown StructureDocument9 pagesWork Breakdown StructureArif ForhadNo ratings yet

- Flow rates and pressure drops for water through Schedule 40 steel pipesDocument1 pageFlow rates and pressure drops for water through Schedule 40 steel pipeslokifaradNo ratings yet

- PM Study NotesDocument7 pagesPM Study Notesabidch143No ratings yet

- Building Codes and IaqDocument35 pagesBuilding Codes and Iaqabidch143No ratings yet